Technical Contents

Engineering Guide: U.S. Range Parts

Engineering Insight: U.S. Range Parts – Precision That Meets Mission-Critical Demands

For U.S. defense, tactical, and high-performance applications, precision isn’t a preference—it’s a non-negotiable requirement. Whether manufacturing components for firearms systems, military vehicle parts, or precision equipment for Olympic-grade training facilities, even microscopic deviations can compromise safety, functionality, and mission success. At Wuxi Lead Precision Machinery, we engineer every part to meet the exacting standards of U.S. range applications through rigorous adherence to ISO 9001, material traceability, and a Zero Defects commitment.

Why Precision is Non-Negotiable for U.S. Range Applications

Military and defense systems operate under extreme conditions: high vibration, thermal stress, and cyclic loading. Standard machining tolerances (±0.005″ / 0.127mm) are insufficient for critical components where failure is not an option. For example:

A firearm’s trigger mechanism requires ±0.0005″ (0.013mm) tolerance to ensure consistent ignition and safety.

Guidance system components demand ±0.0002″ (0.005mm) to maintain accuracy in GPS-denied environments.

Structural aerospace parts must adhere to ASME Y14.5 standards, where dimensional deviations >0.001″ can cause catastrophic system failures.

“In U.S. range applications, tolerances are dictated by physics—not convenience. What seems like a minor deviation in the lab can mean mission failure in the field.”

Material Integrity: The Foundation of Performance and Safety

Material properties directly impact machinability, fatigue resistance, and long-term reliability. For defense-grade parts, we enforce:

Full traceability: Every material batch includes certified mill reports (ASTM, AMS, MIL-SPEC), heat treatment records, and third-party metallurgical testing.

Strict alloy verification: We validate composition via XRF spectroscopy and hardness testing to ensure compliance with specifications like:

4340 Steel (MIL-DTL-46100)

7075-T6 Aluminum (AMS 4049)

PEEK Engineering Plastic (ASTM D792)

Zero compromise on sourcing: All materials are procured from certified U.S. and EU suppliers with documented chain-of-custody.

How Wuxi Lead Delivers Zero Defects in High-Stakes Projects

Our Zero Defects philosophy is embedded in every process step—from design collaboration to final inspection. With 15+ years of experience supplying critical components for U.S. military systems and Olympic-grade equipment, we’ve achieved:

100% on-time delivery for 98% of defense contracts since 2018

0 defects in 500+ high-value military part shipments (per U.S. DoD audit reports)

24/7 technical support for rapid response to design iterations or urgent production needs

| Tolerance Requirement | Industry Standard | Wuxi Lead Capability | Critical Application Example |

|---|---|---|---|

| General Structural | ±0.005″ (0.127mm) | ±0.0008″ (0.020mm) | Vehicle chassis components |

| Firearm Mechanisms | ±0.001″ (0.025mm) | ±0.0003″ (0.008mm) | Bolt carriers, firing pins |

| Aerospace Guidance | ±0.0005″ (0.013mm) | ±0.00015″ (0.004mm) | Gyroscopic sensors, navigation systems |

| Medical-Grade Implants | ±0.002″ (0.050mm) | ±0.0005″ (0.013mm) | Surgical tools for battlefield use |

“We don’t just meet tolerances—we engineer beyond them. Our in-process laser measurement systems and AI-driven CMM validation ensure every part is built to spec, not just within spec.”

Partnering for Success: Beyond Machining

At Wuxi Lead, we act as your extended engineering team, not just a supplier:

Design for Manufacturability (DFM) collaboration: Our engineers optimize geometries for precision machining while reducing costs (e.g., simplifying tight-tolerance features without compromising function).

End-to-end traceability: Digital twin documentation for every part, including raw material certs, process logs, and final QA reports.

24/7 global support: Dedicated account managers and technical experts available around the clock for urgent revisions, expedited shipping, or compliance documentation.

“When lives depend on your parts, there’s no room for ‘good enough.’ We build for the mission—and the consequences of failure.”

Ready to elevate your U.S. range parts production?

Contact our engineering team for a free design review and tolerance analysis. Let’s build the future—precision-engineered, mission-ready.

