Technical Contents

Engineering Guide: Titanium 3D Printing Service

Engineering Insight: Precision in Titanium 3D Printing Services

In the realm of advanced manufacturing, titanium 3D printing services represent the convergence of material science, design innovation, and uncompromising precision. At Wuxi Lead Precision Machinery, we recognize that titanium—renowned for its exceptional strength-to-density ratio, corrosion resistance, and biocompatibility—is not merely a material choice but a performance imperative. However, the true value of titanium additive manufacturing lies not just in the material itself, but in the precision with which it is processed.

Titanium’s reactivity at elevated temperatures and its sensitivity to thermal gradients demand a controlled, repeatable, and highly accurate printing environment. Even minor deviations in laser power, scan speed, or chamber atmosphere can lead to residual stress, porosity, or microstructural inconsistencies—defects that are unacceptable in mission-critical applications. This is where engineering discipline and process mastery become non-negotiable.

At Lead Precision, our approach to titanium 3D printing is grounded in over a decade of high-end custom manufacturing, serving sectors where failure is not an option. Our experience includes producing components for Olympic-level athletic equipment, where marginal gains are measured in milliseconds, and for defense and aerospace systems, where structural integrity under extreme conditions is paramount. These projects have honed our ability to deliver not only geometric accuracy but also consistent mechanical properties across every build.

Our titanium printing capabilities are built on state-of-the-art metal additive systems equipped with in-situ monitoring, closed-loop feedback controls, and inert gas management to ensure optimal build conditions. Each component undergoes rigorous post-processing protocols, including stress relief, hot isostatic pressing (HIP), and precision machining, ensuring dimensional stability and surface integrity that meet or exceed international standards.

