Technical Contents

Engineering Guide: Steel Mold

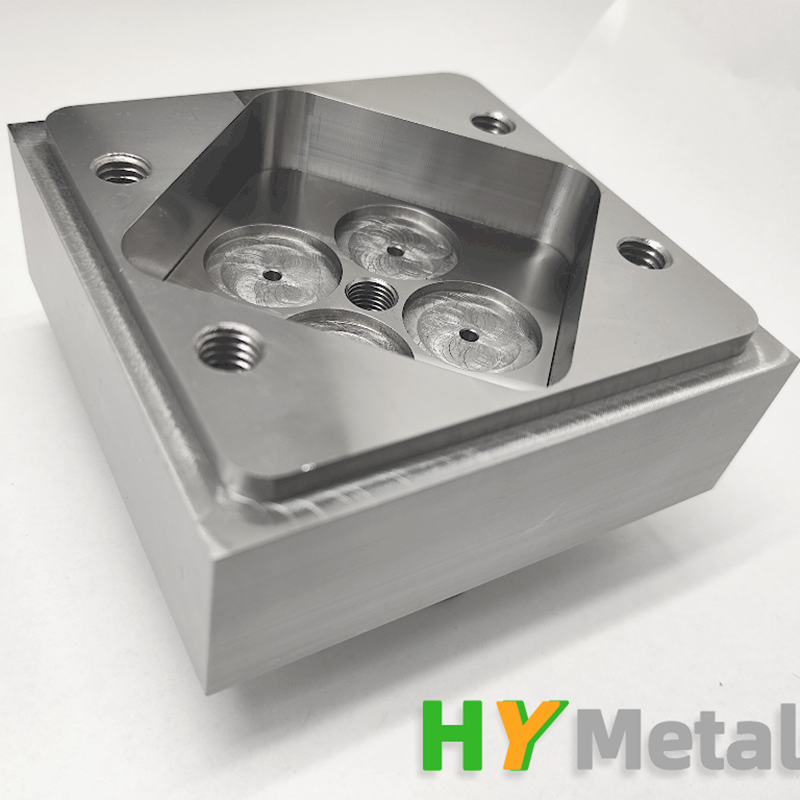

Engineering Insight: The Critical Role of Precision in Steel Mold Manufacturing

In the realm of custom metal manufacturing, steel molds stand as the backbone of high-volume, high-integrity production across industries ranging from automotive to aerospace, medical devices to consumer electronics. At Wuxi Lead Precision Machinery, we recognize that the performance, longevity, and consistency of a steel mold are directly tied to the precision with which it is engineered and fabricated. Even micron-level deviations can lead to part defects, increased cycle times, or premature tool failure—costly outcomes in any industrial application.

Steel molds are subjected to extreme conditions: high pressure, repeated thermal cycling, and constant mechanical stress. To endure these challenges, the mold must be not only constructed from high-grade tool steels such as H13, S136, or P20 but also machined to exacting tolerances. Precision in mold manufacturing ensures uniform wall thickness, accurate part dimensions, and seamless surface finishes—critical for components that must meet strict regulatory or functional standards. At Lead Precision, our CNC machining centers operate within ±0.002 mm tolerances, supported by advanced metrology systems including CMM (Coordinate Measuring Machines) and 3D laser scanning to validate every critical feature.

Our expertise is not theoretical. Over the years, Wuxi Lead has delivered mission-critical steel molds for projects tied to Olympic-grade equipment and military-grade hardware—applications where failure is not an option. These high-stakes assignments have refined our approach, reinforcing the necessity of integrating material science, thermal analysis, and precision engineering from the earliest design stages. Whether producing injection molds for complex polymer components or die-casting molds for aluminum structural parts, our engineering team applies finite element analysis (FEA) to predict stress points, optimize cooling channels, and extend mold life beyond industry averages.

We also emphasize process repeatability. A precisely made mold is only as valuable as its ability to reproduce identical parts over hundreds of thousands of cycles. Our molds are designed with wear-resistant coatings, optimized ejection systems, and alignment features that maintain accuracy over time. This commitment to sustained precision is what enables our clients to achieve lean manufacturing goals, reduce scrap rates, and maintain compliance with ISO and Six Sigma standards.

