Technical Contents

Engineering Guide: Thermoplastic Polyurethane Injection Molding

Engineering Insight Thermoplastic Polyurethane Injection Molding

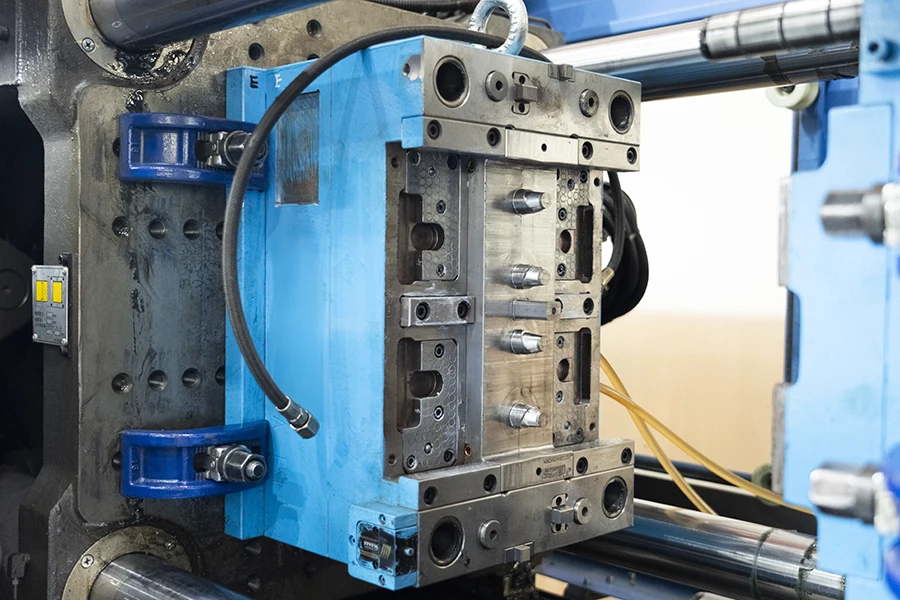

Achieving consistent, high-performance results in thermoplastic polyurethane (TPU) injection molding demands exceptional precision at every stage. TPU’s unique combination of elasticity, abrasion resistance, and transparency makes it invaluable for demanding applications like medical devices, automotive seals, and high-end consumer goods. However, its sensitivity to processing parameters—particularly temperature fluctuations, shear rates, and moisture content—presents significant engineering challenges. Minor deviations in barrel temperature control or injection speed can lead to critical defects: surface imperfections like jetting or splay, inconsistent durometer readings, or compromised mechanical properties such as tensile strength and elongation. The material’s inherent viscosity variations require machinery capable of micron-level repeatability in shot size and pressure application to ensure part-to-part uniformity, especially for thin-walled or complex geometries where flow dynamics are critical.

Wuxi Lead Precision Machinery addresses these challenges through purpose-built CNC-engineered injection molding platforms. Our systems integrate closed-loop servo-hydraulic control with sub-micron positional accuracy on the injection unit and clamping mechanism. This ensures consistent melt homogeneity and precise cavity packing, directly mitigating TPU’s tendency toward sink marks or dimensional drift. Advanced thermal management systems maintain barrel and nozzle zones within ±0.5°C stability, crucial for preventing thermal degradation in sensitive TPU grades. Real-time process monitoring with AI-driven anomaly detection allows immediate correction of deviations before scrap is produced, safeguarding yield rates essential for cost-effective production of high-value TPU components.

This precision engineering capability is proven in mission-critical environments. Lead Precision machinery has supported the production of TPU components for Olympic-grade timing systems requiring microsecond synchronization reliability and military-specification gaskets demanding absolute sealing integrity under extreme thermal cycling and vibration. Such applications tolerate zero defects, validating our machines’ ability to maintain tolerances under sustained operational stress. Our engineering team leverages this deep materials science expertise to configure optimal processing windows for specific TPU formulations, translating material potential into flawless physical parts.

