Technical Contents

Engineering Guide: Steel Plate Cutting Services

Engineering Insight: Steel Plate Cutting Services

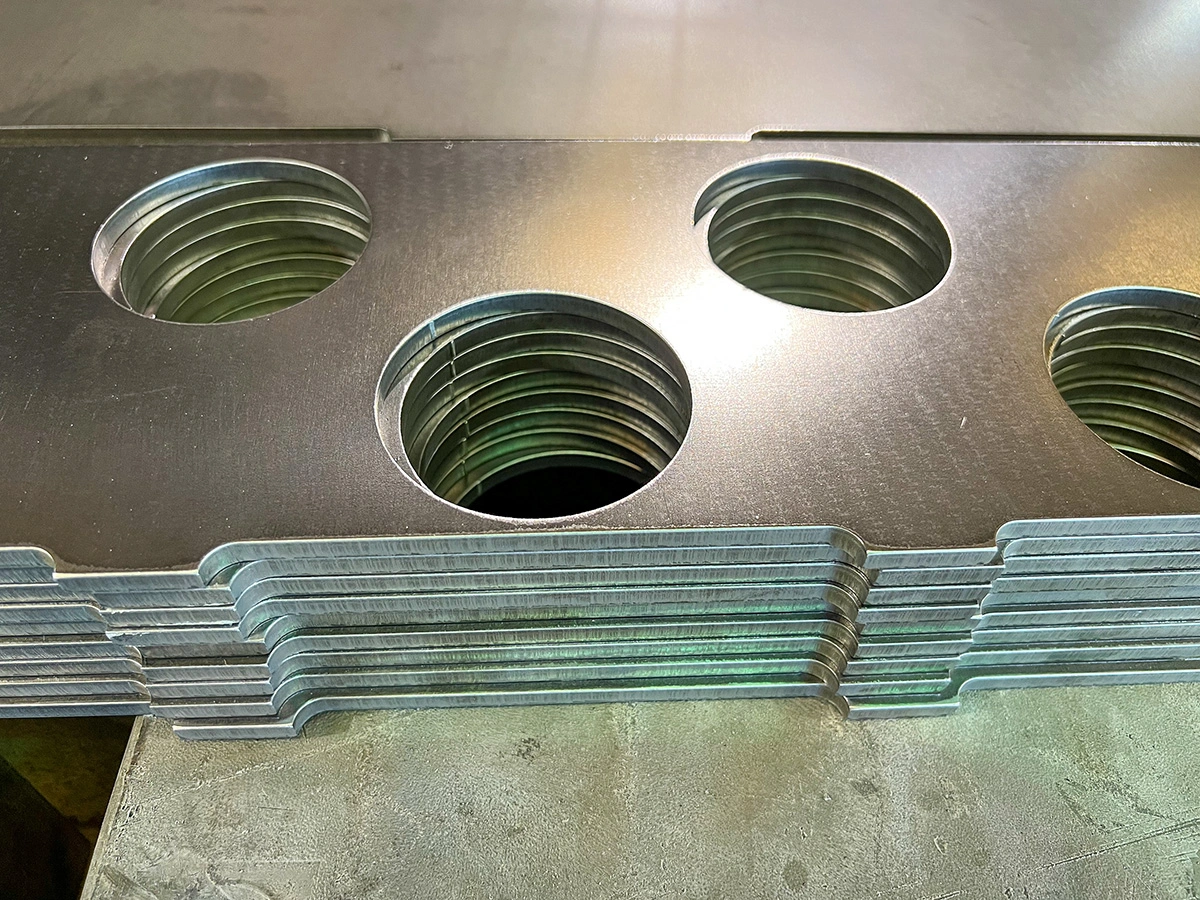

In the realm of custom metal manufacturing, precision in steel plate cutting is not merely a technical requirement—it is a foundational element that defines structural integrity, assembly accuracy, and long-term performance. Whether fabricating components for heavy industrial machinery, aerospace systems, or large-scale infrastructure, the dimensional accuracy and edge quality achieved during the cutting process directly influence downstream operations such as welding, machining, and final assembly. At Wuxi Lead Precision Machinery, we recognize that tolerances measured in fractions of a millimeter can determine the success or failure of a mission-critical application.