Below is a representative specification profile for a high-precision steel mold manufactured at our facility:

| Specification | Detail |

|---|---|

| Material Options | H13, S136, P20, 420 Stainless, SKD61 |

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Finish | Ra 0.05 µm to Ra 0.4 µm (polished options) |

| Maximum Mold Size | 1200 mm × 800 mm × 700 mm |

| Machining Equipment | 5-axis CNC, Wire EDM, High-Speed Milling |

| Quality Assurance | CMM, 3D Scanning, First Article Inspection |

| Lead Time (Average) | 25–40 days (complexity-dependent) |

| Applications | Automotive, Defense, Medical, Consumer Tech |

At Wuxi Lead Precision Machinery, precision is not a target—it is the foundation. Our experience in delivering steel molds for the most demanding applications underscores our capability to meet and exceed the expectations of global manufacturers who rely on flawless performance.

Precision Specs & Tolerances

Advanced Technical Capabilities for Precision Steel Mold Manufacturing

At Wuxi Lead Precision Machinery, our technical infrastructure is engineered to deliver uncompromising precision in steel mold production. Central to this capability is our fleet of state-of-the-art 5-axis CNC machining centers, including DMG MORI and Makino systems. These platforms enable simultaneous multi-directional cutting, eliminating the need for multiple setups and minimizing cumulative error. For complex steel molds—particularly those requiring undercuts, deep cavities, or organic contours—5-axis machining ensures geometric integrity while optimizing material removal rates. Our machines maintain sub-micron positional accuracy through thermal compensation systems and rigid cast-iron frames, critical for managing the thermal expansion inherent in hardened tool steels like H13 or S7. This capability directly translates to reduced cycle times, superior surface finishes (Ra ≤ 0.4 µm), and molds that achieve first-article production readiness.

Quality assurance is non-negotiable in high-stakes mold applications. Every steel component undergoes rigorous metrology-grade verification using Zeiss and Hexagon CMMs (Coordinate Measuring Machines). Our inspection protocol begins with pre-machining material certification and continues through in-process checks at critical stages, culminating in full 3D dimensional validation against CAD models. This closed-loop process identifies deviations in real-time, allowing immediate corrective action before final assembly. All CMM reports are traceable to international standards (ISO 17025) and include GD&T analysis for form, position, and profile tolerances. For aerospace or medical-grade molds, we implement additional protocols such as thermal stability testing and cavity pressure mapping to simulate in-mold behavior.

The following table details our standard and precision tolerance capabilities for steel molds, reflecting the synergy between our 5-axis machining and CMM validation systems. These values represent achievable performance under controlled workshop conditions (20±1°C) using certified gaging equipment.

| Feature Type | Standard Tolerance | Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm |

| Hole Diameter | ±0.008 mm | ±0.003 mm |

| Flatness | 0.015 mm/m | 0.005 mm/m |

| Parallelism | 0.012 mm | 0.004 mm |

| Perpendicularity | 0.010 mm | 0.003 mm |

| Profile of Surface | ±0.015 mm | ±0.006 mm |

| Positional Accuracy | ±0.012 mm | ±0.004 mm |

These tolerances are consistently maintained across mold bases, cavities, cores, and lifters up to 1,200 x 800 x 600 mm. For critical features in optical or micro-molding applications, we achieve ±0.002 mm through diamond-turned finishing and laser interferometer calibration. Our engineering team collaborates with clients during DFM (Design for Manufacturing) reviews to identify tolerance-critical zones, ensuring resources are allocated where precision impacts part functionality most. This disciplined approach—combining advanced hardware, metrology rigor, and process intelligence—makes Wuxi Lead the partner of choice for steel molds demanding zero-defect performance in automotive, medical, and consumer electronics sectors. We transform complex steel mold specifications into production-ready assets with documented repeatability.

