Technical Contents

Engineering Guide: Thick Mold

Engineering Insight: Thick Mold Fabrication and the Critical Role of Precision

In the domain of custom metal manufacturing, thick mold fabrication represents one of the most technically demanding applications. These molds, typically exceeding 150 mm in wall thickness, are engineered to withstand extreme thermal cycling, high clamping forces, and prolonged operational stress. Used extensively in aerospace, defense, and large-scale industrial molding, thick molds demand more than robust materials—they require micron-level precision at every stage of production. At Wuxi Lead Precision Machinery, we recognize that dimensional accuracy, thermal stability, and structural integrity are not optional; they are foundational.

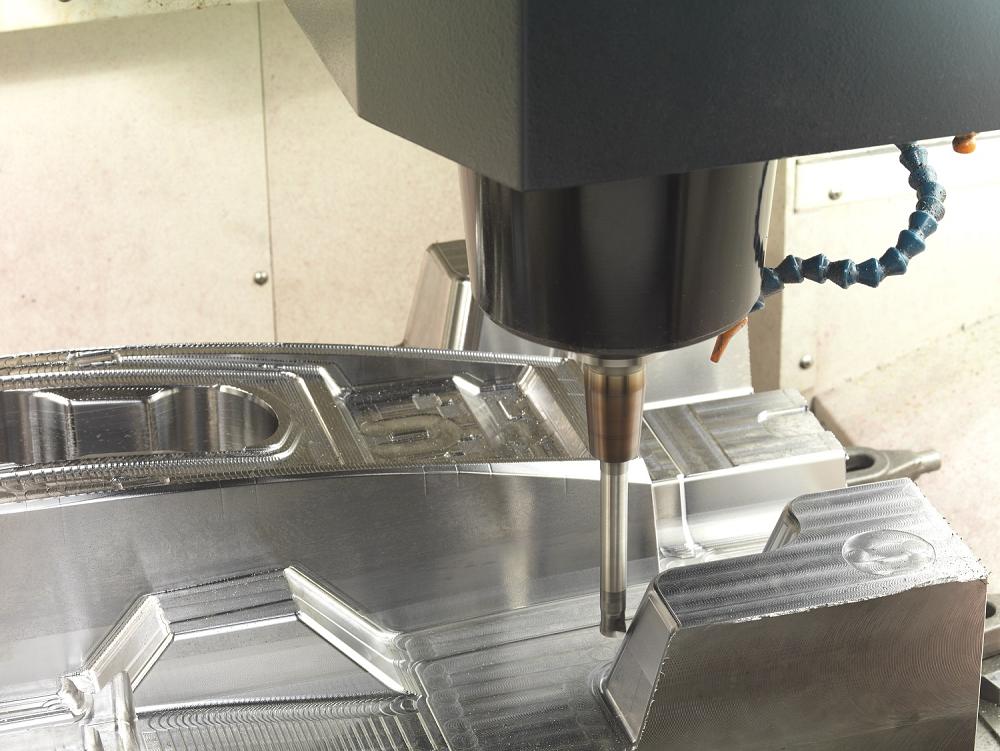

Thick molds present unique engineering challenges. Their mass leads to non-uniform cooling rates, increasing the risk of warpage, internal stress, and surface defects. Even minor deviations in cavity alignment or tolerance can result in part failure, costly rework, or premature tool wear. This is where precision becomes non-negotiable. Our CNC machining centers, calibrated to ±0.002 mm, ensure that core components maintain geometric consistency across large work envelopes. We employ multi-axis simultaneous machining to minimize setup changes, reducing cumulative error and enhancing repeatability.

