Technical Contents

Engineering Guide: Thin Wall Molding

Engineering Insight: The Critical Role of Precision in Thin Wall Molding

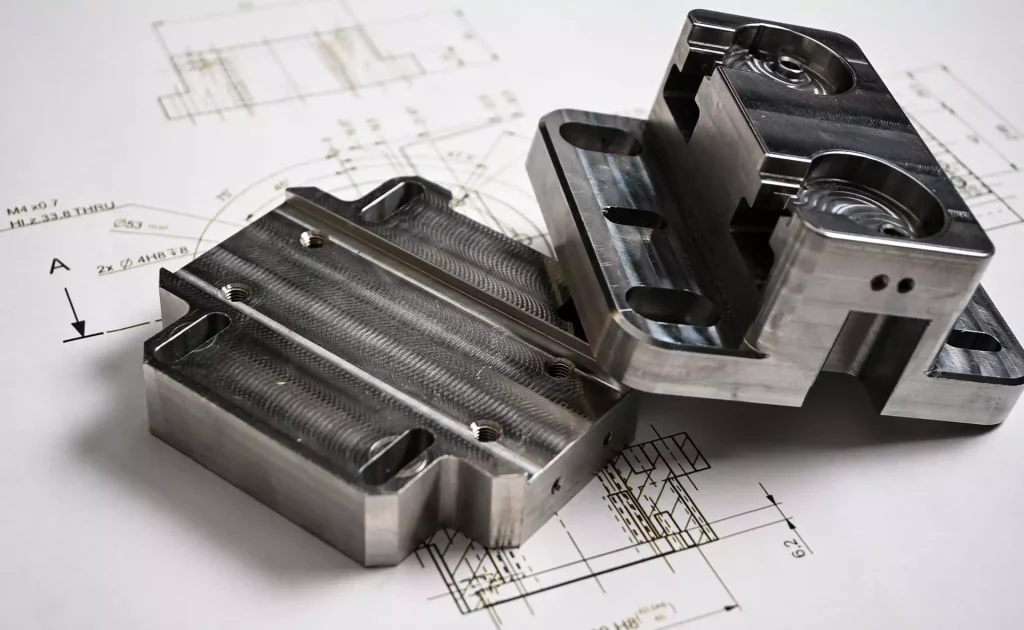

In the realm of high-performance manufacturing, thin wall molding stands as a benchmark for engineering excellence. This specialized process involves the production of lightweight, structurally sound plastic components with wall thicknesses often below 1.0 mm, demanding an extraordinary level of precision in both tooling and injection control. At Wuxi Lead Precision Machinery, we recognize that success in thin wall molding is not merely a function of advanced machinery—it is the result of meticulous design, material science, and process optimization executed with unwavering consistency.

The primary challenge in thin wall molding lies in maintaining uniform material distribution across complex geometries while minimizing cycle time and avoiding defects such as short shots, warpage, or sink marks. These challenges are amplified by the need for high cavity pressures and rapid injection speeds, which place immense stress on molds and equipment. Any deviation in mold alignment, temperature control, or clamping force can lead to part failure or reduced lifespan—unacceptable in industries where reliability is paramount.

Precision in thin wall molding is not optional; it is foundational. At Lead Precision, our engineering team leverages decades of experience in custom metal manufacturing to develop molds with micron-level tolerances. Our in-house design and CNC machining capabilities ensure that every mold base, cavity, and ejector system is crafted to exacting standards. This precision extends to thermal management, where optimized cooling channels prevent thermal distortion and ensure consistent shrinkage rates across production runs.

Our expertise has been validated in some of the most demanding applications globally. We have contributed to components used in Olympic-grade sports equipment, where weight reduction and structural integrity are critical. Additionally, our molds have supported military-grade electronics enclosures, subjected to extreme environmental conditions and rigorous durability testing. These projects underscore our ability to deliver under pressure, meeting not only dimensional specifications but also the broader performance criteria required by elite industries.