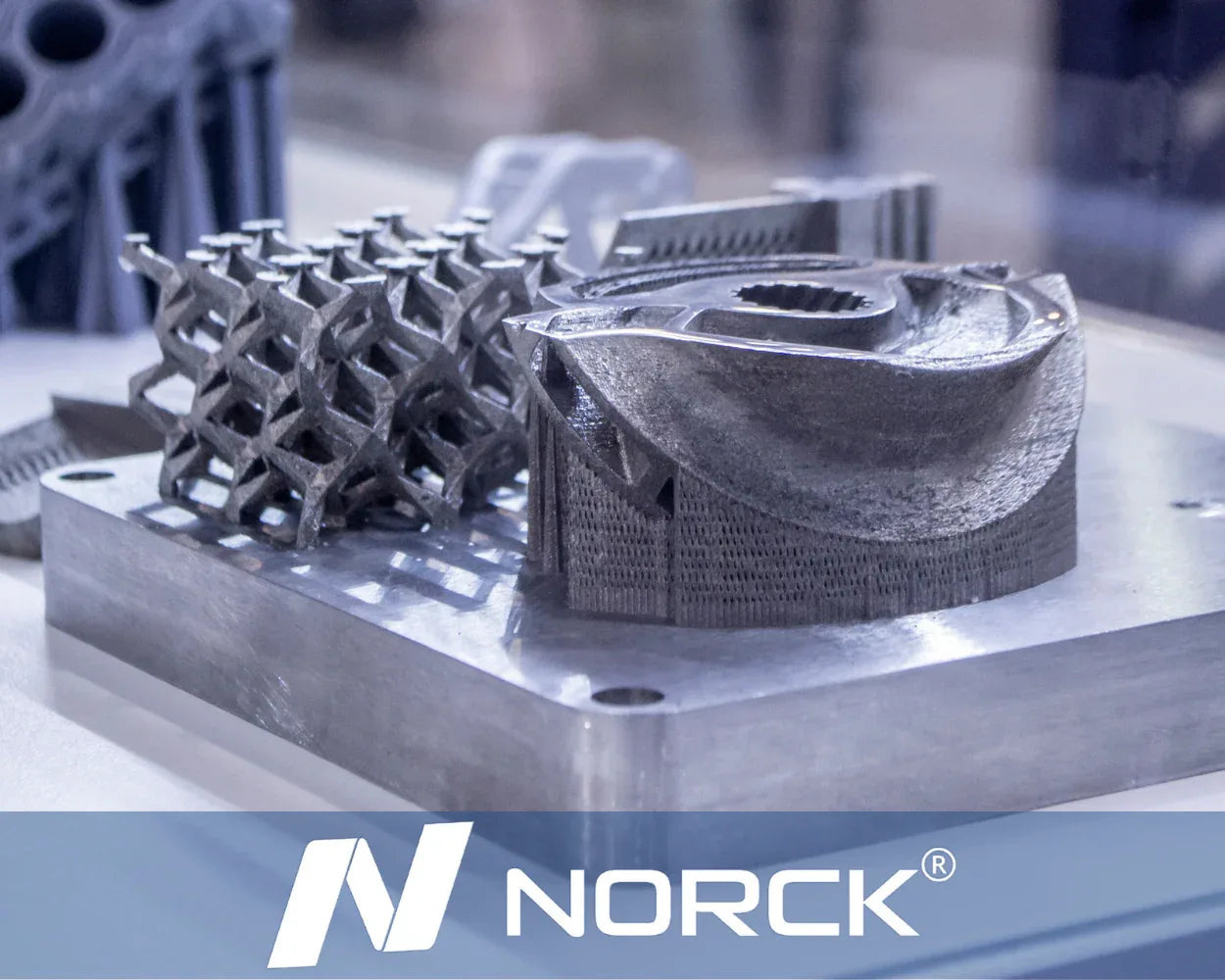

We specialize in complex, low-volume, high-value parts where design freedom and material performance intersect—such as lightweight lattice structures, integrated fluid channels, and topology-optimized components. Our engineering team collaborates closely with clients from design for additive manufacturing (DfAM) through final inspection, ensuring that every part is not just printed, but engineered to perform.

The following table outlines key technical specifications of our titanium 3D printing service:

| Parameter | Specification |

|---|---|

| Material | Ti6Al4V (Grade 5), CP Ti (Grade 2) |

| Build Volume | Up to 250 x 250 x 320 mm |

| Layer Thickness | 20–50 µm |

| Positional Accuracy | ±0.05 mm / 50 mm |

| Surface Roughness (as-built) | Ra 12–18 µm |

| Post-Processing Options | HIP, CNC Machining, Polishing, Coating |

| Quality Standards | ISO 9001, ASTM F2924, AMS7000 |

| Applications | Aerospace, Defense, Medical, High-Performance Sports |

Precision in titanium 3D printing is not an outcome—it is a process. At Wuxi Lead Precision Machinery, we bring the expertise, infrastructure, and commitment to excellence required to transform demanding designs into reliable, high-performance components.

Precision Specs & Tolerances

Technical Capabilities: Precision Titanium Additive Manufacturing & Finishing

Wuxi Lead Precision Machinery delivers mission-critical titanium components through integrated metal additive manufacturing and precision subtractive processes. Our facility specializes in Ti-6Al-4V (Grade 5) and CP Titanium (Grade 2) alloys, leveraging industrial-grade laser powder bed fusion systems with build volumes up to 250 x 250 x 300 mm. Layer resolution of 20–50 µm ensures optimal density (>99.95%) and mechanical properties compliant with ASTM F136 and AMS 4928 standards. This foundation supports complex geometries unachievable through traditional methods, including internal channels, lattice structures, and topology-optimized forms essential for aerospace, medical implant, and high-performance automotive applications.

Post-processing is where Wuxi Lead’s engineering rigor delivers true aerospace-grade precision. Every additively manufactured titanium part undergoes mandatory finishing on our DMG MORI CTX beta 1250 5-axis CNC machining centers. This integrated approach eliminates interface errors between fabrication and finishing stages. The 5-axis capability allows single-setup machining of intricate contours, undercuts, and critical sealing surfaces, maintaining geometric integrity while achieving micron-level positional accuracy. Our toolpath strategies specifically address titanium’s low thermal conductivity and high chemical reactivity, utilizing cryogenic cooling and specialized carbide tooling to prevent work hardening and ensure surface integrity.

Quality validation is non-negotiable. All critical dimensions undergo 100% inspection via Zeiss CONTURA G2 coordinate measuring machines (CMM) operating under ISO/IEC 17025 accreditation. Our metrology lab validates as-built conformity to GD&T callouts per ASME Y14.5, with full traceability from raw powder lot to final inspection report. Statistical process control (SPC) monitoring occurs at every stage—from powder sieving and atmosphere control during printing to final surface roughness verification—ensuring batch-to-batch consistency. Material certification, including tensile, fatigue, and microstructure analysis, is provided with every production run.

The following table defines achievable tolerances for titanium components at Wuxi Lead:

| Process Stage | Dimensional Tolerance | Surface Roughness (Ra) | Critical Feature Detail |

|---|---|---|---|

| As-Printed | ±0.10 mm | 8–15 µm | >0.4 mm internal radii |

| CNC Finished (5-Axis) | ±0.01 mm | 0.8–1.6 µm | <0.1 mm edge breaks |

This technical ecosystem—combining controlled AM builds, precision 5-axis CNC, and metrology-grade validation—enables Wuxi Lead to consistently deliver titanium components meeting the most stringent functional requirements. We transform complex digital models into flight-ready or implant-certified hardware with zero compromise on repeatability or material performance. Clients receive not just parts, but fully documented evidence of conformance to their engineering specifications.

