Technical Contents

Engineering Guide: Summit Range Parts

Engineering Insight: summit range parts

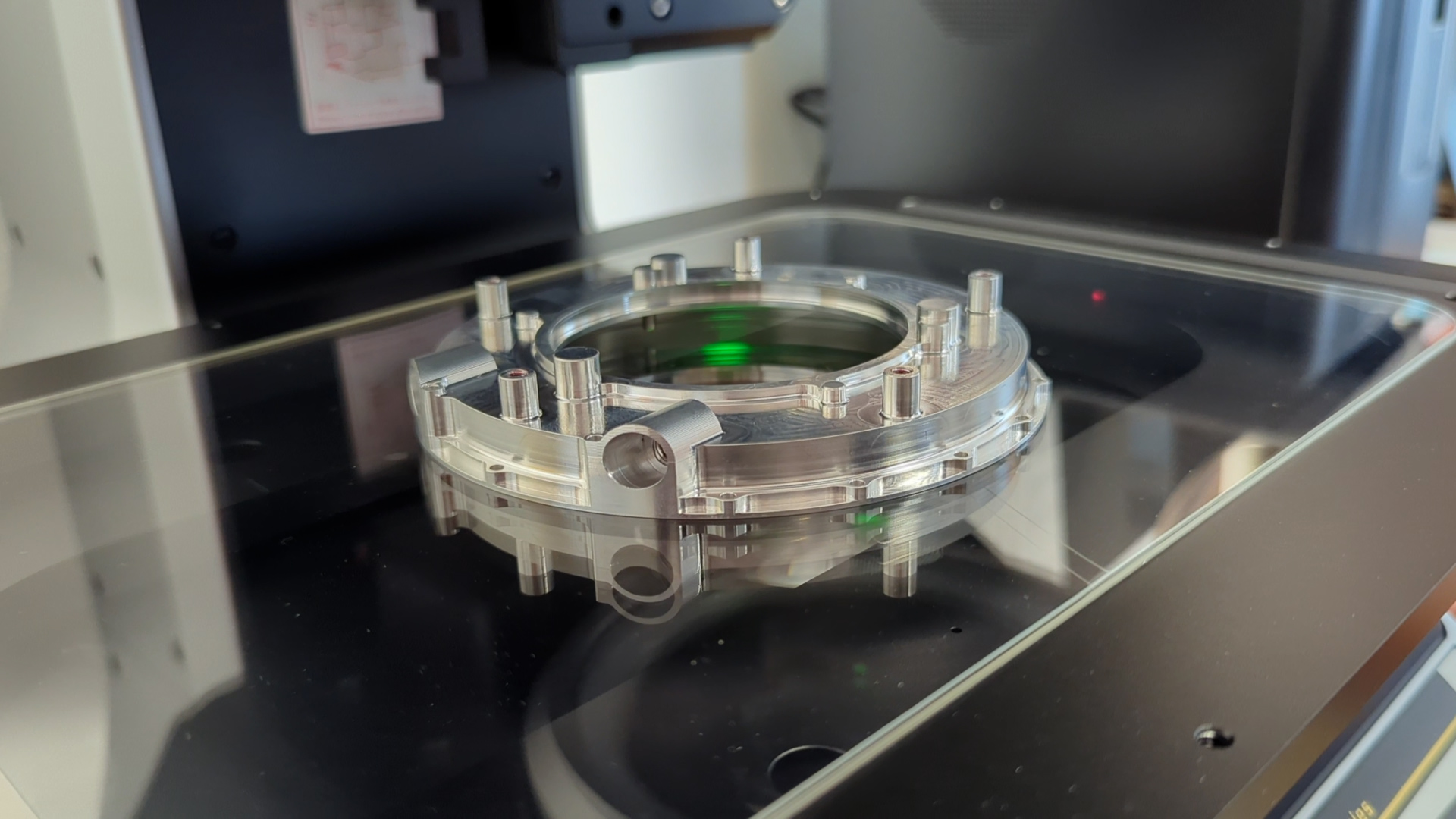

In the realm of high-performance manufacturing, the term summit range parts refers to components engineered to operate at the extreme edges of mechanical demand—where precision, reliability, and material integrity are not merely desired but mandatory. These parts are typically found in aerospace, defense, high-end automation, and advanced energy systems, where failure is not an option and tolerances are measured in microns. At Wuxi Lead Precision Machinery, we define summit range parts not just by their application, but by the uncompromising standards under which they are designed, machined, and validated.

