Technical Contents

Engineering Guide: Titanium Cnc Machining Services

Engineering Insight: Precision Imperatives in Titanium CNC Machining

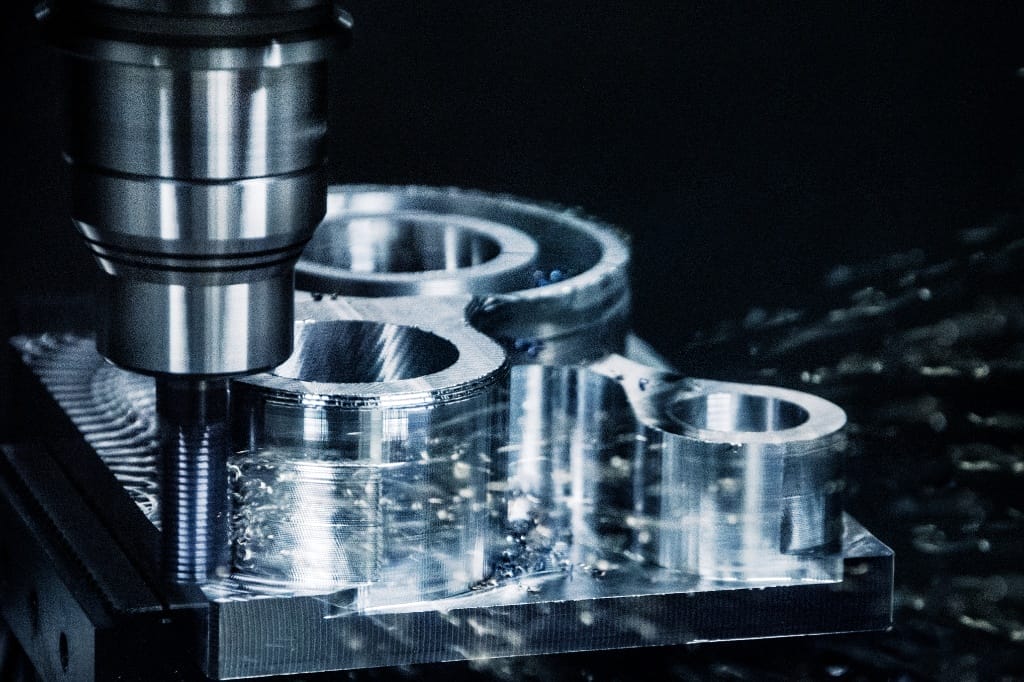

Titanium’s exceptional strength-to-weight ratio and corrosion resistance make it indispensable for aerospace, medical, and defense applications. Yet its low thermal conductivity, high chemical reactivity, and tendency toward work hardening demand extreme precision in CNC machining. Inadequate toolpath strategies or thermal management induce residual stresses, compromising structural integrity and fatigue life. At Wuxi Lead Precision Machinery, we treat precision not as a target but as a non-negotiable process parameter. Our approach begins with material-specific protocols: rigid fixturing to counter chatter, cryogenic cooling to dissipate heat, and adaptive feed-rate control to prevent galling. These measures ensure dimensional stability within microns, critical for components like aircraft landing gear fittings or implantable medical devices where failure is untenable.

Our facility’s ISO 9001 and AS9100 certifications anchor a workflow refined through high-stakes projects. We supplied precision-machined titanium components for Beijing 2022 Winter Olympic timing systems, where sub-micron tolerances guaranteed split-second accuracy under extreme cold. Similarly, our work for Tier-1 defense contractors involves machining titanium alloy missile guidance housings to MIL-STD-810G standards, surviving vibration, thermal cycling, and salt fog exposure. This experience translates to rigorous in-process inspection: 100% of critical features undergo CMM validation against 3D CAD models, with real-time SPC data tracking tool wear and thermal drift.

Material science informs every decision. Grade 5 (Ti-6Al-4V) requires different spindle harmonics than pure Grade 2, while beta alloys demand specialized coatings to resist chip adhesion. Our engineers leverage FEA simulations to pre-empt distortion, ensuring first-article compliance without iterative corrections. This reduces lead times by 30% compared to industry averages while eliminating scrap costs from rework.

