Technical Contents

Engineering Guide: Tooling For Injection Moulding

Engineering Insight: Tooling for Injection Moulding

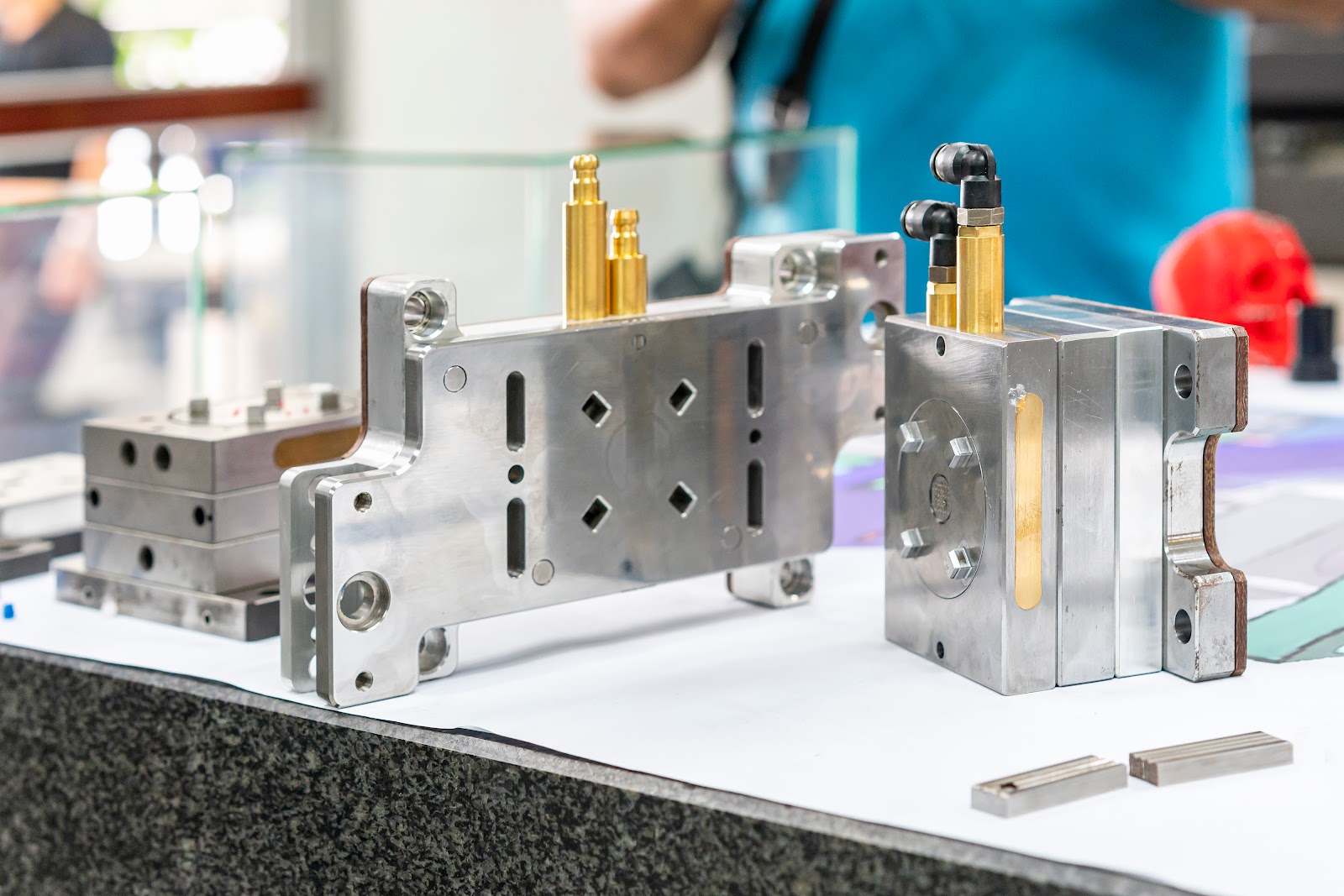

In high-performance manufacturing, injection moulding tooling is not merely a component of the production process—it is the foundation upon which part consistency, repeatability, and quality are built. At Wuxi Lead Precision Machinery, we understand that precision in tooling directly translates to precision in output. Our engineering philosophy centers on micron-level tolerances, thermal stability, and long-term durability, ensuring that every mould performs reliably across thousands, if not millions, of cycles.