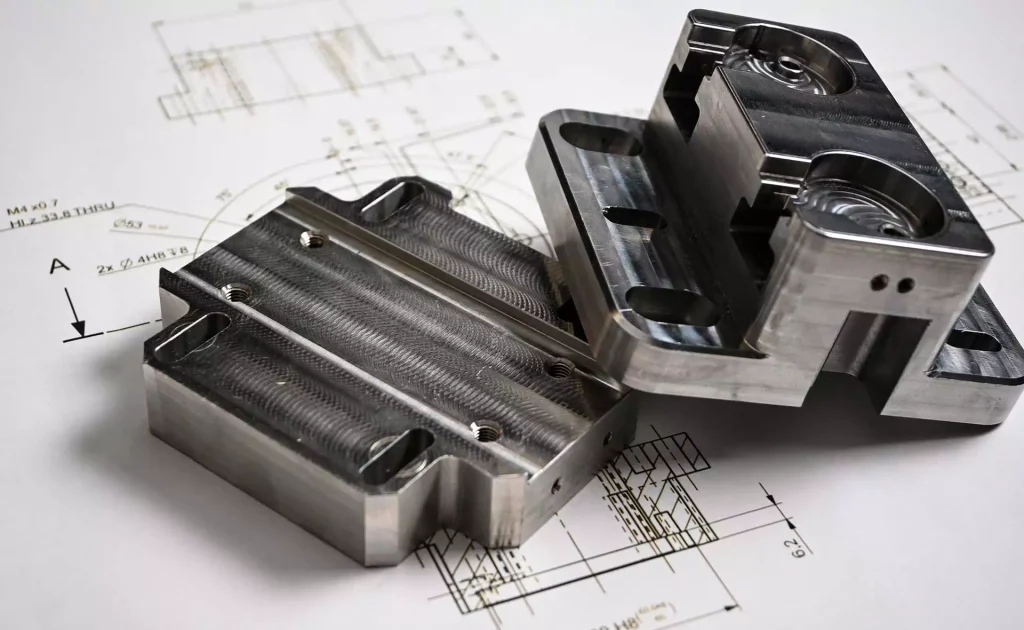

Material selection is equally critical. We utilize pre-hardened tool steels such as H13, P20+, and 42CrMo4, optimized for toughness and thermal conductivity. Each billet undergoes ultrasonic testing and stress-relief annealing prior to machining. Our in-house heat treatment facility allows tight control over hardness profiles, ensuring uniformity through the mold’s cross-section—a necessity when dealing with thick geometries prone to core softening or cracking.

Wuxi Lead Precision Machinery brings over 18 years of experience in high-precision manufacturing for mission-critical sectors. Our work has supported components used in Olympic-grade sporting equipment, where performance margins are measured in microns, and in military-grade defense systems, where reliability under extreme conditions is paramount. These applications demand zero-failure outcomes, and our thick mold solutions are engineered to meet that standard.

Our process integrates advanced simulation software for mold flow and thermal analysis, allowing us to predict deformation and optimize cooling channel placement before metal is cut. This proactive approach reduces trial iterations and accelerates time-to-production. Furthermore, our quality assurance protocols include 3D coordinate metrology and laser scanning to validate internal and external features against CAD models.

Below are typical specifications for our thick mold manufacturing capabilities:

| Specification | Detail |

|---|---|

| Maximum Mold Thickness | 600 mm |

| Tolerance Control | ±0.002 mm |

| Surface Finish | Ra 0.2 – 0.8 µm (polished or machined) |

| Materials | H13, P20+, 42CrMo4, S136, 718H |

| Machining Axes | 3 to 5-axis simultaneous |

| Lead Time (Average) | 25–40 days, depending on complexity |

| Quality Standards | ISO 9001:2015, GD&T compliance |

Precision in thick mold fabrication is not merely a technical objective—it is a commitment to performance, longevity, and trust. At Wuxi Lead Precision Machinery, we engineer every mold as if failure is not an option, because for our clients in high-stakes industries, it never is.

Precision Specs & Tolerances

Technical Capabilities for Precision Thick Mold Manufacturing

Wuxi Lead Precision Machinery delivers exceptional precision and reliability for demanding thick mold applications within the custom metal manufacturing sector. Our core strength lies in advanced multi-axis machining, specifically engineered to overcome the unique challenges presented by large, heavy-walled mold components requiring deep cavities, complex undercuts, and stringent geometric accuracy. Thick molds, essential for high-pressure injection, die casting, and composite forming, demand equipment capable of maintaining rigidity and precision throughout extensive material removal cycles. We address this through a dedicated fleet of high-torque 5-axis CNC machining centers.

These state-of-the-art machines feature robust cast iron structures, high-power spindles (up to 80 Nm torque), and expansive work envelopes (accommodating parts up to 2000 x 1500 x 1200 mm). The simultaneous 5-axis capability is critical for thick mold production, enabling complex geometries to be machined in a single setup. This eliminates cumulative errors from multiple fixturing operations, ensures superior positional accuracy between critical mold features like cores, cavities, and cooling channels, and significantly reduces overall lead time. Our programming expertise leverages advanced CAM software to optimize toolpaths for maximum material removal rates while preserving surface integrity on hardened tool steels (including H13, S7, P20+) and other demanding mold alloys.

Precision is non-negotiable in thick mold manufacturing, where minute deviations directly impact part quality, cycle time, and mold lifespan. Wuxi Lead implements a rigorous, multi-stage quality control protocol centered around certified Coordinate Measuring Machine (CMM) inspection. Every critical dimension, geometric feature, and surface profile is verified against the original CAD model using our Zeiss and Hexagon GLOBAL S 121510 CMMs, operating within a climate-controlled metrology lab (20°C ±0.5°C). This comprehensive inspection provides full traceability and generates detailed reports, ensuring absolute conformity to client specifications before mold assembly or shipment. Proactive in-process checks during machining further guarantee adherence to tolerances, minimizing rework and accelerating time-to-market.