To illustrate the technical capabilities behind our thin wall molding solutions, the following table outlines key specifications achieved through our integrated manufacturing platform:

| Parameter | Specification |

|---|---|

| Wall Thickness Capability | As low as 0.5 mm |

| Dimensional Tolerance | ±0.01 mm |

| Mold Steel Types | S136, 2316, H13, 718H (custom options) |

| Surface Finish | Mirror polish (Ra ≤ 0.05 µm) |

| Cycle Time Reduction | Up to 30% optimized via hot runner |

| Clamping Force Range | 1,000 to 4,500 kN |

| Material Compatibility | PC, ABS, PP, PEI, PPS, LCP |

| Mold Life Expectancy | 1,000,000+ cycles (depending on resin) |

At Wuxi Lead Precision Machinery, we treat every thin wall molding project as a precision engineering challenge. Our proven track record in high-stakes sectors reflects our commitment to excellence, innovation, and long-term reliability. When performance cannot be compromised, manufacturers trust Lead Precision to deliver molds and components that meet the highest global standards.

Precision Specs & Tolerances

Thin Wall Molding Technical Capabilities

Wuxi Lead Precision Machinery delivers exceptional thin wall molding solutions for demanding metal components, where precision, structural integrity, and dimensional stability are non-negotiable. Our expertise centers on overcoming the inherent challenges of thin wall geometries—material flow control, sink marks, warpage, and deflection—through integrated advanced machining and rigorous quality validation. We specialize in producing complex, lightweight metal parts with wall thicknesses as low as 0.3 mm, consistently meeting the stringent requirements of aerospace, medical device, and semiconductor industries. Our end-to-end process ensures repeatability and compliance with ISO 13083 standards for thin wall integrity.

Core to our capability is a dedicated fleet of 5-axis CNC machining centers, featuring DMG MORI CTX beta 2500 and Hermle C 800 U models with Siemens 840D SL controls. These machines enable simultaneous multi-axis contouring, eliminating secondary setups and minimizing workpiece handling-induced errors critical for thin wall stability. High-speed spindles (up to 24,000 RPM) paired with adaptive toolpath strategies ensure minimal cutting forces, preventing wall deformation during machining. Integrated thermal compensation systems maintain micron-level accuracy across extended production runs, while vacuum chucks and custom fixtures provide secure, non-marring workholding for delicate geometries. Material compatibility spans aluminum alloys (6061, 7075), stainless steels (303, 316L), titanium (Gr5), and high-performance nickel alloys.

Quality assurance is anchored by Zeiss CONTURA G3 Coordinate Measuring Machines (CMM) with VAST gold probes and Calypso software. Every thin wall component undergoes 100% critical feature inspection, including wall thickness uniformity, flatness, and positional tolerances. Our CMM protocols include temperature-stabilized metrology labs (20±0.5°C) and traceable NIST-certified standards. Full inspection reports with GD&T analysis are provided, ensuring complete dimensional transparency and process validation for client audits. Statistical Process Control (SPC) data is monitored in real-time to preempt deviations, guaranteeing batch-to-batch consistency.

Tolerance performance is rigorously defined and validated across all production phases. The table below reflects achievable standards for thin wall components under 0.5 mm thickness:

| Feature Type | Standard Tolerance | Tight Tolerance Capability |

|---|---|---|

| Wall Thickness | ±0.025 mm | ±0.010 mm |

| Flatness (per 100 mm) | 0.05 mm | 0.02 mm |

| Positional (Holes) | ±0.020 mm | ±0.008 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Angularity | ±0.1° | ±0.05° |

This precision foundation allows Wuxi Lead to consistently produce thin wall metal components that exceed functional performance expectations. Our engineering team collaborates closely with clients during design for manufacturability (DFM) reviews to optimize wall transitions, gate locations, and support structures—reducing scrap rates by up to 35% versus industry averages. With full in-house tooling, machining, and metrology control, we deliver thin wall solutions where dimensional reliability directly translates to client product success. Trust Wuxi Lead for mission-critical thin wall metal parts engineered to perform.

Material & Finish Options

Material Selection for Thin Wall Molding in Precision Metal Manufacturing

In the realm of thin wall molding, material selection is a critical determinant of both performance and manufacturability. At Wuxi Lead Precision Machinery, we specialize in custom metal components where precision, structural integrity, and weight efficiency are paramount. The most commonly specified materials for these applications are aluminum, steel, and titanium—each offering distinct advantages depending on the operational demands of the final product.