The complexity of modern injection moulding demands more than standard fabrication techniques. Advanced applications in aerospace, medical devices, and high-end consumer electronics require tooling that maintains dimensional accuracy under extreme thermal cycling and mechanical stress. This is where precision engineering becomes non-negotiable. At Lead Precision, our tooling solutions are developed using high-grade tool steels such as H13, S136, and 2738, selected based on application-specific requirements for hardness, corrosion resistance, and polishability. Each mould undergoes rigorous CNC machining, EDM profiling, and surface finishing, followed by comprehensive metrology validation using coordinate measuring machines (CMM) and 3D scanning technologies.

Our expertise is not theoretical. Wuxi Lead Precision Machinery has delivered mission-critical components for projects associated with Olympic-standard equipment and military-grade systems, where failure is not an option. These high-stakes environments have honed our ability to meet and exceed the most stringent quality benchmarks. Whether supporting rapid prototyping or full-scale production runs, our team applies the same disciplined approach: design integrity, material science understanding, and process control.

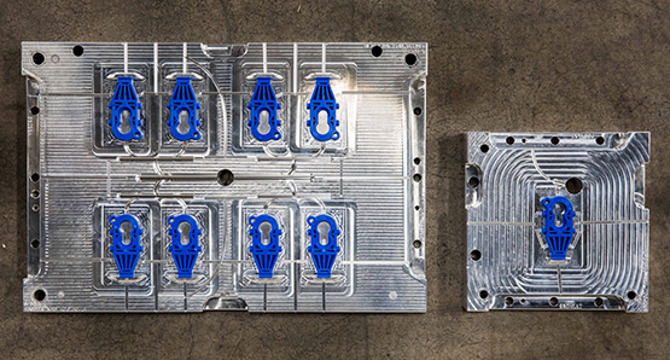

Precision tooling also extends beyond the physical mould. We integrate cooling channel optimization, venting strategies, and ejection system design to minimize cycle times and reduce part defects such as warpage or sink marks. Simulation software is employed during the design phase to predict flow behavior, pressure distribution, and potential stress points, allowing for proactive refinement before metal is cut.

The result is a tool that not only produces high-fidelity parts but also maximizes uptime and reduces total cost of ownership. In industries where a single defective component can compromise an entire assembly, the upfront investment in precision tooling pays exponential dividends in performance and reliability.

Below are key specifications that define our standard for injection moulding tooling:

| Specification | Detail |

|---|---|

| Tolerance Range | ±0.002 mm |

| Tool Steel Options | H13, S136, 2738, NAK80, P20 |

| Surface Finish | Ra 0.05 µm (mirror polish available) |

| Mould Life | 500,000 to 1,000,000+ cycles |

| Cooling Optimization | Conformal cooling channels (additive or drilled) |

| Quality Validation | CMM, 3D scanning, first article inspection (FAI) |

| Lead Time (Standard) | 4–8 weeks, based on complexity |

At Wuxi Lead Precision Machinery, we don’t just manufacture tooling—we engineer performance. Our legacy in high-demand sectors underscores our commitment to excellence, making us a trusted partner for global manufacturers who demand nothing less than perfection.

Precision Specs & Tolerances

Technical Capabilities: Precision Tooling for Injection Moulding

Wuxi Lead Precision Machinery delivers uncompromising precision in custom metal tooling for injection moulding applications. Our advanced manufacturing ecosystem integrates cutting-edge 5-axis CNC machining with rigorous quality control protocols to produce moulds that ensure part consistency, extended service life, and zero-defect production. Every component undergoes a validated process chain designed for geometric complexity and micron-level accuracy, directly addressing the stringent demands of automotive, medical, and consumer electronics sectors.

