Technical Contents

Engineering Guide: Summit Sheet Metal

Engineering Insight: The Non-Negotiable Standard of Precision in Summit-Tier Sheet Metal Fabrication

Achieving true summit-tier performance in sheet metal fabrication demands an uncompromising commitment to precision engineering. At Wuxi Lead Precision Machinery, we recognize that dimensional accuracy is not merely a specification box to tick; it is the foundational element dictating functional integrity, assembly efficiency, and ultimate product lifecycle reliability. In high-stakes applications where components interface within complex systems, tolerances measured in hundredths of a millimeter directly impact structural safety, operational performance, and costly field failures. Deviations beyond critical thresholds cascade into misaligned assemblies, compromised seals, accelerated wear, and catastrophic system breakdowns – consequences unacceptable in aerospace, defense, or advanced medical equipment. Precision is the silent guarantor of performance, ensuring every bend, cut, and formed feature aligns perfectly with the engineered intent, minimizing waste and maximizing value across the production chain.

Our CNC manufacturing ecosystem is engineered to enforce these exacting standards consistently. Advanced multi-axis laser cutting systems, press brakes with real-time angle correction, and sophisticated metrology suites operate under stringent environmental controls. This integrated approach ensures geometric conformity from raw material to finished component, regardless of complexity. The table below reflects the core precision capabilities underpinning our summit-tier fabrication services.

| Process | Typical Tolerance | Surface Finish (Ra) | Material Thickness Range |

|---|---|---|---|

| Fiber Laser Cutting | ±0.05 mm | 0.8 μm | 0.5 mm – 25 mm |

| CNC Turret Punching | ±0.08 mm | 1.6 μm | 0.5 mm – 6.0 mm |

| Precision Bending | ±0.1° angular | As per material | 0.5 mm – 12.0 mm |

| Robotic Welding | ±0.2 mm positional | 3.2 μm (post-process) | 0.8 mm – 10.0 mm |

This technical rigor is validated daily through mission-critical projects. Wuxi Lead’s precision sheet metal solutions form integral structural and functional elements within Olympic infrastructure projects, where aesthetic perfection and structural resilience under immense public use are paramount. More significantly, our components meet stringent military-grade specifications for defense systems, where dimensional integrity directly correlates to operational safety and mission success. These applications impose tolerances far exceeding standard industrial norms, demanding absolute consistency batch after batch. Our ISO 9001 and AS9100 certified processes, combined with decades of metallurgical expertise, ensure every component adheres to these summit-level requirements. Partnering with Wuxi Lead means your fabrication partner doesn’t just meet drawings – we engineer dimensional certainty into every process step, transforming precision from an objective into an operational reality. This is the standard demanded at the summit of manufacturing excellence.

