Technical Contents

Engineering Guide: Tube Mold

Engineering Insight: The Critical Role of Precision in Tube Mold Manufacturing

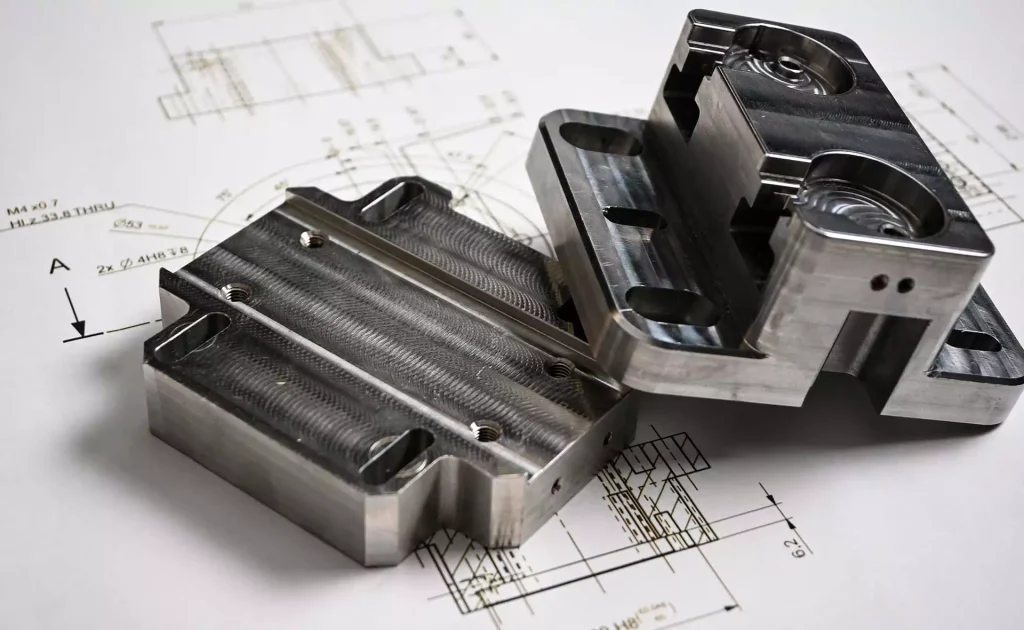

In the realm of custom metal manufacturing, the integrity and performance of a component often hinge on the precision of its forming process. Nowhere is this more evident than in tube mold engineering, where dimensional accuracy, material consistency, and geometric complexity converge to define functional reliability. At Wuxi Lead Precision Machinery, we recognize that tube molds are not merely tools—they are the foundation of high-performance systems in industries where failure is not an option.

Tube molds are employed across critical applications, from hydraulic systems in military vehicles to structural components in Olympic-grade sporting equipment. These applications demand more than standard fabrication; they require molds engineered to micrometer-level tolerances, capable of withstanding extreme pressures, cyclic loading, and harsh environmental conditions. Even a deviation of 0.02 mm can compromise the structural integrity of a formed tube, leading to premature fatigue or system failure.

Our engineering philosophy centers on precision at every stage—from initial CAD modeling and finite element analysis (FEA) to CNC machining and final quality validation. At Wuxi Lead, we utilize advanced simulation software to predict material flow and springback behavior, ensuring that the mold geometry compensates for deformation during the bending or hydroforming process. This predictive accuracy reduces prototyping cycles and accelerates time-to-market without sacrificing reliability.

The materials we select for tube molds are equally critical. High-strength tool steels, hardened to 58–62 HRC, are standard, ensuring wear resistance and longevity across thousands of production cycles. Surface treatments such as nitriding or PVD coating further enhance durability, especially when forming abrasive alloys like stainless steel or titanium.

Our expertise has been validated in some of the most demanding environments. Wuxi Lead has supplied precision tube mold solutions for components used in Olympic athletic equipment, where consistency and weight optimization are paramount. Additionally, our molds have supported defense-sector projects, meeting stringent military specifications for performance under extreme operational stress.

This level of achievement is not accidental. It is the result of over 15 years of focused innovation, a deep understanding of metallurgical behavior, and an unwavering commitment to precision engineering.

