Technical Contents

Engineering Guide: Weldable Steel Rod

Engineering Insight: The Critical Role of Precision in Weldable Steel Rod Manufacturing

In high-performance industrial applications, the integrity of every component matters. Nowhere is this more evident than in the production and application of weldable steel rods, where dimensional accuracy, material consistency, and structural reliability directly influence the success of final assemblies. At Wuxi Lead Precision Machinery, we understand that precision is not a secondary attribute—it is the foundation of performance, safety, and compliance in critical sectors such as aerospace, defense, and large-scale infrastructure.

Weldable steel rods are engineered to withstand extreme mechanical stress, thermal cycling, and corrosive environments. However, even the highest-grade alloy will underperform if manufactured to loose tolerances or inconsistent specifications. Variations in diameter, straightness, or surface finish can lead to poor weld penetration, uneven stress distribution, and premature failure in service. This is particularly critical in applications where failure is not an option—such as military equipment, seismic support systems, or structural frameworks for Olympic-grade stadiums.

Our experience at Wuxi Lead Precision Machinery spans over a decade of delivering mission-critical components for projects that demand uncompromising quality. We have supplied precision-engineered steel components for infrastructure supporting Olympic venues and have met stringent military-grade fabrication standards, where traceability, repeatability, and compliance with international codes are mandatory. These projects require more than advanced machinery—they require a culture of precision that permeates every stage of production, from raw material sourcing to final inspection.