Our commitment to dimensional perfection is quantified through consistently achievable tolerances, as demonstrated below for typical thick mold components machined from tool steel:

| Feature Type | Standard Tolerance | Precision Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | CMM |

| Geometric Form (Flatness, Roundness) | 0.015 mm | 0.008 mm | CMM / Optical Comparator |

| Positional Tolerance | ±0.012 mm | ±0.006 mm | CMM |

| Angular Tolerance | ±0.005° | ±0.002° | CMM / Sine Plate |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | Profilometer |

This combination of high-capacity 5-axis machining and metrology-grade inspection ensures Wuxi Lead produces thick molds that meet the most exacting industry standards. The result is reduced mold trial cycles, exceptional part consistency, extended mold service life, and significant cost savings for our clients in automotive, aerospace, and industrial manufacturing. Partner with us for thick mold solutions where uncompromising precision meets industrial-scale capability.

Material & Finish Options

Material Selection for High-Performance Thick Mold Applications

In the precision manufacturing of thick molds, material selection directly impacts performance, longevity, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal solutions tailored to the structural and thermal demands of heavy-duty molding processes. The optimal material must balance machinability, thermal conductivity, wear resistance, and dimensional stability. Aluminum, steel, and titanium each offer distinct advantages depending on application requirements.

Aluminum alloys, particularly 7075 and 6061, are widely used in mold construction due to their excellent thermal conductivity and lightweight properties. These characteristics enable faster cycle times and reduced energy consumption during molding operations. Aluminum is also highly machinable, allowing for complex geometries and tight tolerances. However, its lower hardness compared to steel makes it less suitable for high-wear environments unless enhanced with surface treatments such as hard anodizing.

Steel remains the standard for molds requiring extreme durability and resistance to deformation. Tool steels like P20, H13, and S136 offer superior hardness, toughness, and resistance to thermal fatigue. These properties make steel ideal for high-volume production runs and applications involving aggressive resins or elevated processing temperatures. While heavier and more challenging to machine than aluminum, steel molds deliver extended service life and dimensional consistency under sustained loads.

Titanium, though less common due to higher material and machining costs, provides exceptional strength-to-density ratio and corrosion resistance. It is particularly advantageous in specialized applications where weight reduction and resistance to chemical degradation are critical. Titanium molds are often found in aerospace and medical device manufacturing, where performance under extreme conditions is non-negotiable.

Surface finishing plays a crucial role in mold performance and part quality. Anodizing, especially hard anodizing, significantly enhances the surface properties of aluminum molds. This electrochemical process creates a thick, wear-resistant oxide layer that improves hardness, reduces friction, and increases resistance to corrosion. Hard anodized aluminum can approach the surface durability of some steels while retaining aluminum’s thermal benefits.

Below is a comparative overview of key material properties relevant to thick mold applications:

| Material | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Hardness (HB) | Common Applications | Anodizing Compatibility |

|---|---|---|---|---|---|

| Aluminum 7075 | 570 | 130 | 150 | Prototype, low-volume molds | Excellent |

| Steel P20 | 950 | 28 | 290 | High-volume plastic molds | Not applicable |

| Steel H13 | 1,550 | 30 | 230 | Die casting, hot work | Not applicable |

| Titanium Grade 5 | 900 | 7 | 360 | Aerospace, medical | Good (Type II/III) |

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on production volume, part complexity, and environmental exposure. Our engineering team ensures every thick mold is optimized for performance, longevity, and cost-effectiveness.

Manufacturing Process & QC

Thick Mold Production: Engineering Precision from Concept to Volume

Thick molds represent critical tooling assets in high-pressure metal forming applications such as die casting, forging, and heavy stamping. Their substantial cross-sections demand exceptional thermal management, structural integrity, and dimensional stability under extreme cyclic loads. At Wuxi Lead Precision Machinery, we execute a rigorously controlled three-phase production workflow designed to eliminate defects before they reach your production floor. Our Zero Defects mandate begins with foundational engineering and extends through every machining pass and validation checkpoint.

The Design phase integrates advanced simulation with deep materials science expertise. Our engineers utilize 3D CAD/CAM suites coupled with Finite Element Analysis (FEA) to model thermomechanical behavior under operational stress. This predicts potential failure points like thermal fatigue cracking or distortion, allowing proactive geometry optimization. Material selection is critical; we specify premium tool steels like H13 for hot-work applications or premium-grade P20 for pre-hardened requirements, ensuring optimal hardenability and wear resistance. Comprehensive tolerance stack-up analysis guarantees that final assembly interfaces and cavity dimensions will meet stringent functional requirements before a single chip is cut.

