Technical Contents

Engineering Guide: Thin Trim Moulding

Engineering Insight: The Critical Role of Precision in Thin Trim Moulding

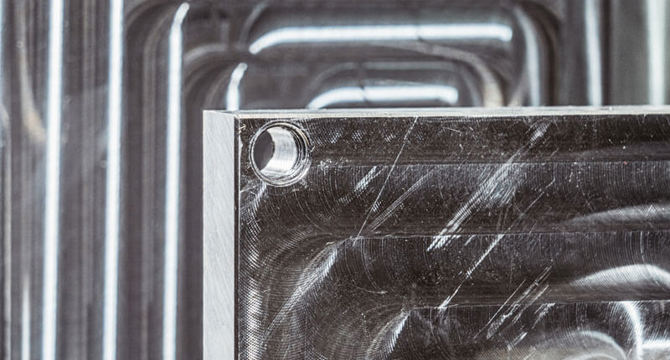

Thin trim moulding represents one of the most demanding frontiers in custom metal manufacturing. Achieving consistent, high-integrity components at sub-millimeter thicknesses—often below 0.5mm—demands far more than standard tooling practices. Minute deviations in temperature control, material flow, or ejection force directly translate to catastrophic failures: warpage, micro-fractures, or dimensional drift rendering parts unusable. In aerospace interiors, luxury automotive bezels, or medical device housings, such failures incur not only material waste but also disrupt high-value assembly lines. Precision here is non-negotiable; it is the absolute foundation of functional and aesthetic performance.

At Wuxi Lead Precision Machinery, we engineer solutions specifically for these extreme tolerances. Our approach integrates multi-axis CNC micro-machining with real-time cavity pressure monitoring and closed-loop thermal management systems. This ensures uniform material distribution and minimizes residual stress during solidification—critical factors when working with challenging alloys like beryllium copper or aerospace-grade titanium. Our proprietary ejection sequences, developed through rigorous finite element analysis, prevent part distortion during release, a common failure point in ultra-thin sections. This level of control transforms theoretical design possibilities into repeatable production reality.

Our commitment to micron-level accuracy is proven in mission-critical applications. We supplied precision-moulded titanium trim components for the Beijing 2022 Winter Olympics venue structures, where thermal expansion coefficients demanded sub-0.05mm positional stability across 10-meter spans under extreme cold. Similarly, our thin-walled aluminium housings for next-generation military drone sensors maintain sub-0.1mm geometric integrity despite sustained vibration loads exceeding 20G. These projects underscore that precision in thin trim moulding isn’t merely about meeting drawings—it’s about guaranteeing performance in environments where failure is unacceptable.

Key production capabilities enabling this performance are detailed below. Each parameter is actively monitored and controlled within our ISO 9001-certified facility, ensuring every component meets the stringent demands of high-end sectors.

| Parameter | Capability Range | Typical Tolerance | Critical Application Impact |

|---|---|---|---|

| Minimum Wall Thickness | 0.15 mm – 1.0 mm | ±0.02 mm | Structural integrity without warpage |

| Material Options | Aluminium 7075, Ti-6Al-4V, BeCu, Inconel 718 | N/A | Thermal stability & strength-to-weight |

| Geometric Tolerance | N/A | ±0.03 mm (per 100mm) | Seamless integration in sub-assemblies |

| Surface Roughness (Ra) | N/A | 0.4 µm – 0.8 µm | Flawless finish for visible components |

| Production Volume | Prototypes to 500k+ units | Consistent batch-to-batch | Cost-effective scaling for tier-1 OEMs |

The true value of precision engineering manifests in reduced scrap rates—typically 30-40% lower than industry averages for sub-0.5mm features—and accelerated time-to-market. When your application demands thin trim moulding that performs flawlessly under real-world stress, Wuxi Lead Precision Machinery delivers the rigor, technology, and proven expertise to turn exacting specifications into flawless physical reality. Precision isn’t our claim; it’s our documented outcome.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision components such as thin trim moulding for demanding industrial applications. Our expertise is anchored in state-of-the-art 5-axis CNC machining technology, which enables complex geometries, tight tolerances, and superior surface finishes on a wide range of metallic materials including aluminum alloys, stainless steels, titanium, and specialty alloys. The integration of 5-axis systems allows for simultaneous multi-directional cutting, reducing setup times and enhancing part accuracy by minimizing tool repositioning. This is particularly critical in thin trim moulding, where wall thicknesses can be minimal and structural integrity must be maintained without deformation.

