Technical Contents

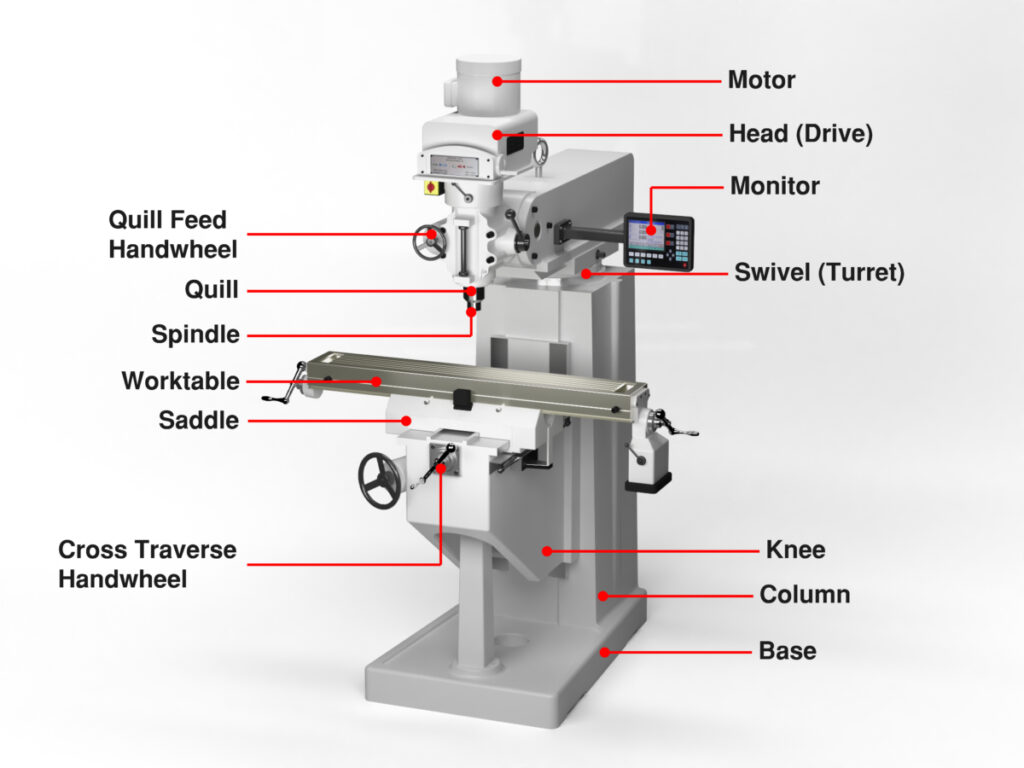

Engineering Guide: Vertical Mill Parts

Engineering Insight: The Critical Role of Precision in Vertical Mill Parts

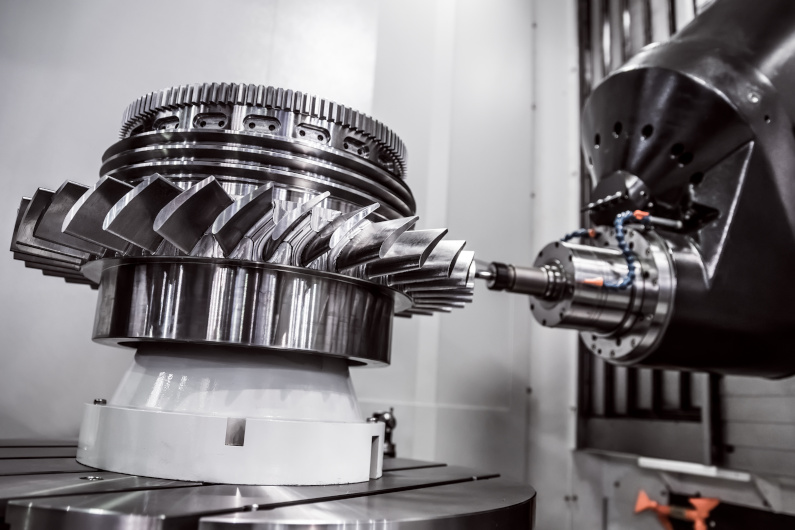

In the realm of high-performance manufacturing, vertical mill parts serve as the backbone of countless industrial systems, from aerospace assemblies to advanced automation equipment. These components demand more than standard machining tolerances—they require micron-level precision, material integrity, and geometric consistency to ensure seamless integration and long-term reliability. At Wuxi Lead Precision Machinery, we understand that the performance of an entire system often hinges on the accuracy of a single milled component.