Our approach to steel plate cutting integrates advanced CNC-controlled technologies with rigorous engineering oversight to ensure repeatability, consistency, and compliance with international standards. Utilizing state-of-the-art plasma, laser, and oxy-fuel cutting systems, we are capable of processing a wide range of steel grades—including mild steel, high-strength low-alloy (HSLA) steel, and abrasion-resistant (AR) plate—up to 100 mm in thickness. Each cutting method is selected based on material type, required edge quality, and project specifications, ensuring optimal efficiency without compromising precision.

What distinguishes Wuxi Lead in the global market is not only our technical capability but also our proven track record in high-stakes manufacturing environments. Our engineering teams have contributed to projects meeting Olympic-standard construction requirements and have delivered components compliant with military-grade fabrication protocols. These experiences have instilled a culture of zero-defect manufacturing, where every cut is verified through in-process inspection and final quality assurance protocols. From initial CAD-based programming to final edge deburring, our workflow is engineered to eliminate variability and ensure that every component meets exacting client specifications.

Precision steel plate cutting also demands expertise in material behavior. Thermal cutting processes introduce heat-affected zones (HAZ), which, if not properly managed, can alter material properties and lead to warping or microstructural changes. Our engineers apply adaptive cutting strategies, including controlled feed rates, optimized kerf compensation, and post-cut stress-relief procedures, to maintain the metallurgical integrity of the base material. This level of technical mastery is essential when serving industries where failure is not an option.

The following table outlines the core capabilities of our steel plate cutting services:

| Parameter | Specification |

|---|---|

| Material Types | Mild Steel, HSLA, AR Plate, Structural Steel |

| Thickness Range | 1 mm – 100 mm |

| Cutting Methods | CNC Plasma, Fiber Laser, Oxy-Fuel |

| Positional Accuracy | ±0.1 mm |

| Repeatability | ±0.05 mm |

| Edge Quality (Laser) | Burr-free, Ra ≤ 6.3 μm |

| Max Work Envelope | 6000 mm × 3000 mm |

| Programming Interface | CAD/CAM Integration, DXF/DWG Native Support |

| Quality Standards | ISO 9001, GB/T 19001, MIL-STD Compliance |

At Wuxi Lead Precision Machinery, we combine decades of metallurgical expertise with cutting-edge automation to deliver steel plate components that meet the highest standards of precision and reliability. For industries where performance under stress is non-negotiable, our steel plate cutting services provide the engineering foundation for success.

Precision Specs & Tolerances

Advanced Steel Plate Cutting Capabilities at Wuxi Lead Precision Machinery

Wuxi Lead Precision Machinery delivers uncompromising precision in steel plate fabrication, engineered for complex industrial applications demanding micron-level accuracy and structural integrity. Our core strength lies in integrating multi-axis CNC technology with rigorous quality control protocols, enabling the production of intricate geometries that exceed standard industry tolerances. This capability is critical for sectors like aerospace, energy, and heavy machinery, where component failure is not an option.

Our flagship 5-axis CNC cutting systems represent the pinnacle of modern metal fabrication. Unlike conventional 3-axis machines, these systems dynamically manipulate the cutting head across five simultaneous axes, eliminating the need for multiple setups. This allows for continuous contouring of complex 3D surfaces, undercuts, and compound angles directly from solid plate stock. The result is significant reduction in secondary operations, minimized handling errors, and exceptional surface continuity. We process carbon steel, stainless steel, and alloy plates up to 300mm thick with consistent edge quality, free from thermal distortion or recast layers common in thermal cutting methods. All machines operate under strict environmental controls to maintain thermal stability, ensuring dimensional repeatability across extended production runs.

Quality assurance is embedded at every process stage, not merely as a final checkpoint. Each component undergoes comprehensive Coordinate Measuring Machine (CMM) inspection using Renishaw probes and PC-DMIS software. This provides full 3D verification against CAD models, capturing deviations in form, position, and critical datums. Inspection data is digitally archived for full traceability, supporting client audit requirements and enabling proactive process refinement. Statistical process control (SPC) methodologies are applied to monitor trends, ensuring capabilities remain within defined parameters for high-volume contracts.

