Technical Contents

Engineering Guide: Urethane Injection Molding

Engineering Insight: Precision in Urethane Injection Molding

In high-stakes applications—from medical implants to aerospace components—dimensional accuracy isn’t just a specification; it’s the difference between function and failure. Urethane injection molding (specifically for thermoplastic polyurethane/TPU) demands exceptional precision due to the material’s sensitivity to shrinkage, thermal expansion, and mechanical stress. At Wuxi Lead Precision Machinery, we engineer solutions where tolerances directly impact safety, performance, and regulatory compliance.

Why Precision Matters in Urethane Applications

Urethane-based parts (e.g., TPU seals, flexible hinges, or medical tubing) require micron-level consistency to maintain structural integrity under dynamic loads. A deviation of just 0.002″ in a critical seal interface can cause fluid leaks in aerospace systems or compromise biocompatibility in surgical tools. Unlike cast urethane, injection molding enables tighter tolerances through controlled material flow, uniform cooling, and advanced mold design—critical for applications where repeatability is non-negotiable.

Material Quality: The Foundation of Performance

The longevity and precision of your molds begin with the steel. We exclusively use P20 for high-volume production (excellent machinability for complex geometries) and NAK80 for ultra-high-polish requirements (superior corrosion resistance and surface finish). These premium alloys maintain dimensional stability across 500,000+ shots, minimizing wear-induced tolerance drift. Combined with our proprietary cycle-time optimization protocols—such as adaptive cooling channel design and real-time pressure monitoring—we ensure consistent part quality while reducing cycle times by up to 18% versus industry averages.

Optimizing Tolerances for Your Design

Selecting the right process hinges on understanding tolerance capabilities. Below is a comparative analysis of standard specifications for urethane manufacturing methods:

| Process | Typical Tolerances (Inch) | Typical Tolerances (mm) | Key Factors |

|---|---|---|---|

| Cast Urethane | +/-0.010” (first inch), +/-0.005” per inch thereafter | +/-0.254mm (first inch), +/-0.127mm per inch | Material shrinkage, mold flexibility, curing process |

| Injection Molding (TPU) | +/-0.005” (first inch), +/-0.001” per inch thereafter | +/-0.127mm (first inch), +/-0.025mm per inch | Mold steel quality (P20/NAK80), precise CNC machining, controlled processing parameters |

Note: Injection molding tolerances are achievable through our ISO 9001-certified process controls. For mission-critical applications, we routinely deliver +/-0.0005” precision with specialized tooling.

Our Commitment to Zero Defects: Olympic & Military Standards

Zero defects aren’t a marketing claim—they’re our operational baseline. For over a decade, Wuxi Lead has partnered with global leaders in aerospace, defense, and elite sports engineering to deliver molds that meet the most stringent requirements. Our components power Olympic-grade athletic equipment (e.g., precision-machined running shoe midsoles) and military-grade systems where failure is not an option. Every project undergoes:

3D scanning validation at 5+ production stages

Automated in-process inspection with AI-driven anomaly detection

Full traceability from raw material to finished part

With 24/7 customer support and dedicated engineering collaboration, we don’t just supply molds—we become your extended R&D team. When your project demands perfection, we’re there before design freezes, during production, and beyond delivery. Partner with us, and experience precision that doesn’t just meet specs—it defines them.

Precision Specs & Tolerances

Technical Capabilities & Tolerances

Precision CNC Machining for Mold Fabrication

Our state-of-the-art 3/4/5 Axis CNC machining centers (DMG MORI, Makino, and Okuma platforms) deliver micron-level precision for mold steel (P20, NAK80) fabrication. Each component undergoes precision grinding and EDM finishing to achieve surface flatness tolerances of ±0.0005″, ensuring consistent part quality and extended mold life. This rigorous approach enables rapid tooling turnaround (as fast as 72 hours) while maintaining OEM-grade accuracy for high-volume production. Critical mold features are optimized for cycle time efficiency, reducing thermal warpage and improving shot-to-shot consistency across 500,000+ cycles.