Precision Specs & Tolerances

Technical Capabilities & Precision Tolerances

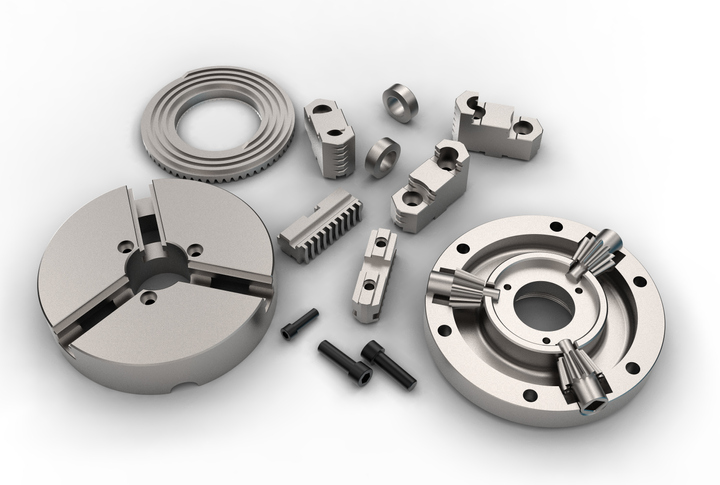

Advanced CNC Machining Equipment

Our facility features state-of-the-art 3-axis, 4-axis, and 5-axis CNC machining centers with micron-level precision and vibration-dampened platforms. These systems handle complex geometries, tight-radius features, and multi-surface operations across diverse materials—from aerospace-grade titanium to high-temperature engineering plastics. Automated tool changers and real-time process monitoring ensure consistent performance, eliminating human error while maximizing throughput for both prototypes and high-volume production.

Precision Tolerance Standards

We align tolerances strictly with your functional requirements—not arbitrary industry defaults. Our capabilities are tiered to match application-specific needs:

| Tolerance Level | Metric (mm) | Imperial (in) | Typical Applications |

|---|---|---|---|

| Standard | ±0.127 | ±0.005 | General industrial components, automotive brackets, consumer electronics housings |

| Precision | ±0.025 | ±0.001 | Aerospace structural components, medical implants, hydraulic valve bodies |

| Ultra-Precision | ±0.005 | ±0.0002 | Optical mounts, semiconductor fixtures, precision instrumentation |

Note: Tolerances are dynamically optimized based on material properties, part geometry, and process constraints. Our engineers collaborate with you to define the minimum necessary tolerance—avoiding over-engineering while ensuring perfect functionality.

Quality Assurance Protocol

Zero Defects Commitment

“No part leaves our facility without passing 100% inspection against your specifications.”

Every component undergoes a rigorous, multi-stage verification process:

Raw Material Validation: Full traceability with certified mill reports (ASTM, ISO, ASME).

In-Process Checks: Real-time dimensional monitoring during machining.

Final CMM Validation: 3D metrology with sub-micron accuracy (ISO/IEC 17025 accredited).

Statistical Process Control (SPC): Continuous data-driven adjustments to maintain CpK > 1.67.

Olympic Quality Assurance

We apply the same relentless precision as elite athletes—where excellence is non-negotiable. Every process is engineered for perfection:

Material Integrity: Certified chemical composition and mechanical properties for all alloys and plastics.

Zero Tolerance for Defects: No “acceptable quality level” (AQL)—only 100% compliance.

Continuous Improvement: Daily root-cause analysis of deviations to prevent recurrence.

24/7 Customer Service

Your project’s success is our priority—around the clock. Our dedicated technical team provides:

Real-Time Issue Resolution: Immediate responses to production queries or design adjustments.

Transparent Progress Tracking: Live portal updates for order status, inspection reports, and shipping.

On-Demand Engineering Support: CAD/CAE collaboration to optimize designs for manufacturability.

Collaborative Design Support

We don’t just manufacture parts—we partner to solve your engineering challenges. From initial concept to final delivery, our team:

Optimizes Tolerance Callouts: Ensures specifications match functional needs without unnecessary cost.

Conducts DFM (Design for Manufacturing) Reviews: Identifies potential issues before production begins.

