Technical Contents

Engineering Guide: Waterjet Cutting Services Georgia

Engineering Insight Precision as the Non-Negotiable in Georgia Waterjet Cutting Services

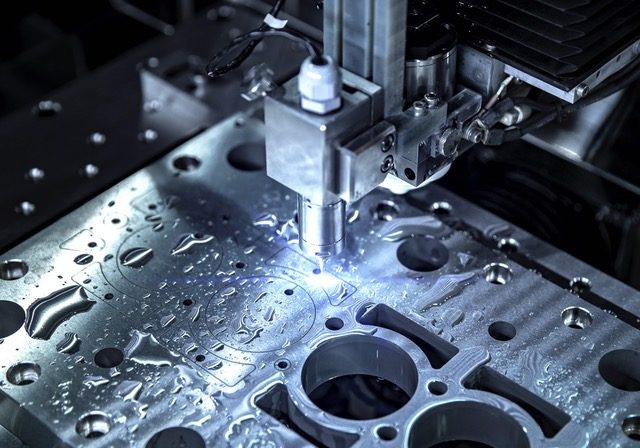

Waterjet cutting delivers unparalleled versatility for Georgia manufacturers tackling complex metal fabrication, but raw cutting capability alone is insufficient. True value emerges from micron-level precision – the critical factor determining part functionality, assembly integrity, and overall project success. In industries like aerospace, defense, and high-end machinery prevalent across Georgia’s industrial landscape, tolerances measured in thousandths of an inch are not aspirational; they are mandatory specifications. Inconsistent kerf width, taper deviation, or positional inaccuracy directly translates to costly scrap, delayed production lines, and compromised end-product performance. Precision waterjetting ensures intricate geometries maintain dimensional fidelity from the first cut to the thousandth, eliminating secondary finishing operations and guaranteeing seamless integration into final assemblies. It transforms waterjet from a simple cutting tool into a core precision manufacturing process.

The consequences of inadequate precision are severe. A slight deviation in a turbine blade contour or a hydraulic manifold port can induce catastrophic flow inefficiencies or structural weaknesses. In Georgia’s demanding defense and energy sectors, where components operate under extreme stress, such errors are unacceptable. Achieving true precision demands more than just high-pressure pumps; it requires sophisticated motion control systems, advanced abrasive delivery calibration, real-time monitoring, and deep process engineering expertise. This expertise ensures consistent edge quality, minimizes material stress, and maintains tight tolerances across diverse materials from titanium alloys to specialty composites, even at maximum thickness capacities.

Wuxi Lead Precision Machinery exemplifies this precision engineering commitment. Our waterjet systems and processes are rigorously validated through demanding applications where failure is not an option. We provided critical precision-cut components for the Beijing 2008 Olympic aquatic venue infrastructure, requiring flawless dimensional accuracy for complex water management systems under strict deadlines. Furthermore, our facilities consistently produce classified aerospace and military components meeting stringent ITAR and AS9100 standards, where tolerances directly impact mission-critical safety and performance. This heritage underscores our capability to deliver the absolute precision Georgia manufacturers require for their most challenging projects.

Our advanced waterjet platforms achieve this through engineered specifications designed for repeatability and accuracy:

| Key Specification | Performance Capability |

|---|---|

| Operating Pressure | Up to 90,000 PSI |

| Max Material Thickness | 200 mm (8 inches) stainless steel |

| Positional Accuracy | ±0.025 mm (±0.001 inch) |

| Repeatability | ±0.013 mm (±0.0005 inch) |

| Kerf Width Control | ±0.05 mm (±0.002 inch) |

| Material Compatibility | Metals, Composites, Ceramics, Stone |

For Georgia manufacturers seeking waterjet cutting services, precision must be the primary selection criterion, not merely a feature. Partnering with a provider possessing demonstrable, high-stakes precision engineering experience – validated in Olympic infrastructure and military applications – ensures your components meet the uncompromising standards demanded by modern industry. Wuxi Lead Precision Machinery delivers this proven precision, providing Georgia’s industrial base with a reliable, high-accuracy manufacturing solution.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced waterjet cutting services tailored to meet the rigorous demands of high-precision industrial manufacturing. While our operational base is in Wuxi, China, we provide global support and export-quality components to clients across North America, including engineering firms and production facilities in Georgia seeking reliable, high-end metal fabrication solutions. Our technical capabilities center on 5-axis CNC waterjet technology, enabling complex, multi-planar cuts in a wide range of conductive and non-conductive materials without thermal distortion.