The following table outlines key specifications of Lead Precision’s TPU-optimized molding platforms, demonstrating the foundational precision required for high-integrity TPU manufacturing:

| Parameter | Specification Range | Precision Tolerance | Relevance for TPU Processing |

|---|---|---|---|

| Clamp Force | 800 – 6500 Tons | ±0.1% | Ensures mold stability during high-pressure packing of viscous TPU melts |

| Shot Size Repeatability | 10 – 10,000 g | ±0.05% | Critical for consistent wall thickness and part weight in thin-walled TPU components |

| Barrel Temp Control | Ambient to 300°C | ±0.5°C | Prevents thermal degradation and maintains optimal melt viscosity |

| Injection Speed | 5 – 1000 mm/s | ±1 mm/s | Controls shear heating to avoid material breakdown during cavity fill |

| Holding Pressure | 0 – 2500 bar | ±5 bar | Compensates for TPU shrinkage without causing flash or over-packing |

Precision in TPU molding is not merely desirable—it is the non-negotiable foundation for functional, reliable end products. Wuxi Lead Precision Machinery delivers the repeatable accuracy, thermal stability, and intelligent process control required to transform challenging TPU formulations into components meeting the most stringent global quality standards. Our commitment to engineering excellence, forged in aerospace and defense applications, ensures your TPU production achieves maximum yield and performance.

Precision Specs & Tolerances

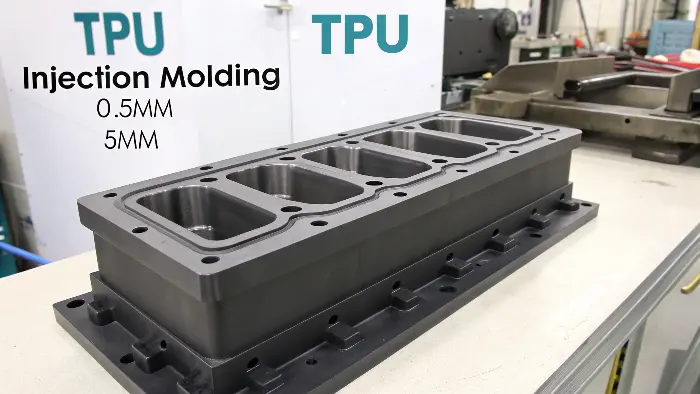

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, engineered to support high-performance applications such as thermoplastic polyurethane (TPU) injection molding. Our expertise extends beyond standard production, integrating precision engineering with advanced material science to meet the demanding requirements of industries including automotive, medical devices, and industrial automation. Central to our operation is a suite of 5-axis CNC machining centers, which enable us to produce complex, high-accuracy molds and tooling components critical for consistent TPU molding performance.

The 5-axis CNC technology we employ allows simultaneous movement across five axes, providing unparalleled flexibility in contouring and machining intricate geometries. This capability is essential when fabricating molds with undercuts, deep cavities, or freeform surfaces commonly required in TPU applications. By minimizing setup changes and tool repositioning, we achieve tighter tolerances, superior surface finishes, and reduced cycle times—key factors in ensuring mold longevity and part repeatability. Our machining centers are equipped with high-speed spindles, thermal compensation systems, and automated tool changers, ensuring consistent output across both prototyping and high-volume production runs.

Quality assurance is embedded throughout our manufacturing workflow. Every component undergoes rigorous inspection using a Coordinate Measuring Machine (CMM), enabling micron-level verification of dimensional accuracy and geometric conformity. The CMM system operates with a calibrated probe and advanced metrology software, allowing for full 3D scanning and comparison against CAD models. This ensures that all mold bases, cavities, cores, and alignment features meet the exact specifications required for reliable TPU injection molding, where even minor deviations can lead to flash, warpage, or ejection issues.

Our commitment to precision is reflected in the tolerances we consistently achieve across various feature types. The table below outlines our standard and high-precision capabilities.

| Feature Type | Standard Tolerance | High-Precision Tolerance | Measurement Method |

|---|---|---|---|

| Linear Dimensions (mm) | ±0.02 mm | ±0.005 mm | CMM, Micrometer |

| Geometric Tolerances (GD&T) | ±0.03 mm | ±0.01 mm | CMM, Optical Comparator |

| Surface Roughness (Ra) | 0.8 µm | 0.2 µm | Surface Roughness Tester |

| Hole Diameter | ±0.015 mm | ±0.008 mm | CMM, Air Gauge |

| Flatness | 0.02 mm | 0.005 mm | CMM, Surface Plate |

These specifications are maintained through continuous process monitoring, environmental control in machining areas, and adherence to international quality standards. At Wuxi Lead Precision Machinery, we combine cutting-edge 5-axis CNC technology with disciplined quality control to deliver tooling solutions that ensure optimal performance in thermoplastic polyurethane injection molding applications.

