Technical Contents

Engineering Guide: Transparent Moldable Plastic

Engineering Insight: Transparent Moldable Plastics and the Precision Imperative

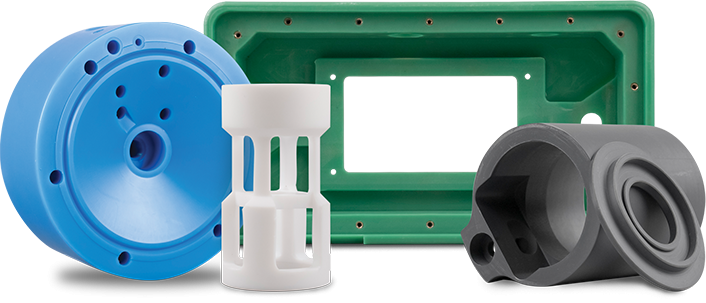

In high-performance manufacturing, transparent moldable plastics are no longer just materials—they are engineered components. Used in aerospace, medical devices, defense systems, and elite consumer products, these polymers demand more than optical clarity. They require dimensional stability, thermal resistance, and repeatability at micron-level tolerances. At Wuxi Lead Precision Machinery, we understand that the success of a transparent plastic component lies not only in the material selection but in the precision of its metal counterpart—the mold.

Transparent plastics such as PMMA (acrylic), polycarbonate (PC), and cyclic olefin copolymers (COC) present unique challenges during injection molding. Their optical performance is highly sensitive to surface finish, flow dynamics, and cooling uniformity. Even microscopic inconsistencies in mold geometry or surface texture can result in haze, warpage, or internal stress—compromising both function and aesthetics. This is where precision metal manufacturing becomes decisive.

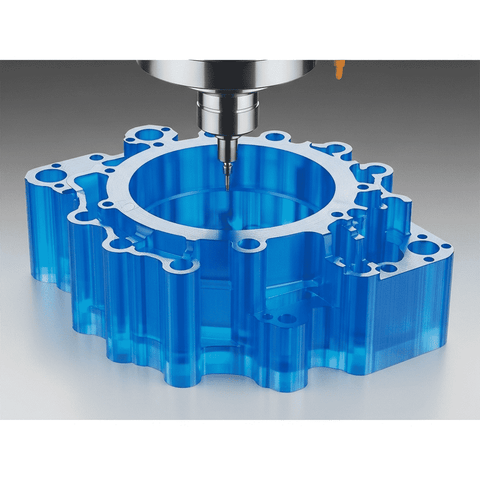

At Lead Precision, we specialize in crafting molds and tooling with tolerances as tight as ±0.002 mm. Our CNC machining centers, equipped with sub-micron probing systems and temperature-controlled environments, ensure that every cavity, core, and ejector pin aligns perfectly. We employ mirror-finish EDM and diamond polishing techniques to achieve surface finishes below Ra 0.025 μm—critical for maintaining light transmission and minimizing post-processing.

Our experience extends to mission-critical applications where failure is not an option. We have contributed to components used in Olympic-grade timing systems, where optical sensors depend on flawless lens clarity, and in military-grade sighting optics, where environmental durability and precision alignment are paramount. These projects demand more than technical capability—they require a culture of precision, traceability, and zero-defect manufacturing.

Material behavior during molding is another domain where precision engineering prevails. Transparent plastics exhibit non-linear shrinkage and flow characteristics. Our team uses advanced mold-flow simulation software to predict warpage and optimize gate locations, cooling channels, and venting. This data-driven approach ensures that the metal tool compensates for material behavior, resulting in consistent, high-yield production.

Below are key specifications that define our mold-making capabilities for transparent plastic applications:

| Parameter | Specification |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish (Optical) | Ra ≤ 0.025 μm (Mirror Polish) |

| Tool Steel Options | S136, NAK80, 420SS, Maraging Steel |

| Cooling Channel Precision | ±0.01 mm positional accuracy |

| EDM Surface Integrity | No micro-cracks, minimal recast layer |

| Mold Flow Simulation | Autodesk Moldflow, 3D mesh analysis |

| Lead Time (Complex Mold) | 6–10 weeks, including testing |

| Quality Certification | ISO 9001, Full First Article Inspection |

Precision in mold making is not a luxury—it is the foundation of performance in transparent plastic components. At Wuxi Lead Precision Machinery, we bring military-grade discipline and Olympic-level consistency to every custom metal solution. When clarity, reliability, and accuracy are non-negotiable, our engineering expertise ensures success.