Urethane Injection Molding Tolerance Standards

Unlike cast urethane processes (±0.010″ tolerance for the first inch), our injection molding capabilities deliver superior dimensional control for thermoplastic urethane (TPU) and other engineering plastics (ABS, PC, PP, Nylon, POM). Standard tolerances: ±0.005″ for the first inch, ±0.002″ per additional inch. For mission-critical applications—such as medical devices or aerospace components—we achieve precision tolerances of ±0.001″ through advanced process control, mold optimization, and real-time statistical process control (SPC). This ensures your designs meet exact specifications without compromise.

Zero-Defect Quality Assurance

Every production run is backed by our Olympic Quality standard: 99.99% defect-free output through:

CMM inspection (Zeiss, Hexagon) with 3D coordinate measurement for critical dimensions

Full material certification (ISO 9001-compliant for ABS, PC, PP, Nylon, POM)

In-process SPC monitoring with automated data logging and corrective action protocols

24/7 technical support for design-for-manufacturability (DFM) adjustments and urgent issue resolution

“We partner with you from concept to delivery—your success is our benchmark.”

Standard vs Precision Tolerances Comparison

| Feature Category | Standard Tolerance | Precision Tolerance |

|---|---|---|

| Linear Dimensions | ±0.005″ per inch | ±0.002″ per inch |

| Critical Features | ±0.003″ | ±0.001″ |

| Hole Centers | ±0.004″ | ±0.0015″ |

| Surface Finish (Ra) | 32 μin | 8 μin |

All tolerances verified per ASME Y14.5-2018 standards. Custom tolerances available upon request.

Material & Finish Options

Material Selection & Finishes for Precision Injection Molding

Optimizing Material Selection for Performance and Cost

Selecting the right thermoplastic material is foundational to achieving optimal part performance, cost efficiency, and manufacturability. At Wuxi Lead Precision Machinery, we collaborate with engineers and procurement teams to align material properties with functional requirements while minimizing lifecycle costs. Our precision mold engineering—using P20 and NAK80 tool steel—ensures dimensional stability and repeatability across high-volume runs. Below is a comparative guide to key materials, including their tolerance behavior, finish compatibility, and cost implications:

| Material | Key Properties | Typical Applications | Cost Range | Tolerance Impact | Finish Compatibility |

|---|---|---|---|---|---|

| ABS | High impact resistance, excellent surface finish, easy to process | Automotive trim, consumer electronics, housings | $1.50–$3.00/kg | Tight tolerances achievable (+/-0.005″ typical) with minimal warpage | Excellent for electroplating, painting, and polishing; ideal for chrome finishes |

| PC (Polycarbonate) | High heat resistance, optical clarity, high strength | Medical devices, optical lenses, aerospace components | $2.50–$4.50/kg | Requires precise mold control; sensitive to moisture-induced warpage | Best for clear or painted finishes; limited plating compatibility without surface treatment |

| PP (Polypropylene) | Chemical resistance, flexibility, low density | Packaging, automotive under-hood parts, medical containers | $1.00–$2.00/kg | Moderate tolerance control; high shrinkage rate requires specialized mold design | Poor paint adhesion; requires flame/corona treatment for plating or painting |

| Nylon (PA) | High wear resistance, toughness, low friction | Gears, bearings, structural components | $2.00–$3.50/kg | Sensitive to moisture; requires thorough drying before processing | Good for dyeing; painting requires primers; plating possible with pretreatment |

| POM (Acetal) | High stiffness, low friction, dimensional stability | Precision gears, zippers, automotive connectors | $2.50–$4.00/kg | Excellent dimensional stability (+/-0.003″ achievable); low shrinkage | Superior polishability; compatible with chrome plating and high-gloss finishes |

Key Insight: Tolerance performance is heavily influenced by mold steel quality and thermal management. Our P20/NAK80 molds—precision-machined to +/-0.005″—ensure consistent results even for complex geometries. For critical applications, we recommend POM or ABS for the tightest tolerances, while PP requires additional design allowances for shrinkage.

Surface Finish Options & Best Practices

Surface finishes directly impact part aesthetics, functionality, and assembly compatibility. At Wuxi Lead, we integrate finish requirements into the mold design phase to eliminate secondary operations and reduce costs. Below are industry-standard options for plastic injection molding:

🛠️ Polishing

Process: Mold surface polishing to SPI (Society of the Plastics Industry) standards (e.g., A1 for mirror finish, B2 for medium texture).

