Technical Contents

Engineering Guide: Thermoplastic Molding

Engineering Insight Thermoplastic Molding Demands Absolute Precision

Thermoplastic molding transcends simple material shaping; it is a science where microscopic deviations dictate functional success or catastrophic failure. In high-stakes applications aerospace components, medical devices, or precision instrumentation even minor inconsistencies in wall thickness, dimensional stability, or surface integrity compromise performance, safety, and longevity. The inherent challenge lies in thermoplastics sensitivity to thermal gradients and pressure fluctuations during injection and cooling. Inadequate temperature control causes warpage and internal stresses; inconsistent pressure leads to sink marks or short shots; improper cooling cycles induce crystallinity variations affecting mechanical properties. Achieving repeatability at micron-level tolerances demands more than robust machinery it requires deep process mastery and uncompromising system integration.

At Wuxi Lead Precision Machinery, we engineer thermoplastic molding solutions where precision is non-negotiable. Our CNC-controlled systems integrate real-time sensor networks monitoring melt viscosity, cavity pressure, and thermal profiles at 1000Hz intervals. This data feeds closed-loop algorithms adjusting parameters within milliseconds, ensuring each cycle replicates the exact conditions defined during rigorous mold validation. Our experience stems from delivering mission-critical components where failure is not an option. We manufactured precision polymer elements for Beijing Winter Olympics infrastructure requiring sub-50-micron dimensional stability under extreme cold. Similarly, our military-grade communication housings for aerospace platforms endure vibration testing exceeding 20G while maintaining hermetic seals and RF shielding integrity specifications. These projects demanded tolerances tighter than ±0.02mm and material certifications meeting MIL-STD-810G and ISO 13485 standards.

The foundation of this capability is our proprietary process control architecture. Unlike standard machines relying on preset timers, our systems dynamically respond to material behavior, compensating for batch variations in resin viscosity or ambient conditions. This translates directly to reduced scrap rates, extended mold life, and components meeting the most stringent geometric dimensioning and tolerancing (GD&T) requirements. For industries where thermoplastic parts interface with metal assemblies or operate in sterile environments, this level of control is paramount.

Critical Thermoplastic Molding Performance Specifications

| Parameter | Specification | Relevance to High-Precision Applications |

|---|---|---|

| Temperature Stability | ±0.5°C across barrel zones | Prevents material degradation and warpage |

| Pressure Control | 0.1 bar resolution, 0.5% accuracy | Ensures consistent packing and minimizes sink |

| Cooling Cycle Precision | ±1.0 second repeatability | Controls crystallinity and dimensional stability |

| Material Compatibility | PEEK, PEI, PSU, LCP, Medical PP | Supports high-temp, biocompatible, low-outgassing |

Demanding applications cannot tolerate process drift. Wuxi Lead Precision Machinery delivers thermoplastic molding where every parameter is engineered, monitored, and controlled to the limits of material science. Our Olympic and military project heritage proves this capability translates to real-world reliability under the most extreme conditions. Contact us for a tolerance analysis specific to your critical component requirements.

