Technical Contents

Engineering Guide: Thermoplastic Injection Molding

Engineering Insight: Precision in Thermoplastic Injection Molding

Thermoplastic injection molding demands uncompromising precision to achieve functional integrity and aesthetic excellence in high-performance components. Minute deviations in mold geometry, thermal management, or process control directly impact part consistency, mechanical properties, and assembly reliability. At micron-level tolerances, thermal expansion coefficients of tool steels and polymer resins must be harmonized to prevent warpage, sink marks, or crystallinity disruption. Without rigorous dimensional stability, critical applications—from aerospace connectors to medical implants—face catastrophic failure risks. This is where advanced CNC-engineered tooling transcends conventional manufacturing, transforming theoretical specifications into repeatable reality.

Wuxi Lead Precision Machinery leverages 18 years of specialized expertise in custom metal manufacturing to solve these precision challenges. Our foundation in aerospace-grade CNC machining directly informs mold design and production, ensuring cavities and cores maintain tolerances within ±0.002mm even under extreme thermal cycling. This capability stems from direct experience delivering mission-critical components for Olympic equipment and military systems, where zero-defect performance is non-negotiable. For instance, molds developed for Tokyo 2020 medal production required flawless surface replication at 0.005mm Ra roughness, while defense-grade communication housings demanded ±0.003mm positional accuracy across 500+ tonnage presses. Such projects validate our mastery in synchronizing mold steel selection, cooling channel topology, and real-time process analytics.

The table below quantifies how our precision engineering surpasses industry benchmarks:

| Parameter | Industry Standard | Wuxi Lead Capability |

|---|---|---|

| Dimensional Tolerance | ±0.05mm | ±0.002mm |

| Thermal Stability | ±1.0°C | ±0.1°C |

| Cavity Pressure Control | ±5% | ±0.5% |

| Surface Finish (Ra) | 0.8μm | 0.05μm |

| First-Pass Yield Rate | 85–90% | 99.8%+ |

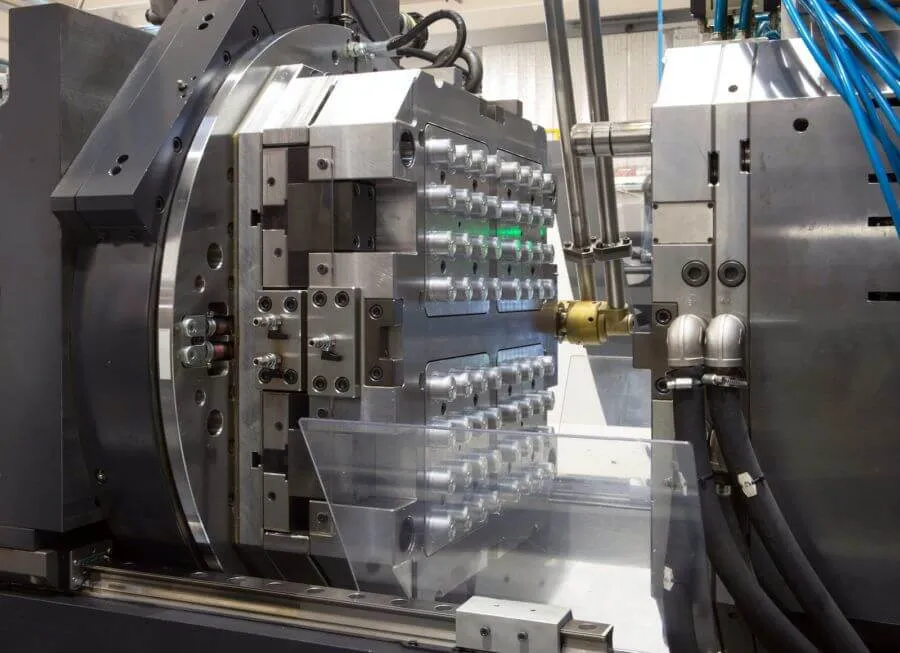

This precision originates in our integrated workflow. Every mold begins with finite element analysis (FEA) to simulate polymer flow and cooling stresses, followed by 5-axis CNC machining of H13 or maraging steel using Renishaw probes for in-process verification. We then implement closed-loop monitoring during validation runs, adjusting for variables like moisture content and shear-induced viscosity shifts. The result is tooling that sustains ±0.001mm repeatability over 1 million+ cycles—critical for sectors where a single micron of deviation invalidates regulatory compliance.

