Technical Contents

Engineering Guide: Window Molding Design

Engineering Insight: Window Molding Design and the Critical Role of Precision

In high-performance architectural and industrial applications, window molding design is far more than an aesthetic consideration—it is a critical engineering component that ensures structural integrity, weather resistance, and long-term durability. At Wuxi Lead Precision Machinery, we understand that even the smallest deviation in dimensional accuracy can compromise the functionality of a window system, leading to air leakage, water infiltration, or premature failure under stress. This understanding drives our commitment to micron-level precision in every custom metal component we manufacture.

Window moldings, particularly those used in commercial skyscrapers, transportation systems, and defense infrastructure, must meet exacting tolerances to ensure seamless integration with glazing units and supporting frames. The forming, bending, and finishing processes involved in producing these components demand advanced CNC technology, rigorous quality control, and deep materials expertise. At Lead Precision, we leverage over 15 years of experience in custom metal manufacturing to deliver window molding solutions that perform reliably under extreme environmental and mechanical conditions.

Our engineering team works closely with clients to optimize designs for manufacturability, taking into account material selection, thermal expansion, corrosion resistance, and load distribution. Whether producing aluminum profiles for energy-efficient curtain walls or stainless steel trim for marine-grade enclosures, we apply finite element analysis (FEA) and prototype validation to anticipate real-world performance. This proactive approach minimizes field issues and reduces lifecycle costs—a value proposition proven across high-stakes projects.

The trust placed in Wuxi Lead Precision Machinery by Olympic venue contractors and military equipment suppliers is not earned lightly. These clients demand components that meet or exceed international standards such as ISO 9001, ASTM B221, and MIL-STD-810. Our production facilities are equipped with state-of-the-art CNC press brakes, laser cutting systems, and automated finishing lines, all calibrated to maintain tolerances within ±0.05 mm. Every batch undergoes comprehensive inspection using coordinate measuring machines (CMM) and optical comparators, ensuring consistency across large-scale production runs.

Our involvement in Olympic infrastructure projects required moldings that combined lightweight construction with exceptional strength and corrosion resistance—qualities essential for structures exposed to heavy foot traffic and variable climates. Similarly, military applications demanded electromagnetic shielding compatibility and resilience under vibration and shock. In both cases, precision in window molding design was not optional—it was foundational to mission success.

Below are key specifications that define our window molding manufacturing capabilities:

| Specification | Detail |

|---|---|

| Material Types | Aluminum 6061, 6063; Stainless Steel 304, 316; Brass; Custom Alloys |

| Tolerance Range | ±0.05 mm to ±0.1 mm (depending on geometry and length) |

| Max Part Length | Up to 6,000 mm |

| Surface Finishes | Anodized, Powder-Coated, Brushed, Polished, Passivated |

| Bending Accuracy | ±0.5° angular tolerance |

| Quality Standards | ISO 9001, ASTM B221, MIL-STD-810, RoHS Compliant |

| Production Capacity | 50,000+ units per month |

Precision in window molding design is not merely a technical requirement—it is a reflection of engineering excellence. At Wuxi Lead Precision Machinery, we combine advanced manufacturing technology with proven experience in mission-critical applications to deliver components that perform with reliability, consistency, and long-term value.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Window Molding Manufacturing

Wuxi Lead Precision Machinery delivers exceptional technical execution for complex window molding components demanded by automotive, aerospace, and premium architectural sectors. Our core strength lies in integrating sophisticated multi-axis machining with rigorous, data-driven quality validation, ensuring every part meets the stringent functional and aesthetic requirements inherent in high-performance window systems. This capability is fundamental to producing moldings that guarantee precise fitment, optimal sealing, thermal stability, and long-term durability within demanding assemblies.