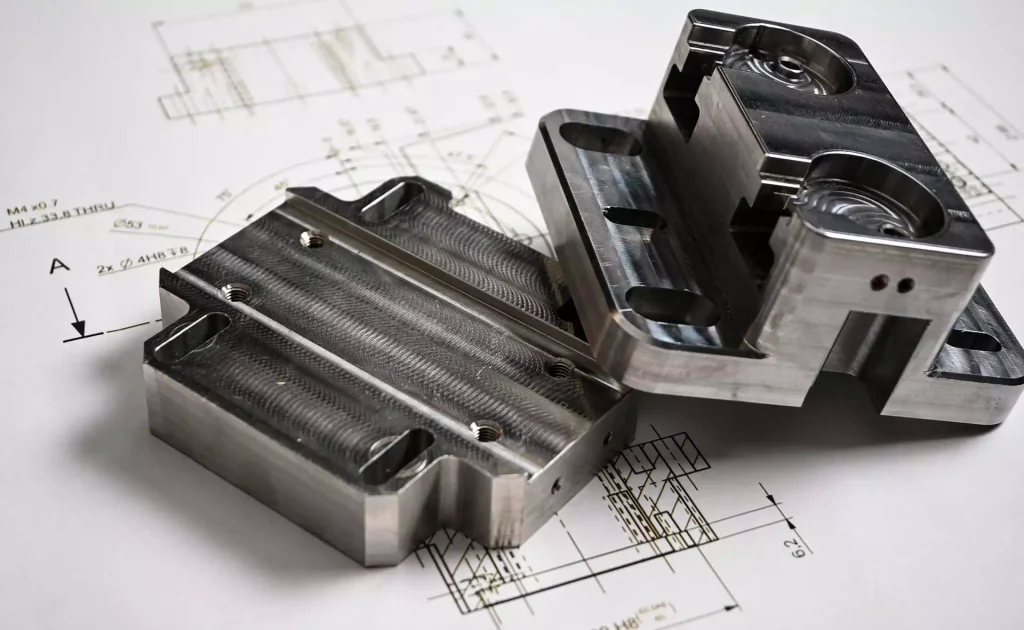

Precision Specs & Tolerances

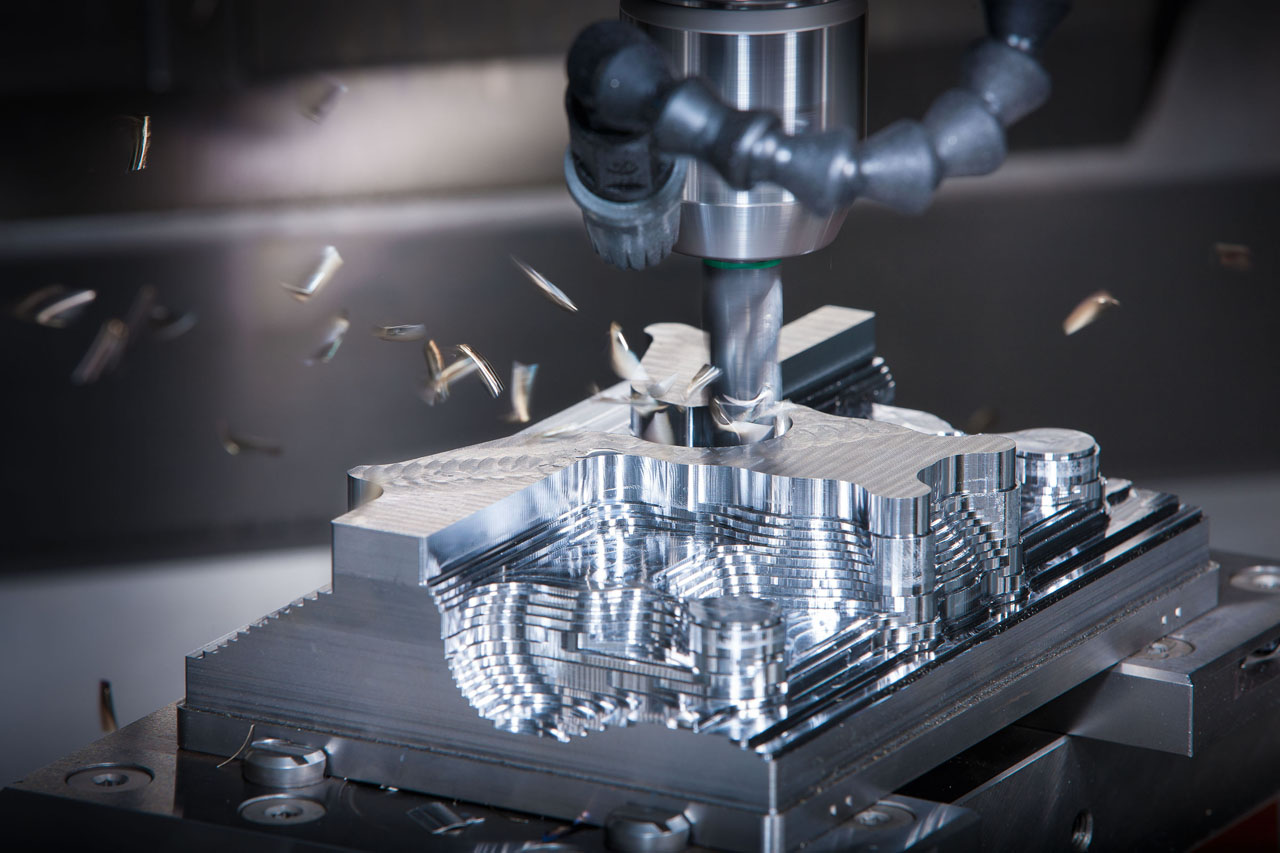

Wuxi Lead Precision Machinery delivers advanced thermoplastic molding solutions through precision engineering and state-of-the-art manufacturing technologies. Our technical capabilities are built upon a foundation of 5-axis CNC machining, enabling us to produce complex, high-tolerance components essential for critical applications in aerospace, medical, automotive, and industrial equipment sectors. By integrating multi-axis machining into our thermoplastic molding process, we achieve superior part accuracy, surface finish, and geometric complexity that traditional 3-axis systems cannot match.

Our 5-axis CNC machines operate with simultaneous motion across all axes, allowing for continuous tool engagement and optimal cutting angles. This capability minimizes setup changes, reduces cycle times, and ensures consistent dimensional accuracy across high-volume and prototype production runs. We work with a wide range of engineering-grade thermoplastics, including PEEK, PEI, PPS, and PTFE, each selected for their thermal stability, chemical resistance, and mechanical performance. The precision of our 5-axis systems ensures that intricate mold cavities and cores are machined to exact specifications, directly influencing the quality and repeatability of the final molded parts.

Quality control is integral to our manufacturing process. Every component undergoes rigorous inspection using a Coordinate Measuring Machine (CMM) to verify conformance to design intent. Our CMM system provides full 3D measurement traceability, ensuring that all critical dimensions, form features, and positional tolerances are validated. Data from each inspection is documented and available for customer review, supporting compliance with ISO 9001 and other industry-specific quality standards. This metrology-backed approach eliminates guesswork and guarantees that every part meets the highest standards of precision and reliability.