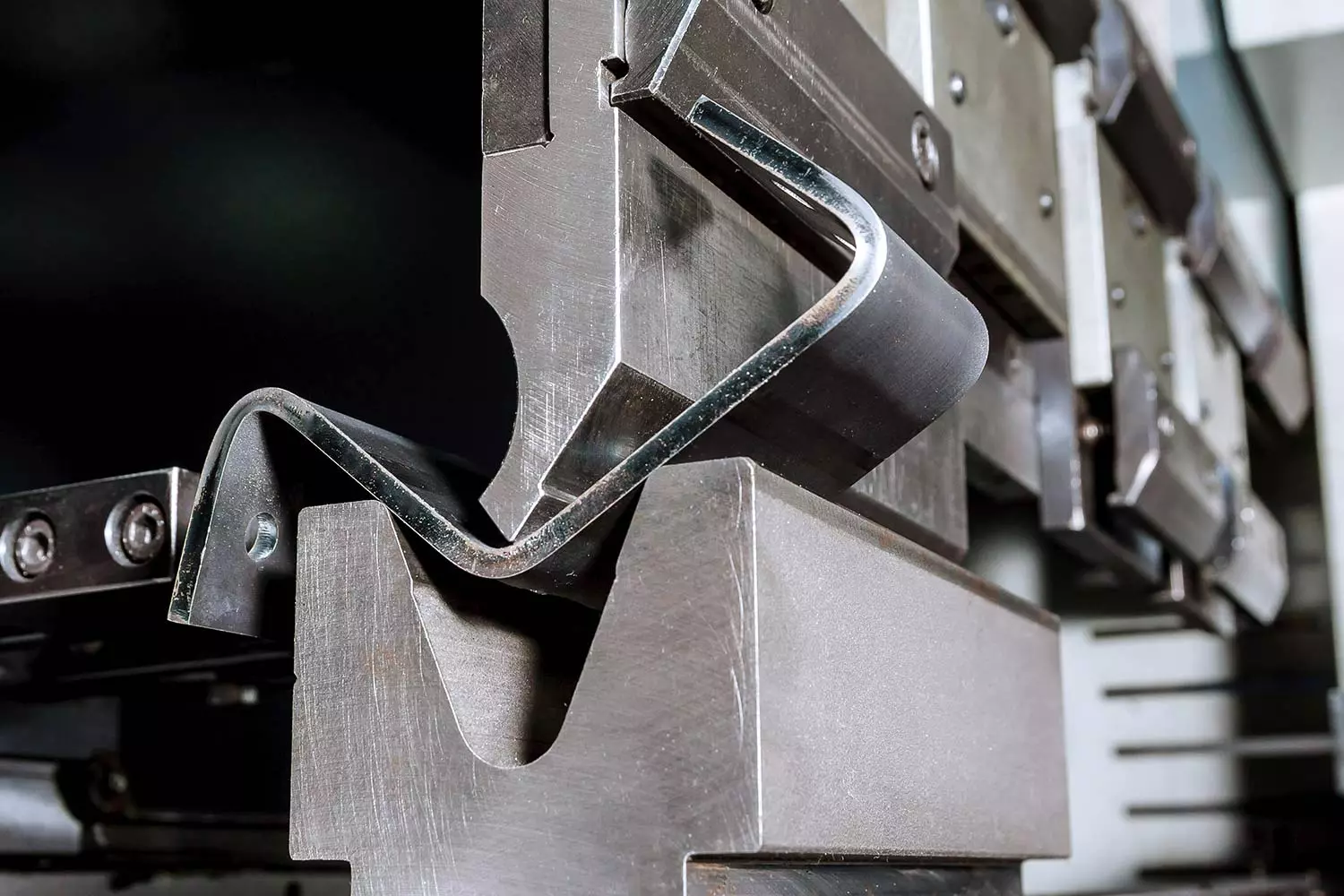

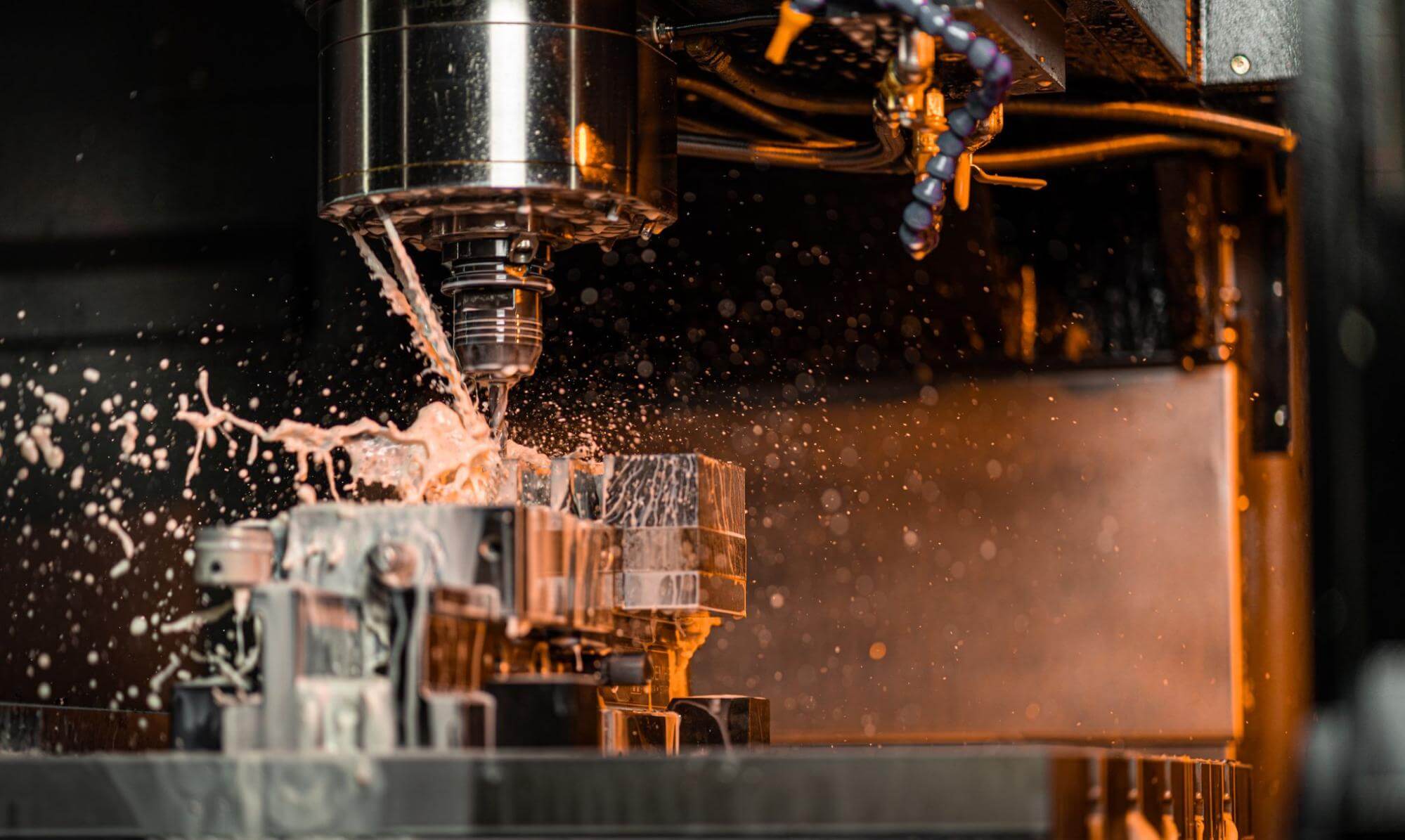

Our manufacturing process for weldable steel rods integrates CNC-controlled rolling, laser-guided straightening, and real-time dimensional monitoring to ensure each rod meets exact customer specifications. We utilize SAE and ASTM-certified alloys, including grades 4140, A36, and 1018, tailored for optimal weldability and mechanical performance. Each batch undergoes rigorous non-destructive testing (NDT), including ultrasonic and magnetic particle inspection, to verify internal homogeneity and surface integrity.