Below outlines our titanium machining capabilities for mission-critical applications:

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Material Grades | Ti-6Al-4V, CP Ti Gr2, Ti-5553 | Custom beta alloys (e.g., Ti-10V-2Fe-3Al) |

| Tolerance Range | ±0.005 mm | ±0.0002 mm (Ra 0.2 µm) |

| Max Part Size | Ø800 x 1200 mm | Ø500 x 800 mm |

| Surface Finish (Ra) | 0.8 µm | 0.1 µm (mirror finish) |

| In-Process Inspection | CMM + optical comparator | On-machine probing + 5-axis laser scanning |

Precision in titanium machining transcends meeting drawings—it’s about guaranteeing performance in the field. Wuxi Lead’s fusion of military-grade process control and Olympic-level exactitude ensures your components operate flawlessly under the most demanding conditions. We don’t just machine titanium; we engineer reliability into every micron.

Precision Specs & Tolerances

Advanced 5-Axis CNC Machining for Titanium Components

Wuxi Lead Precision Machinery delivers elite-level titanium CNC machining services, engineered to meet the rigorous demands of aerospace, medical, and high-performance industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining centers, enabling us to produce complex, high-precision titanium parts with superior surface integrity and dimensional accuracy. Titanium’s exceptional strength-to-density ratio and corrosion resistance make it ideal for mission-critical applications—yet its low thermal conductivity and high chemical reactivity present significant machining challenges. Our advanced equipment, combined with expert process engineering, ensures optimal material removal rates, minimized tool wear, and consistent part quality.

Our 5-axis vertical and horizontal machining centers provide simultaneous multi-axis motion, allowing for intricate geometries to be machined in a single setup. This reduces cumulative error, improves repeatability, and significantly shortens lead times. We utilize high-torque spindles with through-coolant systems and rigid toolholding to maintain stability during deep cavity milling and contouring operations typical in titanium components. All machines are equipped with automated tool measurement and part probing systems, ensuring real-time process control and dimensional verification during production.

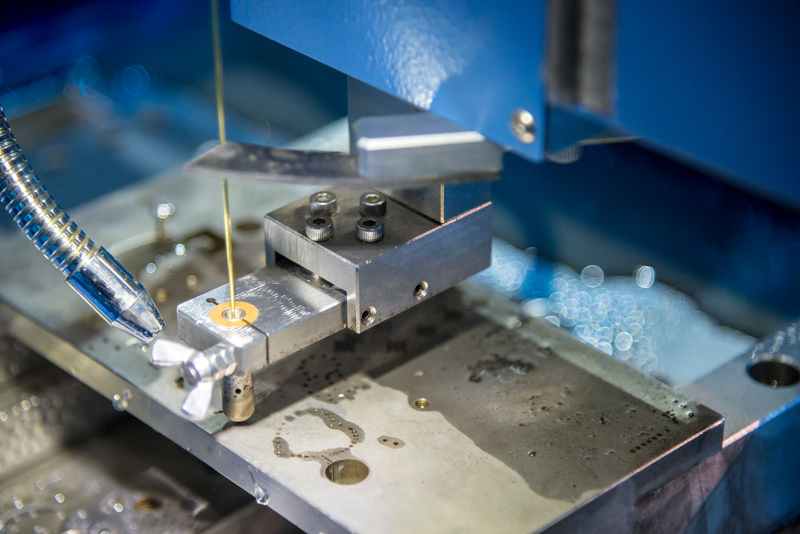

Quality assurance is integral to our machining workflow. Every titanium component undergoes comprehensive inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), capable of sub-micron level accuracy. Our CMM inspection routines are programmed to verify critical features such as hole positions, profile tolerances, surface finishes, and geometric dimensioning and tolerancing (GD&T) callouts per ASME Y14.5 standards. Additionally, first-article inspection reports (FAIR) and production batch certifications are provided upon request, ensuring full traceability and compliance.

We specialize in machining titanium alloys including Ti-6Al-4V (Grade 5), Ti-6Al-7Nb, CP-Ti (Grade 2), and Beta-C titanium, supporting both prototype development and high-volume production runs. Our in-house expertise spans fixture design, toolpath optimization, and chip management strategies specifically tailored to titanium’s unique characteristics, ensuring long tool life and minimal thermal distortion.

The following table outlines our standard machining tolerances and surface finish capabilities for titanium components:

| Specification | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm |

| Positional Tolerance | ±0.03 mm | ±0.015 mm |

| Angular Accuracy | ±0.1° | ±0.05° |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Geometric Tolerances (Flatness, Perpendicularity, etc.) | 0.03 mm | 0.01 mm |

| Feature Size Repeatability (Cpk ≥ 1.33) | 3σ | 6σ |

Our technical capabilities are reinforced by a disciplined, data-driven manufacturing culture, ensuring that every titanium component we produce meets the highest standards of precision, reliability, and performance.