Precision in vertical mill parts transcends mere dimensional accuracy. It encompasses surface finish quality, thermal stability during machining, tool path optimization, and the ability to maintain repeatability across production runs. Even deviations measured in microns can lead to misalignment, increased wear, or catastrophic failure in high-load or high-speed applications. This is especially critical in sectors such as defense and aerospace, where operational environments are extreme and failure is not an option.

Our engineering team at Wuxi Lead leverages over 15 years of experience in custom metal manufacturing, with a proven track record in delivering mission-critical components for Olympic-grade equipment and military-grade systems. These applications demand the highest levels of quality assurance, traceability, and compliance—standards we have consistently met through rigorous process control and advanced CNC vertical milling technologies. Whether producing complex housings, precision shafts, or custom flanges, our focus remains on achieving perfect form, fit, and function.

We utilize state-of-the-art 5-axis vertical machining centers equipped with high-speed spindles and real-time probing systems to ensure each part conforms to exact specifications. Our quality control protocols include first-article inspection, in-process gauging, and full CMM (Coordinate Measuring Machine) validation for critical dimensions. This disciplined approach allows us to maintain tolerances down to ±0.002 mm and surface finishes as fine as Ra 0.4 μm.

Material selection is equally critical. We work with a broad range of metals including aerospace-grade aluminum alloys, titanium, stainless steel, and hardened tool steels, ensuring that each vertical mill part not only meets dimensional requirements but also performs under operational stress.

The following table outlines typical precision capabilities for vertical mill parts at Wuxi Lead Precision Machinery:

| Specification | Standard Capability | High-Precision Capability |

|---|---|---|

| Positional Tolerance | ±0.01 mm | ±0.002 mm |

| Surface Finish (Ra) | Ra 1.6 μm | Ra 0.4 μm |

| Feature Repeatability | ±0.005 mm | ±0.001 mm |

| Maximum Work Envelope | 1200 x 600 x 500 mm | 800 x 500 x 400 mm |

| Material Compatibility | Aluminum, Steel, Stainless, Titanium | Inconel, Tool Steel, Exotic Alloys |

| Quality Certification | ISO 9001:2015 | AS9100D, ITAR (upon request) |

Precision in vertical mill parts is not an incremental advantage—it is a fundamental requirement for performance, safety, and innovation. At Wuxi Lead Precision Machinery, we combine engineering excellence with proven experience in the most demanding applications to deliver components that perform without compromise.

Precision Specs & Tolerances

Precision Manufacturing Capabilities for Vertical Mill Components

Wuxi Lead Precision Machinery delivers exceptional technical execution for critical vertical mill parts through integrated advanced manufacturing and rigorous quality control systems. Our core competency centers on multi-axis CNC machining, specifically leveraging state-of-the-art 5-axis milling centers. This technology enables the production of highly complex geometries inherent in vertical mill spindles, housings, knee assemblies, and precision ways within a single setup. Eliminating multiple fixturing operations significantly enhances positional accuracy, reduces cumulative error, and ensures superior surface finishes essential for high-performance milling applications. Our machine park utilizes hardened cast iron and high-rigidity structural designs, maintaining thermal stability during extended production runs for components demanding micron-level consistency across large work envelopes.

Quality assurance is intrinsically embedded within our manufacturing workflow, not merely a final checkpoint. Every critical dimension and geometric feature on vertical mill components undergoes comprehensive verification using calibrated Coordinate Measuring Machines (CMMs). Our Zeiss and Hexagon metrology systems perform full 3D inspections against CAD models, generating detailed inspection reports traceable to international standards. This process validates dimensional conformance, geometric tolerances (GD&T), and surface integrity, providing documented evidence of part quality for demanding aerospace, medical, and industrial equipment sectors. All inspection protocols adhere strictly to ISO 9001:2015 requirements, ensuring repeatability and reliability in every batch.

