Technical Contents

Engineering Guide: Tpe Molding

Engineering Insight: Precision as the Foundation of TPE Molding Success

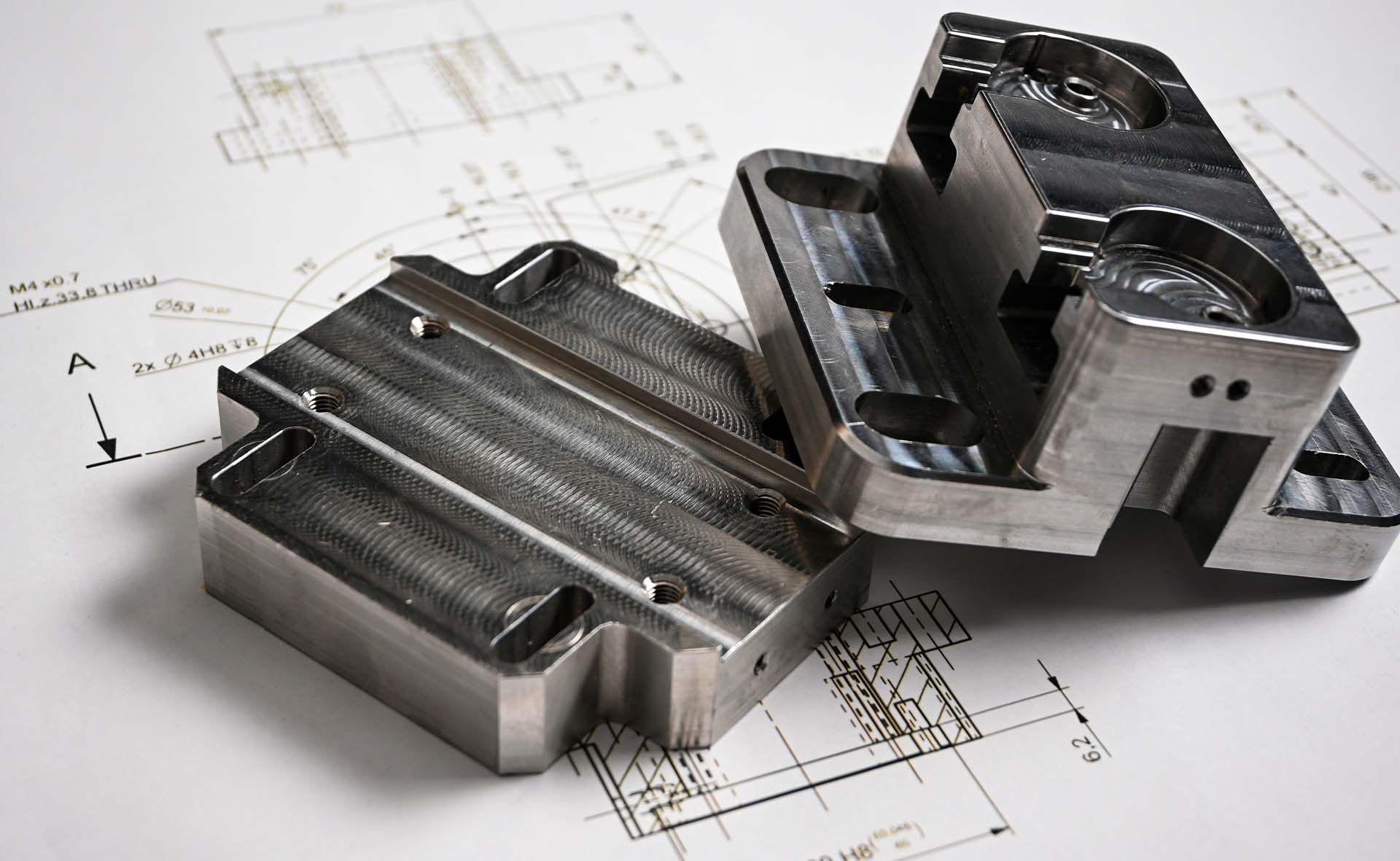

TPE molding demands exceptional precision far beyond standard thermoplastic processes. The inherent elasticity and sensitivity of thermoplastic elastomers to temperature, pressure, and shear stress mean that minute variations in mold geometry or process control directly translate into part inconsistency, flash, poor sealing, or compromised mechanical properties. Achieving repeatable, high-integrity TPE components—especially for critical applications in medical devices, automotive seals, or consumer electronics—relies fundamentally on the dimensional accuracy and thermal stability of the metal mold core. Sub-0.02mm tolerances on critical sealing surfaces and shut-offs are not merely desirable; they are non-negotiable for functional performance and assembly yield. Any deviation in mold steel flatness, cavity alignment, or cooling channel placement induces stress points within the TPE, accelerating fatigue and failure in dynamic applications. Precision engineering of the metal tooling is therefore the absolute prerequisite for successful TPE production, dictating both part quality and process efficiency.

At Wuxi Lead Precision Machinery, we engineer TPE molds with the same uncompromising standards applied to Olympic timing systems and military-spec connectors. Our CNC-machined mold bases, cavities, and cores leverage aerospace-grade alloys and multi-axis grinding to achieve micron-level geometries. We understand that TPE’s low viscosity requires near-perfect cavity sealing and controlled gate shear to prevent material migration and ensure consistent material flow-front fusion. Our process integrates real-time cavity pressure monitoring with closed-loop temperature control, calibrated against the specific rheology of each TPE compound. This level of control stems from direct experience where failure is not an option—such as producing seals for underwater sensor housings deployed in naval operations or vibration-dampening components within precision athletic equipment certified for Olympic competition. We translate this mission-critical manufacturing discipline into every TPE mold we build, ensuring your parts meet the most stringent functional and regulatory requirements.

The table below outlines key precision parameters we consistently achieve for complex TPE molding applications:

| Parameter | Standard Capability | High-Precision Capability | Critical Application Target |