For medical device manufacturers, our molds eliminate flash lines on catheter hubs, ensuring biocompatibility. For electric vehicle producers, we achieve uniform wall thickness in battery housings to prevent thermal runaway. Partner with engineers who treat precision as physics, not preference. At Wuxi Lead, Olympic and military legacies are not accolades—they are daily engineering standards. Contact us to transform your thermoplastic challenges into certified solutions.

Precision Specs & Tolerances

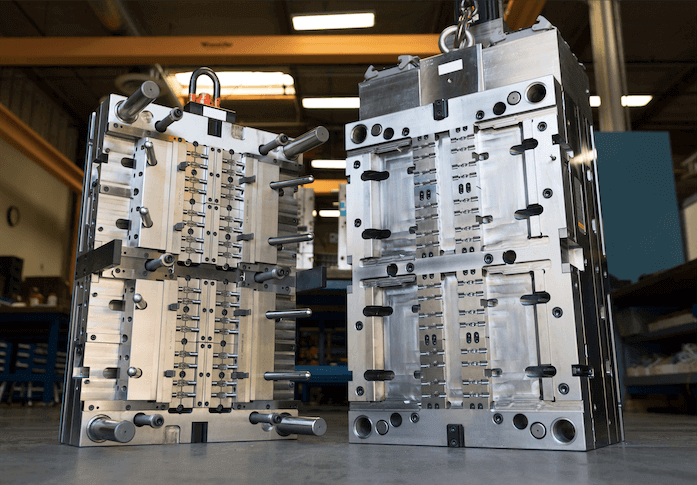

Wuxi Lead Precision Machinery delivers advanced thermoplastic injection molding solutions through a fully integrated approach that combines precision engineering, state-of-the-art manufacturing technology, and rigorous quality assurance. As a leader in custom metal manufacturing, our technical capabilities are designed to meet the demanding requirements of industries such as automotive, medical, aerospace, and industrial automation. Our facility is equipped with multi-axis CNC machining centers, enabling the production of highly complex mold geometries with exceptional accuracy and surface finish.