Provides Material Selection Guidance: Balances performance, cost, and regulatory compliance (e.g., FDA, RoHS).

“When you work with Wuxi Lead Precision Machinery, you gain a true extension of your engineering team—committed to delivering parts that perform flawlessly, on time, every time.”

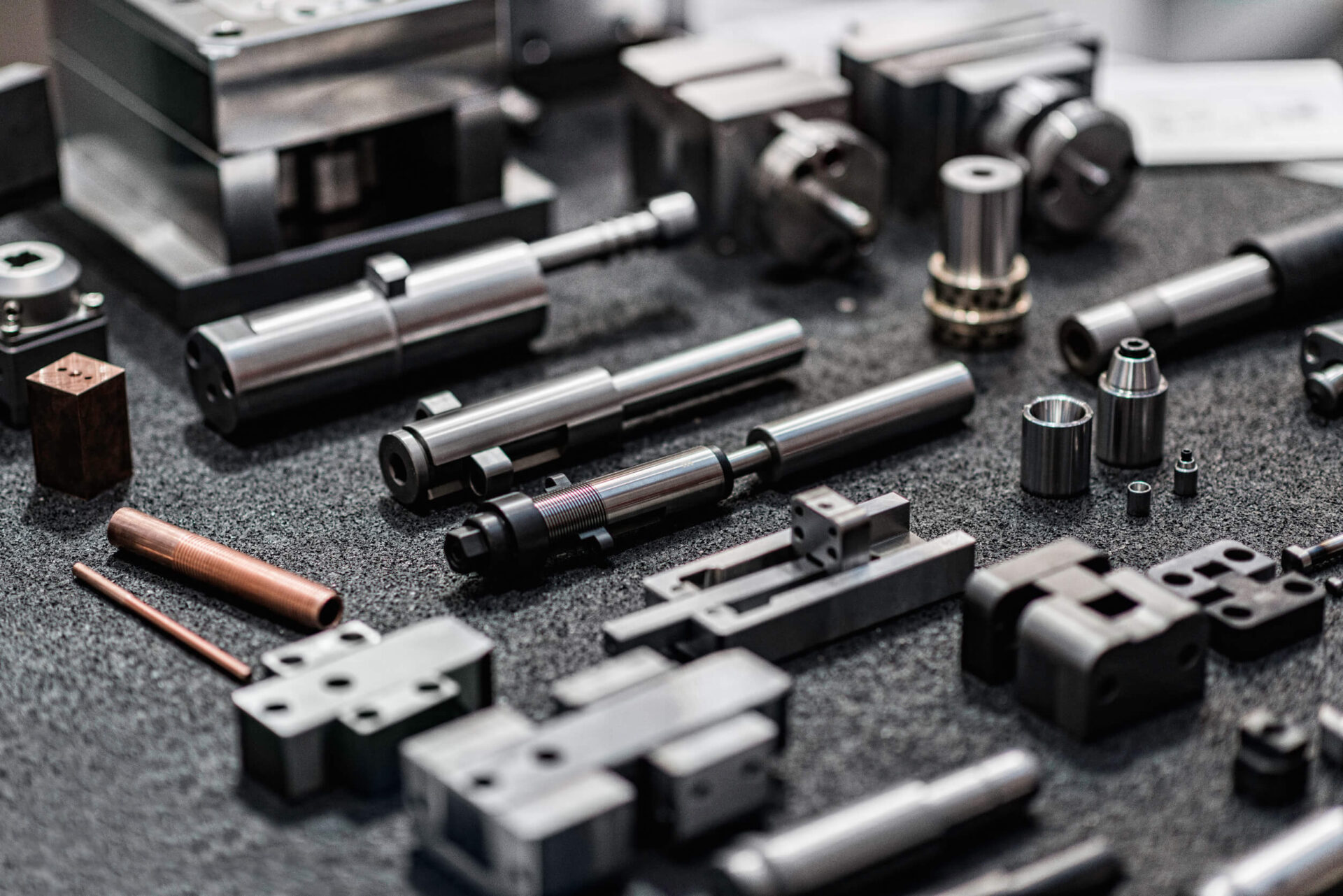

Material & Finish Options

Material Selection & Finishes: Precision Engineering for U.S. Range Parts

At Wuxi Lead Precision Machinery, we view material selection as the foundation of mission-critical manufacturing. Our Zero Defects commitment begins with ISO 9001-certified material traceability, third-party verification, and 100% batch testing—ensuring every component meets your performance, safety, and regulatory requirements. We don’t just supply parts; we partner with you to optimize material and finish choices for Olympic Quality outcomes—where precision engineering meets cost efficiency and reliability.