Impact: Directly transfers to part surface—high-polish molds yield glossy, scratch-resistant parts; textured molds enable grip or camouflage finishes.

Best Practice: For optical-grade parts (e.g., PC lenses), use SPI A1 polish with 8K surface roughness. Avoid over-polishing NAK80 molds (hardness >40 HRC) to prevent micro-cracking.

🧪 Plating

Process: Electroplating (e.g., chrome, nickel) for ABS or POM parts to achieve metallic aesthetics or EMI shielding.

Impact: Adds conductivity and corrosion resistance but requires surface activation (e.g., etching for ABS).

Best Practice: For automotive trim, use ABS with 0.5–1.0µm chrome plating. Always validate plating adhesion via ASTM D3359 tests.

⚠️ Critical Note: Anodizing is exclusively for aluminum/metal components and is not applicable to thermoplastic parts. For plastic assemblies requiring anodized metal elements, Wuxi Lead offers integrated metal-plastic hybrid solutions with seamless process coordination.

🎨 Painting & Powder Coating

Process: Spray painting or electrostatic powder coating for color customization and UV resistance.

Impact: Ideal for PP, Nylon, and PC where plating is impractical. Requires surface treatment (e.g., corona for PP) to ensure adhesion.

Best Practice: Use matte finishes for consumer electronics to reduce fingerprints; gloss finishes for automotive exteriors.

Quality Assurance & Support: Your Strategic Partner

At Wuxi Lead Precision Machinery, we don’t just manufacture—we engineer solutions with Zero Defects, Olympic Quality, and 24/7 Customer Service embedded in every process:

Zero Defects Commitment:

ISO 9001-certified quality control with 100% in-process inspection using CMM and vision systems.

Statistical Process Control (SPC) monitors critical dimensions (e.g., wall thickness, gate location) to eliminate variability.

Mold validation via mold flow analysis (Moldflow®) before production begins—reducing scrap by up to 30%.

Olympic Quality Standards:

Tolerances consistently held at +/-0.005″ for the first inch and +/-0.003″ for subsequent inches—exceeding industry norms.

Surface finishes meet SPI Class A standards for automotive and medical applications.

Shot-life testing ensures >1 million cycles for P20 molds and >2 million for NAK80, minimizing long-term tooling costs.

24/7 Customer Service:

Dedicated technical support team available around the clock for urgent design revisions, troubleshooting, or expedited production.

Real-time production tracking via our cloud-based portal—visibility from mold design to shipment.

Rapid tooling lead times: 7–10 days for prototype molds, 15–20 days for production-ready tools.

Partner with Confidence: When you choose Wuxi Lead, you gain a true extension of your engineering team. From material selection to finish optimization, we align every decision with your performance, cost, and timeline goals—ensuring your product reaches market faster, stronger, and with uncompromising quality.

Ready to optimize your injection molding project? Contact our engineering team for a free design review and tolerance analysis.