Material & Finish Options

Material Selection for High-Performance 3D Printed Components

When engineering mission-critical components for aerospace, medical, or high-performance industrial applications, material selection is a decisive factor in achieving optimal functionality, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing using advanced 3D printing technologies, with a focus on aluminum, steel, and titanium alloys. Each material offers distinct mechanical properties, thermal characteristics, and compatibility with post-processing finishes such as anodizing.

Aluminum alloys, particularly AlSi10Mg, are widely used for lightweight structural components requiring good thermal conductivity and moderate strength. Ideal for rapid prototyping and complex geometries, aluminum 3D printed parts are commonly found in automotive and drone applications. While aluminum is not typically heat-treated to high hardness levels, it responds exceptionally well to anodizing, which enhances surface durability and corrosion resistance. Anodized finishes also allow for color coding and improved wear performance in moving assemblies.

Stainless steel and tool steel variants, including 316L and H13, deliver high tensile strength, excellent toughness, and resistance to wear and corrosion. These materials are preferred for tooling, molds, and components exposed to harsh environments. 3D printed steel parts can be machined, polished, and subjected to various heat treatments to meet stringent performance criteria. Although steel does not anodize, it can be coated with passivation layers, electroplating, or powder coatings to achieve desired surface properties.

Titanium, especially Ti6Al4V (Grade 5), stands at the pinnacle of performance for additive manufacturing. Renowned for its exceptional strength-to-density ratio, biocompatibility, and resistance to extreme temperatures and corrosive media, titanium is the material of choice for aerospace components, medical implants, and deep-sea equipment. Its low thermal expansion and high fatigue resistance make it ideal for parts subjected to cyclic loading and thermal fluctuations. While titanium does not undergo conventional anodizing like aluminum, it can be treated with specialized oxide layering processes that improve surface hardness and provide aesthetic color finishes without compromising biocompatibility.

The following table summarizes key mechanical and processing characteristics of these materials in the context of 3D printing and finishing:

| Material | Tensile Strength (MPa) | Density (g/cm³) | Max Operating Temp (°C) | Anodizing Compatible | Typical Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–450 | 2.67 | 300 | Yes | Drones, heat sinks, lightweight structures |

| 316L Steel | 550–600 | 8.00 | 800 | No | Marine components, chemical processing |

| H13 Steel | 1,800–2,200 | 7.80 | 600 | No | Injection molds, hot forming tools |

| Ti6Al4V | 900–950 | 4.43 | 600 | Specialized oxide layer | Aerospace, medical implants, racing components |

Selecting the right material requires a comprehensive understanding of the operational environment, load conditions, and lifecycle requirements. At Wuxi Lead Precision Machinery, our engineering team collaborates closely with clients to match material properties with application demands, ensuring precision, reliability, and long-term performance in every custom 3D printed component.

Manufacturing Process & QC

Titanium 3D Printing Production Process: Precision from Concept to Volume

At Wuxi Lead Precision Machinery, our titanium additive manufacturing process is engineered for uncompromising quality and repeatability, delivering true zero-defect outcomes for mission-critical aerospace, medical, and industrial components. We integrate deep material science expertise with rigorous process control across three tightly coupled phases.

Design Phase: Engineering Defect Prevention from the Start

Our process begins with intensive Design for Additive Manufacturing (DfAM) collaboration. Our engineers work directly with your team to optimize part geometry, minimizing stress concentrations, ensuring self-supporting angles, and strategically placing support structures to prevent warpage or collapse during build. Finite Element Analysis (FEA) and thermal simulation software predict and mitigate potential distortions or residual stresses inherent in titanium processing. Material selection is critical; we specify certified aerospace-grade Ti6Al4V (Grade 5) or biocompatible Ti6Al4V ELI (Grade 23) based on your application’s fatigue, corrosion, and biocompatibility requirements. This proactive design validation is foundational to eliminating geometric and material-related defects before the build even commences.

Prototyping Phase: Validating Performance and Process Stability

Rapid prototyping serves not merely as a form check but as a critical process qualification step. Using identical machines, materials, and parameters planned for production, we build functional prototypes. These undergo stringent non-destructive testing (NDT), including high-resolution Computed Tomography (CT) scanning to detect internal porosity or inclusions below 50 microns, and dimensional inspection via Coordinate Measuring Machines (CMM) against the validated CAD model. Mechanical property testing on build-attached coupons confirms tensile strength, yield strength, and elongation meet AMS 4928 or ASTM F136 standards. Any deviation triggers immediate root cause analysis and parameter refinement within our closed-loop control system, ensuring the production recipe is perfected.