Typical Tube Mold Specifications at Wuxi Lead Precision Machinery

| Parameter | Standard Range / Specification |

|---|---|

| Material | H13, P20, 420 Stainless, or Custom Alloy |

| Hardness | 58–62 HRC (after heat treatment) |

| Dimensional Tolerance | ±0.01 mm to ±0.03 mm |

| Surface Finish | Ra 0.2–0.8 µm (polished or coated) |

| Max Tube Diameter Supported | Up to 150 mm |

| Min Bend Radius | As low as 1.5× tube diameter |

| Compatible Processes | CNC bending, hydroforming, rotary draw |

| Lead Time (Custom Design) | 4–8 weeks, depending on complexity |

Precision in tube mold manufacturing is not a luxury—it is a necessity. At Wuxi Lead Precision Machinery, we engineer every mold as if it will support a championship or safeguard a mission. Because in many cases, it does.

Precision Specs & Tolerances

Technical Capabilities: Precision Tube Mold Manufacturing

Wuxi Lead Precision Machinery delivers uncompromising precision in custom tube mold manufacturing through advanced 5-axis CNC machining and rigorous quality control. Our integrated technical capabilities are engineered to meet the most demanding specifications for complex tubular components across aerospace, medical, and high-performance industrial sectors. We specialize in transforming challenging geometries from solid bar stock or near-net shapes into finished tube molds with exceptional surface finish and dimensional accuracy, directly supporting our clients’ critical assembly and performance requirements.