Precision Specs & Tolerances

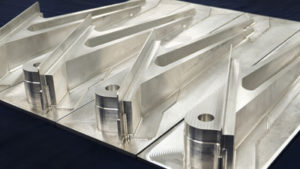

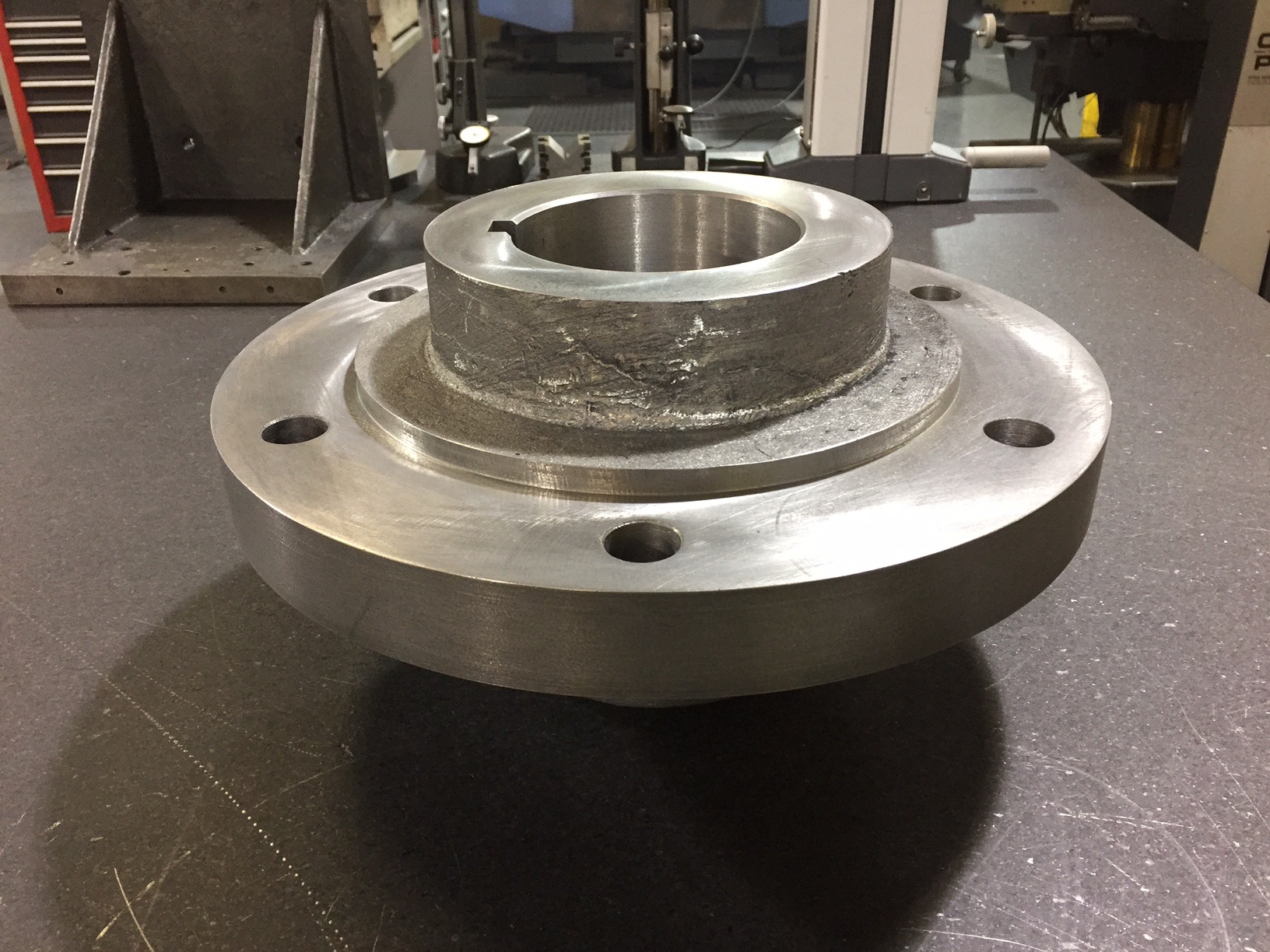

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for precision, repeatability, and performance in high-demand industrial applications. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining systems, enabling us to produce complex geometries with exceptional accuracy and surface finish. These multi-axis platforms allow simultaneous cutting and forming operations across five planes, significantly reducing setup times and part handling while maintaining tight tolerances throughout production. This level of automation ensures consistency across both prototyping and high-volume manufacturing runs, making our facility ideal for aerospace, medical, energy, and advanced automation sectors where dimensional integrity is critical.

Our sheet metal processes integrate laser cutting, precision bending, high-speed stamping, and robotic welding, all supported by a fully digital workflow from CAD/CAM programming to final inspection. The use of 5-axis CNC technology enables us to machine intricate features directly into formed sheet components, eliminating secondary operations and minimizing cumulative error. This capability is particularly advantageous for lightweight structural components, housings, and enclosures requiring tight alignment and fitment across multiple interfaces.

Quality assurance is embedded at every stage of production. All critical dimensions are verified using Coordinate Measuring Machine (CMM) inspection, ensuring compliance with ISO 10360 standards. Our CMM systems provide full 3D metrology reports with traceable data for first article inspection (FAI) and production lot validation. Thermal compensation systems within the inspection lab maintain measurement stability, while probe calibration is performed daily to guarantee repeatability. In addition to CMM, we employ optical comparators, surface roughness testers, and laser trackers for large-format part validation.

The following table outlines the standard tolerances achievable across key fabrication processes at Wuxi Lead Precision Machinery. These values represent our typical production capability under controlled conditions; tighter tolerances are attainable upon engineering review.

| Process | Dimensional Tolerance | Angular Tolerance | Positional Tolerance | Surface Roughness (Ra) |

|---|---|---|---|---|

| 5-Axis CNC Machining | ±0.005 mm | ±0.05° | ±0.01 mm | 0.8 – 3.2 µm |

| Laser Cutting (Fiber) | ±0.05 mm | — | ±0.1 mm | 6.3 – 12.5 µm |

| Precision Bending | ±0.1° | ±0.1 mm | — | N/A |

| Robotic MIG/TIG Welding | ±0.2 mm (post-weld) | ±0.5° | ±0.3 mm | 6.3 – 25 µm |

| CMM Inspection Accuracy | ±0.003 mm (at 20°C) | — | — | — |

All tolerances are subject to material type, thickness, and part geometry. Commonly processed materials include stainless steel (304, 316), aluminum alloys (5052, 6061, 7075), cold-rolled steel, and specialty alloys such as titanium and Inconel. We support sheet thicknesses from 0.5 mm to 25 mm depending on the process and material.