The following table outlines our standard and achievable tolerance capabilities for machined vertical mill parts, reflecting the precision attainable through our optimized processes and metrology:

| Feature | Standard Capability | Tight Tolerance Capability |

|---|---|---|

| Linear Dimension (mm) | ±0.010 mm | ±0.005 mm |

| Linear Dimension (inch) | ±0.0004 in | ±0.0002 in |

| Geometric Tolerance (Flatness, Perpendicularity, etc.) | 0.020 mm / 100 mm | 0.005 mm / 100 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Surface Roughness (Ra) | 0.8 µm (32 µin) | 0.4 µm (16 µin) |

Achieving these stringent tolerances consistently requires more than advanced hardware; it demands deep process expertise. Our engineering team optimizes cutting strategies, toolpath generation, and fixture design specifically for the unique material challenges of mill components, including high-strength steels, cast irons, and specialized alloys. Material stress relief protocols are strictly followed to prevent post-machining distortion. This holistic approach, combining 5-axis precision, real-time process monitoring, and CMM-validated inspection, ensures vertical mill parts meet the exacting performance and longevity requirements of modern high-speed machining centers. Partnering with Wuxi Lead mitigates risk by guaranteeing components that integrate seamlessly and perform reliably under demanding operational loads.

Material & Finish Options

Material Selection for Vertical Mill Parts: Precision Engineering with Purpose

Selecting the right material for vertical mill parts is a critical step in ensuring performance, longevity, and cost-efficiency in demanding industrial applications. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing, leveraging advanced CNC vertical milling technology to deliver components that meet exacting standards. Our expertise enables clients to make informed decisions when choosing between aluminum, steel, and titanium—three of the most widely used metals in high-precision machining.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is ideal for applications where weight reduction is crucial without sacrificing structural integrity, such as in aerospace, automotive, and consumer electronics. The 6061 and 7075 aluminum alloys are particularly popular due to their weldability and high tensile strength. When enhanced surface durability is required, aluminum components are often finished with anodizing—a process that increases wear and corrosion resistance while allowing for color customization.

Steel, particularly alloy and stainless grades, offers superior strength, hardness, and thermal stability. It is the material of choice for heavy-duty parts subjected to high stress, impact, or elevated temperatures. Common applications include industrial tooling, machinery frames, and precision gears. While steel is more challenging to machine than aluminum, our vertical milling centers are equipped to handle its rigors with tight tolerances and excellent surface finishes. Stainless steel variants like 304 and 316 provide additional corrosion resistance, making them suitable for medical, food processing, and marine environments.

Titanium stands at the pinnacle of performance materials, offering an exceptional strength-to-density ratio and outstanding resistance to corrosion and extreme temperatures. Though more expensive and difficult to machine, titanium is indispensable in aerospace, defense, and high-performance automotive sectors. Its biocompatibility also makes it a preferred choice for medical implants and surgical instruments. At Wuxi Lead, we employ specialized tooling and cooling strategies to ensure precision when milling titanium, minimizing tool wear and maintaining dimensional accuracy.

Surface finishing plays a vital role in enhancing both function and appearance. Anodizing, primarily applied to aluminum, creates a durable oxide layer that improves wear resistance and allows for aesthetic customization through dyeing. Other finishes such as passivation (for stainless steel) or shot peening (for high-stress components) can be applied based on operational requirements.

The table below summarizes key mechanical properties and applications of these materials:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Common Alloys | Typical Applications | Suitable Finishes |

|---|---|---|---|---|---|

| Aluminum | 180–570 | 2.7 | 6061, 7075 | Aerospace, automotive, electronics | Anodizing, powder coating |

| Steel | 400–900 | 7.8 | 4140, 304, 316 | Industrial machinery, tooling | Passivation, plating |

| Titanium | 900–1100 | 4.5 | Grade 5 (Ti-6Al-4V) | Aerospace, medical, defense | Anodizing, polishing |

At Wuxi Lead Precision Machinery, we combine material science expertise with state-of-the-art vertical milling to deliver components that meet the highest standards of performance and reliability. Partner with us to ensure your next project is built on the foundation of optimal material selection.

Manufacturing Process & QC

Vertical Mill Parts Production Process: Precision Engineered from Concept to Completion

At Wuxi Lead Precision Machinery, our vertical mill parts production adheres to a rigorously controlled three-phase workflow designed to eliminate defects before they reach your facility. This systematic approach ensures every component meets aerospace and medical-grade tolerances while optimizing lead times for high-volume orders.

Design Phase: Engineering Precision at the Foundation

Our process begins with collaborative engineering analysis using Siemens NX and SolidWorks. We dissect your technical drawings and operational requirements to identify potential stress points, material limitations, and assembly interfaces. Finite element analysis (FEA) validates structural integrity under simulated load conditions, while generative design algorithms optimize weight distribution without compromising rigidity. Critical geometries undergo thermal expansion modeling to account for operational temperature variances. This phase concludes with a formal Design for Manufacturability (DFM) review, where our engineers propose actionable refinements to reduce machining complexity by up to 30% while maintaining your performance specifications.