|---|---|---|---|

| Cavity Tolerance | ±0.03 mm | ±0.015 mm | Medical seals, micro-fluidics |

| Core Alignment | ≤ 0.02 mm | ≤ 0.008 mm | Multi-shot overmolding |

| Surface Flatness | 0.01 mm/m | 0.003 mm/m | Optical bonding, hermetic seals |

| Cooling Channel Position | ±0.05 mm | ±0.02 mm | Uniform part shrinkage control |

| Material Compatibility | All major TPE/TPU | Bio-compatible & Flame-Retardant Grades | Implantable devices, aerospace |

Precision in TPE molding is not an incremental advantage—it is the defining factor between a functional component and a costly failure. Wuxi Lead Precision Machinery delivers the metal tooling integrity and process mastery required to transform sensitive elastomeric materials into reliable, high-performance products. When your application demands zero-defect consistency, partner with engineers proven where precision is measured in microns and consequences are measured in mission success. Demand engineering-grade solutions, not just molds.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components for industries where reliability, repeatability, and dimensional accuracy are paramount. At the core of our production infrastructure is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to execute complex geometries with superior surface finishes and minimal setup transitions. These machines allow simultaneous multi-directional cutting, significantly enhancing machining efficiency and precision for intricate parts commonly required in aerospace, medical, and high-performance industrial applications.

Our 5-axis CNC systems are operated by certified machinists with extensive experience in tight-tolerance manufacturing. Each machine is maintained to OEM specifications and monitored through real-time performance tracking, ensuring consistent output across production runs. The integration of advanced CAM software allows for optimized toolpaths, reduced cycle times, and improved material utilization—critical factors in delivering cost-effective, high-quality components without compromise.

Quality control is embedded at every stage of our manufacturing process. We employ comprehensive inspection protocols, with Coordinate Measuring Machine (CMM) inspection serving as the cornerstone of our dimensional verification system. Our CMM systems are calibrated to international standards and operated in temperature-controlled environments to eliminate measurement drift. This ensures that every component conforms precisely to design intent, with full traceability and detailed inspection reports provided upon request.