Aluminum stands out for its excellent strength-to-weight ratio and inherent corrosion resistance. It is particularly well-suited for thin wall molding due to its high flowability during casting and ease of machining. Grade 6061-T6 is frequently selected for structural components in aerospace, automotive, and consumer electronics, where weight reduction is essential without compromising durability. Its thermal conductivity also makes it ideal for heat dissipation applications.

Steel, particularly in its stainless and tool steel variants, provides superior strength, hardness, and wear resistance. While denser than aluminum, steel is the preferred choice for high-stress or high-temperature environments. For instance, 316L stainless steel offers exceptional resistance to corrosion in harsh chemical or marine environments, making it suitable for medical and offshore applications. However, its higher density and machining complexity require advanced tooling and tighter process control during thin wall molding.

Titanium, specifically Grade 5 (Ti-6Al-4V), offers the highest strength-to-density ratio among the three and excels in extreme environments. It maintains mechanical integrity at elevated temperatures and resists corrosion in aggressive media, making it ideal for aerospace, defense, and high-performance automotive sectors. Despite its higher cost and challenging machinability, titanium’s longevity and performance under stress justify its use in mission-critical components.

Surface finishing plays a pivotal role in enhancing both functionality and aesthetics. Anodizing is the most effective post-processing technique for aluminum components. This electrochemical process thickens the natural oxide layer, significantly improving wear resistance, corrosion protection, and surface hardness. Type II (sulfuric acid) anodizing is widely used for general-purpose applications, while Type III (hardcoat anodizing) provides a dense, abrasion-resistant surface capable of withstanding severe operational conditions. Anodized layers can also be dyed for identification or branding purposes, offering both technical and visual benefits.

Below is a comparative overview of key material properties relevant to thin wall molding applications.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Common Finishes |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | 276 | High | Anodizing, Powder Coating |

| Stainless Steel 316L | 8.0 | 580 | 290 | Very High | Passivation, Electropolishing |

| Titanium Ti-6Al-4V | 4.4 | 900 | 830 | Exceptional | Anodizing, Thermal Spraying |

Selecting the optimal material and finish requires a thorough understanding of the application environment, mechanical loads, and lifecycle expectations. At Wuxi Lead Precision Machinery, our engineering team collaborates closely with clients to ensure every component is optimized for performance, cost-efficiency, and manufacturability in thin wall molding processes.

Manufacturing Process & QC

Thin Wall Molding Production Process: Achieving Zero Defects

Thin wall molding demands exceptional precision at every stage to achieve geometric integrity and structural reliability in components with sub-0.5mm wall thicknesses. At Wuxi Lead Precision Machinery, our Zero Defects philosophy is embedded within a rigorously controlled sequence: Design, Prototyping, and Mass Production. This integrated approach ensures manufacturability and flawless output from the first part.

The Design phase is foundational. Our engineering team collaborates closely with clients to optimize part geometry for thin wall constraints, focusing on uniform wall distribution, strategic gate placement, and minimized stress concentrations. Advanced Mold Flow Analysis (MFA) simulations predict material behavior, cooling rates, and potential warpage under high-speed injection conditions. Material selection is critical; we specify high-flow engineering thermoplastics like LCP or PPSU with precise melt viscosity profiles. Mold design incorporates hardened tool steels, micro-cooling channels for rapid, uniform heat extraction, and precision venting to prevent short shots or burns. Every detail is validated against ISO 9001:2015 and IATF 16949 standards before tooling begins.

Prototyping transitions design into physical validation. Using the production-intent mold, we produce initial batches under controlled parameters. Each prototype undergoes comprehensive metrology: CMM scans verify dimensional accuracy against CAD models, optical comparators assess wall thickness uniformity, and mechanical testing confirms material properties. Statistical Process Control (SPC) data is gathered on critical parameters like cavity pressure and cycle time. This phase identifies and resolves micro-defects—sink marks, weld lines, or slight warpage—through iterative parameter refinement. Only when dimensional stability, surface finish, and functional performance consistently meet the Zero Defects threshold do we approve the process for scale-up.