Material & Finish Options

Material Selection for High-Performance CNC Machined Components

Selecting the optimal material is fundamental to achieving the required performance, longevity, and cost-efficiency in precision CNC machined parts. At Wuxi Lead Precision Machinery, our engineering expertise ensures clients navigate the critical trade-offs between Aluminum, Steel, and Titanium alloys. Each material presents distinct advantages suited to specific demanding applications across aerospace, medical, and energy sectors. Understanding these properties is essential for informed design and procurement decisions.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are favored for applications requiring an exceptional strength-to-weight ratio, excellent thermal conductivity, and inherent corrosion resistance. Their relatively low density and good machinability make them cost-effective for complex, lightweight structural components, enclosures, and heat sinks. However, aluminum lacks the ultimate strength and wear resistance required for highly stressed or abrasive environments.

Carbon and alloy steels (such as 4140, 4340, and 17-4 PH stainless) deliver superior strength, hardness, and wear resistance compared to aluminum. They are the standard choice for high-load applications like shafts, gears, and tooling where dimensional stability under stress is paramount. While stainless variants offer good corrosion resistance, standard carbon steels require protective finishes. Machining steel generally demands more robust tooling and slower parameters than aluminum due to higher strength and work hardening tendencies.

Titanium, especially Grade 5 (Ti-6Al-4V), represents the pinnacle for critical applications demanding the ultimate combination of high strength-to-weight ratio, exceptional corrosion resistance (particularly in saline and chemical environments), and biocompatibility. Its performance at elevated temperatures and fatigue resistance make it indispensable for aerospace structural components, medical implants, and deep-sea equipment. However, titanium’s low thermal conductivity, high chemical reactivity, and tendency to gall present significant machining challenges, requiring specialized tooling, rigid setups, precise coolant application, and deep process expertise to achieve tight tolerances and optimal surface integrity without compromising the material.

The comparative properties of these key engineering materials are summarized below:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating (Free-Machining Steel = 100%) |

|---|---|---|---|---|

| Aluminum 7075-T6 | 2.81 | 503 – 572 | Good (Anodized) | 75 – 85% |

| Steel 4140 | 7.85 | 655 – 1020 | Fair (Rust Prone) | 65% |

| Steel 17-4 PH | 7.75 | 1000 – 1300 | Very Good | 45% |

| Titanium Ti-6Al-4V | 4.43 | 900 – 1100 | Excellent | 22 – 36% |

Surface finish selection is equally critical. Anodizing is the predominant finish for aluminum parts, significantly enhancing surface hardness, wear resistance, and corrosion protection while allowing for color coding. Type II (sulfuric acid) is standard for general use, while Type III (hardcoat) provides maximum durability for high-wear applications. Titanium components typically utilize passivation or specialized coatings like PVD for enhanced surface properties, as traditional anodizing differs significantly from the aluminum process. Wuxi Lead Precision Machinery leverages decades of experience in machining these challenging materials and applying the appropriate finishes. We partner with clients from initial material consultation through precision machining and finishing, ensuring components meet the most stringent performance and quality requirements. Our advanced CNC capabilities and process control are specifically optimized for the unique demands of titanium and other high-performance alloys.

Manufacturing Process & QC

Design Phase: Engineering Excellence from Concept to CAD

The foundation of flawless titanium CNC machining begins with precision engineering during the design phase. At Wuxi Lead Precision Machinery, we collaborate closely with clients to analyze technical drawings, 3D CAD models, and performance requirements. Titanium’s unique properties—high strength-to-density ratio, exceptional corrosion resistance, and performance at elevated temperatures—demand meticulous attention to thermal expansion, toolpath strategy, and material stress behavior. Our engineering team conducts comprehensive Design for Manufacturability (DFM) reviews to optimize geometry, minimize waste, and ensure structural integrity. Finite Element Analysis (FEA) and thermal simulation tools are employed to anticipate deformation risks and refine design parameters before any metal is cut. This proactive approach eliminates costly revisions and ensures the final component meets exacting aerospace, medical, or industrial standards.