Wuxi Lead Precision Machinery combines advanced equipment, rigorous quality control, and deep engineering expertise to deliver sheet metal components that meet the highest standards of performance and reliability.

Material & Finish Options

Material Selection for Precision Sheet Metal Fabrication

Selecting the optimal material is foundational to achieving performance, durability, and cost efficiency in sheet metal components. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your application’s mechanical demands, environmental exposure, and lifecycle requirements. Aluminum, steel, and titanium dominate high-end fabrication, each offering distinct advantages for specific use cases. Understanding these differences ensures your design translates into a reliable, high-yield product.

Aluminum excels in lightweight applications requiring corrosion resistance and thermal conductivity. Grades like 5052-H32 and 6061-T6 are industry standards for enclosures, aerospace brackets, and heat sinks. Its low density reduces assembly weight, while natural oxide formation provides inherent protection in mild environments. However, aluminum’s lower hardness necessitates careful handling to avoid surface marring during fabrication.

Steel remains indispensable for structural integrity and wear resistance. Cold-rolled steel (CRS 1008/1010) offers excellent formability for chassis and brackets, while stainless steel (304/316) delivers superior corrosion resistance for medical or marine components. Steel’s higher tensile strength supports load-bearing designs but requires protective finishes like powder coating in aggressive environments to prevent oxidation.

Titanium is the premium choice for extreme conditions, combining exceptional strength-to-weight ratio with unmatched corrosion resistance. Grade 2 (commercially pure) and Grade 5 (Ti-6Al-4V) are critical in aerospace, defense, and chemical processing where failure is not an option. Though costly and challenging to machine, titanium’s longevity in high-temperature or saline environments justifies its use for mission-critical parts.

Anodizing: Elevating Aluminum Performance

Anodizing transforms aluminum’s surface into a durable, non-conductive oxide layer, significantly enhancing wear and corrosion resistance. Type II (sulfuric acid) anodizing provides standard protection with dye options for branding, while Type III (hard coat) delivers 50–100µm thickness for hydraulic pistons or military hardware exposed to abrasion. At Wuxi Lead, we precision-control anodizing parameters to ensure uniform coating thickness and adhesion, critical for components requiring tight tolerances post-treatment.

Material Comparison for Critical Applications

| Material | Key Grades | Yield Strength (MPa) | Corrosion Resistance | Machinability | Best Applications |

|---|---|---|---|---|---|

| Aluminum | 5052-H32, 6061-T6 | 190–275 | High (natural oxide) | Excellent | Aerospace brackets, heat sinks |

| Steel | CRS 1008, SS304 | 170–210 (CRS) | Low (CRS), High (SS) | Good | Structural frames, medical housings |

| Titanium | Gr2, Gr5 | 275–880 | Exceptional | Moderate | Jet engine components, implants |

Material choice directly impacts manufacturability, total cost of ownership, and field performance. Wuxi Lead’s engineering team collaborates early in your design phase to match material properties with functional requirements, avoiding costly revisions. We validate selections through rigorous prototyping and environmental testing, ensuring your sheet metal components meet the highest standards of precision and reliability. Partner with us to transform material science into your competitive advantage.

Manufacturing Process & QC

Design: Precision Engineering from the First Line

At Wuxi Lead Precision Machinery, the foundation of flawless sheet metal fabrication begins with advanced design engineering. Our team of certified mechanical engineers and CAD specialists collaborate closely with clients to transform conceptual sketches into detailed 3D models using SolidWorks, AutoCAD, and Siemens NX. Every design is rigorously evaluated for manufacturability, structural integrity, and compliance with international standards such as ISO 9001 and ASME Y14.5. We conduct comprehensive Design for Manufacturing and Assembly (DFM/A) reviews to eliminate potential production flaws before any material is cut. Thermal deformation simulations, stress analysis, and tolerance stack-up evaluations ensure that every component meets exact performance requirements under real-world conditions.

Prototyping: Validating Excellence Before Scale

Once the design is finalized, we proceed to precision prototyping—a critical phase in our zero-defect strategy. Utilizing state-of-the-art fiber laser cutting, CNC punching, and automated bending systems, we produce functional prototypes within 72 hours of design approval. Each prototype undergoes full dimensional inspection via coordinate measuring machines (CMM) and 3D scanning to verify geometric accuracy down to ±0.05 mm. Surface finish, weld integrity, and assembly compatibility are validated through in-house testing protocols. Client feedback is integrated swiftly, and iterative refinements are executed without delay. This agile prototyping process ensures that all design assumptions are empirically verified, minimizing risk during mass production.