Mass Production executes the perfected process with uncompromising control. Our automated lines feature real-time cavity pressure monitoring and adaptive process control systems that instantly adjust injection speed or pack pressure to counteract material viscosity drift. Every 15 minutes, automated vision systems inspect parts for surface defects and critical dimensions, feeding data into our closed-loop SPC system. Full traceability links each component to its specific machine parameters, material lot, and operator. Environmental controls maintain strict temperature and humidity levels. This systematic vigilance, combined with operator certification and daily preventive maintenance, sustains a 99.98% first-pass yield rate. Zero Defects is not aspirational; it is the measurable outcome of our integrated process control.

Critical Thin Wall Molding Process Specifications

| Parameter | Target Range | Measurement Method | Control Frequency |

|---|---|---|---|

| Wall Thickness Tolerance | ±0.02 mm | CMM / Optical Comparator | Per Part Batch |

| Warpage (Flatness) | ≤ 0.05 mm | Laser Scanner | Hourly |

| Cycle Time | 15-45 seconds | Machine PLC Data | Continuous |

| Melt Temperature | ±2°C of Setpoint | In-line Thermocouples | Per Shot |

| Cavity Pressure Peak | ±3 bar of Target | Pressure Transducers | Per Shot |

| Part Weight Variation | ≤ 0.1% | Precision Scale | Every 30 Minutes |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Thin Wall Molding and Custom Metal Manufacturing

When precision, speed, and reliability define your production needs, partnering with Wuxi Lead Precision Machinery ensures your thin wall molding projects meet the highest global standards. As a trusted leader in custom metal manufacturing based in China, we specialize in delivering engineered solutions that combine advanced CNC machining, mold design, and high-speed molding technologies. Our facility is equipped to handle complex, high-volume thin wall components used in medical devices, consumer electronics, automotive systems, and packaging industries.

Thin wall molding demands exceptional control over material flow, cooling rates, and cavity pressure. At Lead Precision, we leverage state-of-the-art injection molding machines with tight tolerance control down to ±0.01 mm, supported by in-house tooling design and simulation software to predict and correct potential defects before production begins. Our engineering team collaborates directly with clients from concept to final part, ensuring design for manufacturability (DFM) principles are applied at every stage.

We understand that your supply chain depends on consistency and on-time delivery. That’s why our manufacturing process integrates real-time monitoring, automated quality inspection, and lean production methodologies to minimize waste and maximize throughput. With over 15 years of experience serving Tier-1 clients across North America, Europe, and Asia, we have built a reputation for technical excellence and responsive customer service.

Our commitment extends beyond production. We offer comprehensive project management, material sourcing support, and full traceability documentation to meet ISO 9001 and IATF 16949 compliance standards. Whether you require rapid prototyping or large-scale serial production, Lead Precision scales with your needs—delivering parts that are not only dimensionally accurate but also cost-optimized.

To ensure seamless integration with your engineering workflows, we support all major CAD formats including STEP, IGES, and Parasolid, and provide detailed mold flow analysis reports upon request. Our team is fluent in English and technical terminology, enabling clear communication across time zones and disciplines.

Explore how we can elevate your next thin wall molding project with precision engineering and reliable execution.

Technical Specifications at a Glance

| Parameter | Capability |

|---|---|

| Wall Thickness Range | 0.2 mm – 1.0 mm |

| Tolerance Control | ±0.01 mm |

| Clamping Force Range | 180–1,200 Tons |

| Shot Weight (Maximum) | Up to 1,500 grams (PS) |

| Materials Supported | PS, PP, ABS, PC, PE, Bio-plastics |

| Production Cycle Time | As low as 8 seconds (optimized molds) |

| Tooling Standards | HASCO, DME, MISUMI (customizable) |

| Quality Certification | ISO 9001, IATF 16949 |

| Lead Time (Prototype) | 25–35 days from design approval |

| Monthly Production Capacity | 10 million+ parts |

Contact us today to discuss your project requirements. Send your 3D drawings and specifications to [email protected] and receive a detailed feasibility assessment within 48 hours. Let Wuxi Lead Precision Machinery be your strategic partner in high-precision thin wall molding and custom metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.