The combination of advanced CNC technology and disciplined quality assurance enables Wuxi Lead Precision Machinery to achieve exceptional tolerance control across a range of geometries and part sizes. Below is a summary of our standard capability tolerances for machined components used in thermoplastic molding applications.

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Measurement Method |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm | CMM, High-Precision Micrometers |

| Flatness | 0.02 mm | 0.005 mm | CMM, Optical Flat |

| Roundness / Cylindricity | 0.015 mm | 0.008 mm | CMM, Roundness Tester |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | CMM |

| Surface Finish (Ra) | 0.8 µm | 0.4 µm | Surface Roughness Tester |

| Angular Features | ±0.05° | ±0.02° | CMM, Precision Protractor |

These tolerances reflect our commitment to precision and repeatability, ensuring that molds and components perform reliably in demanding thermoplastic molding environments. At Wuxi Lead Precision Machinery, we combine technical excellence with rigorous quality control to deliver custom metal manufacturing solutions that meet the highest global standards.

Material & Finish Options

Material Selection for High-Performance Thermoplastic Molding Tooling

Selecting the optimal material for thermoplastic molding tooling directly impacts part quality, production efficiency, and tool longevity. At Wuxi Lead Precision Machinery, we prioritize technical alignment between material properties and application demands. Aluminum, steel, and titanium each offer distinct advantages for custom metal manufacturing in injection molding, compression molding, and extrusion dies. Understanding their thermal, mechanical, and economic profiles ensures optimal return on investment.