Prototyping: Validating Precision at the Micro Level

Once the design is finalized, we proceed to prototype development using multi-axis CNC milling and turning centers equipped with high-rigidity spindles and advanced cooling systems. Titanium’s low thermal conductivity and high reactivity require specialized carbide tooling, controlled feed rates, and precise coolant application to prevent work hardening and tool wear. Each prototype is machined from certified aerospace-grade titanium alloys such as Ti-6Al-4V (Grade 5) or commercially pure Grade 2, with full material traceability. Prototypes undergo rigorous in-process inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers. Dimensional accuracy is verified to ±0.005 mm, ensuring conformity to nominal CAD data. Functional testing, including fit checks and environmental exposure simulations, confirms performance under real-world conditions. Feedback from this stage is integrated into the final production program, closing the loop on design validation.

Mass Production: Zero Defects Through Process Control

With prototype approval, we transition to high-volume production under a Zero Defects manufacturing philosophy. Our ISO 13485 and AS9100-certified facility employs automated CNC cells with real-time tool wear monitoring, in-process gauging, and closed-loop feedback systems. Every titanium component is machined under consistent environmental controls to eliminate thermal drift. We utilize statistical process control (SPC) to track critical dimensions across batches, ensuring Cp/Cpk values exceed 1.67. Full first-article inspection reports (FAIR) and production part approval processes (PPAP) are generated for traceability and compliance.

Material and process specifications are maintained with strict adherence:

| Parameter | Specification |

|---|---|

| Material Grades | Ti-6Al-4V (Grade 5), Ti-6Al-7Nb, Grade 2, Grade 9 |

| Tolerances | ±0.005 mm (standard), ±0.002 mm (tight tolerance) |

| Surface Finish | Ra 0.8 µm (standard), Ra 0.4 µm (polished) |

| Max Part Size | 800 x 500 x 400 mm |

| Equipment | 5-axis CNC machining centers, Swiss lathes, CNC turning-milling combos |

| Quality Standards | ISO 9001, ISO 13485, AS9100, PPAP Level 3, FAIR |

Each finished component undergoes 100% visual inspection and batch sampling for metallurgical verification. With integrated ERP and MES systems, Wuxi Lead ensures full production transparency, on-time delivery, and uncompromised quality in every titanium part we produce.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Mission-Critical Titanium Components

Titanium machining demands more than standard CNC capabilities. Its low thermal conductivity, high chemical reactivity, and propensity for work hardening require specialized expertise, precision tooling, and process control to avoid costly scrap, tool failure, or compromised part integrity. At Wuxi Lead Precision Machinery, we engineer titanium solutions where failure is not an option. Our dedicated titanium workflow integrates material science with advanced 5-axis milling and turning, ensuring optimal chip evacuation, thermal management, and surface finish for aerospace, medical implant, and defense applications.

We eliminate the guesswork in titanium production through proprietary toolpath strategies and real-time process monitoring. Our engineers collaborate from the design phase, identifying potential manufacturability risks and recommending geometry adjustments that preserve performance while maximizing yield. This proactive approach reduces lead times by up to 30% and minimizes expensive material waste—critical when working with premium-grade Ti-6Al-4V or CP titanium.

Our facility operates under strict AS9100 and ISO 13485 frameworks, with in-house metrology validating every dimension against your most stringent specifications. Below are core capabilities defining our titanium machining excellence:

| Specification | Capability | Industry Relevance |

|---|---|---|

| Material Grades | Ti-6Al-4V, Ti-5553, CP Grade 1-4 | Aerospace structural, medical |

| Tolerance Control | ±0.0002″ (5µm) consistently | Critical bearing surfaces |

| Max Work Envelope | Ø32″ x 40″ (813mm x 1016mm) | Large-scale airframe components |

| Surface Finish | Ra 8µin to 32µin (as-machined) | Implant biocompatibility |

| In-Process Verification | On-machine probing + CMM validation | Zero-defect delivery guarantee |

Choosing a titanium machining partner is a strategic decision impacting product performance and total cost of ownership. Generic CNC shops treat titanium as another metal; we treat it as a high-stakes engineering challenge requiring domain-specific mastery. Our clients trust us because we deliver certified first-pass yield rates exceeding 98.5%—transforming titanium’s machining challenges into competitive advantages for their end products.

Do not compromise on precision when your application demands titanium’s strength-to-weight ratio. Contact our engineering team today to discuss your project’s thermal, geometric, and metallurgical requirements. We will provide a detailed manufacturability analysis and timeline within 24 hours of receiving your CAD files and specifications.

Email [email protected] with “Titanium Project Review” in the subject line. Include your part drawings and volume requirements. Our engineers will respond with actionable insights—not a generic quote. Let Lead Precision become your certified source for zero-defect titanium components, delivered on schedule, every time.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.