Material & Finish Options

Material Selection for High-Performance Steel Molds in Precision Manufacturing

Selecting the appropriate material for steel molds is critical in achieving optimal performance, longevity, and cost-efficiency in high-volume or precision manufacturing applications. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions that prioritize material integrity, thermal stability, and wear resistance. While the term “steel mold” suggests the use of steel, the broader context often includes alternative materials such as aluminum and titanium, each offering distinct advantages depending on production requirements. Additionally, surface finishes like anodizing play a vital role in enhancing durability and performance, particularly when applied to non-ferrous materials.

Steel remains the dominant choice for molds subjected to high pressure, abrasive materials, or extended production cycles. Tool steels such as P20, H13, and S136 offer excellent hardness, thermal fatigue resistance, and polishability, making them ideal for injection molding, die casting, and stamping applications. These steels can be heat-treated to achieve hardness levels exceeding 50 HRC, ensuring long service life under demanding conditions.

Aluminum alloys, particularly 7075 and 6061, are increasingly used in prototype molds or low-to-medium volume production due to their excellent machinability, thermal conductivity, and reduced weight. While softer than steel, aluminum molds significantly reduce cycle times and tooling costs during early-stage manufacturing. When enhanced surface durability is required, anodizing is a preferred finishing process. Anodizing creates a hard, corrosion-resistant oxide layer on the aluminum surface, improving wear resistance and enabling better release properties for molded parts.

Titanium alloys, though less common in mold construction, are utilized in highly specialized applications where extreme strength-to-density ratios, corrosion resistance, and performance at elevated temperatures are required. While costly and challenging to machine, titanium molds are suitable for aerospace and medical components where material purity and dimensional stability are non-negotiable.

The decision between aluminum, steel, and titanium must consider production volume, part complexity, material being formed, and environmental exposure. Below is a comparative overview of key material properties relevant to mold performance.

| Material | Hardness (HRC) | Tensile Strength (MPa) | Thermal Conductivity (W/m·K) | Typical Applications | Surface Treatment Options |

|---|---|---|---|---|---|

| P20 Steel | 28–32 | 950–1100 | 28–31 | Injection molds, large cavities | Nitriding, polishing, coating |

| H13 Steel | 48–52 | 1200–1400 | 30–35 | Die casting, hot work tools | PVD coating, laser hardening |

| 7075 Aluminum | 15–20 | 500–570 | 130–150 | Prototyping, low-volume production | Anodizing (Type II & III), coating |

| Titanium (Grade 5) | 35–40 | 900–1000 | 7–8 | Aerospace, medical implants | Anodizing, plasma nitriding |

Anodizing, particularly hard anodizing (Type III), is highly effective for aluminum molds, increasing surface hardness up to 60 HRC and providing excellent resistance to galling and corrosion. This finish is especially beneficial when molding abrasive or reinforced polymers.

At Wuxi Lead Precision Machinery, we guide clients through material and finish selection based on technical specifications, lifecycle costs, and performance goals. Our engineering team ensures that every mold is optimized for its intended application, combining material science with precision manufacturing excellence.

Manufacturing Process & QC

Precision Steel Mold Production: From Concept to Zero-Defect Fulfillment

At Wuxi Lead Precision Machinery, our steel mold manufacturing process is engineered for uncompromising quality and repeatability, ensuring zero defects from initial concept through high-volume production. This rigorous methodology is fundamental to delivering molds that meet the exacting demands of aerospace, medical, and automotive applications where failure is not an option. Our integrated workflow eliminates traditional handoffs, embedding quality control at every critical juncture.

The process commences with Advanced Digital Design & Simulation. Our engineering team utilizes Siemens NX and Autodesk Moldflow to create 3D models incorporating precise draft angles, cooling channel optimization, and stress analysis. Finite Element Analysis (FEA) validates structural integrity under operational loads, while Computational Fluid Dynamics (CFD) ensures uniform thermal distribution. This phase defines critical parameters such as cavity pressure resistance (up to 2000 bar) and surface finish requirements (Ra 0.025 µm achievable). Rigorous thermal stability analysis prevents warpage, and all designs undergo cross-functional review against ISO 9001:2015 standards before release. Material selection focuses on premium tool steels like H13, S7, or custom alloys, specified for hardness (50-54 HRC typical), wear resistance, and thermal fatigue performance.