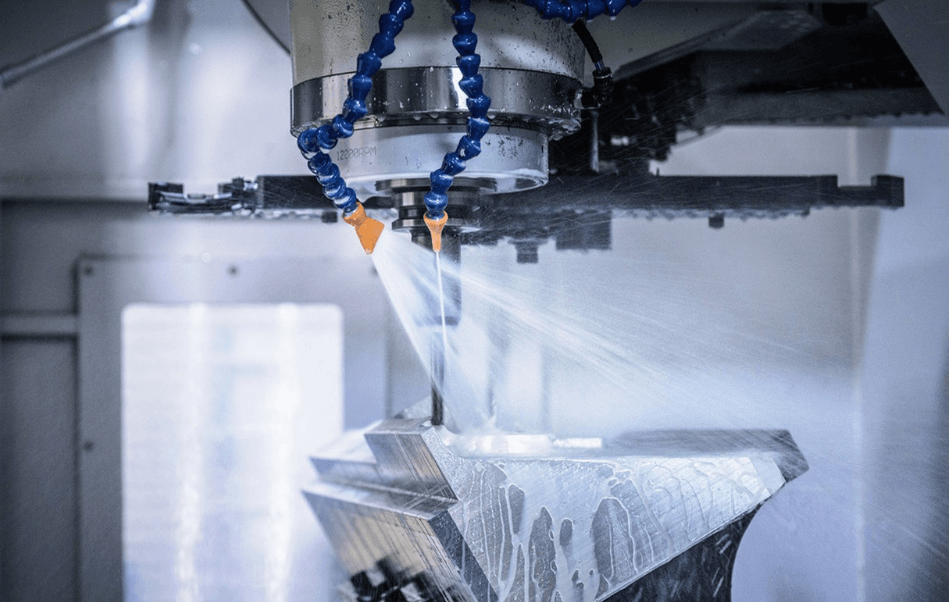

Central to our window molding production is a dedicated fleet of state-of-the-art 5-axis CNC machining centers. These systems provide the simultaneous multi-directional toolpath control essential for manufacturing intricate profiles, complex undercuts, and seamless transitions characteristic of modern window frames and trim. Unlike conventional 3-axis machining, 5-axis technology allows us to machine highly contoured geometries in a single setup. This eliminates cumulative errors from multiple fixtures, significantly improves surface finish consistency critical for visible components, and drastically reduces lead times by minimizing secondary operations. Our programming expertise leverages advanced CAM software to optimize toolpaths for material integrity, especially vital when working with challenging alloys like aluminum 6061-T6, 7075-T6, or stainless steel 304/316, ensuring dimensional stability throughout the machining process and subsequent finishing stages.

Quality assurance is not a final checkpoint but an integrated, continuous process embedded within our manufacturing workflow. Every critical dimension and geometric feature of your window molding is validated using calibrated Coordinate Measuring Machines (CMM). Our CMM inspection routines are meticulously programmed to verify complex GD&T callouts against your original CAD model, providing comprehensive traceable reports. This includes precise measurement of profile tolerances, angular relationships, hole patterns for mounting hardware, and critical sealing surface geometries. Statistical process control (SPC) data is actively monitored, allowing for immediate process adjustments to maintain consistency across entire production runs, batch after batch. This systematic approach guarantees that every component shipped meets or exceeds the specified requirements, directly contributing to your assembly line efficiency and final product reliability.

The following table details our standard achievable tolerance capabilities for machined window molding components, reflecting our commitment to precision manufacturing. These values represent typical performance under controlled conditions for common aerospace and automotive alloys; tighter tolerances are achievable upon engineering review.

| Feature Type | Standard Capability | Reference Standard | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm (0.001″) | ISO 2768-mK | Up to 300 mm; tighter on request |

| Angular Dimensions | ±0.1° | ISO 2768-cK | Verified via CMM vector measurement |

| Positional Tolerance | ±0.05 mm (0.002″) | ISO 1101 | Including hole patterns & critical loci |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | ISO 1302 | Typical machined finish; finer available |

| Profile of Surface | 0.05 mm (0.002″) | ISO 1660 | Complex contours per GD&T specification |

This combination of advanced 5-axis CNC machining, material expertise, and uncompromising CMM-based quality control forms the foundation of Wuxi Lead’s ability to manufacture window moldings that perform flawlessly in the most demanding applications. We partner with you to transform intricate designs into reality, ensuring every component contributes to the structural integrity, weatherproofing, and aesthetic excellence of the final window assembly.