In addition to CMM inspection, we utilize optical comparators, surface roughness testers, and metallurgical analysis tools to validate material properties and surface integrity. Our quality management system is aligned with ISO 9001 standards, supporting a culture of continuous improvement and customer-specific compliance.

The following table outlines the standard tolerances we consistently achieve across various machining parameters:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.005 mm | ±0.002 mm | Depending on part geometry and material |

| Angular Dimensions | ±0.05° | ±0.02° | Verified via CMM and optical inspection |

| Positional Tolerance | ±0.01 mm | ±0.005 mm | GD&T-compliant reporting available |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Achieved with fine finishing toolpaths |

| Form Tolerance (Flatness, Roundness) | 0.01 mm | 0.005 mm | Validated using CMM and surface plates |

These capabilities are not theoretical benchmarks—they represent the actual performance levels maintained across our production floor. By combining advanced 5-axis CNC technology with rigorous quality assurance practices, Wuxi Lead Precision Machinery ensures that every component meets the most demanding engineering specifications. Our technical team works closely with clients during the design-for-manufacturability phase to optimize part geometry, material selection, and process planning—ensuring seamless transition from prototype to full-scale production.

Material & Finish Options

Material Selection for TPE Molding Tooling and Components

Selecting appropriate metals for tooling and structural components in TPE molding operations is critical for performance longevity and cost efficiency. While TPE itself is a polymer, the metal components supporting the molding process—such as mold bases inserts machine frames and ejector systems—demand rigorous material evaluation. At Wuxi Lead Precision Machinery we prioritize metals that balance thermal management mechanical strength and corrosion resistance to ensure optimal cycle times part quality and tool life. Aluminum steel and titanium each serve distinct roles based on application severity production volume and environmental exposure.

Aluminum alloys like 6061-T6 and 7075-T6 excel in prototyping and low-to-medium volume production due to superior thermal conductivity enabling rapid cooling and reduced cycle times. However their lower hardness necessitates protective surface treatments for extended use with abrasive TPE compounds. Steel variants including P20 H13 and 4140 dominate high-volume applications where wear resistance and dimensional stability under repeated thermal cycling are paramount. Titanium Ti-6Al-4V offers exceptional strength-to-weight ratio and corrosion immunity for niche aerospace or medical applications though its cost and machining complexity limit broad adoption. Surface finishing particularly anodizing is non-negotiable for aluminum components exposed to TPE processing environments. Type II (sulfuric acid) anodizing provides basic corrosion resistance while Type III (hard coat) anodizing delivers enhanced surface hardness up to 60 HRC critical for wear-prone areas like guide pins or cavity surfaces. Note that anodizing applies solely to aluminum; steel requires alternatives like nitriding or chrome plating.

The following table summarizes key material properties for TPE molding applications:

| Material | Hardness (Typical) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Primary Application in TPE Molding |

|---|---|---|---|---|

| Aluminum 6061-T6 | 95 HB | 310 | 167 | Prototype molds low-volume production |

| Aluminum 7075-T6 | 150 HB | 570 | 130 | High-stress inserts structural components |

| Steel H13 | 52 HRC | 1300 | 28 | High-volume core/cavity blocks |

| Steel 4140 | 28 HRC | 655 | 42 | Mold bases ejector plates |

| Titanium Ti-6Al-4V | 36 HRC | 900 | 7.2 | Corrosive environments weight-sensitive |

Strategic material pairing directly impacts your TPE molding ROI. For instance aluminum with Type III anodizing reduces cooling time by 15–20% versus untreated steel in moderate cycles yet steel H13 remains indispensable for 500k+ shot runs involving glass-filled TPE. Titanium’s value emerges only when salt-spray resistance or extreme weight reduction justifies its 3x aluminum cost. Wuxi Lead Precision Machinery engineers collaborate with clients to model thermal loads wear patterns and lifecycle costs ensuring your material selection aligns with production targets. We avoid over-engineering—recommending aluminum for 10k-shot medical device molds but mandating H13 steel for automotive seals exceeding 250k cycles. Consult our team early in the design phase to optimize material-finish combinations for your specific TPE formulation and operational demands.