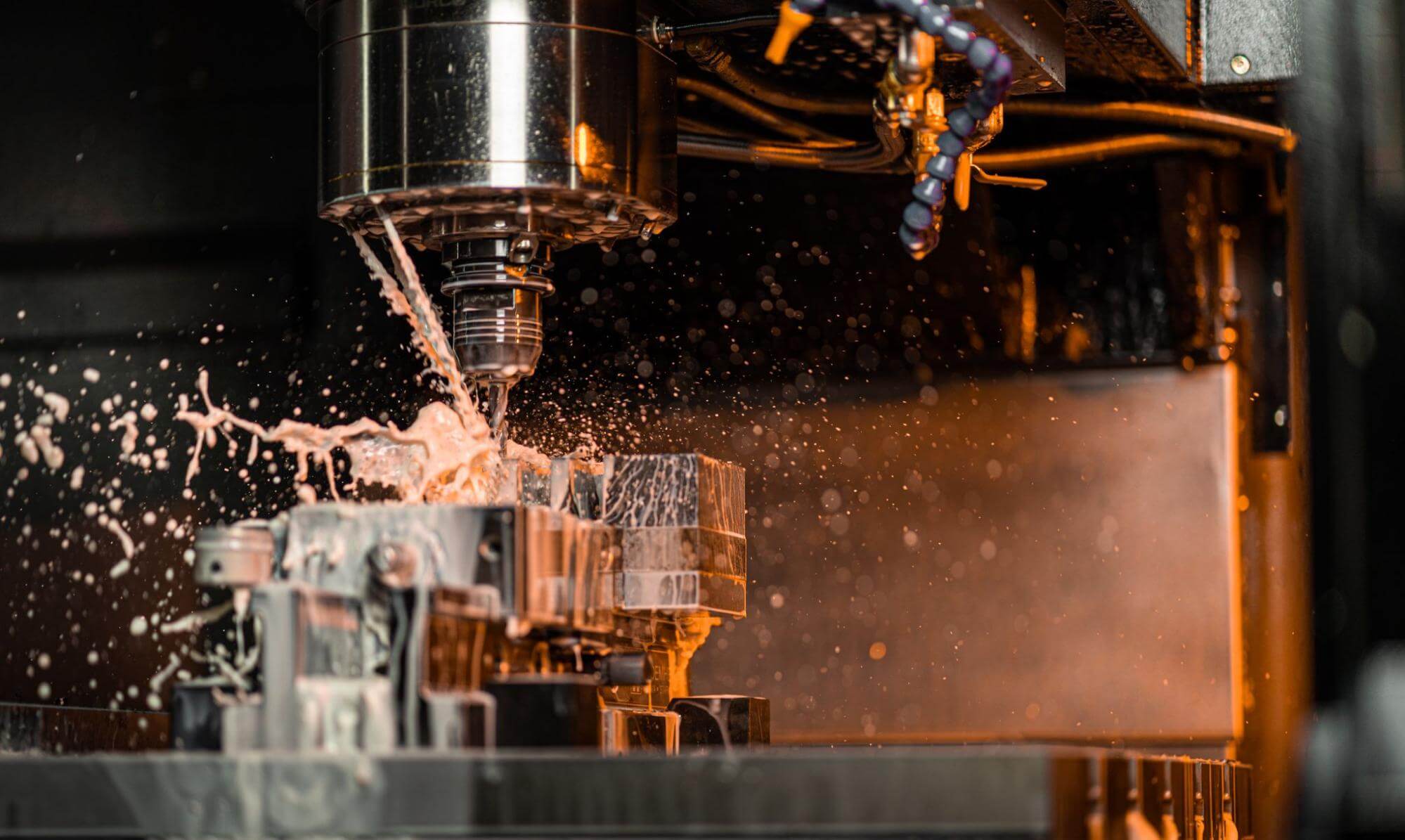

Central to our process is a dedicated fleet of high-torque, high-precision 5-axis CNC machining centers. These systems enable simultaneous multi-axis movement, eliminating the need for multiple setups and significantly reducing cumulative error. This capability is essential for machining intricate internal passages, compound angles, and undercuts inherent in sophisticated tube mold designs. Our machines handle a wide range of materials including stainless steels (304, 316, 17-4PH), titanium alloys (Ti-6Al-4V), inconel, aluminum alloys, and specialized brasses, maintaining tight tolerances regardless of material hardness or complexity. Advanced toolpath strategies and in-process probing ensure optimal material removal rates while preserving critical feature integrity and surface quality down to Ra 0.4 µm.

Quality verification is non-negotiable. Every critical dimension on finished tube molds undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMM). Our Zeiss and Hexagon CMM systems, operating within a climate-controlled metrology lab, provide traceable, NIST-calibrated validation of geometric dimensioning and tolerancing (GD&T) to micron-level accuracy. This systematic CMM inspection process verifies concentricity, cylindricity, positional tolerances, and complex profile deviations, guaranteeing that each component conforms precisely to the engineering drawing before shipment. Real-time SPC data from machining and inspection feeds directly into our continuous improvement loop, ensuring process stability and predictability across all production runs.

Our commitment to precision is quantified in achievable tolerances, consistently maintained through our integrated manufacturing and inspection systems. The following table details standard and tight tolerance capabilities for critical tube mold features:

| Feature Type | Standard Capability (mm) | Tight Capability (mm) | Conditions |

|---|---|---|---|

| Diameter (Internal) | ±0.025 | ±0.005 | Up to 100mm depth; material dependent |

| Diameter (External) | ±0.020 | ±0.003 | Up to Ø150mm; verified with air gaging |

| Length / Depth | ±0.030 | ±0.010 | Up to 300mm; critical faces |

| Concentricity | Ø0.025 | Ø0.008 | Relative to primary datum; full length |

| Positional Tolerance | Ø0.020 | Ø0.005 | Holes/patterns; relative to datums |

| Surface Roughness (Ra) | 0.8 | 0.4 | Machined surfaces; specified areas only |

This technical foundation—combining 5-axis precision, material expertise, and CMM-validated quality control—ensures Wuxi Lead produces tube molds that guarantee repeatability in the client’s forming or assembly process. We partner with engineering teams from prototype through volume production, providing the dimensional integrity and geometric complexity required for mission-critical tubular components. Our capabilities translate directly into reduced assembly scrap, extended tool life, and superior end-product performance for our global manufacturing partners.

Material & Finish Options

Material Selection for Precision Tube Mold Manufacturing

Selecting the appropriate material for tube mold applications is critical to ensuring performance, longevity, and cost-efficiency in high-precision manufacturing. At Wuxi Lead Precision Machinery, we specialize in custom metal solutions tailored to the exacting demands of industries such as aerospace, automotive, and medical device manufacturing. The most commonly used materials in tube mold production are aluminum, steel, and titanium, each offering distinct advantages depending on application requirements.