Our core manufacturing infrastructure centers on state-of-the-art 5-axis CNC machining centers, including DMG MORI and Makino systems. These platforms enable simultaneous multi-surface machining of complex cavities, cores, and slides in a single setup. This eliminates cumulative alignment errors inherent in 3-axis processes and dramatically reduces lead times for intricate geometries such as undercuts, free-form surfaces, and micro-features. High-speed machining capabilities combined with rigid thermal compensation systems ensure dimensional stability across extended production runs, even with challenging materials like hardened tool steels (P20, H13, S136) and high-temperature alloys.

Quality assurance is embedded at every stage through our metrology-controlled workflow. All critical features are verified using Zeiss and Hexagon CMMs with sub-micron resolution (±0.0001″). Automated inspection routines compare as-machined parts against nominal CAD data, generating comprehensive GD&T reports for full traceability. Surface integrity is validated via profilometry, ensuring optimal finish for release characteristics and aesthetic requirements. This closed-loop process guarantees that every mould component meets the exacting tolerances demanded by high-cavitation or multi-material injection processes.

The following table details our standard and advanced tolerance capabilities for critical mould features:

| Feature Category | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Cavity/Core Dimensions | ±0.015 mm | ±0.005 mm | CMM (ISO 10360-2) |

| Slide & Lift Alignment | ±0.020 mm | ±0.008 mm | CMM + Optical Comparator |

| Ejector Pin Bore | H7 (±0.007 mm) | H6 (±0.005 mm) | Air Gauging |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Profilometer (ISO 4287) |

| Flatness (per 100 mm) | 0.010 mm | 0.003 mm | CMM + Surface Plate |

Material selection and heat treatment are optimized per application requirements, with in-house vacuum hardening and stress-relieving cycles to minimize distortion. We specialize in conformal cooling channel integration via 5-axis milling, enhancing thermal management for faster cycle times and reduced part warpage. All tooling components are finished with wear-resistant coatings (e.g., TiAlN, CrN) where specified, validated through adhesion and thickness testing per ASTM B489.

Wuxi Lead Precision Machinery’s technical execution ensures your injection moulds achieve first-article accuracy and sustained performance. Our capabilities transform design intent into production reality through engineered precision, validated through inspection, and proven in global manufacturing environments. Partner with us to eliminate trial-and-error in mould validation and accelerate time-to-market for your critical components.

Material & Finish Options

Material Selection for Injection Moulding Tooling: A Precision Engineering Perspective

Selecting the appropriate material for injection moulding tooling is a critical decision that directly impacts production efficiency, part quality, and tool longevity. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored to the demanding requirements of high-performance tooling. Our expertise spans aluminum, steel, and titanium—each offering distinct advantages depending on production volume, part complexity, and environmental conditions.

Aluminum is often favored for prototyping and low-to-medium volume production due to its excellent machinability and thermal conductivity. It enables faster cycle times and reduces wear on machining equipment during tool fabrication. While not as durable as steel, modern high-grade aluminum alloys such as 7075 and 6061-T6 provide sufficient strength and dimensional stability for many applications. When combined with surface treatments like hard anodizing, aluminum tools gain improved wear resistance and extended service life.

Steel remains the standard for high-volume production runs. Tool steels such as P20, H13, and S136 offer superior hardness, wear resistance, and thermal stability under prolonged use. These characteristics make steel ideal for complex moulds producing thousands or even millions of parts. The choice between pre-hardened (e.g., P20) and hardened steels (e.g., H13) depends on required durability and post-machining heat treatment needs. Stainless variants like S136 are particularly suited for applications requiring corrosion resistance, such as medical or food-grade components.

Titanium, while less common in standard tooling, is gaining traction in specialized applications requiring extreme strength-to-weight ratios and exceptional corrosion resistance. Though more expensive and challenging to machine, titanium’s performance in high-temperature environments and aggressive chemical exposure makes it a strategic option for niche industrial processes. Its use is typically reserved for critical components within the mould assembly rather than full cavity blocks.

Surface finishing, particularly anodizing, plays a vital role in enhancing tool performance—especially with aluminum. Hard anodizing creates a thick, wear-resistant oxide layer that improves surface hardness up to 60–70 HRC, reduces galling, and increases resistance to abrasive wear. Decorative anodizing also offers aesthetic benefits for visible tool components. For steel tools, alternatives such as nitriding or chrome plating are more common, though anodizing is not applicable due to material limitations.