Mass Production Phase: Sustained Zero-Defect Execution

Volume production leverages the validated process window with enhanced controls. Builds occur in inert argon atmospheres with oxygen levels maintained below 100 ppm to prevent embrittlement. In-situ melt pool monitoring and layer-wise thermal imaging provide real-time anomaly detection, automatically pausing the build for intervention if deviations occur. Every part benefits from full traceability: material lot numbers, machine calibration logs, and real-time process data are digitally recorded. Post-processing, including precision stress-relief heat treatment per AMS 2750, HIP (Hot Isostatic Pressing) for critical components, and multi-axis CNC machining for critical features, occurs within our integrated facility under strict environmental controls. Final inspection includes 100% dimensional verification and batch-certified material test reports, guaranteeing every shipped component meets your exacting specifications.

Wuxi Lead Titanium 3D Printing Technical Specifications

| Parameter | Specification | Quality Impact |

|---|---|---|

| Material Grades | Ti6Al4V (AMS 4928), Ti6Al4V ELI (ASTM F136) | Certified mechanical/biocompatible properties |

| Layer Thickness | 20-60 µm (adjustable) | Surface finish & feature resolution |

| Build Volume | Ø350 x 400 mm (Standard Platform) | Accommodates complex assemblies |

| Dimensional Accuracy | ±0.05 mm per 100 mm (post-machining) | Critical feature repeatability |

| Surface Roughness (As-Built) | Ra 12-25 µm (support-optimized) | Minimizes post-processing requirements |

| Inert Atmosphere | Argon, O₂ < 100 ppm | Prevents oxygen embrittlement |

| Post-Processing | Stress Relief, HIP, CNC Machining, Polishing | Ensures structural integrity & fit |

| Certifications | ISO 9001, NADCAP (Pending), Material Traceability | Full compliance & audit readiness |

This integrated approach—where design rigor, prototyping validation, and production discipline converge under a single quality management system—ensures Wuxi Lead delivers titanium components where failure is not an option. We transform complex designs into flawless, high-performance reality.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Titanium 3D Printing Expertise

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision-engineered solutions that redefine what’s possible in high-performance manufacturing. As a trusted leader in custom metal manufacturing, we specialize in titanium 3D printing services tailored to the most demanding industries, including aerospace, medical technology, defense, and advanced industrial applications. When you partner with us, you gain access to cutting-edge additive manufacturing technology, deep metallurgical expertise, and a commitment to quality that meets international standards.

Titanium is renowned for its exceptional strength-to-density ratio, corrosion resistance, and performance under extreme conditions. However, machining titanium through traditional methods presents challenges in cost, lead time, and design limitations. Our titanium 3D printing service overcomes these barriers, enabling complex geometries, lightweight structures, and rapid prototyping with full material integrity. Whether you require a single prototype or low-volume production runs, our industrial-grade metal additive systems ensure repeatability, accuracy, and full traceability.

Our facility in Wuxi, China, is equipped with state-of-the-art laser powder bed fusion (LPBF) machines, operating under controlled environments to guarantee consistent build quality. We use certified Grade 5 (Ti-6Al-4V) and Grade 2 titanium powders, sourced from reputable suppliers and tested for purity and flow characteristics. Every build undergoes rigorous in-process monitoring, post-processing heat treatment, and dimensional inspection using coordinate measuring machines (CMM) to meet your exact specifications.

We understand that in high-stakes industries, specifications matter. Below are the key technical capabilities of our titanium 3D printing service:

| Parameter | Specification |

|---|---|

| Material Options | Ti-6Al-4V (Grade 5), Ti-6Al-4V ELI, Grade 2 |

| Build Envelope | Up to 250 × 250 × 300 mm |

| Layer Thickness | 20–50 µm |

| Typical Build Accuracy | ±0.05 mm per 100 mm |

| Surface Roughness (as-built) | Ra 10–15 µm;可polished to Ra < 2 µm |

| Post-Processing Options | Stress relief, HIP, CNC machining, polishing, anodizing |

| Quality Standards | ISO 9001:2015, full material and process traceability |

Our engineering team collaborates closely with clients from design for additive manufacturing (DfAM) through final inspection. We provide design feedback, simulation support, and rapid iteration to accelerate your time to market. With a responsive supply chain and strict IP protection protocols, we ensure your projects remain secure, scalable, and on schedule.

For engineering teams pushing the boundaries of innovation, the right manufacturing partner makes all the difference. Contact us today at [email protected] to discuss your titanium 3D printing requirements. Let Wuxi Lead Precision Machinery be the precision behind your next breakthrough.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.