Aluminum is widely favored for prototyping and low-to-medium volume production due to its excellent machinability, lightweight nature, and good thermal conductivity. It enables faster cycle times in molding processes and reduces wear on machining tools. However, aluminum’s lower hardness and wear resistance make it less suitable for high-volume or high-stress applications. It is best employed when rapid development and cost control are priorities.

Steel, particularly tool steel grades such as H13, P20, and 420 stainless, provides superior durability, hardness, and resistance to wear and deformation under high pressure and temperature. This makes steel the preferred choice for high-volume tube mold production where dimensional stability and long service life are paramount. While steel is more challenging to machine and heavier than aluminum, its longevity often justifies the higher initial investment.

Titanium stands at the premium end of material selection, offering an exceptional strength-to-density ratio, outstanding corrosion resistance, and stability at elevated temperatures. Though significantly more expensive and difficult to machine, titanium is ideal for specialized applications in aerospace and medical fields where weight reduction, biocompatibility, and resistance to extreme environments are non-negotiable.

Surface finish plays a crucial role in mold performance and part quality. Anodizing is a widely used finishing process, particularly for aluminum molds. It enhances surface hardness, improves wear and corrosion resistance, and allows for color coding through dye integration. Type II (sulfuric acid) and Type III (hardcoat) anodizing are the most common, with Type III providing thicker, more durable coatings suitable for demanding operational conditions. For steel and titanium molds, alternative surface treatments such as nitriding, PVD coating, or electropolishing are typically recommended.

Below is a comparative overview of key material properties for tube mold applications.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Density (g/cm³) | Thermal Conductivity (W/m·K) | Typical Applications |

|---|---|---|---|---|---|

| Aluminum (6061-T6) | 310 | 15–20 | 2.7 | 167 | Prototypes, low-volume molds |

| Steel (H13) | 1,560 | 48–52 | 7.8 | 36 | High-pressure, high-volume |

| Steel (420 Stainless) | 1,700 | 50–54 | 7.7 | 26 | Corrosive environments |

| Titanium (Ti-6Al-4V) | 950 | 36–40 | 4.4 | 7.2 | Aerospace, medical |

At Wuxi Lead Precision Machinery, we work closely with clients to match material and finish choices to operational demands, ensuring optimal performance and return on investment.

Manufacturing Process & QC

Tube Mold Production Process: Precision Engineering from Concept to Volume

At Wuxi Lead Precision Machinery, our tube mold manufacturing process is engineered for absolute reliability in precision-critical applications. We implement a rigorously controlled sequence—Design, Prototyping, Mass Production—anchored by our Zero Defects philosophy. This systematic approach eliminates costly errors and ensures seamless transition from specification to high-volume output, safeguarding your production timelines and component integrity.

The foundation lies in meticulous Design Engineering. Our team utilizes advanced CAD/CAE software to model complex tube geometries, internal channels, and critical sealing surfaces. Finite Element Analysis (FEA) simulates material flow, thermal distribution, and structural stresses under operational pressures, identifying potential weaknesses before metal is cut. Client specifications, material properties (stainless steel, aluminum alloys, titanium), and stringent industry standards (ISO, ASME) are integrated into every design iteration. This phase culminates in a fully validated digital twin, approved by both our engineers and the client, ensuring the mold architecture inherently supports defect-free production.

Prototyping is not a formality but a critical validation stage. We produce functional prototype molds using the same hardened tool steels and precision machining processes intended for full production. These prototypes undergo rigorous testing cycles on our dedicated molding presses, replicating actual production parameters—pressure, temperature, cycle time. Every molded tube sample is subjected to comprehensive metrology: CMM verification of dimensional tolerances, pressure decay testing for leak integrity, and surface finish analysis. Deviations trigger immediate design or process refinement. This iterative loop continues until the prototype consistently yields parts meeting all specifications, providing irrefutable proof of process capability before mass production investment.