Beyond material and process control, we emphasize design collaboration. Our engineering team works directly with clients to optimize rod geometry, threading, and surface treatment for specific welding protocols—whether MIG, TIG, or submerged arc—ensuring seamless integration into complex assemblies.

The following table outlines key specifications we routinely achieve for custom weldable steel rod production:

| Parameter | Standard Tolerance | High-Precision Option | Testing Method |

|---|---|---|---|

| Diameter | ±0.1 mm | ±0.02 mm | Laser micrometer |

| Straightness | ≤1 mm/m | ≤0.2 mm/m | Optical bench measurement |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Profilometer |

| Length | ±1 mm | ±0.5 mm | CNC-controlled cutoff |

| Material Grades | A36, 4140, 1018, 4340 | Custom alloys available | Spectrometric analysis |

| Weldability Certification | AWS D1.1, ISO 3834 | MIL-STD-2219, EN 1090 | Procedure qualification |

At Wuxi Lead Precision Machinery, we do not merely manufacture steel rods—we engineer reliability. When performance is paramount, precision is the difference between success and compromise.

Precision Specs & Tolerances

Technical Capabilities: Precision Manufacturing for Weldable Steel Rod Applications

Wuxi Lead Precision Machinery delivers uncompromising accuracy for weldable steel rod components where dimensional integrity directly impacts welding performance and final assembly strength. Our integrated manufacturing approach ensures rods meet stringent aerospace, energy, and heavy equipment specifications, preventing weld distortion and fit-up failures. Precision machining prior to welding is non-negotiable; we eliminate secondary operations through single-setup 5-axis CNC processing, maintaining material homogeneity critical for post-weld heat treatment.

Our DMG MORI CTX beta 1250 5-axis CNC centers provide simultaneous multi-surface machining with sub-micron repeatability. This capability is essential for complex rod geometries requiring weld-prep features like beveled ends, counterbores, or precision threads within a single clamping cycle. Eliminating repositioning errors ensures concentricity between functional zones and weld interfaces, directly enhancing joint integrity. High-pressure through-spindle coolant systems manage thermal loads during deep drilling or threading of high-strength alloys like AISI 4140 or 4340, preventing micro-cracking that compromises weld zones. All steel stock undergoes full material certification verification per EN 10204 3.1 before processing.

Quality control is non-negotiable. Every rod batch undergoes 100% first-article inspection using Zeiss CONTURA G2 CMMs with 2.2 + L/300 µm accuracy. Critical weld interfaces are verified for form, profile, and location relative to datums per ISO 1101. Surface roughness is measured via portable profilometers to ensure Ra values support optimal weld penetration without excessive spatter. Final inspection reports include full CMM datasets traceable to NIST standards, providing auditable proof of conformance for AS9100 or API Q2 frameworks.

Achievable tolerances reflect our process capability for weldable steel rods up to Ø150mm and 3000mm length. These values represent standard production capability without special process controls:

| Feature | Standard Tolerance | Wuxi Lead Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.05 mm | ±0.005 mm |

| Angular Features | ±0.1° | ±0.02° |

| Concentricity | Ø0.1 mm | Ø0.01 mm |

| Positional Tolerance | Ø0.08 mm | Ø0.015 mm |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

This precision foundation ensures weldable steel rods integrate seamlessly into automated welding cells. Consistent geometry minimizes fixturing adjustments, while controlled surface finishes prevent weld undercutting. We partner with clients during DFM to optimize rod features for both machinability and weldability, reducing scrap rates in downstream processes. Every component ships with full material traceability and inspection documentation, providing the reliability demanded by mission-critical applications. Contact our engineering team to discuss tolerance stack-up analysis for your specific welding methodology.

Material & Finish Options

Material selection is a critical phase in custom metal manufacturing, directly influencing product performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision-engineered components tailored to meet the exact demands of industrial applications. When considering weldable steel rod, understanding its comparative advantages against alternative materials such as aluminum and titanium is essential for achieving optimal results.