Prototyping transforms validated designs into physical proof. We employ multi-axis CNC machining centers with sub-micron positioning accuracy to fabricate initial mold sets. Each prototype undergoes exhaustive metrological validation against the digital twin. Critical features are measured using calibrated Coordinate Measuring Machines (CMM) and optical comparators, verifying geometric dimensioning and tolerancing (GD&T) compliance. Functional testing in controlled press environments assesses cooling efficiency, ejection dynamics, and initial wear patterns. Only when all dimensional, thermal, and performance metrics exceed client specifications do we approve the prototype for volume replication. This phase is non-negotiable for risk mitigation.

Mass Production leverages our certified lean manufacturing systems with embedded Statistical Process Control (SPC). Every machining operation follows documented work instructions referencing the approved prototype. In-process inspections at critical control points monitor parameters like surface roughness, hardness gradients, and cavity symmetry. Real-time SPC charts track key variables, triggering automatic process adjustments if trends approach tolerance limits. Final assembly occurs in a climate-controlled environment, followed by 100% inspection of all critical surfaces and interfaces. This closed-loop system ensures every mold set shipped meets the identical performance standard as the validated prototype, eliminating batch-to-batch variation.

Our commitment to Zero Defects is quantifiable through measurable process capabilities. The following specifications define the output quality standard for all thick mold projects:

| Specification Category | Requirement | Measurement Method | Acceptance Criteria |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm | CMM (Calibrated to ISO 10360) | 100% of critical features within tolerance |

| Surface Roughness (Cavity) | Ra ≤ 0.4 μm | Stylus Profilometer | Verified on 3+ locations per cavity |

| Hardness Uniformity | ±3 HRC across section | Rockwell C Scale Tester | Max deviation from target spec |

| Cooling Channel Alignment | ≤ 0.02 mm runout | Optical Alignment System | Full channel length verification |

Partnering with Wuxi Lead means your thick molds are engineered for maximum service life and consistent part quality. We transform complex metal forming challenges into reliable production assets through uncompromising process discipline. Contact our engineering team to discuss your next high-integrity tooling project.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Thick Mold Manufacturing

When precision, durability, and performance define your production standards, partnering with Wuxi Lead Precision Machinery ensures your thick mold applications are engineered to exceed expectations. As a leading custom metal manufacturing solution provider based in China, we specialize in the design, machining, and integration of high-load, high-strength molds used in demanding industrial sectors including automotive, aerospace, energy, and heavy machinery. Our advanced CNC capabilities, combined with decades of engineering experience, enable us to deliver thick molds that maintain dimensional accuracy, thermal stability, and long service life under extreme operating conditions.

Thick molds present unique challenges—thermal expansion, material consistency, and structural integrity under repeated stress demand more than standard fabrication techniques. At Lead Precision, we address these challenges with a systems-driven approach. From raw material selection to final inspection, every phase of production is controlled in-house using state-of-the-art 5-axis milling, high-torque boring, and precision grinding equipment. Our facility is ISO 9001 certified, ensuring compliance with international quality standards while supporting tight tolerances down to ±0.005 mm and surface finishes as fine as Ra 0.4 µm.

We understand that each client’s application is unique. Whether you require molds for high-pressure die casting, composite forming, or large-scale forging, our engineering team collaborates closely with yours to optimize design for manufacturability, performance, and cost-efficiency. Rapid prototyping, DFM analysis, and finite element analysis (FEA) are integrated into our workflow to mitigate risk and accelerate time-to-market.

Our clients rely on us not only for technical excellence but also for responsive, transparent partnership. With streamlined communication and project management, we ensure full traceability and real-time updates from concept to delivery. As a trusted manufacturing partner to global OEMs and Tier-1 suppliers, we are equipped to support low-volume specialty runs as well as high-volume production series with consistent quality and on-time delivery.

Below are key technical specifications that define our thick mold manufacturing capabilities:

| Specification | Capability |

|---|---|

| Maximum Workpiece Size | 3000 mm × 1200 mm × 1000 mm |

| Material Compatibility | 42CrMo, H13, P20, S45C, Stainless Steel, Tool Steel, and Custom Alloys |

| Tolerance | ±0.005 mm |

| Surface Finish | Ra 0.4 – 3.2 µm (adjustable per requirement) |

| Machining Equipment | 5-Axis CNC, High-Torque Boring Mills, CNC Lathes, Surface & Cylindrical Grinders |

| Quality Standards | ISO 9001:2015, Full Inspection Reports (CMM, Hardness, NDT) |

| Lead Time | 15–45 days (depending on complexity and size) |

Partnering with Wuxi Lead Precision Machinery means choosing a manufacturer that combines technical depth with operational reliability. We are committed to being an extension of your engineering team, delivering solutions that stand up to the most rigorous industrial demands.

For inquiries or to submit a project specification, contact us at [email protected]. Let us help you build stronger, smarter, and more precise thick mold systems—engineered for performance, built to last.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.