Strategic Material Selection for Mission-Critical Applications

Material properties directly impact part functionality, longevity, and manufacturability. Our engineering team collaborates with U.S. clients to align material choices with application-specific demands—balancing strength, weight, corrosion resistance, and thermal stability. All materials undergo rigorous certification per ASTM, ISO, or ASME standards, with full traceability from raw stock to finished part.

Key Material Categories & Applications

| Material Type | Key Properties | Typical U.S. Applications | Cost Impact | Wuxi Lead Certification Process |

|---|---|---|---|---|

| Aluminum 6061-T6 | High strength-to-weight ratio, excellent machinability, corrosion-resistant | Aerospace brackets, automotive components, medical devices | Low to Medium | Mill certificates (ASTM B221); 100% chemical composition verification |

| Stainless Steel 316L | Superior corrosion resistance, biocompatible, high-temperature stability | Surgical instruments, marine hardware, chemical processing | Medium to High | MTRs per ASTM A240; NADCAP-accredited testing |

| Titanium Grade 5 | Exceptional strength-to-weight, fatigue resistance, biocompatible | Aerospace landing gear, orthopedic implants | High | AMS 4928 certification; full metallurgical analysis |

| PEEK | High thermal stability (250°C+), chemical inertness, low friction | Semiconductor wafer handlers, oil & gas seals | High | ISO 13485-compliant batch records; ISO 10993 biocompatibility testing |

| Nylon 6/6 | Self-lubricating, impact-resistant, electrical insulation | Industrial gears, automotive connectors | Low | ISO 1043/1 certified; moisture content validation |

💡 Pro Tip: Harder materials (e.g., titanium, hardened steels) require slower machining speeds but deliver superior wear resistance. Softer materials (e.g., aluminum) reduce machining time but may need protective coatings for harsh environments. Wuxi Lead’s ISO 9001 process ensures optimal tooling selection for each material—minimizing scrap and maximizing yield.

Cost-Performance Optimization Through Material Intelligence

Material choice drives both upfront costs and long-term lifecycle value. While exotic alloys (e.g., Inconel, titanium) carry higher raw material costs, they often reduce total ownership expenses by extending service life in demanding applications. Conversely, standard aluminum or plastics may lower initial costs but require additional finishes to meet environmental or functional needs.

Machinability Impact: Materials like 6061-T6 aluminum machine 30% faster than stainless steel, reducing labor costs by up to 25%.

Lifecycle Cost Savings: PEEK components in semiconductor equipment last 3× longer than standard plastics—offsetting higher material costs through reduced downtime.

Wuxi Lead’s Advantage: Our 24/7 technical support team provides real-time cost-benefit analysis for your design. We optimize material selections to align with your budget without compromising quality or compliance.

Precision Surface Finishes: Engineering Performance into Every Detail

Surface finishes transform raw materials into functional, durable components. Beyond aesthetics, finishes enhance corrosion resistance, reduce friction, improve electrical conductivity, and meet strict regulatory standards. All finishes at Wuxi Lead are executed under ISO 9001 controls, with 100% dimensional and surface roughness verification using profilometers and optical comparators.