Prototyping: Validating Performance Before Scale

Prototyping is not a checkpoint but a validation sprint. Using HAAS VF-3 SS vertical mills with 0.0001″ resolution, we produce 3-5 functional units from your specified material stock. Each prototype undergoes:

Coordinate Measuring Machine (CMM) inspection against 100% of critical dimensions

Hardness and grain structure verification per ASTM E384

Dynamic load testing on custom jigs replicating mill spindle forces

Surface finish validation via profilometry (Ra ≤ 0.8 μm)

Feedback loops between your engineering team and our technicians drive rapid iterations. Only when all prototypes pass 100% of functional tests do we approve the final digital twin for mass production.

Mass Production: Zero Defects Through Systemic Control

Our ISO 9001-certified production floor implements closed-loop quality management. Each vertical mill part progresses through:

Real-time tool wear monitoring with Renishaw probes triggering automatic tool compensation

In-process CMM checks at 50-part intervals against statistical process control (SPC) limits

100% first-article inspection and batch traceability via laser-etched QR codes

Final cleaning in ultrasonic baths and VOC-compliant passivation per AMS 2700

The result is consistent delivery of components that exceed OEM specifications. Below are typical capabilities for vertical mill spindle housings, quill assemblies, and knee brackets:

| Specification | Standard Capability | Tight-Tolerance Option |

|---|---|---|

| Material Range | Aluminum 6061-T6, 7075; Steel 4140, 4340; Stainless 304, 17-4PH | Inconel 718, Titanium Gr5 |

| Dimensional Tolerance | ±0.010 mm | ±0.005 mm |

| Surface Finish (Ra) | 1.6 μm | 0.4 μm |

| Geometric Tolerance | ±0.020 mm | ±0.008 mm |

| Max Work Envelope | 1000 x 600 x 500 mm | Custom up to 1500 mm |

Wuxi Lead’s production ecosystem integrates German metrology equipment, predictive maintenance algorithms, and operator certification programs to sustain 99.98% first-pass yield rates. We treat every vertical mill component as mission-critical—because in your facility, downtime is not an option. Partner with us to transform precision requirements into flawless operational reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Vertical Mill Parts Manufacturing

At Wuxi Lead Precision Machinery, we understand that precision, reliability, and repeatability are non-negotiable in high-performance vertical milling applications. As a leading custom metal manufacturing partner based in China, we specialize in delivering engineered-to-order vertical mill components that meet the most stringent industrial standards. Whether you are upgrading existing systems, developing new machinery, or scaling production, our team provides end-to-end support from design consultation to final delivery.

Our advanced CNC vertical machining centers, combined with decades of engineering expertise, allow us to produce complex mill parts with tight tolerances down to ±0.005 mm. We work with a broad range of materials including hardened steel, aluminum alloys, stainless steel, titanium, and specialty composites—ensuring each component is optimized for strength, wear resistance, and thermal stability. Every part undergoes rigorous in-process and final inspections using coordinate measuring machines (CMM) and 3D laser scanning to guarantee dimensional accuracy and surface finish consistency.

We serve industries where performance under extreme conditions is critical—automotive, aerospace, energy, medical equipment, and industrial automation. Our clients rely on us not just for component quality but for our ability to solve complex manufacturing challenges through innovation and collaboration. From prototype development to high-volume production runs, we adapt our processes to your timeline, volume requirements, and quality benchmarks.

Below are key technical capabilities that define our vertical mill parts manufacturing:

| Specification | Detail |

|---|---|

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Positioning Accuracy | ±0.003 mm |

| Repeatability | ±0.002 mm |

| Spindle Speed | Up to 24,000 RPM |

| Surface Finish | As low as Ra 0.4 µm (polished to Ra 0.1 µm upon request) |

| Materials Processed | Carbon steel, stainless steel, aluminum, titanium, brass, PEEK, and engineered composites |

| Tolerance Range | ±0.005 mm standard, ±0.001 mm on critical features |

| Quality Standards | ISO 9001:2015 certified, full traceability, first-article inspection reports (FAIR) available |

We believe the best manufacturing partnerships are built on trust, transparency, and technical excellence. When you choose Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a strategic ally committed to your success. Our engineering team is ready to review your prints, suggest design improvements for manufacturability, and provide fast-turnaround quotations.

Contact us today to discuss your vertical mill parts requirements. Email us at [email protected] and one of our precision manufacturing specialists will respond within 24 hours. Let Lead Precision be the foundation of your next high-performance machining project.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.