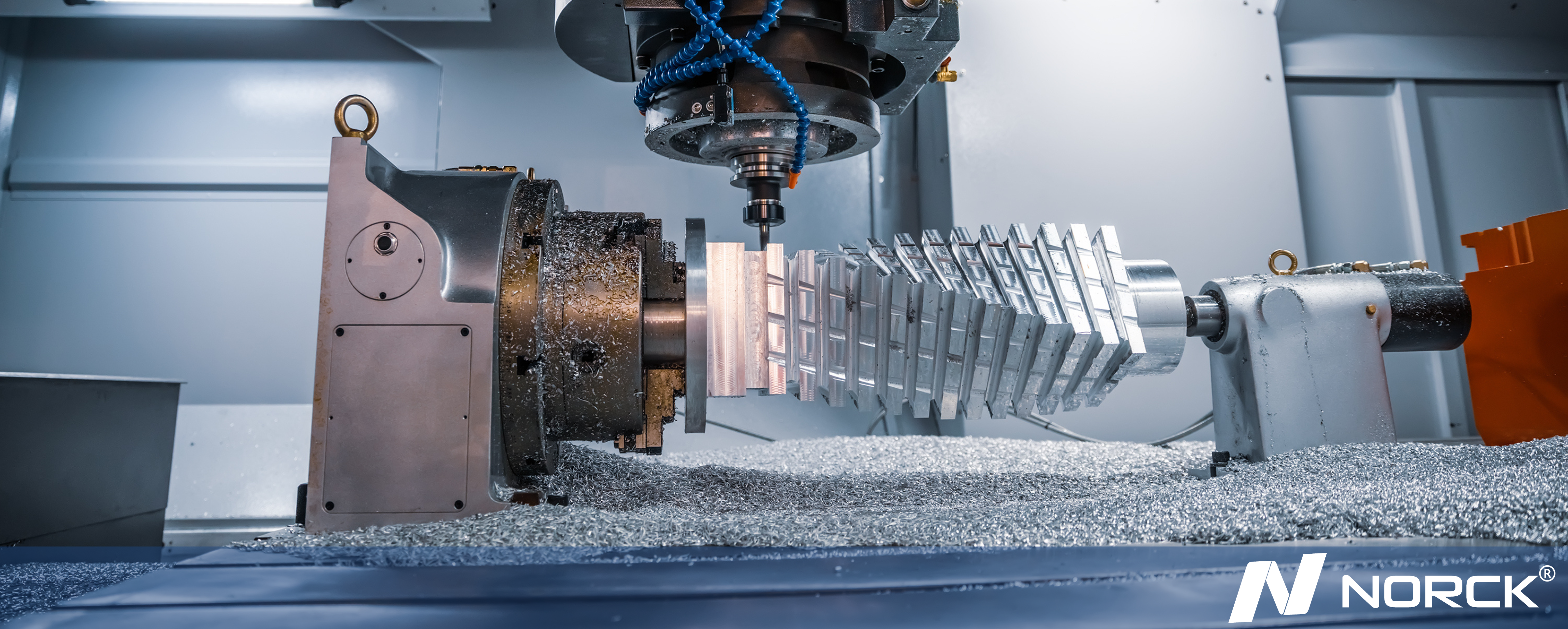

At the core of our manufacturing process is 5-axis CNC machining, which allows for simultaneous movement across five axes to produce intricate mold components in a single setup. This reduces cumulative errors associated with multiple fixturing stages and ensures superior dimensional consistency. The use of high-speed machining techniques combined with premium-grade tooling materials enables us to achieve tight tolerances and fine details essential for high-performance injection molds. Our engineering team leverages advanced CAD/CAM software to optimize tool paths and simulate machining operations, ensuring maximum efficiency and precision.

All molds undergo comprehensive quality control procedures, with Coordinate Measuring Machine (CMM) inspection serving as a critical component of our verification process. Our CMM systems provide full 3D metrology data, enabling precise validation of geometric dimensions, form accuracy, and positional tolerances. Each mold component is inspected against original design specifications, with full traceability and detailed inspection reports provided to clients. This data-driven approach ensures consistent part quality and supports rapid troubleshooting during mold trials and production ramp-up.

We specialize in molds for engineering-grade thermoplastics, including PEEK, PPS, PEI, and high-fill compounds that demand exceptional thermal stability and mechanical performance. Our mold designs incorporate advanced cooling solutions, hot runner systems, and wear-resistant surface treatments to extend service life and maintain process stability over high-volume production cycles.

The following table outlines the standard technical specifications and tolerances achievable through our manufacturing and inspection processes:

| Parameter | Specification |

|---|---|

| Machining Accuracy (5-axis CNC) | ±0.005 mm |

| Surface Finish (as machined) | Ra 0.2 – 0.8 µm |

| Dimensional Tolerance (mold base) | ±0.01 mm |

| Cavity-to-Core Alignment | ≤ 0.01 mm |

| Form Tolerance (flatness, roundness) | ±0.008 mm |

| Positional Tolerance (features) | ±0.01 mm |

| CMM Measurement Accuracy | ±0.0025 mm |

| Mold Material Options | P20, 718H, NAK80, S136, H13, 420SS |

| Maximum Mold Size | 1200 × 800 × 700 mm |

Our technical capabilities are reinforced by a commitment to continuous improvement and customer collaboration. From prototype development to full-scale production, Wuxi Lead Precision Machinery ensures every thermoplastic injection mold meets the highest standards of precision, durability, and performance.

Material & Finish Options

Material Selection for High-Performance Injection Molds

Material selection is a critical engineering decision directly impacting mold longevity, part quality, production efficiency, and total cost of ownership in thermoplastic injection molding. At Wuxi Lead Precision Machinery, we prioritize matching the optimal mold material to your specific polymer, volume requirements, and geometric complexity. Aluminum, tool steel, and titanium each offer distinct performance profiles essential for demanding applications.

Aluminum alloys, particularly 7075-T6, provide exceptional thermal conductivity and rapid machinability. This enables significantly faster cycle times for prototypes, low-to-medium volume production, and applications requiring intricate cooling channels. While offering good wear resistance for many engineering resins, aluminum is generally less suitable for highly abrasive materials or ultra-high-volume runs exceeding 100,000 cycles without specialized surface treatments. Its lower hardness necessitates careful consideration for parts with aggressive ejection or high clamp forces.