Material & Finish Options

Material Selection for Thermoplastic Polyurethane Injection Molding

Selecting the optimal mold material is critical for thermoplastic polyurethane (TPU) injection molding success. TPU’s inherent elasticity, high friction coefficient, and tendency for part adhesion demand molds engineered for exceptional wear resistance, precise thermal management, and superior surface release. Poor material choice accelerates wear, increases ejection forces, and compromises part quality and production longevity. At Wuxi Lead Precision Machinery, we prioritize mold longevity and part consistency by matching material properties to your specific TPU grade, part geometry, and production volume.

The following table compares key properties of common mold materials for TPU applications:

| Material | Hardness (Typical) | Thermal Conductivity (W/m·K) | Wear Resistance | Cost Factor | Best Suited For TPU Runs |

|---|---|---|---|---|---|

| Aluminum (7075-T6) | 150 HB | 130 | Low | Low | Prototypes, very low volumes (<5k shots) |

| Tool Steel (P20) | 28-32 HRC | 28-36 | Moderate | Medium | Medium volumes (50k-200k shots), simple geometries |

| Tool Steel (H13) | 48-52 HRC | 24-30 | High | High | High volumes (>200k shots), complex parts, aggressive TPU grades |

| Titanium Alloy | 33-36 HRC | 7-10 | Moderate-High | Very High | Specialized applications only (corrosive environments, weight critical) |

Aluminum molds offer rapid machining and lower initial cost but lack the hardness required for sustained TPU production. TPU’s abrasiveness quickly erodes aluminum surfaces, leading to dimensional drift, increased flash, and frequent polishing. We restrict aluminum use to initial prototyping or extremely low-volume runs where part count justifies the risk of premature mold failure.

Standard tool steels like P20 provide a practical balance for moderate TPU production. When properly heat-treated and polished, P20 handles many TPU formulations adequately. However, for demanding applications involving high-durometer TPU, intricate part features requiring tight ejection tolerances, or extended production cycles, P20’s moderate hardness becomes a limitation. Surface wear and galling can occur, necessitating more frequent maintenance.

H13 tool steel is our definitive recommendation for serious TPU manufacturing. Its high hardness (48-52 HRC) after heat treatment delivers exceptional resistance to abrasive wear from TPU pellets and friction during ejection. Combined with precise mirror polishing and appropriate surface treatments, H13 ensures consistent part release, maintains critical dimensions over hundreds of thousands of cycles, and minimizes downtime. The higher initial investment in H13 is consistently offset by extended mold life and reduced per-part costs in medium to high-volume production.

Anodizing aluminum molds provides marginal improvement for TPU but cannot overcome inherent hardness limitations. For steel molds, specialized hard chrome plating or PVD coatings like TiN are far more effective for enhancing release and wear resistance with challenging TPU grades. Wuxi Lead Precision Machinery engineers evaluate your specific TPU formulation, part complexity, and volume targets to prescribe the optimal material and surface solution, ensuring maximum productivity and part quality from your injection molding investment. Contact our technical team for a tailored material assessment.

Manufacturing Process & QC

Design Phase: Precision Engineering for Thermoplastic Polyurethane Injection Molding

The foundation of a successful thermoplastic polyurethane (TPU) injection molding process begins with meticulous design engineering. At Wuxi Lead Precision Machinery, we integrate advanced CAD/CAM software with deep material science expertise to develop mold designs that account for TPU’s unique viscoelastic behavior. Shrinkage rates, flow dynamics, and thermal sensitivity are modeled using finite element analysis (FEA) to predict warpage and optimize gate locations, cooling channels, and parting lines. Our engineers collaborate closely with clients to ensure dimensional accuracy, structural integrity, and manufacturability from the earliest stages. Design for manufacturability (DFM) reviews are conducted to eliminate potential defects such as sink marks, voids, or weld lines, ensuring that every component meets stringent performance and aesthetic standards.

Prototyping: Validating Performance and Precision

Once the mold design is finalized, a high-precision prototype is produced using CNC-machined tool steel molds, typically in single or low-cavity configurations. This phase is critical for validating both the mold functionality and the TPU material behavior under actual processing conditions. We utilize controlled injection parameters—temperature, pressure, and cooling time—to produce functional prototypes that mirror final production quality. These prototypes undergo rigorous testing, including dimensional inspection via coordinate measuring machines (CMM), tensile strength analysis, and environmental exposure trials. Feedback from this stage informs any necessary mold adjustments, ensuring process stability before transitioning to full-scale manufacturing. This iterative validation process is central to our zero-defect philosophy, minimizing risks in mass production.