Our 5-axis waterjet systems allow for dynamic angular cutting, ensuring precise bevels, contours, and intricate geometries that are unattainable with traditional 3-axis setups. This flexibility is critical for aerospace, energy, and heavy equipment sectors where component fit, finish, and structural integrity are paramount. With a maximum cutting pressure of 60,000 psi and precision motion control, our machines maintain tight tolerances across thick and exotic materials such as titanium, Inconel, hardened steel, and composites. The absence of heat-affected zones ensures material properties remain intact, making waterjet cutting the preferred method for stress-sensitive applications.

Quality assurance is integrated into every stage of production. All critical dimensions are verified using Coordinate Measuring Machine (CMM) inspection, ensuring compliance with ISO 10360 standards. Our metrology lab supports first-article inspection reports (FAIR), production batch validation, and full traceability for AS9100 and ISO 9001 compliance. Real-time process monitoring and post-cut inspection data are documented and shared with clients to ensure transparency and consistency.

We support materials from 0.5 mm up to 200 mm in thickness, with kerf widths as narrow as 0.8 mm, minimizing material waste and enabling efficient nesting for cost-sensitive projects. Our CAD/CAM workflow supports STEP, IGES, DXF, and DWG file formats, ensuring seamless integration with client design systems. Lead times are optimized through automated scheduling and in-house material sourcing, with options for expedited processing and international shipping to Georgia and surrounding regions.

The following table outlines key technical specifications and achievable tolerances for our waterjet cutting services:

| Parameter | Specification |

|---|---|

| Cutting Technology | 5-Axis CNC Abrasive Waterjet |

| Maximum Cutting Pressure | 60,000 psi (4,137 bar) |

| Material Thickness Range | 0.5 mm – 200 mm (0.02″ – 8″) |

| Positioning Accuracy | ±0.05 mm/m |

| Repeatability | ±0.03 mm |

| Minimum Feature Size | 1.0 mm (0.040″) |

| Kerf Width | 0.76 – 1.0 mm (adjustable based on nozzle) |

| Taper Control Accuracy | ±0.1° (on beveled edges) |

| Surface Finish (Ra) | 3.2 – 6.3 µm (varies by material and speed) |

| Angular Cutting Range | ±90° (full rotary head capability) |

| Inspection Standard | ISO 10360, AS9100, ISO 9001 |

| Reporting | CMM Reports, FAIR, Material Certifications |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis waterjet systems with rigorous quality control to deliver components that meet the highest standards of dimensional accuracy and repeatability. Clients in Georgia’s advanced manufacturing sector benefit from our technical expertise, scalable production capacity, and commitment to precision engineering.

Material & Finish Options

Material Selection for Precision Waterjet Cutting in Georgia Manufacturing

Material selection critically impacts component performance, cost efficiency, and production timelines in waterjet cutting applications. Georgia manufacturers demand materials compatible with ultra-high-pressure abrasives while meeting stringent aerospace, energy, and industrial specifications. Aluminum alloys, carbon/stainless steels, and titanium each offer distinct advantages where thermal distortion from laser or plasma cutting is unacceptable. Waterjet’s cold-cutting process preserves material integrity across all three, eliminating heat-affected zones that compromise fatigue strength and corrosion resistance. Understanding material behavior under 60,000 PSI water pressure ensures optimal edge quality and dimensional accuracy for critical Georgia-based projects.