Precision in summit range manufacturing transcends tight tolerances. It encompasses thermal stability, surface finish consistency, geometric accuracy, and long-term fatigue resistance. A deviation of even 5 microns can cascade into system-level failure in a high-speed turbine or a satellite positioning mechanism. This is why our engineering approach begins with material science analysis—selecting alloys such as Inconel 718, Ti-6Al-4V, or custom maraging steels—then progresses through finite element analysis (FEA), iterative prototyping, and full metrological validation using 5-axis CMMs and laser interferometry.

Our experience in producing mission-critical components for Olympic-grade timing systems and classified military subsystems has reinforced a fundamental truth: repeatable precision demands more than advanced machinery—it requires a culture of engineering discipline. For example, in the development of a gyrostabilization housing for a defense contractor, we achieved ±2µm positional accuracy across 12 mating interfaces, with surface finishes consistently below Ra 0.4µm. This level of control was maintained across a production run of 300 units, validated batch by batch.

Wuxi Lead’s facility in Jiangsu integrates 5-axis milling, wire EDM, and micro-turning centers—all operating within temperature-controlled environments to minimize thermal drift. Our CNC programmers use hyperMILL and Mastercam to optimize toolpaths that reduce vibration and tool wear, directly contributing to dimensional repeatability. Every summit range part undergoes a traceability protocol: raw material certification, in-process inspection, final validation, and digital archiving for full lifecycle tracking.

The following table outlines typical specifications achievable for summit range components at Wuxi Lead Precision Machinery:

| Specification | Capability | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.002 mm | ISO 2768-m |

| Surface Finish (Ra) | As low as 0.2 µm | ISO 1302 |

| Geometric Accuracy (GD&T) | ±0.003 mm | ASME Y14.5 |

| Material Range | Ti, Inconel, Stainless, Tool Steel, Al alloys | ASTM/AMS |

| Max Part Weight | 200 kg | Custom fixturing available |

| Production Volume | 1–500 units (batch) | Scalable process validation |

Summit range parts represent the apex of custom metal manufacturing—a domain where engineering excellence is non-negotiable. At Wuxi Lead, our legacy in high-stakes industries informs every process, ensuring that when performance reaches its limit, the component does not.

Precision Specs & Tolerances

Technical Capabilities: Precision Engineered for Summit Range Performance

Wuxi Lead Precision Machinery delivers uncompromising precision for mission-critical summit range components through advanced manufacturing infrastructure and rigorous process control. Our core competency lies in complex, high-integrity metal parts demanding micron-level accuracy and exceptional repeatability, serving aerospace, medical device, and energy sector leaders. Central to this capability is our dedicated fleet of state-of-the-art 5-axis CNC machining centers, featuring知名品牌 like DMG MORI and Makino. These systems enable complete part geometry realization in a single setup, eliminating cumulative error from multiple fixtures. This is essential for intricate contours, deep cavities, and compound angles inherent in summit range designs. We machine a comprehensive range of materials including titanium alloys (Grade 5, CP), Inconel 718 & 625, stainless steels (17-4PH, 316L), aluminum alloys (7075, 6061), and specialty engineering plastics with equal mastery. Process optimization leverages high-speed machining strategies, adaptive toolpathing, and in-process probing to ensure thermal stability and dimensional fidelity throughout production runs, from rapid prototyping to high-volume fulfillment.

Our commitment to precision extends beyond machining into integrated quality assurance. Every summit range component undergoes comprehensive metrology-grade verification. Primary inspection utilizes industry-leading Coordinate Measuring Machines (CMM), including Zeiss and Hexagon systems with scanning probe technology. This provides full 3D geometric dimensioning and tolerancing (GD&T) validation against CAD models, capturing critical form, position, and profile deviations invisible to manual methods. Statistical Process Control (SPC) is embedded in high-volume production, monitoring key characteristics in real-time to preempt deviations. Surface integrity is equally critical; we achieve and verify fine finishes down to Ra 0.4 μm (16 μin) using specialized tooling, polishing techniques, and profilometry. Material certification, first-article inspection reports (FAIR), and full traceability documentation are standard deliverables, providing auditable proof of conformance to AS9100, ISO 13485, and customer-specific quality mandates.

The following table details our standard and precision tolerance capabilities for summit range manufacturing. Achievable tolerances are material and geometry-dependent; our engineering team collaborates closely with clients during design for manufacturability (DFM) reviews to optimize part specifications for cost-effective precision.

| Feature Type | Standard Tolerance | Precision Range |

|---|---|---|

| Linear Dimensions | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) |

| Angular Dimensions | ±0.1° | ±0.02° |

| Positional Tolerance | ±0.05 mm (±0.002″) | ±0.01 mm (±0.0004″) |

| Surface Roughness | Ra 1.6 μm (63 μin) | Ra 0.4 μm (16 μin) |

Wuxi Lead Precision Machinery’s integrated approach—combining cutting-edge 5-axis CNC technology, deep material science expertise, and CMM-backed quality systems—ensures summit range parts meet the most stringent performance and reliability demands. We transform complex engineering visions into physically perfect components, batch after batch. Partner with us for precision that ascends beyond specification.