Material & Finish Options

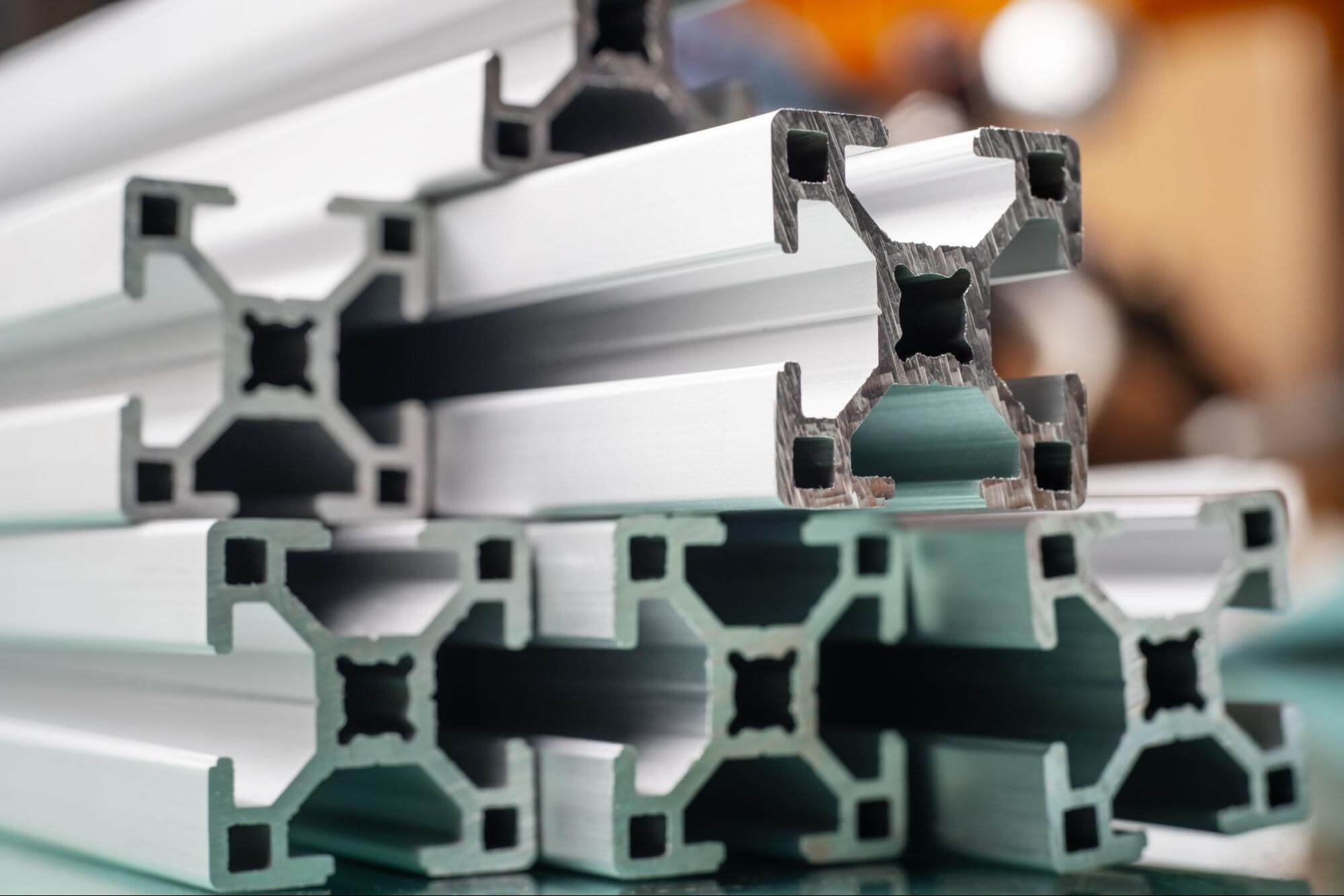

Material selection is a critical phase in the design and manufacturing of precision window moldings, directly influencing performance, durability, and aesthetic quality. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to high-end architectural and industrial applications. When engineering window moldings, the choice between aluminum, steel, and titanium must align with structural demands, environmental exposure, and design intent.