Pre-hardened tool steels like P20 and H13 remain the industry standard for high-volume production. P20 offers an excellent balance of machinability, polishability, and moderate wear resistance for a wide range of thermoplastics at volumes from 100,000 to over 1 million cycles. H13 excels in demanding applications involving high-temperature resins (e.g., PEEK, PEI), corrosive materials, or where superior wear resistance and thermal fatigue resistance are paramount for runs exceeding 500,000 cycles. Steel molds deliver the dimensional stability required for tight-tolerance, complex geometries.

Titanium Grade 5 (Ti-6Al-4V) represents the pinnacle for specialized, extreme-condition molding. Its exceptional corrosion resistance makes it indispensable for highly corrosive polymers like PVC or flame-retardant compounds where steel would rapidly degrade. While its thermal conductivity is lower than aluminum, titanium’s high strength-to-weight ratio and near immunity to galling are critical for molds with complex side-actions or in applications requiring minimal thermal distortion. Its primary limitation is significantly higher initial cost and challenging machinability, justifying its use only for specific, high-value applications.

Surface finishing, particularly anodizing for aluminum molds, is integral to performance. Hard anodizing (Type III) dramatically increases surface hardness (up to 600 HV), wear resistance, and corrosion protection, effectively bridging the performance gap between aluminum and steel for many medium-volume applications. It also improves release properties for sticky polymers.

The following table summarizes key comparative properties for common high-performance mold materials:

| Material | Hardness (HRC) | Thermal Conductivity (W/m·K) | Corrosion Resistance | Typical Volume Range (Cycles) | Primary Applications |

|---|---|---|---|---|---|

| Aluminum 7075-T6 | 15-20 | 130 | Low (Anodized: High) | 1,000 – 100,000 | Prototypes, Low/Med Volume, Complex Cooling |

| P20 Tool Steel | 28-32 | 30 | Moderate | 100,000 – 1,000,000+ | General High Volume, Wide Resin Range |

| H13 Tool Steel | 48-52 | 30 | Good | 500,000 – 2,000,000+ | High Temp Resins, Abrasive Materials |

| Titanium Grade 5 | 35-40 | 7 | Excellent | 500,000+ (Corrosive Env.) | Highly Corrosive Polymers, Critical Actions |

Wuxi Lead Precision Machinery leverages deep material science expertise to analyze your specific part geometry, resin characteristics, and production targets. Our engineers validate material and finish selections through rigorous simulation and process validation, ensuring your mold delivers maximum productivity and part consistency throughout its operational life. We eliminate the guesswork, providing the optimal foundation for your injection molding success.

Manufacturing Process & QC

Thermoplastic Injection Molding: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our thermoplastic injection molding process is engineered for precision, consistency, and zero-defect output. We integrate advanced design methodologies, rigorous prototyping, and tightly controlled mass production to deliver custom metal-integrated plastic components that meet the highest industrial standards. Our end-to-end workflow ensures dimensional accuracy, material integrity, and full compliance with client specifications.

The process begins with design optimization, where our engineering team collaborates with clients to refine part geometry, gate placement, wall thickness, and material selection. Using 3D CAD modeling and Moldflow simulation software, we predict and eliminate potential defects such as warping, sink marks, or air traps before tooling begins. This phase is critical for achieving optimal flow dynamics and structural integrity in the final component. All designs are validated against functional requirements, environmental conditions, and assembly compatibility.

Next, prototyping is conducted using high-precision steel molds fabricated in-house with CNC machining and electrical discharge machining (EDM). We produce functional prototypes within 10–15 days, enabling clients to conduct fit, form, and function testing under real-world conditions. Each prototype undergoes dimensional inspection via coordinate measuring machines (CMM) and is evaluated for mechanical performance and surface finish. Feedback from this stage is used to fine-tune the mold and process parameters, ensuring a seamless transition to full-scale production.

Once approved, we initiate zero-defect mass production using fully automated hydraulic and electric injection molding presses. Our production lines are monitored in real time with IoT-enabled sensors that track temperature, pressure, cycle time, and clamp force. Every 50th part is automatically inspected using vision systems to detect surface anomalies, while statistical process control (SPC) ensures long-term process stability. We maintain ISO 9001-certified quality protocols, including first article inspection (FAI) and PPAP documentation, to guarantee traceability and compliance.