Mass Production: Consistency, Control, and Quality Assurance

With design and prototyping complete, production scales using multi-cavity molds engineered for maximum repeatability and efficiency. Our automated TPU injection molding lines are equipped with real-time monitoring systems that track melt temperature, injection speed, and clamp force for every cycle. Closed-loop process control ensures deviations are corrected instantly, maintaining tight tolerances across high-volume runs. Each component is inspected using inline vision systems and statistical process control (SPC) methodologies to uphold zero-defect standards. All molds are built from premium-grade tool steel with optimized surface finishes and corrosion resistance, ensuring longevity and consistent part quality over millions of cycles.

Key Process Specifications

| Parameter | Specification Range |

|---|---|

| Material Type | Thermoplastic Polyurethane (TPU) |

| Hardness Range (Shore A) | 60A – 95A |

| Melt Temperature | 190°C – 230°C |

| Injection Pressure | 80 – 120 MPa |

| Mold Temperature | 30°C – 60°C |

| Cycle Time (typical) | 20 – 60 seconds |

| Tolerance (standard) | ±0.05 mm |

| Tool Steel Material | H13, 420 Stainless, or S136 |

| Surface Finish | SPI A1, A2, B1, B2, or custom textures |

| Production Capacity | Up to 500,000 units/month per mold |

Through integrated design, prototyping, and production workflows, Wuxi Lead Precision Machinery delivers defect-free TPU injection molded components tailored to the exacting demands of automotive, medical, and industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Thermoplastic Polyurethane Injection Molding Excellence

Achieving consistent, high-integrity thermoplastic polyurethane (TPU) components demands more than standard injection molding capabilities. TPU’s unique viscoelastic properties, sensitivity to temperature fluctuations, and potential for hydrolysis require engineered solutions where material science meets micron-level process control. At Wuxi Lead Precision Machinery, we bridge this gap through purpose-built machinery and deep metallurgical expertise. Our custom metal manufacturing heritage—forged over 15 years in aerospace and medical device tooling—directly translates to TPU molding systems that eliminate flash, sink marks, and molecular degradation. We engineer molds with proprietary thermal management channels and hardened steel alloys resistant to TPU’s abrasive additives, ensuring dimensional stability across 500,000+ cycles.

Unlike generic molding platforms, our systems integrate closed-loop pressure monitoring and adaptive screw recovery to manage TPU’s narrow processing window. This precision prevents shear-induced discoloration and maintains Shore hardness tolerances within ±2 points. Below are core specifications defining our TPU-optimized platforms:

| Parameter | Capability Range | TPU-Specific Advantage |

|---|---|---|

| Clamping Force | 100–2,500 Tons | Eliminates mold deflection under high-viscosity TPU flow |

| Shot Size Accuracy | ±0.15% | Ensures consistent wall thickness for flexible seals |

| Melt Temperature Control | ±1.5°C | Prevents thermal degradation of polyester-based TPUs |

| Injection Speed Range | 5–800 mm/s | Adapts to TPU’s shear-thinning behavior |

| Material Compatibility | All TPU grades (ether/ester) + filled compounds | Handles 30%+ glass/carbon additives without corrosion |

Partnering with Lead Precision means accessing a vertically integrated workflow where your TPU application’s mechanical, chemical, and regulatory requirements drive every design decision. Our engineers collaborate from material selection through DOE validation, leveraging in-house metrology labs equipped with FTIR spectrometers and dynamic mechanical analyzers. We validate each mold with actual production-grade TPU—not substitutes—to confirm part performance under ISO 10993 or UL 94 compliance frameworks. This eliminates costly rework during scale-up.

Your complex TPU components deserve a partner who treats polymer physics as seriously as metal fatigue. We deliver zero-defect production through preemptive thermal mapping and real-time viscosity compensation—techniques refined in critical applications like catheter hubs and automotive sensor housings. Stop compromising between cycle time and part integrity. Contact our engineering team to discuss how our metallurgical approach to TPU molding solves your specific adhesion, rebound, or chemical resistance challenges.

Initiate your precision TPU project with documented process validation and lifetime mold support. Email [email protected] with your material grade, part geometry, and annual volume. Our technical sales engineers will respond within 4 business hours with a feasibility assessment and DFM report—no generic quotations. Partner with the machinery builder who treats TPU not as a commodity plastic, but as an engineering material demanding metal-grade discipline.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.