Mass Production: Consistency Through Automation and Control

With prototype approval, we transition seamlessly into high-volume manufacturing with the same tooling and programming used in prototyping, ensuring complete process continuity. Our smart factory in Wuxi integrates Industry 4.0 principles, featuring automated material handling, real-time machine monitoring, and closed-loop quality control systems. Each production batch is tracked through a digital twin platform, enabling full traceability of materials, processes, and inspection data. In-line vision systems and automated optical inspection (AOI) detect deviations instantly, triggering corrective actions before defective parts progress. All finished components are packaged in ESD-safe, anti-corrosion materials and shipped with detailed first-article inspection (FAI) reports and material certifications.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Material Types | Cold-rolled steel, stainless steel (304, 316), aluminum (5052, 6061), galvanized steel, copper |

| Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance (Bending) | ±0.1° angular, ±0.1 mm linear |

| Dimensional Accuracy | ±0.05 mm (via CMM verification) |

| Surface Roughness | Ra ≤ 1.6 μm (as standard) |

| Max Part Size | 3000 mm × 1500 mm |

| Welding Processes | TIG, MIG, spot welding, robotic laser welding |

| Finishing Options | Powder coating, anodizing, passivation, plating, brushing |

Through disciplined integration of design intelligence, prototype validation, and automated production control, Wuxi Lead delivers zero-defect sheet metal solutions at scale—consistently, reliably, and globally.

Why Choose Wuxi Lead Precision

Why Partner with Wuxi Lead Precision Machinery?

Achieving true summit-level performance in sheet metal fabrication demands more than standard manufacturing capabilities. It requires a partner engineered for precision, reliability, and seamless integration into your most demanding production ecosystems. At Wuxi Lead Precision Machinery, we operate exclusively at this summit tier, serving global leaders who refuse to compromise on quality, consistency, or technical execution. Our foundation is built upon advanced CNC infrastructure, rigorous ISO 9001:2015 certified processes, and an engineering team with deep expertise in complex, low-tolerance applications across aerospace, medical device, and high-end industrial sectors. We understand that your reputation hinges on every component; our zero-defect manufacturing philosophy ensures yours remains unblemished.

Our technical capacity is specifically calibrated for summit sheet metal challenges. We deploy state-of-the-art Amada and Trumpf laser cutting, CNC turret punching, and robotic bending cells, all maintained to micron-level calibration standards. This investment translates into capabilities that consistently exceed industry norms for tight-tolerance forming, intricate geometries, and exceptional surface integrity on demanding materials. The following table details our core precision sheet metal specifications, reflecting the summit standard we deliver daily.

| Capability | Specification Range | Key Advantage |

|---|---|---|

| Material Thickness | 0.5mm – 6.0mm (Stainless/Al/Cu) | Precision handling of thin & thick gauges |

| Tolerance Control | ±0.02mm (Critical Features) | Guaranteed dimensional repeatability |

| Minimum Bend Radius | 0.5 x Material Thickness | Complex geometries without deformation |

| Surface Finish (Ra) | ≤ 0.8 µm (As-Formed) | Eliminates secondary polishing for critical apps |

| Max. Part Dimension | 3000mm x 1500mm | Large-scale precision without compromise |

| Lead Time (Complex Parts) | 7-15 Days (From Approved CAD) | Accelerated throughput with zero quality loss |

Partnering with Lead Precision means integrating a manufacturing extension of your own engineering rigor. We provide full DFM collaboration, real-time production tracking, and IP-protected processes – transforming your summit sheet metal designs from blueprint to flawless reality. Our commitment extends beyond the shop floor to ensure on-time delivery, supply chain resilience, and continuous improvement aligned with your strategic objectives. The cost of substandard fabrication – rework, delays, reputational damage – far exceeds the value of a true precision partnership.

Initiate your precision partnership today. Contact our engineering sales team directly at [email protected] to discuss your specific summit sheet metal requirements. Provide your project specifications, and we will deliver a detailed capability assessment and production timeline within 24 business hours. Do not settle for near-peak performance; demand the summit standard. Let Wuxi Lead Precision Machinery become your definitive partner for mission-critical sheet metal fabrication where excellence is non-negotiable. Lead Precision: Where Summit Sheet Metal Becomes Reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.