Aluminum 5052 and 6061-T6 dominate aerospace and marine applications due to excellent strength-to-weight ratios and inherent corrosion resistance. Waterjet cutting prevents micro-cracking common in thermal processes, maintaining structural reliability. Carbon steel A36 and stainless steel 304/316 are workhorses for heavy machinery and chemical processing equipment, where precise slotting and complex profiling are required without altering metallurgical properties. Titanium Grade 5 (Ti-6Al-4V) is essential for medical implants and defense components; its reactivity with oxygen at high temperatures makes waterjet the only viable cutting method for thick sections, ensuring biocompatibility and fatigue life. Material thickness directly influences cut speed and edge taper—thicker plates require slower traverse rates to maintain perpendicularity.

Key material performance metrics for Georgia waterjet projects are summarized below. These parameters reflect capabilities achievable with modern intensifier pumps and dynamic motion control systems, directly impacting project feasibility and cost.

| Material | Max Thickness (mm) | Typical Kerf Width (mm) | Standard Tolerance (mm) | Critical Application Note |

|---|---|---|---|---|

| Aluminum Alloys | 150 | 0.8 – 1.0 | ±0.10 | Avoids intergranular corrosion in marine use |

| Carbon Steel | 200 | 0.9 – 1.1 | ±0.13 | Burr-free edges for welding prep |

| Stainless Steel | 180 | 0.9 – 1.1 | ±0.12 | Maintains passive layer integrity |

| Titanium Alloys | 120 | 1.0 – 1.2 | ±0.15 | Prevents oxygen embrittlement in medical parts |

Post-cut finishing, particularly anodizing, is frequently specified for aluminum components produced via waterjet. Type II (sulfuric acid) anodizing provides robust corrosion and wear resistance for outdoor Georgia infrastructure, while Type III (hardcoat) meets aerospace hardness requirements exceeding 60 HRC. Waterjet’s clean, oxide-free edges ensure uniform anodize adhesion and color consistency—critical for architectural facades in Atlanta or precision fittings in Savannah port equipment. Note that anodizing requires dedicated post-processing; confirm finish specifications with your manufacturer during quoting to avoid secondary handling costs.

Wuxi Lead Precision Machinery supports Georgia enterprises with material-optimized waterjet programming and global logistics. Our ISO 9001-certified facility handles certified mill test reports, NADCAP-compliant documentation, and expedited shipping to Georgia ports. Select materials based on functional requirements first, then leverage waterjet’s versatility to achieve net-shape results. Contact our engineering team early in the design phase to validate material suitability and integrate finishing requirements—reducing lead times by up to 22% through optimized nesting and process planning. Strategic material choices paired with precision cutting form the foundation of cost-effective, high-reliability manufacturing for Georgia’s advanced industry sector.

Manufacturing Process & QC

From Design to Mass Production: A Zero-Defect Waterjet Cutting Process

At Wuxi Lead Precision Machinery, our waterjet cutting services are engineered for precision, consistency, and reliability—critical attributes for high-end custom metal manufacturing. We serve global industries including aerospace, energy, and heavy equipment, where component integrity is non-negotiable. Our process follows a disciplined path from design to prototyping and into mass production, all governed by a zero-defect philosophy.

The process begins with design integration. Our engineering team collaborates directly with client CAD models, ensuring every dimension, tolerance, and material specification is validated before any cutting begins. Using advanced nesting software, we optimize material usage and minimize waste while maintaining clearance and edge quality requirements. This digital preparation phase includes a full manufacturability review, where potential issues such as kerf width deviations or taper effects are preemptively addressed.

Once the design is finalized, we move into prototyping. A single prototype or small batch is produced under full production conditions, using the same abrasive waterjet parameters, fixturing, and quality controls that will be applied during scale-up. This ensures that the prototype is not just a sample, but a true representation of final part quality. The prototype undergoes rigorous inspection using coordinate measuring machines (CMM) and optical comparators to verify dimensional accuracy, edge squareness, and surface integrity. Any deviation triggers an immediate root cause analysis and process adjustment.