Aluminum is the most widely used material in window molding applications due to its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suitable for large-profile moldings where weight reduction is essential without sacrificing rigidity. The natural oxide layer provides inherent protection, but when enhanced with anodizing, aluminum achieves superior surface hardness and long-term weather resistance. Anodized finishes also offer design flexibility, allowing for matte, satin, or glossy appearances in a range of standard or custom colors.

Steel, particularly stainless grades such as 304 and 316, delivers exceptional mechanical strength and impact resistance. It is ideal for structural window frames and moldings exposed to high mechanical stress or harsh environments, including coastal or industrial zones. While heavier than aluminum, stainless steel offers unmatched durability and fire resistance. Its surface can be polished to a mirror finish or treated with protective coatings, though it does not support anodizing. Regular maintenance may be required in aggressive environments to prevent surface staining, especially with lower-grade alloys.

Titanium stands at the premium end of material options, offering extraordinary corrosion resistance, especially in chloride-rich atmospheres, and a high strength-to-density ratio. It is typically reserved for specialized architectural projects where longevity and minimal maintenance are paramount, such as in marine environments or high-exposure facades. Though significantly more expensive and challenging to machine, titanium develops a stable oxide layer that ensures decades of service without degradation. It is not anodized in the traditional sense but can be color-tinted through controlled thermal or electrochemical oxidation for aesthetic differentiation.

Below is a comparative overview of key material properties relevant to window molding design.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Finish Options | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | High (with anodizing) | Anodized, Powder Coated | Excellent |

| Stainless Steel 304 | 8.0 | 505 | Very High | Polished, Brushed, Coated | Moderate |

| Titanium Grade 2 | 4.5 | 345 | Exceptional | Natural Oxide, Heat-Tinted | Poor |

Selecting the optimal material requires balancing performance, cost, and manufacturability. At Wuxi Lead Precision Machinery, we support clients in making informed decisions through material testing, prototyping, and finish validation. Our expertise in precision CNC machining ensures that each window molding meets exacting dimensional and surface quality standards, regardless of material choice.

Manufacturing Process & QC

Precision Window Molding Production: From Concept to Flawless Delivery

Achieving zero-defect window moldings demands an integrated production methodology where design integrity, rigorous validation, and controlled mass manufacturing converge. At Wuxi Lead Precision Machinery, we execute this through a disciplined three-phase workflow, ensuring every component meets exacting aerospace and automotive standards before it reaches your assembly line.

The process begins with advanced digital design engineering. Our team collaborates directly with your CAD data, performing comprehensive manufacturability analysis using Siemens NX and SolidWorks. We identify potential stress points, material flow challenges, and tolerance stack-ups early, optimizing the geometry for both performance and producibility. Critical factors like material grain direction for aluminum alloys (6061-T6, 7075-T6) or stainless steel (304, 316) are modeled to prevent distortion. This phase establishes the foundational blueprint where dimensional accuracy to ±0.05mm is non-negotiable, directly influencing downstream success and eliminating costly revisions.

Prototyping transitions the validated design into physical reality under full production conditions. Utilizing high-speed 5-axis CNC machining centers with sub-micron positioning accuracy, we produce functional prototypes from your specified production-grade material. Each prototype undergoes stringent first-article inspection per AS9102 standards. Dimensional verification employs Zeiss CONTURA CMMs and optical comparators, while material properties are confirmed via certified lab testing. This stage is not merely a sample check; it is a critical process validation proving the manufacturing sequence, tooling, and quality controls can consistently achieve zero defects at scale. Client sign-off at this stage locks the approved process.

Mass production leverages the perfected parameters from prototyping within our ISO 9001 and IATF 16949 certified facility. Automated CNC cells run under real-time SPC monitoring, with in-process checks verifying critical dimensions every 30 minutes. Full batch traceability is maintained via laser-etched part IDs linked to material certs and machine logs. Final inspection employs 100% visual examination against master samples and automated dimensional scanning of key features. This closed-loop system, combined with our zero-defect culture rooted in poka-yoke error-proofing, ensures every molding ships meeting the original design intent without compromise.

