Technical Contents

Engineering Guide: Walls Molding

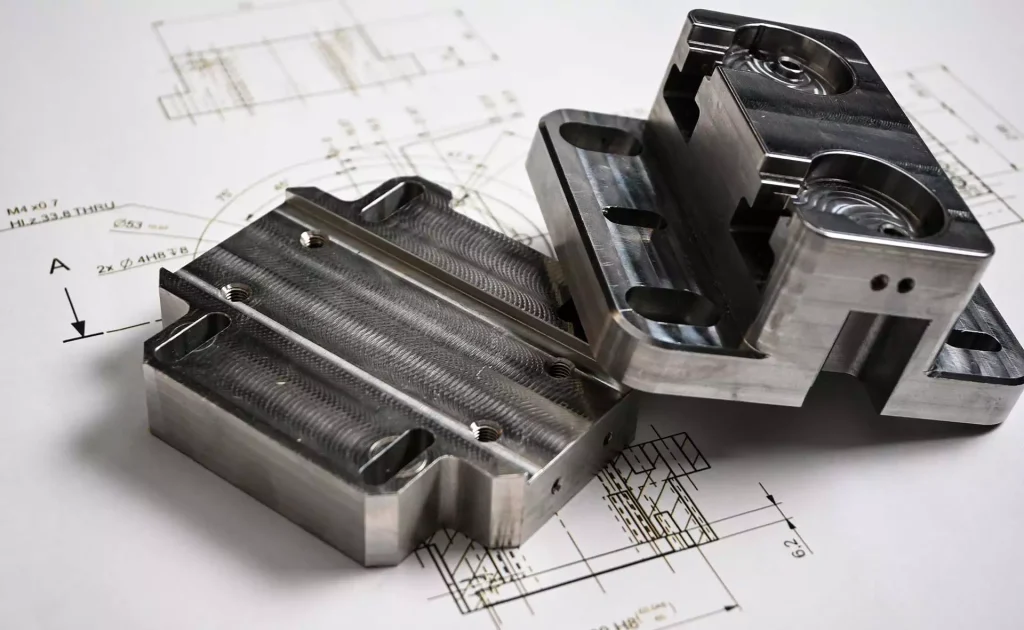

Engineering Insight Precision in Walls Molding for Critical Applications

Achieving dimensional accuracy in custom metal walls molding is non-negotiable for structural integrity and seamless integration within complex assemblies. In high-stakes environments like aerospace infrastructure, defense installations, and landmark architectural projects, deviations measured in microns can cascade into system failures or costly rework. Walls molding components often serve as load-bearing elements or critical interfaces where geometric fidelity directly impacts safety, performance, and longevity. At Wuxi Lead Precision Machinery, we treat precision not as a target but as the foundational requirement embedded in every process stage—from initial material selection through CNC forming, welding, and final inspection. Our engineering philosophy centers on proactive tolerance management, ensuring that complex wall geometries maintain specified flatness, angularity, and feature alignment under operational stresses.

Our commitment to precision is validated through demanding real-world applications. We engineered and manufactured critical structural wall components for multiple Beijing Winter Olympic venues, where extreme environmental conditions and stringent safety codes demanded absolute reliability. Similarly, our precision-molded metal wall systems are deployed in sensitive military facilities, meeting exacting MIL-STD specifications for dimensional stability and resistance to environmental degradation. These projects required tolerances often exceeding standard industry benchmarks, achieved through our integrated approach combining advanced multi-axis CNC press brakes, real-time in-process metrology, and stringent material traceability protocols. Experience on such projects proves that precision walls molding transcends basic fabrication; it is a systems engineering challenge requiring deep material science understanding and process control.

