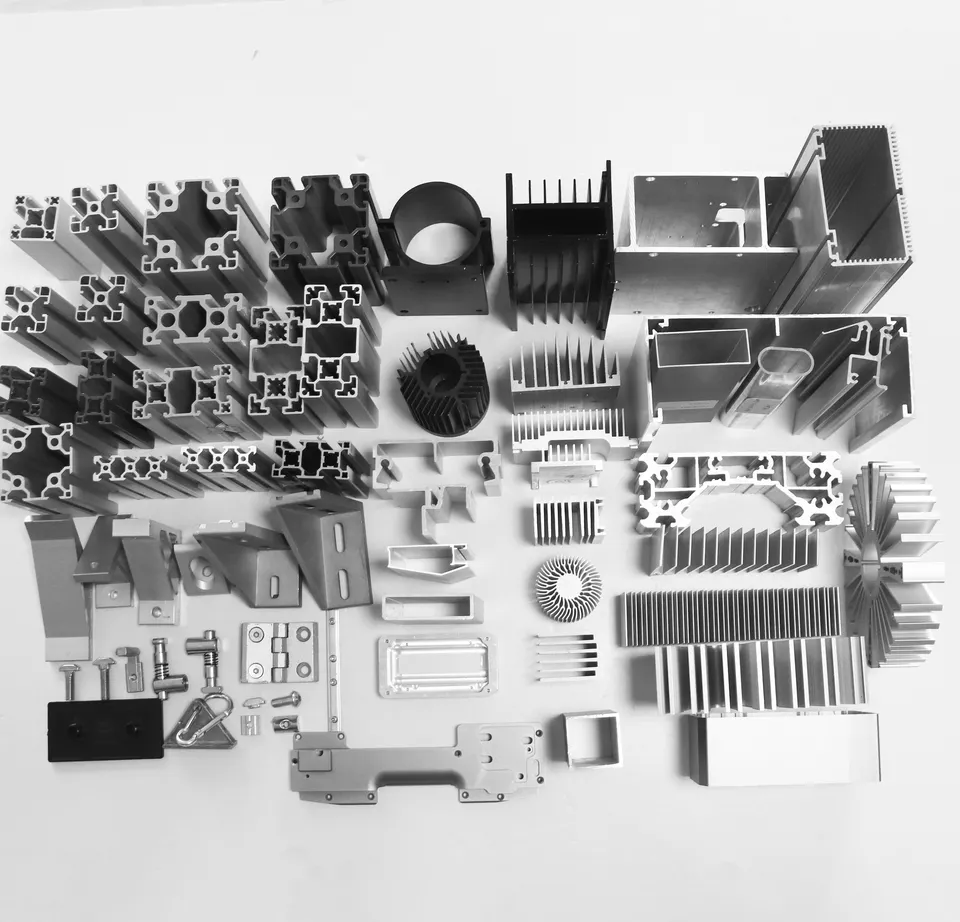

In the realm of manufacturing, both CNC machining and Custom Aluminum Extrusion have carved significant niches for themselves. While they both offer unique advantages, understanding their distinct capabilities is crucial for selecting the right process for a project. This article delves into a comparison between these two prominent manufacturing techniques, drawing insights from various industry leaders, including Wuxi Lead Precision Machinery.

The Basics

CNC Machining: A subtractive manufacturing process, CNC machining involves removing material from a workpiece using computer-controlled tools. It’s known for its precision, flexibility, and ability to produce complex parts from a variety of materials.

Custom Aluminum Extrusion: This is a process where aluminum is heated and then forced through a mold to produce profiles with specific cross-sectional shapes. It’s a cost-effective method for producing parts with consistent cross-sections.

CNC Machining vs. Custom Aluminum Extrusion

| Aspect | CNC Machining | Custom Aluminum Extrusion |

|---|---|---|

| Principle | Material removal using computer-controlled tools | Forming profiles by forcing heated aluminum through a mold |

| Materials | Various (metals, plastics, etc.) | Primarily Aluminum |

| Complexity | High (can produce intricate designs) | Moderate (limited by mold design) |

| Production Volume | Suitable for low to medium volumes | Best for high-volume production |

| Precision | High precision and tight tolerances | Moderate precision, dependent on mold quality |

| Setup Cost | Moderate | Higher due to mold creation |

| Lead Time | Relatively quick for prototypes | Longer initial lead time due to mold preparation, but faster for subsequent runs |

| Post-Processing | Often required for finishing | May require post-extrusion CNC machining for added details |

Deep Dive

Flexibility & Design Complexity: CNC machining, as offered by Wuxi Lead Precision Machinery, stands out when intricate designs and high precision are paramount. It’s especially suitable for prototypes or unique components. On the other hand, while Custom Aluminum Extrusion can produce profiles with complex cross-sections, its complexity is somewhat constrained by the design of the extrusion mold.