Precision Specs & Tolerances

Precision Metal Mold Fabrication for Transparent Plastic Applications

At Wuxi Lead Precision Machinery, we engineer metal molds that define the performance ceiling for transparent moldable plastics in optics, medical devices, and consumer electronics. Our expertise lies in transforming P20, H13, and stainless steel billets into ultra-precise mold cavities where surface integrity and dimensional stability directly dictate plastic part clarity. Unlike standard mold shops, we treat mold steel as the foundational element for light transmission—any micro-defect or thermal distortion in the metal propagates as haze, distortion, or stress fractures in the final plastic component. This demands sub-10-micron surface finishes and thermal management precision unattainable through conventional machining.

Our 5-axis CNC milling platform—featuring DMG MORI CTX beta 1250 and Hermle C400 U machines—enables monolithic cavity fabrication with zero parting lines or electrode marks. Simultaneous 5-axis contouring achieves undercuts and organic geometries critical for complex lenses or fluidic channels while maintaining Ra ≤ 0.05 µm surface roughness. High-speed spindles (30,000 RPM) with thermal compensation systems prevent micro-deformation during extended polishing cycles, ensuring consistent geometry across large mold bases. Crucially, we machine all critical sealing surfaces and venting channels in a single setup to eliminate cumulative alignment errors that cause flash lines—optical killers in transparent plastics.

Quality validation is non-negotiable. Every mold undergoes full CMM inspection using Zeiss CONTURA systems with 0.5 µm volumetric accuracy, measuring against 3D CAD nominal data. We prioritize features impacting transparency: cavity flatness, spherical radius deviations, and gate vestige height. Statistical process control (SPC) tracks critical dimensions across 30+ measurement points per cavity, with real-time correction if deviations exceed 30% of tolerance limits. Full inspection reports—including GD&T callouts, surface roughness maps, and thermal distortion analysis—are provided pre-shipment, ensuring traceability for ISO 13485 or automotive audits.

The table below reflects our standard and enhanced tolerance capabilities for mold cavities used in transparent plastic molding. Tighter tolerances are achievable through iterative process refinement for mission-critical applications.

| Feature | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Cavity Flatness | ±0.010 mm | ±0.003 mm | CMM + Laser Interferometry |

| Bore Diameter (Ø10-50 mm) | ±0.008 mm | ±0.002 mm | CMM + Air Gaging |

| Spherical Radius | ±0.005 mm | ±0.0015 mm | CMM + Form Tester |

| Step Height (Parting Line) | ±0.005 mm | ±0.001 mm | CMM + Optical Comparator |

| Surface Roughness (Ra) | 0.10 µm | 0.025 µm | Profilometer |

This disciplined convergence of metal machining capability and metrology ensures molds consistently produce plastic parts with >92% light transmission and zero internal stress patterns. For applications demanding optical-grade clarity, our process eliminates the need for post-mold polishing—a common source of surface defects. Partner with us to convert material science requirements into manufacturable reality, where every micron of metal precision translates to flawless plastic performance.

Material & Finish Options

Material selection is a critical phase in the development of high-precision molds for transparent moldable plastics. The performance, clarity, and surface quality of the final plastic component are directly influenced by the mold’s material composition and surface treatment. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing for injection molds, leveraging advanced metallurgy and finishing techniques to ensure optimal replication of optical-grade surfaces.

For transparent plastic molding—such as with polycarbonate, PMMA (acrylic), or COC (cyclic olefin copolymer)—the mold must exhibit excellent thermal conductivity, dimensional stability, and resistance to wear and corrosion. Aluminum, steel, and titanium each offer distinct advantages depending on production volume, part complexity, and required surface finish.