Manufacturing Process & QC

Design: Engineering Precision from Concept to Blueprint

At Wuxi Lead Precision Machinery, the TPE molding process begins with a comprehensive design phase grounded in engineering excellence. Our team of senior design engineers collaborates closely with clients to translate functional requirements into precise 3D models and technical drawings. Utilizing advanced CAD software such as SolidWorks and Autodesk Inventor, we optimize part geometry for both performance and manufacturability. Special attention is given to material flow, wall thickness uniformity, and bonding interfaces between the rigid substrate and the overmolded TPE. Finite Element Analysis (FEA) is applied to simulate stress points and thermal behavior, ensuring long-term reliability under operational loads. Design for Manufacturing and Assembly (DFM/A) principles are strictly enforced to eliminate inefficiencies early, reducing cycle times and minimizing scrap rates in downstream stages.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to rapid prototyping using high-precision CNC-machined molds or 3D-printed tooling, depending on the complexity and required turnaround. These prototypes are produced on the same class of electric and hybrid injection molding machines used in full production, ensuring accurate representation of final part characteristics. Each prototype undergoes rigorous functional testing, including adhesion strength evaluation between the metal substrate and TPE layer, compression set analysis, and environmental exposure trials. Dimensional inspection is performed using coordinate measuring machines (CMM) and optical comparators to verify conformance to tolerances as tight as ±0.02 mm. Client feedback is integrated iteratively, allowing for design refinements before committing to mass production tooling. This phase is critical in achieving our zero-defect objective by identifying and resolving potential failure modes at the earliest stage.

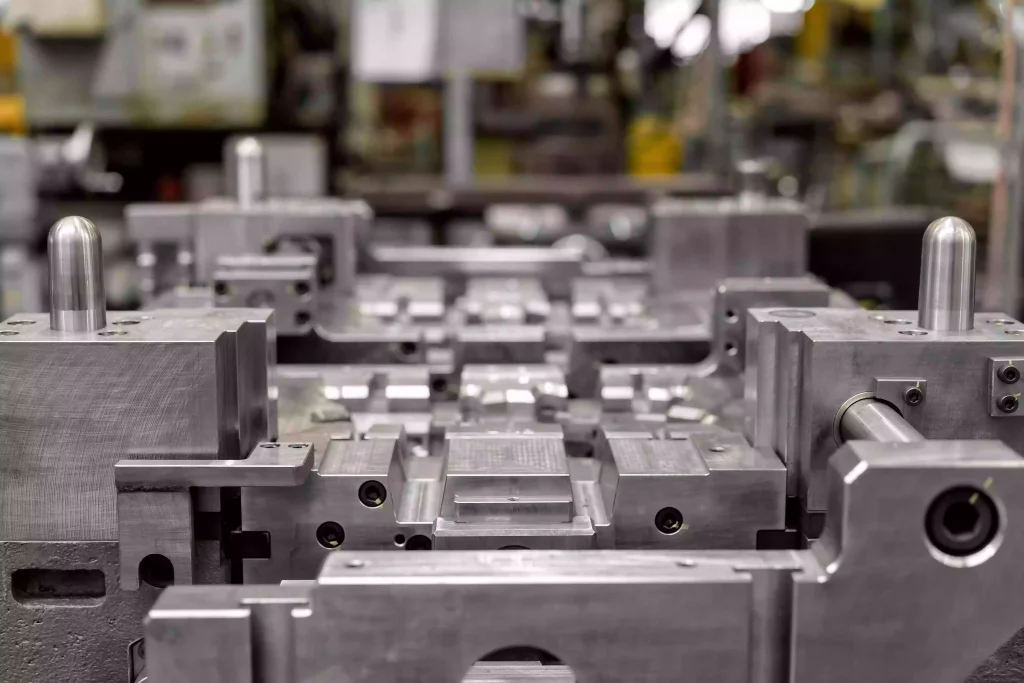

Mass Production: Consistency, Control, and Zero Defects

With approved prototypes, we transition to full-scale production using hardened steel molds manufactured in-house with tight process control. Our TPE molding lines are equipped with real-time monitoring systems that track injection pressure, temperature profiles, and clamp force for every cycle. Automated vision inspection systems and inline metrology ensure 100% part verification, rejecting any unit outside spec without human intervention. All processes adhere to ISO 9001 and IATF 16949 standards, with full traceability from raw material lot to finished component. Statistical Process Control (SPC) is employed to maintain process capability indices (Cp/Cpk) above 1.67, ensuring long-term stability and minimal variation.