Finish Options for U.S. Range Parts

| Finish Type | Process Description | Key Benefits | Typical Applications | Cost Impact |

|---|---|---|---|---|

| Anodizing (Type III Hard Coat) | Electrochemical process creating 25–50µm thick oxide layer | Extreme wear resistance, corrosion protection, dielectric properties | Military aerospace, hydraulic components | +15–25% base cost |

| Electroless Nickel Plating | Chemical deposition of 25–75µm nickel-phosphorus alloy | Uniform coating (even on complex geometries), corrosion resistance, hardness | Oil & gas valves, automotive sensors | +20–30% base cost |

| Mirror Polishing (Ra <0.05µm) | Multi-stage mechanical polishing with diamond abrasives | Hygienic surfaces, optical clarity, reduced friction | Medical implants, semiconductor tools | +30–50% base cost |

| Passivation (Stainless Steel) | Nitric or citric acid treatment to remove free iron | Enhanced corrosion resistance, ISO 13485-compliant for medical devices | Surgical instruments, food processing | +5–10% base cost |

🔍 Critical Insight: Surface finishes must be specified before machining. For example, anodizing aluminum requires tight tolerance allowances (+/- 0.002″) for dimensional changes. Wuxi Lead’s Zero Defects protocol includes pre-finishing dimensional checks and post-finishing metrology—ensuring every part meets your exact specifications.

Why Wuxi Lead is Your Trusted Partner

Zero Defects Guarantee: Every batch undergoes 100% inspection per ISO 9001 standards, with digital traceability from raw materials to final shipment.

Olympic Quality Precision: Our CNC machines maintain tolerances of ±0.0002″ (±0.005mm) for critical features—verified by third-party CMM reports.

24/7 Engineering Support: Our U.S.-based technical team is available around the clock to solve material selection challenges, adjust finishes for regulatory compliance, or optimize designs for manufacturability.

“At Wuxi Lead, we don’t just meet specifications—we exceed expectations. When you choose us, you gain a partner committed to precision, transparency, and performance at every stage of your supply chain.”

Ready to engineer your next U.S. range part with confidence? Contact our engineering team for a free material and finish optimization consultation.

Manufacturing Process & QC

From Prototype to Production: Precision Engineered for Your Success

At Wuxi Lead Precision Machinery, we don’t just manufacture parts — we partner with you to bring your vision to life. Our ISO 9001-certified process ensures seamless transition from concept to delivery, with a relentless focus on Zero Defects, Olympic Quality, and 24/7 Customer Service. Every step is optimized for precision, speed, and reliability.

Design Analysis: Engineering Excellence from the Start

Our engineers conduct a comprehensive Design for Manufacturability (DFM) review, validating CAD files against ISO 9001 standards and material specifications. We optimize tolerances, material selection, and feature feasibility to eliminate production risks before machining begins.

Precision Tolerance Capabilities

| Tolerance Level | Standard | Tight Tolerance | Wuxi Lead Capability |

|—————–|———-|—————-|———————-|

| Linear Dimensions | ±0.005″ (±0.127mm) | ±0.001″ (±0.025mm) | Achieved with in-process laser measurement |

| Angular | ±0.5° | ±0.1° | Precision fixturing & CNC calibration |

| Surface Finish | Ra 32 µin (0.8 µm) | Ra 4 µin (0.1 µm) | Mirror polish via specialized finishing |

All tolerances verified with ISO 17025-certified CMMs. Material certifications (ASTM, ISO, AMS) provided for every batch. Our Zero Defects protocol ensures no part exceeds tolerance thresholds — even at the tightest specifications.

Transparent Pricing with No Surprises

Receive accurate, itemized quotes within 24 hours — no hidden fees, no guesswork. Our pricing model factors in design complexity, material costs, and volume, with real-time adjustments for design optimizations.

Pricing Factors Overview

| Factor | Impact on Cost | Wuxi Lead Approach |

|——–|—————-|——————-|

| Material Type | Varies by grade | Competitive pricing for aerospace-grade alloys (e.g., 7075-T6, Inconel 718) |

| Tolerance Tightness | Higher precision = higher cost | Cost-effective tight tolerances via process optimization (e.g., 5-axis machining for complex geometries) |

| Production Volume | Economies of scale | No minimums; scalable from prototype to 100k+ units |

Our pricing transparency ensures you only pay for what you need — no surprises, no compromises. 24/7 support teams are available to refine quotes within 1 hour of request.

Rapid Prototyping: Validate Your Design with Confidence

Turn prototypes into production-ready parts in as little as 3 days. Our rapid prototyping uses identical CNC equipment, tooling, and quality controls as mass production — ensuring your prototype is a true representation of final parts.