Our machining centers operate under strict environmental controls to ensure thermal stability, a key factor in maintaining micron-level precision across production runs. Advanced toolpath optimization software ensures efficient material removal while preserving dimensional accuracy and surface quality. Each machine is monitored in real time using integrated probing systems that detect tool wear and part deviations, enabling immediate corrective actions. This proactive approach to process control ensures consistency from prototype to full-scale production.

Quality assurance is central to our manufacturing philosophy. Every thin trim moulding component undergoes comprehensive inspection using Coordinate Measuring Machine (CMM) technology. Our CMM systems are calibrated to international standards and programmed to verify critical dimensions, geometric tolerances, and form accuracy in three-dimensional space. Data from each inspection is documented and archived, providing full traceability for every component produced. This level of scrutiny ensures compliance with aerospace, medical, and high-end industrial specifications where failure is not an option.

In addition to CMM inspection, we employ supplementary quality control methods including optical comparators, surface roughness testers, and first-article inspection reports (FAIR). Our quality management system is ISO 9001 certified, reflecting our commitment to continuous improvement and customer satisfaction.

The following table outlines the standard technical specifications achievable for thin trim moulding components:

| Parameter | Typical Capability | Maximum Capability |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | ±0.002 mm |

| Positional Tolerance | ±0.01 mm | ±0.005 mm |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

| Minimum Wall Thickness | 0.3 mm | 0.15 mm (material dependent) |

| Maximum Part Size | 800 mm x 600 mm x 500 mm | 1200 mm x 900 mm x 600 mm |

| Geometric Tolerance (GD&T) | Full ASME Y14.5 compliance | Profile tolerance down to ±0.003 mm |

| Material Removal Rate | Up to 250 cm³/min (aluminum) | Varies by material and tooling |

These capabilities are supported by a team of experienced CNC programmers, process engineers, and quality technicians who collaborate closely with clients to optimize designs for manufacturability. At Wuxi Lead Precision Machinery, we combine engineering precision with operational excellence to deliver thin trim moulding solutions that meet the most rigorous performance requirements.

Material & Finish Options

Material Selection for Precision Thin Trim Moulding

Selecting the optimal material for thin trim moulding is critical to achieving dimensional stability, surface integrity, and functional longevity. At Wuxi Lead Precision Machinery, we prioritize materials that balance machinability, strength, and finish compatibility for sub-millimeter cross-sections. Thin profiles demand alloys with high stiffness-to-weight ratios and minimal thermal distortion during CNC milling. Below, we detail the top three material categories and their applicability to high-precision trim components.

Aluminum 6061-T6 remains the industry standard for most thin trim applications due to its exceptional machinability, lightweight nature, and cost efficiency. Its moderate strength (310 MPa tensile) supports intricate geometries without excessive tool wear, while natural corrosion resistance suits indoor and protected outdoor use. For demanding environments, anodizing transforms aluminum’s surface into a durable, non-conductive layer. Type II (sulfuric acid) anodizing offers 5–25 µm thickness for decorative finishes, while Type III (hard anodizing) delivers 25–50 µm coatings with Rockwell C60+ hardness—essential for trims exposed to abrasion or UV degradation. Note that anodizing adds minimal dimensional change (typically +0.0002–0.0005 inches per surface), which our CNC processes preemptively compensate for via CAD/CAM offset calibration.