| Parameter | Specification |

|---|---|

| Material Compatibility | TPE, TPU, TPR, Silicone (over metal substrates) |

| Mold Tolerance | ±0.01 mm |

| Part Dimensional Tolerance | ±0.02 mm |

| Production Capacity | Up to 500,000 units/month |

| Cycle Time Range | 30–120 seconds (depending on complexity) |

| Quality Standard | ISO 9001, IATF 16949, 100% inline inspection |

Through seamless integration of design insight, prototyping validation, and tightly controlled manufacturing, Wuxi Lead Precision Machinery delivers TPE-molded metal components with uncompromised quality and zero-defect consistency.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised TPE Molding Excellence

In the demanding realm of thermoplastic elastomer (TPE) molding, precision engineering is non-negotiable. Sub-micron tolerances, material consistency, and thermal stability define success—compromises risk part failure, production delays, and reputational damage. At Wuxi Lead Precision Machinery, we engineer solutions where standard machinery falls short. Our TPE molding systems are built for aerospace seals, medical device components, and automotive dampeners—applications where failure is not an option. We integrate proprietary temperature control algorithms and closed-loop injection systems to eliminate flash, sink marks, and material degradation. This is not generic manufacturing; it is physics-defying precision tailored to your polymer’s molecular behavior.

Our technical foundation rests on decades of metallurgical expertise applied to mold fabrication and machine design. We deploy hardened H13 tool steel with PVD coatings for extended mold life under aggressive TPE formulations, coupled with real-time cavity pressure monitoring to ensure repeatability within ±0.005mm. Below are critical specifications defining our TPE molding capability:

| Parameter | Specification Range | Precision Standard |

|---|---|---|

| Clamping Force | 500–3000 Tons | ±0.5% repeatability |

| Shot Weight Capacity | 50–5000 grams | ±0.1% accuracy |

| Melt Temperature Control | 150–300°C | ±1.0°C stability |

| Injection Speed | 0–1000 mm/s | ±0.05% consistency |

| Position Repeatability | Full stroke | ±0.002mm |

These metrics translate to zero-defect production runs for complex geometries like multi-lip seals or overmolded assemblies. Unlike commodity suppliers, we validate every system with your specific TPE compound—Santoprene, Tecoflex, or custom blends—through rigorous DOE trials before shipment. Our engineering team collaborates from DFM analysis to process validation, embedding quality into every phase. This eliminates costly iterations and accelerates time-to-market for regulated industries.

Partnering with Lead Precision means aligning with a certified ISO 9001:2015 and IATF 16949 facility where traceability is absolute. Every component undergoes spectral material verification, and our in-house metrology lab (equipped with CMMs and optical comparators) certifies tooling to ASME Y14.5 standards. We provide full documentation—mold flow analysis, process windows, and SPC datasets—to satisfy your quality auditors. Our commitment extends beyond delivery: remote diagnostics and 24/7 engineering support ensure 98%+ uptime, while predictive maintenance protocols preempt failures. This is the infrastructure high-stakes manufacturers demand but rarely find in a single partner.

Do not settle for machinery that merely meets specifications. Demand systems engineered to exceed them. Contact our TPE molding specialists today to discuss your most challenging application. Forward your part drawings and material requirements to [email protected]. Our engineers will respond within 4 business hours with a tailored capability assessment—including mold design recommendations and process validation protocol. Let us prove how precision engineering transforms TPE molding from a production hurdle into your competitive advantage. Engineer your advantage with Lead Precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.