Critical Process Specifications

| Parameter | Design Phase | Prototyping Phase | Mass Production Phase |

|---|---|---|---|

| Dimensional Tolerance | ±0.05mm (CAD Analysis) | ±0.02mm (CMM Verified) | ±0.02mm (SPC Controlled) |

| Material Validation | FEA Simulation | Certified Mill Test Reports | Batch Traceability + 100% Verification |

| Inspection Frequency | N/A | 100% First Article (AS9102) | 100% Visual + Key Feature Scanning |

| Process Validation | DFM Report | PPAP Level 3 Submission | Real-time SPC Monitoring |

| Primary Equipment | Siemens NX, SolidWorks | DMG MORI 5-Axis, Zeiss CMM | Automated CNC Cells, Optical Scanners |

This seamless integration of engineering rigor, physical validation, and statistically controlled manufacturing is how Wuxi Lead Precision Machinery guarantees zero-defect window moldings. We transform your design specifications into consistently perfect metal components, minimizing your total cost of ownership through eliminated scrap and accelerated time-to-market. Partner with us for precision you can measure and reliability you can trust.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Window Molding Design and Custom Metal Manufacturing Solutions

In the competitive landscape of architectural and industrial design, precision-engineered window moldings are no longer just functional components—they are critical elements that define structural integrity, aesthetic continuity, and long-term performance. At Wuxi Lead Precision Machinery, we specialize in delivering high-end custom metal manufacturing solutions tailored to the exacting demands of modern window molding design. As a trusted partner to global OEMs, architectural firms, and industrial fabricators, we combine advanced CNC machining, material science expertise, and rigorous quality control to bring your most complex designs to life.

Our engineering team works closely with clients from concept to completion, ensuring that every molding profile meets dimensional accuracy, surface finish requirements, and environmental durability standards. Whether you are developing intricate stainless steel trims for high-rise façades, corrosion-resistant aluminum channels for marine environments, or custom brass inlays for luxury interiors, our capabilities span a full spectrum of alloys, tolerances, and production volumes. We utilize state-of-the-art 5-axis milling, precision bending, and automated welding systems to achieve repeatability within ±0.02 mm, ensuring seamless integration into your final assemblies.

What sets Lead Precision apart is our commitment to co-engineering success. We don’t just manufacture parts—we optimize them. Our design-for-manufacturability (DFM) reviews help reduce material waste, lower assembly costs, and improve performance without compromising aesthetics. From prototyping to high-volume production, we maintain full traceability, ISO 9001-certified processes, and real-time quality monitoring to guarantee consistency across every batch.

Below are key technical specifications that define our window molding manufacturing capabilities:

| Specification | Detail |

|---|---|

| Material Range | Aluminum (6061, 6063, 7075), Stainless Steel (304, 316), Brass, Copper, Titanium |

| Tolerance | ±0.02 mm (standard), up to ±0.005 mm (precision) |

| Surface Finish | Mill finish, brushed, polished (up to 8K), anodized, powder-coated, PVD |

| Maximum Part Length | 6,000 mm |

| Minimum Feature Size | 0.5 mm (milled), 1.0 mm (formed) |

| Production Capacity | 50,000+ units/month |

| Certifications | ISO 9001:2015, RoHS compliant, GD&T proficient |

| Lead Time | 15–25 days (production), 5–7 days (prototypes) |

We understand that every project has unique technical, logistical, and aesthetic requirements. That’s why we offer dedicated engineering support, 3D CAD/CAM collaboration, and rapid sample turnaround to accelerate your time to market. Our facility in Wuxi, China, is equipped with smart manufacturing systems that enable real-time production tracking and secure data exchange, ensuring transparency and agility throughout the supply chain.

If you are seeking a manufacturing partner capable of transforming sophisticated window molding designs into high-performance, repeatable metal components, contact us today. Email [email protected] to connect with our engineering team, request a DFM analysis, or receive a competitive quote. At Wuxi Lead Precision Machinery, we don’t just meet specifications—we elevate standards.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.