Mass Production executes the validated process with unwavering discipline under our Zero Defects framework. Production occurs in climate-controlled cells using CNC machining centers with sub-micron repeatability and automated mold handling systems. Real-time monitoring is non-negotiable: cavity pressure sensors, temperature arrays, and vision systems feed data into our Statistical Process Control (SPC) platform. Every critical dimension is verified via automated inline CMM checks at defined intervals, with results plotted against control limits. Any parameter drift triggers automatic process correction or machine stoppage. Operator training emphasizes proactive defect prevention, not just detection. This integrated system—combining precision equipment, real-time analytics, and empowered personnel—guarantees sustained conformance and eliminates escapes.

Our commitment translates into measurable outcomes for your supply chain. The table below summarizes the core process capabilities delivered across all phases:

| Parameter | Capability | Verification Method | Standard Met |

|---|---|---|---|

| Dimensional Tolerance | ±0.02 mm (critical features) | CMM, Optical Comparator | ISO 2768-mK |

| Surface Roughness (Ra) | 0.2 µm – 0.8 µm (cavity) | Profilometer | Client Spec / ISO |

| Pressure Integrity | 100% leak-tested (1.5x op. press) | Automated Pressure Decay | ASTM D3297 |

| Process Capability (CpK) | ≥ 1.67 (sustained) | SPC Chart Analysis | AIAG MSA 4th Ed. |

| Material Traceability | Full lot/batch control | ERP Integrated Tracking | ISO 9001:2015 |

This integrated Design-Prototype-Production workflow, underpinned by relentless data-driven quality control, ensures your tube molds perform flawlessly from the first part to the millionth, minimizing total cost of ownership and maximizing your operational uptime. Wuxi Lead delivers not just molds, but guaranteed manufacturing success.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Expertise in Custom Tube Mold Manufacturing

When precision, durability, and performance define your product requirements, partnering with a trusted leader in custom metal manufacturing becomes essential. At Wuxi Lead Precision Machinery, we specialize in delivering high-performance tube mold solutions engineered to meet the exact demands of aerospace, automotive, medical, and industrial applications. Our commitment to excellence is reflected in every phase of production—from initial design and material selection to final inspection and delivery.

With over a decade of experience in advanced CNC machining and precision tooling, we combine cutting-edge technology with deep engineering insight to produce tube molds that exceed industry standards. Our in-house capabilities include multi-axis milling, wire EDM, surface grinding, and laser measurement, ensuring micron-level accuracy and repeatability. Whether you require single-cavity prototypes or high-volume production molds, our team works closely with your engineers to optimize design for manufacturability, reduce cycle times, and enhance overall part integrity.

At Lead Precision, we understand that a tube mold is not just a tool—it’s the foundation of your component’s dimensional accuracy, surface finish, and structural consistency. That’s why we use only premium-grade tool steels and high-wear-resistant alloys, heat-treated and polished to exact specifications. Our quality control protocols include 100% dimensional verification using coordinate measuring machines (CMM) and optical comparators, guaranteeing every mold performs reliably under real-world production conditions.

We support global clients with end-to-end project management, rapid prototyping, and strict adherence to international quality standards including ISO 9001:2015. Our facility in Wuxi, China, is equipped for full-scale production with lean manufacturing principles, enabling cost-efficiency without compromising quality.

Below are key technical specifications we routinely achieve in our tube mold manufacturing:

| Specification | Capability |

|---|---|

| Maximum Mold Size | 1200 mm × 800 mm × 600 mm |

| Minimum Wall Thickness | 0.5 mm |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.1 – 0.4 µm (polished) |

| Materials | H13, P20, S136, 420SS, Inconel, Titanium alloys |

| Machining Equipment | 5-axis CNC, Wire EDM, Surface Grinder, CMM |

| Lead Time (Prototype) | 15–25 days |

| Production Volume Support | Low to high volume, batch or continuous |

Collaborating with Wuxi Lead Precision Machinery means gaining a strategic manufacturing partner focused on your long-term success. We don’t just build molds—we engineer solutions that enhance your production efficiency, product quality, and time-to-market.

For technical inquiries or to initiate a project discussion, contact us today at [email protected]. Let our team of precision engineers help you transform your tube mold concept into a high-precision reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.