The table below summarizes key material properties and applications in injection moulding tooling.

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Use Case | Surface Treatment Compatibility |

|---|---|---|---|---|

| Aluminum 7075 | 40–50 (T6) | 130 | Prototyping, low-volume production | Hard anodizing, chromate conversion |

| P20 Steel | 28–32 | 30 | Medium to high-volume production | Nitriding, chrome plating, polishing |

| H13 Steel | 48–52 | 35 | High-stress, high-temperature moulds | Nitriding, PVD coating |

| S136 Steel | 50–54 | 25 | Corrosion-resistant, precision moulds | Electropolishing, passivation |

| Titanium Grade 5 | 36–41 | 7 | Specialized, high-performance inserts | Anodizing (Type III), thermal barrier coatings |

At Wuxi Lead Precision Machinery, we support clients in matching material and finish to application demands, ensuring optimal tool performance and cost-efficiency across the production lifecycle.

Manufacturing Process & QC

Precision Tooling Production Process: Achieving Zero Defects in Injection Moulding

At Wuxi Lead Precision Machinery, our custom injection mould tooling process is engineered from inception to delivery for uncompromising quality and Zero Defects performance. With 15+ years serving global automotive, medical, and aerospace clients, we integrate advanced engineering with rigorous process control across three critical phases.

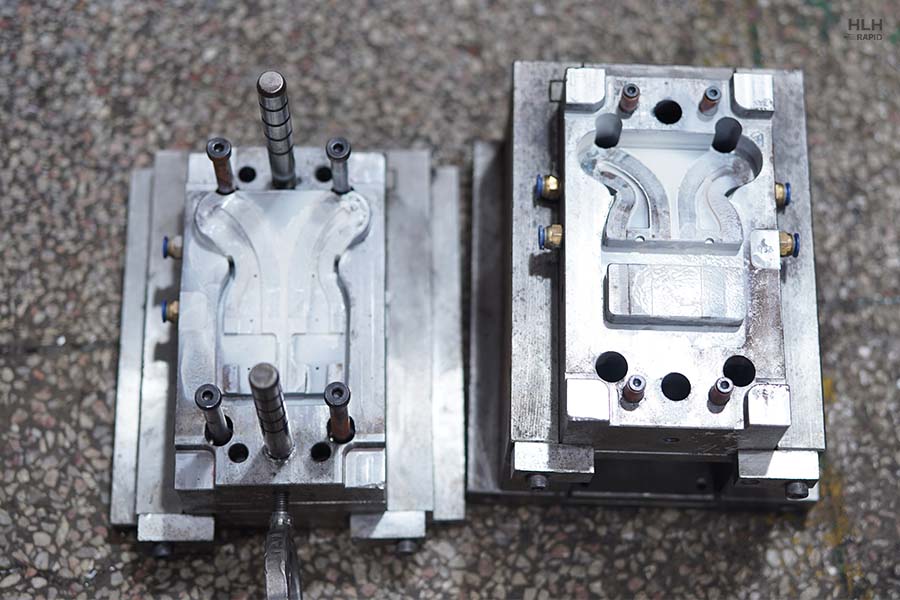

Design phase begins with deep collaboration. Our engineers conduct comprehensive Design for Manufacturability (DFM) analysis using Siemens NX and Moldflow simulation software. This identifies potential flow imbalances, weld lines, or cooling inefficiencies before metal is cut. We enforce strict material-specific shrinkage calculations and thermal stability modeling, resolving over 90% of potential defects digitally. Critical cavity/core interfaces are optimized for micron-level precision, ensuring part geometry consistency under high-pressure cycles. Client sign-off on validated virtual prototypes is mandatory before progression.