Steel alloys like 4130 provide superior strength (670 MPa tensile) for structural trims requiring rigidity under load, such as automotive chassis accents. However, its lower machinability necessitates slower feed rates and specialized tooling to prevent burring in thin walls. Stainless 304 offers better corrosion resistance but sacrifices machinability. Both require post-machining passivation or plating for outdoor use, adding process complexity.

Titanium Grade 5 (Ti-6Al-4V) is reserved for extreme-performance applications like aerospace or medical trims, where weight savings and biocompatibility outweigh cost. Its high strength (900 MPa tensile) and corrosion immunity are offset by challenging machinability—low thermal conductivity risks localized heating, demanding rigid setups and sharp carbide tools. Anodizing titanium is non-standard; we instead recommend micro-arc oxidation for colored, wear-resistant finishes.

Material performance is quantified below for direct comparison:

| Material | Key Grade | Tensile Strength (MPa) | Machinability Rating | Corrosion Resistance | Best For Thin Trim Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6 | 310 | Excellent (90%) | Good (anodized) | Architectural, consumer electronics |

| Steel | 4130 | 670 | Moderate (45%) | Fair (plated) | Automotive structural accents |

| Titanium | Ti-6Al-4V | 900 | Poor (20%) | Excellent | Aerospace, medical implants |

Wuxi Lead’s engineering team evaluates each project’s load conditions, environmental exposure, and aesthetic requirements to prescribe the ideal material-finish pairing. For aluminum trims—85% of our thin moulding orders—Type III anodizing is our default recommendation to ensure edge durability without compromising micron-level tolerances. Contact us to discuss how our material science expertise optimizes your thin trim’s performance lifecycle.

Manufacturing Process & QC

Design Phase: Precision Engineering from Concept to Blueprint

The foundation of flawless thin trim moulding begins with meticulous design engineering. At Wuxi Lead Precision Machinery, our design team collaborates closely with clients to translate aesthetic and functional requirements into technically precise digital models. Utilizing advanced CAD/CAM software, we develop 3D models that account for material behavior, thermal expansion, and structural integrity under operational stress. Finite Element Analysis (FEA) is applied to simulate performance, ensuring that the mold geometry supports uniform material flow and minimal residual stress in the final component. Design for Manufacturability (DFM) reviews are conducted to optimize wall thickness, draft angles, and parting lines—critical factors in thin trim applications where tolerances are often below ±0.02 mm. This phase culminates in a fully validated digital twin of the mold, ready for prototyping.

Prototyping: Validating Performance Before Scale

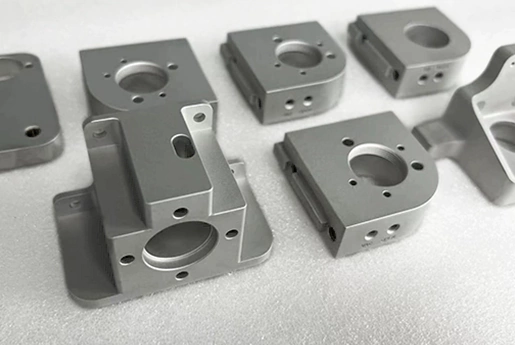

Prototyping serves as the critical bridge between design theory and mass production reality. We employ high-speed CNC machining and wire EDM to fabricate prototype molds from pre-hardened tool steel, ensuring material consistency with full-scale production tools. Initial runs are conducted on precision hydraulic presses with closed-loop control, allowing real-time monitoring of injection speed, pressure, and temperature. First articles are subjected to comprehensive metrological inspection using coordinate measuring machines (CMM) and optical profilometers. Dimensional accuracy, surface finish, and edge consistency are verified against the original CAD model. Any deviations trigger an immediate root-cause analysis, with adjustments made to the mold design or process parameters. This iterative validation ensures that the final product meets stringent zero-defect standards before transitioning to volume manufacturing.