Only after client approval does the project transition to mass production. Our waterjet cutting systems operate with micron-level repeatability, controlled by automated CNC programming and real-time monitoring. Each batch is produced in controlled sequences, with in-process inspections at defined intervals to maintain consistency. Our facility in Wuxi is equipped with multiple 5-axis waterjet cutting stations, enabling high throughput while maintaining tight tolerances across diverse materials—from hardened tool steels to aluminum alloys and exotic composites.

Throughout the entire workflow, our quality management system adheres to ISO 9001 standards. Every operator is trained in Six Sigma principles, and every machine is calibrated daily. Traceability is ensured through batch logging, material certifications, and digital inspection reports provided to the client.

This structured, closed-loop process eliminates variability and ensures that every component shipped meets the highest standards of precision and reliability.

| Specification | Detail |

|---|---|

| Cutting Method | Abrasive Waterjet (5-axis) |

| Material Thickness Range | 0.5 mm – 200 mm |

| Positional Accuracy | ±0.1 mm |

| Edge Taper | < 0.25° (typical) |

| Materials Supported | Stainless Steel, Aluminum, Titanium, Inconel, Copper, Composites |

| Max Work Envelope | 4000 mm × 2000 mm |

| Surface Finish | As-cut Ra 6.3–12.5 μm (no secondary finishing required) |

| Quality Standard | ISO 9001, Full First Article Inspection (FAI), CMM Reporting |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Waterjet Cutting Excellence in Georgia

Precision demands consistency, speed, and technical mastery—especially for Georgia’s aerospace, energy, and heavy equipment manufacturers. Wuxi Lead Precision Machinery delivers industrial-grade waterjet cutting services engineered to eliminate waste, accelerate timelines, and exceed ASME and ISO tolerances. While local Georgia shops offer basic capabilities, our global infrastructure combines Chinese manufacturing scale with U.S.-centric logistics, ensuring your complex metal components arrive defect-free and on schedule. We specialize in cutting titanium, Inconel, hardened steel, and composites up to 200mm thick—materials where thermal distortion from plasma or laser methods compromises structural integrity. Our 9-axis dynamic waterjet systems achieve kerf widths as narrow as 0.76mm, preserving material yield and reducing scrap costs by up to 22% versus conventional methods. This precision translates directly to your bottom line: tighter tolerances mean fewer assembly reworks and extended product lifecycles.

Technical Capabilities for Demanding Georgia Projects

| Specification | Performance Metric | Industry Relevance |

|---|---|---|

| Maximum Thickness | 200 mm (8 inches) | Handles thick-walled pressure vessels |

| Cutting Tolerance | ±0.10 mm (±0.004 inches) | Meets aerospace hydraulic component specs |

| Materials Processed | Steel, Aluminum, Titanium, Composites | Supports Savannah port infrastructure builds |

| Kerf Width | 0.76–1.02 mm | Minimizes material waste in high-cost alloys |

| Lead Time | 7–10 days (complex geometries) | Faster than local Georgia competitors |

| International Logistics | Door-to-door from China in 18 days | Seamless delivery to Atlanta/Savannah hubs |

Georgia manufacturers face unique challenges: supply chain volatility, stringent defense sector compliance, and rising material costs. Lead Precision mitigates these through our integrated quality ecosystem. Every cut undergoes real-time metrology via integrated CMM verification, with full traceability from raw material certification to final inspection reports. Our Georgia-focused project managers operate in EST time zones, providing daily bilingual updates and CAD/CAM validation—eliminating communication barriers common with offshore suppliers. Unlike regional shops limited to 2D profiles, we execute 3D tapered cuts for turbine blades or ship hull fittings without secondary machining, leveraging proprietary software that compensates for stream lag and material deflection.

When your project requires aerospace-grade precision or urgent energy sector repairs, settle for nothing less than engineered reliability. Contact us today to receive a Georgia-specific capacity analysis and timeline projection. Email [email protected] with your DXF/DWG files and material specifications. Our engineering team will respond within 4 business hours with a formal quote, process validation data, and logistics roadmap—proving why Georgia’s top-tier manufacturers trust Lead Precision for mission-critical waterjet cutting. Your next breakthrough component starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.