Aluminum alloys, particularly 7075 and 6061, are widely used for prototyping and low- to medium-volume production. Their high thermal conductivity enables faster cooling cycles, improving throughput during molding. Aluminum is also easier to machine, allowing for complex geometries with tight tolerances. However, its lower hardness makes it less suitable for long production runs unless enhanced with surface treatments.

Steel, especially hardened tool steels like P20, H13, and S136, is the preferred choice for high-volume manufacturing. These steels provide superior hardness, wear resistance, and longevity under repeated thermal cycling. Stainless variants like S136 offer excellent corrosion resistance, critical when molding abrasive or chemically reactive transparent resins. While steel molds have longer lead times and higher machining costs, their durability justifies the investment for large-scale production.

Titanium and its alloys are emerging in specialized optical molding applications where extreme precision and corrosion resistance are paramount. Though more expensive and challenging to machine, titanium offers a high strength-to-density ratio and exceptional resistance to thermal deformation, making it ideal for aerospace and medical-grade optical components.

Surface finish plays an equally important role in achieving optical clarity. Anodizing is a key finishing process, particularly for aluminum molds. It enhances surface hardness, wear resistance, and provides a non-conductive, corrosion-resistant layer. Type II (sulfuric acid) anodizing is commonly used for general protection, while Type III (hard anodizing) delivers thicker, more durable coatings suitable for demanding environments. For optical molds, a mirror-polished surface followed by anodizing ensures minimal light scattering and high replication fidelity.

Below is a comparative overview of key mold materials used in transparent plastic molding:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Use Case |

|---|---|---|---|---|

| Aluminum 7075 | 15–20 | 130 | Low | Prototypes, low-volume production |

| P20 Steel | 28–32 | 30 | Moderate | Medium-volume, general-purpose molds |

| H13 Steel | 48–52 | 35 | Moderate | High-temperature, high-wear molding |

| S136 Steel | 50–54 | 25 | High | Corrosion-resistant optical molds |

| Titanium Grade 5 | 35–40 | 7 | Very High | Aerospace, medical, precision optics |

Selecting the right material and finish requires a balance of technical requirements, cost, and production goals. At Wuxi Lead Precision Machinery, we work closely with clients to engineer molds that meet the exacting standards of transparent plastic manufacturing.

Manufacturing Process & QC

Precision Production Process for Transparent Moldable Plastic Components

At Wuxi Lead Precision Machinery, we engineer transparent moldable plastic components to exacting optical and dimensional standards for aerospace, medical, and high-end consumer applications. Our end-to-end process eliminates defects through integrated engineering controls, ensuring every part meets zero-tolerance specifications.

Design Phase: Engineering Flawless Foundations

Our engineers collaborate with clients during initial design to optimize geometry, material selection, and manufacturability. Finite Element Analysis (FEA) simulates stress points, thermal behavior, and light transmission properties specific to transparent polymers like PMMA, PC, or medical-grade resins. We resolve potential warpage, sink marks, or optical distortions before tooling begins, using GD&T standards compliant with ISO 2768-mK. Critical parameters—wall thickness uniformity, gate placement, and venting—are validated via Moldflow analysis to prevent flow lines or trapped air that compromise clarity.

Prototyping: Validated Performance at Scale

Rapid prototyping employs CNC-machined aluminum molds or 3D-printed master patterns for silicone molding, producing functional samples within 10–15 days. Each prototype undergoes rigorous metrology:

Optical clarity measured via haze meter (ASTM D1003)

Dimensional verification using metrology-grade CMM (accuracy ±2μm)

Environmental stress cracking tests per ASTM D543

Client feedback drives iterative refinements, with full First Article Inspection (FAI) reports documenting conformance to AS9102 or PPAP Level 3 requirements. This phase de-risks mass production by confirming material behavior and process stability.