The following table details our standard achievable tolerances for milled steel plate components, validated through CMM inspection and adhering to ISO 2768-mK and ISO 1302 standards. These specifications apply to finished parts after stress relief and final machining.

| Material Thickness | Dimensional Tolerance | Surface Finish (Ra) | Process |

|---|---|---|---|

| ≤ 50 mm | ±0.025 mm | 0.8 µm | 5-Axis Precision Milling |

| 51–150 mm | ±0.05 mm | 1.6 µm | 5-Axis Precision Milling |

| 151–300 mm | ±0.1 mm | 3.2 µm | 5-Axis Precision Milling |

These tolerances reflect our commitment to delivering components ready for direct assembly, reducing client scrap rates and downstream rework costs. Our technical team collaborates closely with clients during the design phase to optimize manufacturability, leveraging simulation software to identify potential stress points or tolerance stack-ups before cutting commences. This proactive engineering approach ensures your steel plate components meet the highest functional and regulatory standards, providing a definitive competitive advantage in demanding global markets. Wuxi Lead transforms raw plate into mission-critical assets through technology, discipline, and unwavering attention to detail.

Material & Finish Options

Material selection is a critical step in precision steel plate cutting services, directly influencing product performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing, offering expert guidance on material and finish choices tailored to your industrial application. The three most widely used metals in high-precision plate cutting—aluminum, steel, and titanium—each possess distinct mechanical and chemical properties that make them suitable for specific environments and functional requirements.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and electrical conductivity. It is ideal for aerospace, transportation, and electronics applications where lightweight components are essential. However, aluminum requires careful handling during cutting due to its softness and thermal conductivity, which can affect edge quality if not managed with precision equipment.

Steel remains the backbone of industrial manufacturing due to its high tensile strength, durability, and cost-effectiveness. Carbon steel and stainless steel variants offer versatility across sectors such as construction, energy, and heavy machinery. Carbon steel provides superior strength for structural applications, while stainless steel adds corrosion resistance through chromium content, making it suitable for food processing, medical devices, and outdoor installations. Our advanced laser and plasma cutting systems ensure clean, burr-free edges on steel plates up to 40 mm thick.

Titanium stands out for extreme environments requiring exceptional strength, corrosion resistance, and performance at elevated temperatures. Commonly used in aerospace, defense, and medical implant industries, titanium is challenging to cut due to its low thermal conductivity and tendency to react with cutting tools. Wuxi Lead employs high-precision fiber laser technology and controlled atmospheres to maintain material integrity and dimensional accuracy when processing titanium plates.

For enhanced surface performance and aesthetics, anodizing is a recommended finish for aluminum components. This electrochemical process thickens the natural oxide layer, improving wear and corrosion resistance while allowing for color customization. Anodized finishes are non-conductive and maintain dimensional stability, making them ideal for precision enclosures and architectural elements.

Below is a comparative overview of key properties for common plate materials used in our cutting services.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Max Plate Thickness (mm) | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 90–700 | 2.7 | High | 50 | Aerospace, electronics, transport |

| Carbon Steel | 370–630 | 7.8 | Low (uncoated) | 40 | Construction, machinery, tooling |

| Stainless Steel | 515–1000 | 8.0 | Very High | 35 | Medical, food processing, marine |

| Titanium | 240–1200 | 4.5 | Excellent | 25 | Aerospace, defense, medical implants |

Selecting the right material and finish ensures optimal performance and cost-efficiency in your final product. Wuxi Lead Precision Machinery combines advanced cutting technology with material science expertise to deliver precision-cut metal components that meet exacting industrial standards.

Manufacturing Process & QC

Precision Steel Plate Cutting: Integrated Workflow from Design to Zero-Defect Production

At Wuxi Lead Precision Machinery, our steel plate cutting process is engineered for uncompromising quality and efficiency, eliminating defects before they occur. We execute a seamless transition from concept to high-volume manufacturing through rigorously controlled phases, ensuring every component meets exacting international standards. This integrated workflow is the cornerstone of our zero-defect commitment for global industrial clients.

The process begins with collaborative Design & Engineering Validation. Our engineering team works directly with client CAD files or technical specifications to optimize geometry for manufacturability. Using advanced simulation software, we analyze stress points, thermal distortion risks, and nesting efficiency specific to steel alloys. Material grade, thickness, and surface condition are verified against project requirements, with immediate feedback provided for design adjustments. This phase prevents 95% of potential production errors by resolving conflicts before material is cut.

Prototyping & Dimensional Verification follows immediately for critical components. A single prototype is produced on our production-grade fiber laser systems, not separate R&D equipment. This ensures process consistency. The prototype undergoes comprehensive metrology: CMM inspection validates geometric tolerances per ISO 2768-mK, while optical comparators check edge quality and angular precision. Material properties are spot-tested. Only after full dimensional sign-off and client approval does the workflow advance. This stage confirms process capability and catches any unanticipated material behavior.