Weldable steel rod, typically made from low-carbon or alloyed steels like ASTM A36 or AISI 1018, offers excellent tensile strength, impact resistance, and weldability. It is widely used in structural frameworks, machinery bases, and load-bearing components due to its robust mechanical properties and cost-effective fabrication. Unlike high-carbon steels, weldable grades are engineered to minimize cracking during fusion processes, making them ideal for automated and manual welding operations. Steel also provides superior wear resistance and can be heat-treated or coated for enhanced longevity in harsh environments.

Aluminum, while significantly lighter than steel, presents different trade-offs. It exhibits good corrosion resistance and conductivity but has lower tensile strength compared to steel. Aluminum alloys such as 6061-T6 are weldable but require specialized techniques like TIG or MIG welding under controlled conditions to avoid distortion and porosity. Its lightweight nature makes it suitable for aerospace, transportation, and portable equipment, though it comes at a higher raw material cost and reduced rigidity under heavy loads.

Titanium stands at the premium end of the spectrum, offering an exceptional strength-to-density ratio and outstanding resistance to corrosion, particularly in marine and chemical environments. However, titanium is challenging to weld, requiring inert gas shielding and precision control to prevent embrittlement. It is also significantly more expensive than both steel and aluminum, limiting its use to high-performance sectors such as aerospace, medical implants, and defense systems.

Surface finishing further influences material performance. While anodizing is a common finish for aluminum—enhancing wear and corrosion resistance—it is not applicable to steel or titanium in the same form. For steel components, alternatives such as zinc plating, powder coating, or passivation are used to improve durability and appearance. Titanium can be anodized for decorative or identification purposes, but this does not enhance wear resistance to the extent seen in aluminum.

The following table summarizes key mechanical and fabrication properties of these materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Weldability | Common Finishes | Typical Applications |

|---|---|---|---|---|---|

| Weldable Steel (A36) | 400–550 | 7.85 | Excellent | Zinc plating, painting | Structural frames, machinery parts |

| Aluminum 6061-T6 | 310 | 2.70 | Good | Anodizing, powder coating | Aerospace, automotive, enclosures |

| Titanium Grade 5 | 900 | 4.50 | Moderate | Anodizing, passivation | Medical devices, aircraft engines |

Selecting the right material requires balancing performance requirements, environmental exposure, fabrication complexity, and budget. At Wuxi Lead Precision Machinery, we support clients in making informed decisions through engineering consultation and prototyping services, ensuring that every component meets the highest standards of quality and reliability.

Manufacturing Process & QC

Weldable Steel Rod Production: Precision Engineering from Concept to Consignment

At Wuxi Lead Precision Machinery, producing weldable steel rod for critical industrial applications demands an uncompromising, integrated process. Our decades of experience in aerospace and energy sector components inform a rigorous methodology focused on weld integrity and absolute dimensional consistency. The journey begins with collaborative design engineering. We work directly with your technical team to translate functional requirements into optimized rod geometry and material specifications. Finite Element Analysis (FEA) simulates thermal stresses during welding and service loads, ensuring the design inherently minimizes distortion and crack susceptibility. Material selection prioritizes controlled carbon equivalents (CE) and low residual elements to guarantee weldability per ASTM A572 or EN 10025 standards, alongside precise machinability for downstream operations. This phase establishes the foundation for zero defects by eliminating theoretical weaknesses before metal is cut.

Prototyping is not merely a formality; it is a critical validation gate. Using our advanced CNC turning and grinding centers, we produce functional prototypes from the exact production-grade steel batch. Each prototype rod undergoes comprehensive destructive and non-destructive testing. Tensile, Charpy impact, and bend tests verify mechanical properties meet or exceed specifications. Dye penetrant inspection (DPI) and ultrasonic testing (UT) scrutinize surface and subsurface integrity. Crucially, we perform actual weld procedure qualification tests (PQT) using your specified parameters, examining the weld zone microstructure and hardness profiles to confirm no heat-affected zone (HAZ) embrittlement occurs. Any deviation triggers immediate root cause analysis and design or process refinement. This phase ensures the manufacturability and weld performance are proven before scaling.

Mass production leverages our fully integrated, IoT-enabled manufacturing ecosystem for consistent zero-defect output. Raw material traceability from certified mills is mandatory, with each heat number logged. Precision CNC machining centers, operating under strict Statistical Process Control (SPC), maintain tolerances within ±0.025mm. In-process gauging at critical stages prevents drift. Every rod batch undergoes 100% dimensional verification and surface finish checks. Final inspection includes spectrographic material verification, hardness mapping across the cross-section, and random batch testing replicating the prototype PQT protocol. Our closed-loop system feeds real-time data from machining and inspection back to process engineers, enabling micro-adjustments before non-conformances occur. This relentless focus on process control and verification, from initial design validation through every production run, guarantees weldable steel rod that performs flawlessly in your assembly.