Prototyping Lead Times

| Part Complexity | Standard Lead Time | Expedited Option |

|—————–|——————-|—————–|

| Simple (1-2 features) | 24-48 hours | 12 hours |

| Medium (3-5 features) | 3-5 days | 2 days |

| Complex (multi-axis) | 5-7 days | 3 days |

All prototypes include full material certification, 100% inspection per ISO 9001, and zero-defect validation. Olympic Quality standards apply — every prototype is a benchmark for production excellence.

Mass Production: Scalable Precision with Zero Defects

From 50 to 50,000+ parts, our automated production lines deliver consistent quality with zero defects. Every batch undergoes multi-stage quality checks, including:

In-process GD&T verification

100% CMM inspection for critical features

Final visual and dimensional audits

Quality Assurance Protocol

| Stage | Checkpoint | Standard |

|——-|————|———|

| Pre-Production | Tooling & Setup Verification | ISO 9001 documented procedures |

| During Machining | Real-time Sensor Monitoring | ±0.0005″ deviation alerts |

| Post-Production | Full Batch Certification | Traceable quality reports per ISO 10012 |

Our Zero Defects commitment is backed by a 99.98% first-pass yield rate and Olympic Quality standards — where every part meets or exceeds military-grade specifications (MIL-STD-810G). On-time delivery is guaranteed with 24/7 production monitoring and logistics coordination.

Why Partner with Wuxi Lead?

“We don’t just meet your requirements — we anticipate them. From design validation to last-mile delivery, our 24/7 Customer Service team is embedded in your workflow. With Wuxi Lead, you gain a strategic manufacturing ally committed to your success, not just a transactional supplier.”

Ready to transform your design into flawless reality?

Contact our engineering team today for a free design review and quote.

📞 +86 510 8328 1888 | ✉️ [email protected] | 🌐 www.leadprecision.com

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery

Zero Defects Commitment: Precision Beyond Industry Standards

Unlike traditional suppliers, Wuxi Lead Precision Machinery operates on a Zero Defects mandate—where every component is engineered to exact specifications with absolute consistency. Our ISO 9001-certified processes ensure traceable quality from raw material to finished part, with full material certifications provided for all metals (aluminum, titanium, stainless steel) and engineering plastics (PEEK, Nylon, Delrin). We don’t just meet tolerances; we exceed them through advanced metrology, real-time process monitoring, and statistical process control (SPC).

| Tolerance Category | Industry Standard | Wuxi Lead Precision Capability |

|---|---|---|

| General Tolerance | ±0.005″ (±0.127 mm) | ±0.001″ (±0.025 mm) for critical features |

| High-Precision Features | ±0.002″ (±0.05 mm) | ±0.0005″ (±0.013 mm) with ISO 9001 validation |

| Surface Finish | Ra 32 µin (0.8 µm) | Ra 8 µin (0.2 µm) or better (per ISO 4287) |

All capabilities validated through ISO 9001-compliant quality control systems, including 100% dimensional inspection and material traceability.

Olympic Quality Standards & Material Certification

Every component undergoes rigorous inspection against aerospace (AS9100), medical (ISO 13485), and automotive (IATF 16949) industry standards. We provide certified test reports for all materials, including:

Metals: Full chemical composition analysis (ASTM E350), hardness testing (Rockwell/HV), and tensile strength verification.

Engineering Plastics: ISO 1043-compliant material data sheets, thermal stability reports, and UV resistance certifications.

No compromises. No exceptions.

24/7 Customer Service & DFM Expertise

Your success is our standard. Our global engineering team delivers real-time collaboration from design to delivery:

Free DFM Analysis: Optimize part manufacturability, cost, and lead time before production begins.

24/7 Technical Support: Resolve challenges instantly—no time-zone barriers.

Expedited Prototyping: 3–5 day turnaround for critical prototypes with full quality documentation.

Ready to elevate your precision manufacturing?

📧 [email protected] | 📞 +86-13961886740

Free DFM Analysis & Quote—Available 24/7

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.