The table below outlines the precision parameters we consistently achieve for custom walls molding projects, reflecting capabilities honed through high-compliance sector work.

| Specification Parameter | Standard Capability | High-Precision Capability (Olympic/Military Grade) |

|---|---|---|

| Dimensional Tolerance | ±0.15 mm | ±0.05 mm |

| Flatness Tolerance per m² | 0.3 mm | 0.1 mm |

| Angular Accuracy | ±0.5° | ±0.1° |

| Material Thickness Range | 0.5 mm – 12.0 mm | 0.8 mm – 8.0 mm (for critical tolerances) |

| Maximum Formed Part Size | 3000 mm x 1500 mm | 2500 mm x 1200 mm (for tightest tolerances) |

| Surface Finish (Ra) | 3.2 µm | 1.6 µm |

This level of control is sustained through our certified ISO 9001:2015 quality management system and investment in state-of-the-art coordinate measuring machines (CMM) and laser trackers for final verification. For B2B partners requiring walls molding where failure is not an option, Wuxi Lead delivers the confluence of engineering rigor, proven project execution, and uncompromising precision. We transform complex architectural and engineering specifications into flawlessly manufactured components, ensuring your critical structures perform as designed for their operational lifetime. Partner with us to elevate your project’s foundational integrity through precision metal manufacturing.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for demanding industrial applications. At the core of our production capacity is a fully integrated 5-axis CNC machining platform, enabling us to produce complex geometries with exceptional accuracy and surface finish. This advanced machining technology allows simultaneous movement across five axes, significantly enhancing our ability to manufacture intricate parts in a single setup. The result is reduced cycle times, improved part consistency, and the elimination of potential alignment errors associated with multi-setup processes.

Our 5-axis CNC systems are operated by certified machinists with extensive experience in aerospace, medical, and industrial equipment manufacturing. These professionals utilize industry-leading CAD/CAM software to optimize tool paths, manage material removal rates, and ensure the highest level of precision across diverse alloys, including aluminum, stainless steel, titanium, and high-performance engineering materials. Whether producing low-volume prototypes or scaling to medium production runs, our machining centers maintain tight tolerances and repeatability, meeting the rigorous standards required in mission-critical applications.

Quality control is embedded into every stage of our manufacturing process. All components undergo comprehensive inspection using a Zeiss Coordinate Measuring Machine (CMM), ensuring dimensional accuracy and geometric conformity to customer specifications. The CMM system provides full 3D measurement verification, generating detailed inspection reports that are available to clients upon request. This metrology-grade verification process ensures compliance with ISO 9001 standards and supports traceability across all production batches.

In addition to advanced equipment and rigorous inspection protocols, we maintain strict environmental controls within our machining and inspection zones to minimize thermal variation, a critical factor in sustaining micron-level accuracy. Our facility is equipped with real-time tool monitoring systems and automated calibration routines to further enhance process stability.

The following table outlines typical tolerance capabilities achieved through our 5-axis CNC and quality assurance processes:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Depending on part size and material |

| Angular Tolerance | ±0.1° | ±0.05° | Verified via CMM |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | Includes hole patterns and features |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Achieved without secondary finishing |

| Geometric Tolerances (Flatness, Roundness) | ±0.02 mm | ±0.008 mm | Measured per ISO 1101 |

These technical capabilities, combined with our commitment to process excellence, position Wuxi Lead Precision Machinery as a trusted partner for high-end custom manufacturing solutions. We support global clients requiring precision-engineered metal components where performance, reliability, and consistency are non-negotiable.

Material & Finish Options

Material Selection for Precision Wall Molding: Performance-Driven Choices

Selecting the optimal material for custom wall molding applications is a critical engineering decision impacting structural integrity, longevity, aesthetics, and total cost of ownership. At Wuxi Lead Precision Machinery, our CNC manufacturing expertise ensures your chosen material is perfectly matched to functional requirements and environmental exposure. Aluminum alloys, particularly 6061-T6, represent the dominant choice for architectural and industrial wall systems due to their exceptional strength-to-weight ratio, inherent corrosion resistance, and superior machinability. This facilitates the production of complex, lightweight profiles with tight tolerances essential for seamless installation and clean aesthetics. Steel, specifically 304 stainless, is indispensable where maximum structural strength, fire resistance, or extreme mechanical wear are primary concerns, such as in heavy industrial facilities or structural supports. Its higher density necessitates robust mounting solutions but delivers unmatched durability under high stress. Titanium Grade 5 (Ti-6Al-4V) serves niche, high-value applications demanding the ultimate in corrosion resistance combined with strength, such as marine environments, chemical processing plants, or critical medical cleanroom walls, though its significant cost requires careful justification.