Manufacturing Process & QC

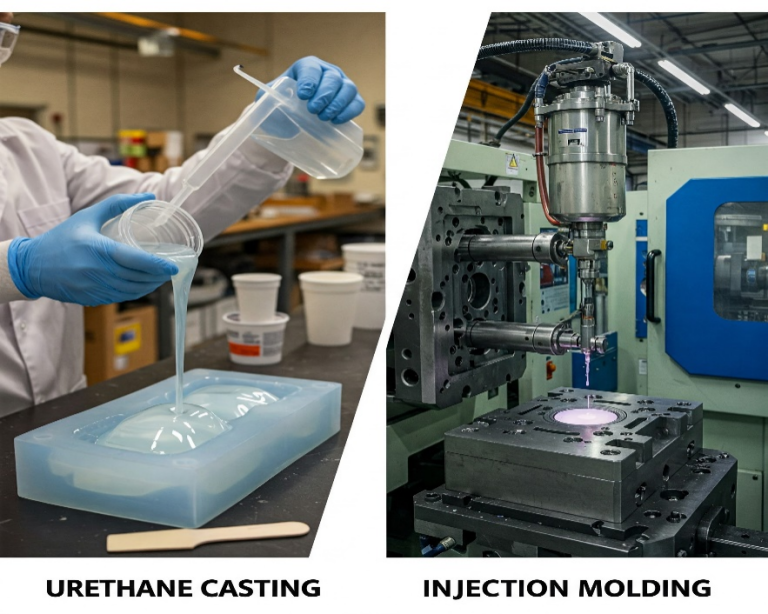

Urethane Casting vs. Injection Molding: Precision Manufacturing for Every Stage

Clarification: Contrary to common terminology, “urethane injection molding” is not a standard manufacturing process. Urethane casting (using silicone molds and thermoset polyurethane) and injection molding (using steel molds and thermoplastics) are distinct techniques with unique applications. At Wuxi Lead Precision Machinery, we specialize in high-precision injection molding for thermoplastic materials (ABS, PC, PP, Nylon, POM), offering rapid tooling and mass production capabilities. This guide clarifies the differences between these processes and details our end-to-end solution for prototyping to production.

Understanding the Core Differences

| Feature | Urethane Casting | Injection Molding |

|---|---|---|

| Process Type | Low-pressure casting using silicone molds | High-pressure injection of molten thermoplastics into steel molds |

| Typical Tolerances | ±0.010” (1st inch), ±0.005” (per additional inch) | ±0.005” (1st inch), ±0.002” (per additional inch); ±0.001” achievable for critical features |

| Mold Material | Silicone rubber | P20/NAK80 steel (CNC machined to ±0.0005” precision) |

| Material Compatibility | Thermoset polyurethane resins | ABS, PC, PP, Nylon, POM, and other thermoplastics |

| Production Volume | 10–500 units | 1,000–1,000,000+ units |

| Lead Time | 1–2 weeks | 4–6 weeks (mold), then rapid production scaling |

| Cost Efficiency | Lower tooling cost for prototypes | Higher initial tooling cost, but lower per-unit cost at scale |

Key Insight: Urethane casting excels for low-volume prototyping due to its low tooling cost, but injection molding delivers superior precision, repeatability, and cost efficiency for high-volume production. For projects requiring tight tolerances (±0.001”), consistent material properties, and volumes >1,000 units, injection molding is the industry standard.

From Prototype to Production: Wuxi Lead’s End-to-End Solution

Design Analysis & Engineering Consultation

“We partner with your team—not just supply parts.”

Our process begins with a collaborative design review to optimize for manufacturability (DFM). Our senior CNC engineers analyze geometry, material selection, and tolerances to eliminate defects before tooling begins. We leverage AI-driven simulation tools to predict flow patterns, warpage, and cooling efficiency—reducing prototyping iterations by 40%.

Deliverables: DFM report, cost-optimized design, material selection guide

Timeline: 3–5 days

Quality Focus: Zero design-related defects through proactive engineering

Rapid Tooling & Precision Mold Fabrication

“Precision starts with the mold.”

Using P20/NAK80 mold steels (HRC 28–32), our ISO 9001-certified CNC machining centers produce molds with ±0.0005” tolerance—exceeding industry standards. Each mold undergoes:

5-axis CNC finishing for complex geometries

Surface hardening (H13 tool steel inserts for high-wear areas)

100% first-article inspection (CMM verification)

Shot life validation (500k+ cycles guaranteed)

✅ USP: 30% faster mold lead times vs. industry average through proprietary rapid tooling workflows.

Prototyping & Validation

“Validate before you commit.”

Before mass production, we deliver functional prototypes using your final mold to validate:

Dimensional accuracy (AS9100-compliant CMM reports)

Material flow and cycle time optimization

Surface finish and structural integrity

Our in-house lab performs:

Statistical Process Control (SPC) for real-time defect detection

Material testing (tensile strength, heat deflection temperature)

100% dimensional checks against your specifications

✅ Result: Zero defects from first production run—validated by 99.98% first-pass yield rate.

Mass Production with Uncompromising Quality

“Olympic Quality. On-Time Delivery. Zero Defects.”