Aluminum alloys, particularly 6061-T6 and 7075-T6, excel in prototyping and low-to-medium volume production due to superior thermal conductivity and machinability. This reduces cycle times significantly compared to steel, accelerating time-to-market. However, aluminum’s lower hardness limits wear resistance in abrasive or glass-filled thermoplastics. Steel remains the industry standard for high-volume runs. Pre-hardened grades like P20 offer balanced machinability and durability, while H13 tool steel provides exceptional thermal fatigue resistance for demanding applications involving high-temperature resins. Titanium alloys, though costly, deliver unmatched strength-to-weight ratios and corrosion resistance for specialized aerospace or medical molds where weight reduction and chemical exposure are critical.

Surface finishes further enhance performance. Anodizing is essential for aluminum tooling, creating a hard, non-conductive oxide layer that improves wear resistance and release properties. Type II (sulfuric acid) anodizing provides standard corrosion protection, while Type III (hardcoat) anodizing achieves 50-70 µm thickness for severe abrasion resistance. For steel molds, alternatives like nitriding or PVD coatings are typically preferred, though anodizing remains exclusive to aluminum substrates. Always specify anodizing requirements early in design to avoid dimensional interference.

The following table summarizes key material properties for thermoplastic molding tooling:

| Material | Hardness (Typical) | Thermal Conductivity (W/m·K) | Tensile Strength (MPa) | Primary Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 95 HB | 167 | 310 | Prototypes, low-volume production |

| P20 Tool Steel | 28-32 HRC | 28-36 | 950-1100 | Medium/high-volume commodity parts |

| H13 Tool Steel | 46-52 HRC | 25-30 | 1200-1600 | High-temp resins, long-run production |

| Ti-6Al-4V | 36 HRC | 7.2 | 900-1000 | Aerospace, medical, corrosive environments |

Material choice must align with resin type, part geometry, volume, and surface finish requirements. Abrasive fillers like glass fiber necessitate hardened steel or specialized coatings, while complex geometries may benefit from aluminum’s ease of machining. Wuxi Lead Precision Machinery leverages decades of CNC expertise to analyze your specific thermoplastic molding challenges. We provide data-driven recommendations to optimize tool life, minimize downtime, and ensure dimensional stability across production cycles. Partner with us to transform material science into manufacturing advantage.

Manufacturing Process & QC

Thermoplastic molding at Wuxi Lead Precision Machinery is executed with precision engineering and rigorous quality control to deliver zero-defect components for high-performance industries. Our process integrates advanced design, iterative prototyping, and scalable mass production, ensuring compliance with the strictest international standards. This systematic approach guarantees consistency, durability, and dimensional accuracy across every production run.

The process begins with collaborative design engineering. Our team works closely with clients to analyze component requirements, including thermal resistance, mechanical load, chemical exposure, and part geometry. Utilizing CAD/CAM software and finite element analysis (FEA), we optimize mold design for material flow, cooling efficiency, and ejection dynamics. This stage ensures manufacturability while minimizing stress points and warpage risks inherent in thermoplastic materials.

Following design finalization, we move to precision prototyping. A functional prototype is produced using the same thermoplastic resins and process parameters intended for full-scale production. This allows for real-world validation of fit, form, and function. Prototypes undergo comprehensive testing, including tensile strength, impact resistance, and dimensional inspection via coordinate measuring machines (CMM). Feedback from this phase informs any necessary mold adjustments, ensuring the final design is both robust and repeatable.

Once approved, the project transitions to mass production on our automated thermoplastic molding lines. These systems are equipped with real-time monitoring for pressure, temperature, and cycle time. Each molding machine is integrated with sensor-based quality assurance systems that detect deviations at the micro-level, enabling immediate correction. Our cleanroom-compatible production environment minimizes particulate contamination, critical for medical, automotive, and aerospace applications.