Prototyping transitions virtual models into physical validation. We utilize high-speed CNC milling and EDM for rapid tool fabrication, employing the exact grade of P20, H13, or stainless steel designated for final production. Each prototype tool undergoes rigorous material flow trials using the client’s specified resin. We measure dimensional accuracy against CAD data, validate ejection sequences, and assess surface finish under production-rate cycles. Iterative adjustments are made based on real-world data until all critical-to-quality characteristics meet ±0.005mm tolerances. Client approval of first-article inspection reports precedes mass production tooling.

Mass production leverages our certified Zero Defects framework. Production tools are manufactured on 5-axis DMG MORI machines with sub-micron repeatability, featuring integrated temperature control channels and hardened wear surfaces. Real-time process monitoring tracks cavity pressure, melt temperature, and clamp force against predefined SPC charts. Every tool undergoes 72-hour continuous run testing with 100% dimensional verification of critical features. We implement automated in-process gaging and statistical process control to detect drift before non-conformances occur. Final tool delivery includes full traceability documentation, maintenance protocols, and lifetime support guaranteeing sustained Zero Defects output.

Precision Tooling Process Specifications

| Phase | Key Activities | Tolerance Range | Lead Time | Validation Method |

|---|---|---|---|---|

| Design | DFM analysis, Moldflow simulation, Shrinkage compensation | Virtual validation | 10-15 business days | Simulation reports, DFM sign-off |

| Prototyping | CNC/EDM fabrication, Material trials, Surface finish validation | ±0.005mm | 20-25 business days | First-article inspection (FAI), CMM reports |

| Mass Production | 5-axis machining, SPC monitoring, 72h run testing | ±0.002mm | 45-60 business days | In-process gaging, Final audit, Lifetime traceability |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Injection Moulding Tooling

At Wuxi Lead Precision Machinery, we understand that precision, durability, and consistency are non-negotiable in high-performance injection moulding operations. As a trusted leader in custom metal manufacturing based in China, we specialize in delivering advanced tooling solutions engineered to meet the exacting demands of global industries—from automotive and medical devices to consumer electronics and industrial components. Our commitment goes beyond manufacturing; we are your strategic partner in achieving operational excellence, reduced downtime, and superior part quality.

Our engineering team brings over 15 years of experience in designing and producing high-precision moulds using advanced CNC machining, EDM, and surface treatment technologies. Every tool we produce is built to exact client specifications, incorporating optimized cooling channels, wear-resistant materials, and modular designs for ease of maintenance and longevity. Whether you require single-cavity prototypes or multi-cavity production tooling capable of millions of cycles, we deliver robust solutions that ensure repeatability and dimensional accuracy down to ±0.002 mm.

We operate a 12,000 m² state-of-the-art facility equipped with Siemens and Fanuc-controlled machines, enabling tight integration from design to final inspection. Our quality management system is ISO 9001:2015 certified, and we employ full-process quality control using coordinate measuring machines (CMM), 3D scanning, and in-house metallurgical analysis to guarantee material integrity and performance.

Below are key technical specifications that define our injection moulding tooling capabilities:

| Specification | Detail |

|---|---|

| Maximum Mould Size | 1,200 mm × 800 mm × 900 mm |

| Mould Weight Capacity | Up to 8,000 kg |

| Tolerance | ±0.002 mm |

| Surface Finish | Ra 0.05 μm to Ra 1.6 μm (polished, textured, or coated) |

| Materials Used | P20, 718H, S136, H13, 420 Stainless Steel, Aluminum 7075 |

| Mould Life | 500,000 to 2,000,000 cycles (depending on material and design) |

| Lead Time | 4–10 weeks (based on complexity) |

| Standards Supported | DME, HASCO, MISUMI, or custom |

We collaborate closely with OEMs and contract manufacturers worldwide, offering full technical consultation, design-for-manufacturability (DFM) analysis, and rapid prototyping services to accelerate time-to-market. Our bilingual engineering support team ensures seamless communication and project transparency at every stage.

When you partner with Wuxi Lead Precision Machinery, you gain more than a supplier—you gain a precision-focused ally dedicated to your long-term success. Let us help you elevate your injection moulding performance with tooling engineered for excellence.

Contact us today at [email protected] to discuss your next project. Our team is ready to provide a detailed quote, technical review, or sample evaluation—tailored to your production needs.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.