Material performance characteristics must be evaluated holistically against project demands. Key properties include yield strength for load-bearing capacity, density influencing weight and handling, corrosion resistance dictating lifespan in specific atmospheres, and machinability affecting production cost and precision. The following comparative analysis provides essential baseline data for initial selection:

| Material | Typical Grade | Yield Strength (MPa) | Density (g/cm³) | Key Advantages | Primary Applications | Cost Factor |

|---|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 240-275 | 2.7 | Light weight, excellent corrosion resistance, easy machining, good anodizing response | Architectural walls, cleanrooms, general industrial | 1.0 |

| Stainless Steel | 304 | 205-310 | 8.0 | High strength, superior fire resistance, excellent mechanical durability | Structural supports, heavy industrial, food processing | 1.8 |

| Titanium | Grade 5 | 827-895 | 4.43 | Exceptional corrosion resistance, high strength-to-weight, biocompatible | Marine, chemical, critical medical, aerospace | 5.0+ |

Surface finishing, particularly for aluminum wall moldings, is not merely cosmetic but a vital performance enhancer. Anodizing creates a durable, wear-resistant oxide layer integral to the metal substrate. Type II (Sulfuric Acid) anodizing offers good corrosion protection and a base for coloring, suitable for most interior and protected exterior applications. For demanding environments requiring maximum abrasion resistance and longevity, Type III (Hardcoat) anodizing is essential. It produces a significantly thicker, harder coating capable of withstanding heavy use and harsh weather, maintaining appearance and function for decades. Wuxi Lead Precision Machinery employs tightly controlled anodizing processes integrated with our CNC workflow, ensuring consistent coating thickness, precise color matching (including architectural standards), and critical dimensional stability – preventing tolerance issues common with poorly managed post-machining treatments.

Ultimately, the optimal material and finish selection balances performance requirements, environmental factors, lifecycle costs, and aesthetic goals. Wuxi Lead Precision Machinery provides comprehensive engineering consultation, leveraging our deep material science knowledge and advanced CNC manufacturing capabilities. We analyze your specific wall molding application to recommend the most cost-effective solution, ensuring dimensional accuracy, structural reliability, and long-term performance. Partner with us for material selection guidance backed by precision manufacturing execution. Contact our engineering team for a detailed dimensional tolerance analysis and finish specification review.

Manufacturing Process & QC

The production process for high-precision walls molding at Wuxi Lead Precision Machinery is engineered to deliver zero-defect components through a rigorously controlled sequence: Design, Prototyping, and Mass Production. Each phase integrates advanced engineering practices, precision tooling, and real-time quality assurance to ensure dimensional accuracy, structural integrity, and long-term performance in demanding industrial applications.

Design begins with a collaborative engineering review, where our technical team analyzes customer specifications, material requirements, and functional conditions. Utilizing 3D CAD modeling and finite element analysis (FEA), we simulate mechanical behavior under load, thermal variation, and environmental exposure. This phase ensures optimal wall thickness distribution, stress relief geometry, and mold flow characteristics. Design for manufacturability (DFM) principles are applied to eliminate potential defects such as warping, sink marks, or porosity. All designs are validated through digital mock-ups and undergo formal customer sign-off before progression.

Prototyping follows with the fabrication of high-fidelity pre-series units using production-intent tooling. We employ CNC-machined molds or soft tooling based on project timelines and volume requirements. Each prototype is subjected to comprehensive metrology testing, including coordinate measuring machine (CMM) inspection, optical scanning, and first-article reporting (FAI). Material certifications, mechanical testing, and fit-check assemblies are conducted to verify compliance with technical standards. Feedback from this stage is used to refine mold geometry, gating systems, and process parameters. Only after full dimensional and functional validation do we approve transition to mass production.