Throughout all stages, Wuxi Lead applies a zero-defect philosophy. Statistical process control (SPC) is used to track key performance indicators, and every batch undergoes 100% visual inspection supplemented by random sampling for destructive and non-destructive testing. Traceability is maintained via laser marking and digital logs, ensuring full accountability from raw material to finished component.

The following table outlines key technical specifications of our thermoplastic molding capabilities:

| Parameter | Specification |

|---|---|

| Material Compatibility | PEEK, PEI, PPS, PA6, PC, PBT, ABS, and custom compounds |

| Tolerance Range | ±0.05 mm to ±0.1 mm depending on geometry |

| Mold Precision | H7 class cavities, hardened steel (HRC 48–52) |

| Clamping Force Range | 80 to 1,200 tons |

| Production Capacity | 1,000 to 500,000 units per month |

| Quality Standards | ISO 9001, IATF 16949, ISO 13485 (medical) |

| Surface Finish Options | SPI A1, B2, or custom textures |

| Secondary Operations | Ultrasonic welding, insert molding, CNC trimming |

By aligning precision tooling, advanced process control, and continuous validation, Wuxi Lead ensures that every thermoplastic component meets the highest benchmarks in performance and reliability.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Thermoplastic Molding Excellence

Thermoplastic molding demands absolute precision in tooling to achieve repeatable part quality, cycle efficiency, and cost control. At Wuxi Lead Precision Machinery, we engineer custom metal molds that transform thermoplastic production from a variable process into a strategic advantage. With over 20 years of specialization in high-tolerance mold manufacturing for aerospace, medical, and automotive sectors, we solve the critical pain points that derail production: dimensional drift, premature wear, and unplanned downtime. Our integrated approach combines advanced metallurgy, multi-axis CNC machining, and rigorous validation protocols to deliver molds that consistently meet ±0.002mm tolerances under 500+ tonnage injection pressures.

Unlike generic mold suppliers, we treat your thermoplastic application as a system—not just a cavity. Our engineers collaborate from concept to validation, optimizing gate design, cooling channels, and material selection to eliminate warpage, sink marks, and cycle time inflation. This reduces scrap rates by up to 35% and extends mold life beyond 1.5 million cycles. The table below outlines our core capabilities for thermoplastic molding tooling:

| Specification | Capability Range | Industry Standard Benchmark |

|---|---|---|

| Tolerance | ±0.002mm to ±0.005mm | ±0.01mm to ±0.025mm |

| Mold Materials | H13, S136, 420SS, Beryllium Copper | P20, 718H |

| Max Clamp Force Support | 500–3,500 tons | Up to 2,000 tons |

| Cavity Configuration | 1–16 cavities (family/single) | Typically 1–8 cavities |

| Surface Finish | SPI A1 (Diamond Polish) to MT-13000 | SPI B1 to MT-3000 |

| Lead Time (Complex) | 8–12 weeks | 12–20 weeks |

This precision is non-negotiable when your thermoplastic components require medical-grade biocompatibility or aerospace structural integrity. We validate every mold through 72-hour continuous run testing under your specified resin and process parameters, ensuring zero surprises at your production floor. Our clients report 22% faster time-to-market and 18% lower total cost of ownership by eliminating iterative tool corrections and secondary operations.

The cost of thermoplastic molding failures extends beyond scrap—it erodes customer trust and stalls production lines. Partnering with Lead Precision mitigates these risks through engineering accountability. We provide full digital traceability from raw billet to final assembly, including material certs, CMM reports, and mold flow analysis. This transparency ensures your supply chain meets ISO 13485, AS9100, and IATF 16949 requirements without compromise.

Initiate your precision molding partnership today. Contact our engineering team at [email protected] with your part drawings, resin specifications, and production targets. We will respond within 4 business hours with a feasibility assessment and timeline. For urgent projects requiring sub-10 week delivery, reference code TPM-2024 in your inquiry. Let us transform your thermoplastic challenges into competitive advantage—where metal precision meets polymer performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.