Zero-Defect Mass Production leverages the validated parameters at scale. Our automated production cells run with real-time process monitoring: laser power, assist gas pressure, and cutting speed are continuously logged against the approved prototype profile. In-line vision systems inspect every part for burr formation, dross, and dimensional drift, automatically quarantining outliers. Statistical Process Control (SPC) charts track critical dimensions across batches, enabling predictive adjustments. Full material traceability—from steel mill certificate to final shipment—is maintained digitally. This closed-loop system ensures batch-to-batch consistency and immediate root-cause analysis if deviations occur.

Key production capabilities enabling this workflow are maintained across our facility:

| Parameter | Value | Application Impact |

|---|---|---|

| Material Thickness | 0.5 mm – 30 mm | Handles thin gauge to heavy industrial plate |

| Positioning Accuracy | ±0.03 mm/m | Ensures precise fit for welded assemblies |

| Edge Quality | Ra ≤ 6.3 µm (standard) | Reduces or eliminates secondary finishing |

| Materials | Carbon Steel, Stainless Steel, Alloy Steel | Full coverage for structural & critical components |

| Max. Work Envelope | 4000 x 20000 mm | Accommodates large-scale industrial parts |

This end-to-end control—from digital design validation through prototype metrology to SPC-monitored production—forms our zero-defect guarantee. Wuxi Lead’s process eliminates waste, reduces time-to-market, and delivers steel plate components that perform reliably in the most demanding applications. Every cut reflects our engineering discipline and commitment to your operational success.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Steel Plate Cutting Services

When precision, reliability, and efficiency define your production standards, partnering with a trusted leader in custom metal manufacturing becomes essential. At Wuxi Lead Precision Machinery, we specialize in high-performance steel plate cutting services tailored to meet the exacting demands of global industries. From heavy equipment and energy infrastructure to transportation and precision engineering, our capabilities are engineered to deliver accuracy, consistency, and value at every stage of fabrication.

Our advanced CNC-controlled cutting systems integrate fiber laser, plasma, and waterjet technologies to process steel plates with superior edge quality and dimensional accuracy. Whether you require intricate contours or large-scale structural components, our facility in Wuxi, China, is equipped to handle low-volume prototypes and high-volume production runs with equal expertise. We process carbon steel, stainless steel, and alloy plates up to 40 mm in thickness, supporting custom specifications in sizes up to 6,000 mm × 2,500 mm.

What sets us apart is our end-to-end quality control system. Every project undergoes rigorous material verification, real-time process monitoring, and post-cut inspection using coordinate measuring machines (CMM) and optical profiling. This ensures that each component meets international standards for flatness, tolerance, and surface integrity. Our team of certified engineers collaborates directly with clients to optimize cutting paths, reduce material waste, and accelerate turnaround times—delivering not just parts, but solutions.

We understand that in today’s competitive manufacturing landscape, supply chain resilience and technical agility are critical. That’s why we maintain ISO 9001-certified processes, in-house programming, and rapid prototyping capabilities to support fast iterations and just-in-time delivery. Our logistics network ensures seamless export operations with reliable lead times to North America, Europe, and Southeast Asia.

For OEMs, fabricators, and engineering firms seeking a long-term manufacturing partner, Wuxi Lead Precision Machinery offers the technical depth, capacity, and commitment to excellence that global projects demand.

Contact us today to discuss your steel plate cutting requirements. Our engineering team is ready to review your drawings, provide technical feedback, and deliver a competitive quote tailored to your project’s scope and timeline.

Send inquiries to [email protected] and experience the precision advantage.

| Specification | Capability |

|---|---|

| Material Types | Carbon Steel, Stainless Steel, Alloy Steel |

| Plate Thickness | 0.5 mm – 40 mm |

| Maximum Cutting Area | 6,000 mm × 2,500 mm |

| Tolerance | ±0.1 mm – ±0.3 mm (depending on process) |

| Cutting Methods | Fiber Laser, Plasma, Waterjet |

| Edge Quality | Burr-free, minimal dross, ready for welding or coating |

| Quality Standards | ISO 9001, ISO 13920 (weldment tolerances), ISO 2768 (general tolerances) |

| File Formats Accepted | DXF, DWG, STEP, IGES, PDF (with dimensions) |

| Lead Time | 7–15 days (varies by order volume and complexity) |

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.