Material & Finish Options

Material Selection for Summit Range Parts – Precision Engineering from Wuxi Lead

Selecting the appropriate material is a foundational decision in high-performance custom manufacturing. At Wuxi Lead Precision Machinery, we engineer Summit Range Parts to meet exacting standards in aerospace, automotive, medical, and industrial automation sectors. Our expertise in aluminum, steel, and titanium machining ensures optimal performance, longevity, and reliability under demanding operational conditions. Each material offers distinct mechanical and thermal properties, making material choice a critical factor in design success.

Aluminum is widely favored for its excellent strength-to-weight ratio, corrosion resistance, and machinability. It is particularly suited for applications where weight reduction is essential without sacrificing structural integrity. Grade 6061-T6 is a common choice for prototyping and production components due to its weldability and dimensional stability. For more demanding environments, 7075-T6 offers superior strength, often used in aerospace frameworks and high-stress mechanical systems.

Steel provides unmatched durability and load-bearing capacity. Among carbon and alloy steels, 4140 and 1045 are frequently specified for their hardness, wear resistance, and response to heat treatment. These grades are ideal for shafts, gears, and structural components exposed to high mechanical stress. Stainless steel variants such as 304 and 316 offer enhanced corrosion resistance, making them suitable for medical devices and marine environments. While heavier than aluminum, steel’s resilience under extreme conditions ensures long service life in rugged applications.

Titanium, particularly Grade 5 (Ti-6Al-4V), stands at the pinnacle of performance materials. It combines exceptional strength, low density, and outstanding resistance to fatigue and corrosion—even at elevated temperatures. Its biocompatibility and non-magnetic properties make it indispensable in aerospace and medical implant manufacturing. Though more challenging to machine and higher in cost, titanium delivers unparalleled value in mission-critical applications where failure is not an option.

Surface finishing further enhances material performance. Anodizing is a key process for aluminum components, providing a controlled oxide layer that improves wear resistance, corrosion protection, and aesthetic consistency. Type II (sulfuric acid) anodizing is standard for decorative and moderate-duty applications, while Type III (hardcoat anodizing) delivers a thicker, denser layer for industrial and aerospace use. Anodized layers are electrically insulating and can be dyed for identification, supporting both functional and visual requirements.

At Wuxi Lead, we integrate material science with precision CNC machining to deliver Summit Range Parts that exceed expectations. Our engineering team collaborates closely with clients to match material and finish to operational demands, ensuring optimal performance and cost-efficiency.

Material Comparison for Summit Range Applications

| Material | Tensile Strength (MPa) | Density (g/cm³) | Key Advantages | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 2.7 | Lightweight, corrosion-resistant, weldable | Enclosures, brackets, prototypes |

| Aluminum 7075-T6 | 570 | 2.8 | High strength, fatigue-resistant | Aerospace, defense components |

| Steel 4140 | 655 | 7.85 | High toughness, heat-treatable | Shafts, tooling, industrial parts |

| Stainless 316 | 580 | 8.0 | Excellent corrosion resistance | Medical, marine, food processing |

| Titanium Ti-6Al-4V | 950 | 4.43 | High strength-to-density, biocompatible | Aircraft, implants, racing systems |

Manufacturing Process & QC

Summit Range Production Process: Engineering Precision from Concept to Volume

At Wuxi Lead Precision Machinery, the Summit Range represents our pinnacle of custom metal manufacturing, engineered for mission-critical aerospace, medical, and energy applications where zero defects are non-negotiable. Our integrated process ensures uncompromising quality through three rigorously controlled phases: Design Validation, Precision Prototyping, and Scalable Mass Production.

The journey begins with Design Validation, where our engineering team collaborates directly with clients to optimize part geometry for manufacturability. We conduct in-depth Design for Manufacturing (DFM) analysis using Siemens NX software, identifying potential stress points, material inefficiencies, or tolerance conflicts before metal is cut. This phase includes thermal and structural simulations to preempt real-world performance issues, reducing downstream revisions by up to 70%. Client sign-off on validated digital twins is mandatory, ensuring alignment on tolerances, surface finishes, and material specifications.