Mass Production is executed in our ISO 9001-certified facility with full process traceability and statistical process control (SPC). Automated molding systems are monitored in real time, with closed-loop feedback adjusting pressure, temperature, and cycle time to maintain consistency. Every component undergoes 100% visual inspection and selective in-line metrology sampling. Our zero-defect philosophy is enforced through layered quality audits, preventive maintenance schedules, and operator certification programs. Finished parts are packaged in ESD-safe or corrosion-protected materials, with full documentation including inspection reports and material traceability records.

Throughout the entire process, Wuxi Lead applies continuous improvement methodologies, ensuring not only compliance but sustained excellence in every walls molding solution delivered.

| Specification | Detail |

|---|---|

| Material Options | Aluminum Alloys (6061, 7075), Stainless Steel (304, 316), Carbon Steel, Brass |

| Tolerance Range | ±0.02 mm to ±0.05 mm (depending on geometry and size) |

| Surface Finish | As-machined, Anodized (Type II/III), Powder Coating, Passivated |

| Maximum Part Size | 1200 mm × 800 mm × 500 mm |

| Production Capacity | Up to 500,000 units/month (scalable with multi-cavity tooling) |

| Quality Standards | ISO 9001:2015, IATF 16949, RoHS, Full FAI and PPAP Support |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Architectural Metal Excellence

In high-end construction and design, the integrity of wall molding systems defines both aesthetic vision and structural longevity. Substandard components compromise building facades, invite maintenance liabilities, and erode project value. At Wuxi Lead Precision Machinery, we engineer custom metal molding solutions where micron-level accuracy meets architectural ambition. Our vertically integrated facility in Wuxi combines German-engineered CNC platforms with ISO 9001-certified processes, transforming complex 3D models into flawless aluminum, brass, and stainless steel profiles. We specialize in low-volume, high-complexity runs where tolerances below ±0.02mm are non-negotiable—ensuring seamless integration, weather resistance, and decades of performance.

Precision begins with partnership. Our engineering team collaborates from concept to certification, utilizing FEA simulation to preempt thermal expansion issues and material stress points unique to vertical installations. Unlike mass producers, we prioritize your design intent over throughput, dedicating resources to intricate geometries, bespoke surface finishes, and rapid prototyping. This approach eliminates field rework and accelerates project timelines, directly impacting your bottom line. The table below outlines our core capabilities for architectural molding applications:

| Specification Category | Performance Standard | Relevance to Wall Molding Systems |

|---|---|---|

| Dimensional Tolerance | ±0.02 mm | Ensures perfect panel alignment and joint integrity across large facades |

| Material Range | Aluminum 6061-T6, 316L Stainless, C36000 Brass | Corrosion resistance for coastal/high-humidity environments |

| Max Profile Complexity | 12-axis simultaneous machining | Supports organic curves, undercut details, and integrated mounting channels |

| Surface Finish Options | Anodized (architectural grade), Powder-Coated (AAMA 2605), Brushed | Meets LEED sustainability criteria and design-specific textures |

| Lead Time (Prototype) | 12–18 business days | Accelerates design validation before full production |

When your project demands moldings that perform as impeccably as they appear, generic suppliers fall short. Lead Precision delivers certified material traceability, in-process CMM validation at every stage, and packaging engineered for global logistics—protecting delicate profiles during transit. We serve Tier-1 contractors and luxury developers across Europe, North America, and the Middle East, where building codes and aesthetic expectations leave zero margin for error.

Initiate your precision molding project with confidence. Contact our engineering sales team directly at [email protected] to submit CAD files or discuss technical requirements. Include project location, material specifications, and target completion dates for a tailored capability assessment within 24 business hours. For urgent requests, reference “WALLS MOLDING URGENT” in your subject line. Let us prove why global architects specify Lead Precision: where exacting standards aren’t just met—they’re engineered into every component. Your vision, perfected.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.