Mass Production: Zero-Defect Execution

Full-scale manufacturing leverages our 50+ electric and hybrid injection molding presses (50–2,500 tons), all equipped with real-time cavity pressure monitoring and closed-loop temperature control. Key protocols ensure perfection:

Material Handling: Desiccant drying at -40°C dew point; automated conveying to prevent moisture absorption

Process Control: Statistical Process Control (SPC) tracking shot-to-shot consistency; Cpk ≥1.67 maintained via automated parameter adjustments

In-Process Inspection: 100% automated vision systems detect micro-scratches, bubbles, or particulate contamination; inline spectrophotometry verifies color consistency (ΔE <0.5)

Final Validation: Every batch undergoes accelerated aging tests and biocompatibility screening (ISO 10993) where applicable

Critical Process Specifications

| Parameter | Standard Tolerance | Measurement Method | Acceptance Criteria |

|---|---|---|---|

| Optical Clarity (Haze) | ≤0.5% | ASTM D1003 | <1.0% |

| Dimensional Accuracy | ±0.025mm | CMM (ISO 10360-2) | GD&T per drawing |

| Surface Roughness (Ra) | 0.05–0.1 μm | Profilometer (ISO 4287) | ≤0.2 μm |

| Part Weight Variation | ±0.1% | Precision Scale | Cpk ≥1.67 |

Continuous Assurance

Our ISO 9001:2015 and IATF 16949-certified facility implements poka-yoke error-proofing at every stage, from material traceability to final packaging. Real-time data from 200+ sensors per press feeds into our MES, enabling predictive maintenance and instantaneous process correction. This systematic rigor—proven across 12,000+ production runs—delivers transparent components where optical perfection and structural integrity are non-negotiable. Partner with Wuxi Lead to transform demanding designs into flawless, high-volume reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Custom Metal Manufacturing Solutions in Transparent Moldable Plastics

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision custom metal components engineered specifically for advanced applications involving transparent moldable plastics. As a trusted leader in China’s precision manufacturing sector, we combine decades of engineering expertise with state-of-the-art CNC machining, stamping, and molding technologies to support industries ranging from medical devices and optics to consumer electronics and automotive systems. When your project demands flawless integration of metal and transparent polymer materials, our engineering team becomes your strategic partner from concept to production.

Transparent moldable plastics—such as polycarbonate, PMMA (acrylic), and COP/COC—require exacting metal tooling and component design to ensure clarity, dimensional stability, and structural integrity. Our in-house capabilities include high-tolerance mold fabrication, insert molding support, and precision metal frame production, all executed under strict cleanroom and quality-controlled environments. We understand that even microscopic surface imperfections or thermal mismatches can compromise optical performance or sealing integrity. That’s why every component we manufacture undergoes rigorous metrology testing, including CMM inspection, surface roughness analysis, and material compatibility verification.

Our engineering collaboration begins with a deep dive into your application requirements. Whether you’re developing lens housings, sensor windows, microfluidic device frames, or hermetic sealing components, we analyze thermal expansion coefficients, mating tolerances, and long-term environmental exposure to deliver metal parts that perform seamlessly with transparent plastics. We also provide DFM (Design for Manufacturability) feedback early in the development cycle to reduce cycle times, minimize part stress, and optimize assembly efficiency.

Below are key technical specifications supported by our manufacturing platform:

| Specification | Capability |

|---|---|

| CNC Machining Accuracy | ±0.002 mm |

| Surface Roughness (Ra) | As low as 0.05 µm |

| Maximum Part Size | 800 × 600 × 500 mm |

| Minimum Feature Size | 0.1 mm (micro-machining) |

| Materials | Stainless Steel, Aluminum Alloys, Titanium, Invar, Kovar |

| Secondary Processes | Passivation, Anodizing, Plating, Laser Marking |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), RoHS compliant |

We serve global OEMs and R&D institutions that demand reliability, repeatability, and technical responsiveness. Our facility in Wuxi is equipped with real-time production monitoring and traceability systems, ensuring full transparency and compliance across every batch.

Partnering with Lead Precision means gaining a manufacturing ally focused on innovation, precision, and long-term success. Let us help you overcome the unique challenges of integrating metal components with transparent moldable plastics.

Contact us today at [email protected] to discuss your project requirements and receive expert engineering support tailored to your application.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.