Critical Weldable Steel Rod Production Specifications

| Parameter | Standard Requirement | Wuxi Lead Control Limit | Verification Method |

|---|---|---|---|

| Material Grade | ASTM A572 Gr 50 / S355JR | Exact Heat Certified | Mill Cert + In-House OES |

| Carbon Equivalent | Max 0.45% (CEIIW) | Max 0.42% | Spectrographic Analysis |

| Dimensional Tol. | ±0.05mm (Typical) | ±0.025mm | CMM / Laser Micrometer |

| Surface Roughness | Max Ra 1.6 µm | Max Ra 1.0 µm | Profilometer |

| Bend Test | 180° w/o Cracks (D=3a) | 180° w/o Cracks (D=2a) | Destructive Test per ASTM |

| Weld HAZ Hardness | Max 350 HV | Max 320 HV | Microhardness Traverse |

| Hydrogen Content | Max 5 ml/100g (Post-Weld) | Max 3 ml/100g | Mercury Method per ISO |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Weldable Steel Rod Manufacturing

At Wuxi Lead Precision Machinery, we don’t just manufacture weldable steel rods—we engineer performance-driven solutions tailored to the exact demands of high-precision industrial applications. As a trusted leader in custom metal manufacturing, we specialize in delivering superior-grade weldable steel rods that meet rigorous international standards while aligning with your project’s technical, logistical, and economic requirements. Whether you operate in heavy machinery, construction, automotive fabrication, or energy infrastructure, our engineering team collaborates closely with you to ensure every rod we produce supports your operational excellence.

Our advanced production capabilities are built on decades of metallurgical expertise and a fully integrated manufacturing ecosystem. From raw material sourcing to final inspection, every stage of our process is controlled to guarantee consistency, weld integrity, and mechanical reliability. We utilize premium-grade carbon and alloy steels, precision-drawn or hot-rolled to your exact dimensional tolerances, with controlled chemical compositions that enhance weldability, tensile strength, and fatigue resistance. Our in-house quality assurance lab conducts comprehensive testing, including tensile, hardness, bend, and impact evaluations, ensuring full compliance with ASTM, GB, and ISO specifications.

What sets us apart is our commitment to customization and partnership. We understand that off-the-shelf solutions rarely meet the challenges of complex engineering environments. That’s why we offer fully configurable options in diameter, length, surface finish, and mechanical properties. Whether you require rods with enhanced corrosion resistance, specific yield strength thresholds, or special packaging for international shipping, we adapt our production to your needs—not the other way around.

Our clients rely on us not only for product quality but also for responsive engineering support and on-time delivery. We operate a 12,000-square-meter facility equipped with CNC drawing machines, induction heating systems, and automated inspection lines, enabling scalable production runs from prototype batches to high-volume orders. With export experience across North America, Europe, and Southeast Asia, we are fully equipped to manage global logistics, customs documentation, and just-in-time supply chain integration.

To ensure seamless collaboration, our technical sales team provides direct engineering consultation, material certification packages, and rapid sample turnaround—typically within 7 to 10 business days. We are committed to transparency, traceability, and long-term partnership growth.

For your next project requiring precision-engineered weldable steel rods, contact us today. Let Wuxi Lead Precision Machinery become your strategic manufacturing partner.

Technical Specifications Overview

| Property | Standard Range / Value | Customizable Options |

|---|---|---|

| Material Grades | Q235, Q345, 20#, 45#, 40Cr, etc. | ASTM A36, SAE 1018, 4140, or client spec |

| Diameter | 6 mm – 100 mm | Up to 150 mm upon request |

| Length | 1 m – 6 m | Cut-to-length per drawing |

| Tensile Strength | 400 – 1000 MPa | Adjustable based on alloy and treatment |

| Yield Strength | 235 – 850 MPa | As per application needs |

| Surface Finish | Bright drawn, hot rolled, peeled | Zinc-coated, phosphate, or oiled |

| Weldability | Excellent (low carbon variants) | Pre-tested for MIG, TIG, SMAW |

| Certifications | ISO 9001, GB/T standards | Mill Test Certificates (EN 10204 3.1) |

Contact us at [email protected] to discuss your requirements and receive a tailored solution.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.