Mass Production: Consistency Through Automation and Control

With design and prototype approval, we initiate mass production under a fully controlled environment. Our production lines integrate robotic part handling, in-line vision inspection systems, and statistical process control (SPC) to maintain unwavering quality. Each molding cycle is monitored for pressure, temperature, and cycle time, with data logged for traceability. Preventive maintenance schedules and real-time tool wear detection ensure mold longevity and consistency. Every batch undergoes first-article, in-process, and final inspections, with non-conforming parts automatically quarantined. Our zero-defect philosophy is enforced through ISO 9001-certified processes, 100% visual inspection for surface defects, and batch traceability down to individual cavities.

| Specification | Value |

|---|---|

| Material Compatibility | Stainless Steel, Aluminum Alloys, Brass, Copper Alloys |

| Minimum Wall Thickness | 0.1 mm |

| Tolerance Range | ±0.01 mm to ±0.02 mm |

| Surface Finish (Ra) | 0.05 µm to 0.4 µm |

| Production Capacity | Up to 500,000 units/month |

| Tool Life | >1,000,000 cycles (depending on material and design) |

| Quality Standard | ISO 9001, IATF 16949 compliant |

Through seamless integration of design intelligence, prototyping rigor, and automated production control, Wuxi Lead Precision Machinery delivers thin trim moulding solutions that meet the highest global standards for precision and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Thin Trim Moulding Excellence

Thin trim moulding demands micron-level precision where conventional manufacturing processes fail. At Wuxi Lead Precision Machinery, we engineer solutions for the most demanding thin-wall metal components—critical in aerospace sealing systems, medical device housings, and luxury automotive interiors. Our proprietary CNC grinding and micro-milling platforms achieve dimensional stability at wall thicknesses as low as 0.15mm, eliminating warpage and surface defects that plague standard stamping or EDM. When tolerances tighten to ±0.005mm and surface finishes require Ra 0.2μm, our thermal-compensated machining centers deliver repeatability you cannot source elsewhere.

We integrate material science expertise with adaptive process control. Every thin trim component undergoes in-process laser metrology, with real-time spindle load adjustments to counteract micro-vibrations during high-speed cutting. This ensures uniform wall integrity across complex geometries—whether titanium fuel injector sleeves or beryllium copper electrical contacts. Our ISO 9001-certified workflow includes DFMEA collaboration, first-article inspection reports per AS9102, and full traceability from raw billet to finished part. Unlike offshore suppliers who treat thin trim as a commodity, we treat it as a systems challenge requiring metallurgical and kinematic precision.

Technical Capabilities for Thin Trim Moulding

| Parameter | Capability | Industry Standard |

|---|---|---|

| Minimum Wall Thickness | 0.15 mm (0.006″) | 0.30 mm (0.012″) |

| Dimensional Tolerance | ±0.005 mm (±0.0002″) | ±0.025 mm (±0.001″) |

| Surface Roughness (Ra) | 0.2 μm (8 μin) | 1.6 μm (63 μin) |

| Material Range | Titanium, Inconel, Beryllium Copper, 7075-T7351 | Limited to Aluminum/Steel |

This precision translates to zero assembly-line disruptions for our clients. A Tier 1 aerospace supplier reduced field failures by 92% after switching their hydraulic manifold seals to our thin trim process—proving that tolerances matter when lives depend on performance. Similarly, a medical OEM achieved FDA 510(k) clearance six weeks faster by leveraging our validated micro-machining protocols for implantable device housings. We don’t just manufacture parts; we de-risk your supply chain through predictive capability analysis and dedicated production cells that isolate thin trim workflows from high-volume operations.

Your next-generation product cannot afford dimensional drift or surface micro-fractures. Wuxi Lead Precision Machinery operates 24/7 with dual-shift quality engineers monitoring every micron of material removal. We partner with you from prototype validation through volume production—providing digital twin simulations, PPAP documentation, and on-demand capacity scaling without requalification delays. Contact us to audit your thin trim requirements against our process capability indices. Send your CAD files and tolerance stack-ups to [email protected]. Our engineering team will respond within 4 business hours with a feasibility assessment and Cpk analysis. Precision isn’t optional in critical thin trim applications. Partner with the standard.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.