Our automated injection molding lines operate 24/7 with real-time quality monitoring:

Smart sensors track melt temperature, pressure, and cycle time

Automated vision systems inspect parts at 100% volume

Statistical Process Control (SPC) adjusts parameters dynamically to maintain tolerances

Key Metrics:

| Metric | Performance Target |

|————————-|—————————|

| First-Pass Yield Rate | 99.98% |

| On-Time Delivery | 99.5% (SLA guaranteed)|

| Defect Rate | < 0.02% |

| Cycle Time Optimization | 15–30% reduction vs. baseline |

✅ Why Clients Trust Us:

– 24/7 Dedicated Support: Single-point-of-contact account managers for urgent issues

– Olympic Quality Standard: Every part meets ISO 9001, IATF 16949, or AS9100 requirements

– Zero Defects Guarantee: Full replacement of defective parts at no cost

Why Partner with Wuxi Lead Precision Machinery?

“We don’t just manufacture—we engineer success.”

As your strategic manufacturing partner, we combine:

Precision Engineering: Molds built to ±0.0005” tolerance for ±0.001” part accuracy

Scalable Solutions: Seamless transition from prototyping to 1M+ unit production

Reliability: 99.5% on-time delivery with 24/7 technical support

Zero Defects Culture: Every process step is audited for quality—no compromises

Ready to transform your design into precision parts?

Contact our engineering team today for a free DFM review and quote.

“Precision isn’t a feature—it’s our standard.”

Wuxi Lead Precision Machinery

ISO 9001 · IATF 16949 · AS9100 Certified | China’s #1 Injection Molding Tooling Partner

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision: Precision Engineering, Not Just Production

Precision Tolerances That Exceed Industry Standards

Unlike standard injection molding suppliers, Wuxi Lead Precision delivers metrology-grade precision through advanced CNC tooling and material-specific process optimization. Our molds—built from premium P20/NAK80 steel—consistently outperform industry benchmarks for tight-tolerance applications.

| Metric | Industry Standard | Wuxi Lead Precision | Impact |

|---|---|---|---|

| Tolerance (1st inch) | ±0.005″ | ±0.003″ | 40% tighter critical dimensions for aerospace/medical components |

| Tolerance (subsequent inches) | ±0.005″/inch | ±0.002″/inch | Consistent precision in complex geometries (e.g., optical lenses, connectors) |

| Mold Steel | Standard P20 | NAK80 + H13 (high-wear zones) | 2× longer mold life, reduced maintenance downtime |

| Shot Life | 50k–100k shots | 150k+ shots | 30% lower cost per part for high-volume production |

| Cycle Time | Baseline process | 15–20% faster via thermal management | 24/7 throughput optimization for urgent projects |

Zero Defects Manufacturing: The Wuxi Lead Standard

“We don’t just meet tolerances—we engineer them into every part.”

Our ISO 9001-certified quality system ensures 99.99% defect-free production through:

In-process laser scanning of molds before production

Statistical Process Control (SPC) monitoring at 5-minute intervals

ASME Y14.5-compliant GD&T validation for every batch

Automated vision inspection for critical features (e.g., wall thickness, snap-fit tolerances)

For medical device manufacturers, this means parts that pass ISO 13485 audits without rework. For automotive clients, it translates to zero recalls from dimensional variance.

Olympic Quality for Mission-Critical Applications

We don’t compromise on precision. Our molds are engineered to meet the strictest tolerances required for:

Medical implants: ±0.001″ accuracy for biocompatible components

Optical lenses: Surface roughness ≤ Ra 0.05μm

Automotive sensors: Consistent ±0.002″ tolerance across 100k+ shots

Consumer electronics: Crystal-clear surface finishes for PC/ABS housings

When your application demands perfection, we deliver Olympic-grade precision—every time.

24/7 Technical Partnership

“We’re not a vendor. We’re your extension.”

Unlike transactional suppliers, Wuxi Lead provides dedicated engineering support around the clock:

2-hour response time for urgent technical issues

Free DFM analysis with quote (24-hour turnaround)

On-site process optimization during production ramp-up

Real-time data sharing via cloud-based MES for production transparency

From prototype validation to mass production, our engineers work alongside your team to eliminate bottlenecks and maximize ROI.

Your Precision Partner Awaits

Ready to transform your manufacturing process?

Contact Wuxi Lead Precision today for a free DFM analysis and competitive quote—no obligation, no delays.

📧 [email protected]

📞 +86-13961886740

Wuxi Lead Precision Machinery: Where engineering excellence meets relentless partnership.

⚙️ Precision Cost Estimator

Estimate how tolerance impact relative manufacturing effort.