Precision Prototyping follows immediately, leveraging our 5-axis DMG MORI and Makino machining centers to produce functional prototypes in the exact production alloy. Each prototype undergoes destructive and non-destructive testing per AS9100 and ISO 13485 standards, including CMM validation, X-ray fluorescence material verification, and fatigue cycle simulation. We prioritize rapid iteration—typical prototype turnaround is 72 hours—with full metrology reports provided for client review. This phase confirms that design intent translates flawlessly to physical reality, eliminating assumptions before volume commitment.

Scalable Mass Production activates only after prototype approval, deploying our zero-defect framework across 32 CNC workcells. Statistical Process Control (SPC) monitors critical dimensions in real-time, with automated tool-wear compensation and in-process gauging at every station. Each part receives full traceability via laser-etched serial numbers linked to material certificates, machine parameters, and operator logs. Final inspection uses Zeiss metrology-grade CMMs and optical comparators, with 100% first-article inspection and AQL 0.65 sampling for batches. This closed-loop system ensures consistent conformance to the tightest tolerances, with defect rates consistently below 50 PPM.

Our commitment to zero defects is embedded in every stage, transforming complex designs into flawless components while accelerating time-to-market. The table below summarizes core Summit Range capabilities:

| Parameter | Standard Specification | Verification Method |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm | Zeiss CONTURA CMM (Calibrated to ISO 17025) |

| Surface Finish | Ra 0.4 µm (as-machined) | Mitutoyo SJ-410 Profilometer |

| Material Compliance | AMS, ASTM, EN standards | XRF Spectroscopy + Mill Certificates |

| Batch Traceability | 100% part serialization | ERP-linked QR code tracking |

| Production Capacity | 50,000+ units/month | Automated pallet system (24/7) |

Wuxi Lead’s Summit Range process merges German-engineered precision with Chinese-scale efficiency, delivering parts that perform flawlessly in the most demanding environments. Every component is a testament to our philosophy: perfection is not an outcome—it is the process.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Excellence in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we don’t just manufacture parts—we engineer success. As a leading provider of high-precision custom metal components in China, we specialize in delivering engineered solutions that meet the exacting demands of advanced industries including aerospace, medical devices, automation, and high-performance industrial equipment. Our commitment to quality, precision, and reliability positions us as the preferred manufacturing partner for global innovators who demand nothing less than perfection.

The Summit Range Parts series represents the pinnacle of our engineering capability. Designed for applications where tolerances are tight, materials are challenging, and performance is non-negotiable, these components are built to exceed expectations. Whether you require complex CNC-machined housings, high-strength alloy shafts, or fully assembled subunits with micron-level accuracy, our team ensures every part meets your technical, functional, and regulatory requirements.

Our facility in Wuxi is equipped with state-of-the-art 5-axis CNC machines, advanced metrology systems, and a full suite of secondary processing capabilities. We combine cutting-edge technology with decades of hands-on expertise to deliver parts that are not only dimensionally accurate but also optimized for performance, durability, and cost-efficiency. From prototype development to high-volume production, we scale with your needs—offering rapid turnaround, full traceability, and certified quality control at every stage.

What sets us apart is our collaborative approach. We don’t see ourselves as just a vendor—we are an extension of your engineering team. Our engineers work closely with yours to review designs, recommend material and process optimizations, and ensure manufacturability without compromising performance. This proactive partnership reduces time-to-market, minimizes rework, and enhances overall product integrity.

When you choose Wuxi Lead Precision Machinery, you gain more than a manufacturer—you gain a strategic ally committed to your success. We understand the stakes involved in high-end manufacturing, and we uphold the highest standards in every component we produce.

Contact us today to begin your next precision project. Let our team at Lead Precision bring your Summit Range Parts to life with unmatched accuracy and reliability.

Email us at [email protected] to discuss your requirements, request a quote, or schedule a technical consultation.

| Specification | Detail |

|---|---|

| Material Range | Aluminum Alloys, Stainless Steel, Titanium, Inconel, Brass, Carbon Steel, Plastics (PEEK, Delrin) |

| Tolerance Capability | ±0.005 mm (±0.0002″) |

| Max Work Envelope | 1200 x 800 x 600 mm (47 x 31.5 x 23.6 in) |

| Surface Finish | As low as Ra 0.4 µm (16 µin), with polishing, anodizing, and coating options |

| Certifications | ISO 9001:2015, ISO 13485 (medical), RoHS compliant |

| Lead Time | Prototype: 7–10 days; Production: 15–25 days (varies by complexity and volume) |

| Quality Control | Full CMM inspection, GD&T reporting, First Article Inspection (FAI), PPAP documentation |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.