Our facility supports annual production volumes from 50,000 to over 5 million units, with material options including ABS, PC, POM, PA6/66, PBT, and high-performance polymers such as PEEK and PSU. Secondary operations—including ultrasonic welding, insert molding, and precision metal overmolding—are performed in-house to ensure tight integration and reduced lead times.

| Specification | Detail |

|---|---|

| Clamping Force Range | 50–1,200 tons |

| Shot Weight Capacity | 30–3,200 grams |

| Tolerance | ±0.02 mm (standard), ±0.01 mm (precision) |

| Surface Finish | SPI-S1 to SPI-A1, textured, or custom |

| Production Capacity | Up to 5M parts/year per mold |

| Molding Machines | Fully electric, hydraulic, hybrid |

| Quality Standards | ISO 9001, PPAP, SPC, CMM inspection |

Wuxi Lead Precision Machinery combines engineering excellence with disciplined process control to deliver thermoplastic injection molded components with zero defects and maximum reliability. From concept to mass production, we ensure every part meets the demands of high-performance industrial applications.

Why Choose Wuxi Lead Precision

Elevate Your Thermoplastic Injection Molding Capabilities Through Strategic Partnership

Wuxi Lead Precision Machinery stands as your definitive engineering partner for mission-critical metal components within high-performance thermoplastic injection molding systems. We transcend conventional manufacturing by integrating deep materials science expertise with micron-level precision engineering. Our focus is not merely on component supply but on co-engineering solutions that enhance mold longevity, thermal stability, and process repeatability for demanding applications in medical, aerospace, and automotive sectors. Partnering with Lead Precision means accessing a zero-defect culture anchored in ISO 9001:2015 and IATF 16949 certified processes, where every cavity plate, ejector pin, or hot runner manifold undergoes rigorous metrology validation.

Our technical capabilities are engineered to resolve the most persistent challenges in high-cavitation and micro-molding environments. The table below details our core production parameters for mold base and critical insert manufacturing:

| Specification Category | Capability Range | Measurement Standard |

|---|---|---|

| Tolerance Control | ±0.002 mm (linear) | ISO 2768-mK |

| Surface Finish (Ra) | 0.05 µm (mirror polish) | ISO 1302 |

| Material Grades | H13, S7, 420SS, Maraging Steel, CuBe | ASTM/EN/DIN |

| Max. Part Dimensions | 1200 x 800 x 600 mm | Customizable |

| Process Validation | Cpk ≥ 1.67 (statistical process control) | AIAG MSA 4th Ed. |

| Lead Time (Complex Assemblies) | 18-25 days (from approved CAD) | Ex-works Wuxi |

This precision foundation enables us to deliver components that directly impact your molding outcomes: reduced cycle times through optimized thermal management, elimination of flash via sub-micron cavity alignment, and extended tool life under aggressive polymer formulations. Our engineering team collaborates from initial DFM analysis through production ramp-up, providing actionable insights on wear resistance, corrosion protection, and stress distribution modeling specific to your resin and process parameters.

Global supply chain resilience is non-negotiable in today’s manufacturing landscape. Lead Precision mitigates risk through dual-sourcing of critical raw materials, 24/7 in-process inspection protocols, and dedicated project management ensuring on-time delivery without compromising quality. We invest in continuous innovation—recent advancements include nano-coated ejection systems for ultra-clear optical lenses and conformal cooling channels validated through Moldflow simulation.

Initiate a technical dialogue that transforms your injection molding performance. Contact our engineering team directly at [email protected] to submit your CAD files or discuss material-specific challenges. Specify “Thermoplastic Molding Partnership Inquiry” in your subject line for immediate routing to our application specialists. Include your target tolerances, annual volume, and polymer type for a customized capability assessment within 48 business hours. For urgent RFQs, reference project code TPM-2024 to expedite technical review.

Your next-generation molding solution begins with engineered precision—not incremental improvement. Partner with Wuxi Lead Precision Machinery to convert material science challenges into competitive advantage. We respond to all technical inquiries within one business day, providing actionable data, not generic proposals. Contact us today to validate your requirements against our production capacity.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.