Volume & Cost: For large-scale production, Custom Aluminum Extrusion often emerges as the more economical choice, especially when the same profile is being produced in large quantities. The initial cost associated with mold creation can be amortized over a large production run. CNC machining, while versatile, might entail higher costs for large-scale production.

Post-Processing: After extrusion, the aluminum profiles might require further CNC machining to add intricate details, holes, or other features. This is where companies like Wuxi Lead Precision Machinery can play a pivotal role, offering precision CNC services to refine and finish the extruded parts.

Conclusion

Both CNC machining and Custom Aluminum Extrusion have their distinct places in the manufacturing landscape. The choice between them hinges on the specific requirements of a project, such as design complexity, production volume, budget, and lead time. By understanding the strengths and limitations of each process, manufacturers can make informed decisions, ensuring optimal results for their projects.

FAQ: CNC Machining vs. Custom Aluminum Extrusion

1. What is the primary difference between CNC machining and Custom Aluminum Extrusion?

CNC machining is a subtractive process where material is removed from a workpiece using computer-controlled tools. Custom Aluminum Extrusion involves forcing heated aluminum through a mold to produce profiles with specific cross-sectional shapes.

2. Which method is more suitable for high-volume production?

Custom Aluminum Extrusion is generally more suitable for high-volume production, especially when producing consistent profiles in large quantities.

3. Can CNC machining handle materials other than aluminum?

Yes, CNC machining can handle a variety of materials, including metals, plastics, and woods.

4. What are the limitations in design complexity for Custom Aluminum Extrusion?

The complexity of profiles produced by Custom Aluminum Extrusion is limited by the design of the extrusion mold.

5. Why might an extruded aluminum profile require further CNC machining?

After extrusion, the aluminum profiles might need additional details, holes, or other features that were not part of the initial extrusion process. CNC machining can add these intricate details post-extrusion.

6. How do setup costs compare between the two methods?

While CNC machining has moderate setup costs, Custom Aluminum Extrusion might have higher initial costs due to mold creation. However, this cost can be spread out over large production runs, making it economical in the long run.

7. Which method offers greater precision?

CNC machining is known for its high precision and tight tolerances. While Custom Aluminum Extrusion offers moderate precision, the exactness is largely dependent on mold quality.

8. How does lead time compare between CNC machining and Custom Aluminum Extrusion?

CNC machining can be relatively quick, especially for prototypes. Custom Aluminum Extrusion might have a longer initial lead time due to mold preparation but can be faster for subsequent production runs.

9. Can both methods handle complex part designs?

CNC machining excels in producing intricate designs. Custom Aluminum Extrusion can produce profiles with complex cross-sections, but its complexity is somewhat constrained by the mold design.

10. Which companies offer these manufacturing services?

Wuxi Lead Precision Machinery is one of the companies that offer both CNC machining and post-extrusion CNC services for added details on extruded profiles.

CNC machining and Custom Aluminum Extrusion services Companies List

1. 3ERP

- CNC machining: 3ERP offers a wide range of CNC machining services suitable for various materials and intricate designs.

- Custom Aluminum Extrusion: 3ERP provides custom aluminum extrusion services. They have a significant number of CNC machines, allowing them to perform precision post-extrusion machining in-house.

2. Star Rapid

- CNC machining: Star Rapid offers high-quality CNC machining services suitable for a variety of materials and complex designs.

- Custom Aluminum Extrusion: Star Rapid provides custom aluminum extrusion services and can manufacture profiles in various sizes and shapes. Post-extrusion, they offer multi-axis CNC machining services for added details, such as drilling and threading.

3. Lynch Metals

- CNC machining: Post-extrusion, Lynch Metals offers CNC machining services, especially for drilling and threading.

- Custom Aluminum Extrusion: Lynch Metals provides a broad spectrum of custom aluminum extrusion services, including manufacturing, painting, and anodizing. Their team of experts assists in designing optimal engineering solutions.