Precision Prototyping & Validation follows, utilizing the exact production-grade steel and CNC processes. We machine prototype cavities and cores on our 5-axis DMG MORI centers, achieving tolerances down to ±0.005 mm. This is not a soft-metal trial; it is a full functional validation under simulated production conditions. Each prototype undergoes comprehensive metrology via Zeiss CONTURA CMMs and optical comparators, verifying all geometric dimensions and critical features. Moldflow results are benchmarked against actual injection trials, analyzing fill patterns, weld lines, and sink marks. Only after achieving 100% conformance to the digital twin and passing stringent first-article inspection (FAI) per AS9102 is the design locked for production. This phase identifies and resolves potential defects before tooling investment scales.

Zero-Defect Mass Production leverages our validated process within a controlled environment. Production occurs on dedicated, monitored CNC machining centers and sinker EDMs, with real-time in-process gauging ensuring dimensional stability. All critical operations employ Statistical Process Control (SPC), tracking Cp/Cpk values continuously. Every mold undergoes 100% post-machining inspection against the FAI baseline, including hardness testing, surface roughness verification, and full assembly functional checks. Final validation includes minimum 500-shot production runs with full part dimensional reporting. Our integrated quality management system, certified to ISO 9001 and IATF 16949, mandates traceability of all materials and processes, ensuring every steel mold shipped meets the zero-defect commitment our global clients require.

| Phase | Key Activities | Typical Tolerances | Critical Quality Controls |

|---|---|---|---|

| Design | CAD/CAM Modeling FEA/CFD Simulation Material Specification | Model: ±0.01 mm Feature: ±0.025 mm | Digital Twin Validation Cross-Functional Review ISO 9001 Compliance |

| Prototyping | Hard Steel Machining (5-axis CNC) Moldflow Validation First Article Inspection | ±0.005 mm Surface: Ra 0.05 µm | CMM Verification (100%) Optical Comparison Production Trial Analysis AS9102 FAI |

| Mass Production | Dedicated CNC/EDM Machining SPC Monitoring Final Assembly Validation | ±0.008 mm Surface: Ra 0.1 µm | Real-Time In-Process Gauging 100% Post-Machining Inspection 500+ Shot Validation IATF 16949 Traceability |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Steel Mold Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-performance, custom-engineered steel molds that meet the most demanding industrial requirements. With over 15 years of precision manufacturing experience, we have established ourselves as a trusted partner for global OEMs, automotive suppliers, and industrial equipment manufacturers. Our integrated approach combines advanced CNC machining, rigorous quality control, and deep metallurgical expertise to produce steel molds that deliver superior durability, dimensional accuracy, and production efficiency.

When you choose to partner with Lead Precision, you gain more than a supplier—you gain a technical collaborator committed to your success. From initial design consultation to final inspection and global logistics, our engineering team works closely with clients to optimize mold performance, reduce cycle times, and ensure seamless integration into existing production lines. We understand that in high-volume manufacturing, even minor imperfections can lead to costly downtime. That’s why every steel mold we produce undergoes comprehensive metrology validation using Zeiss CMM systems and 3D scanning technology, ensuring precision within ±0.002 mm.

Our facility in Wuxi, China, spans over 12,000 square meters and is equipped with state-of-the-art vertical and horizontal machining centers, EDM systems, and vacuum heat treatment furnaces. We work with a wide range of tool steels, including H13, P20, S136, and 1.2344, tailored to your application’s thermal stability, wear resistance, and corrosion protection needs. Whether you require injection molds, die-casting molds, or compression molds for complex metal forming, our team ensures every component meets international standards such as ISO 9001:2015 and IATF 16949.

We pride ourselves on transparency, responsiveness, and on-time delivery. Our project managers provide real-time updates throughout the manufacturing cycle, and we offer full traceability with material certifications, process reports, and post-delivery technical support. With strategic shipping partnerships, we deliver to North America, Europe, and Southeast Asia within 4–6 weeks, depending on complexity.

Below are the key technical capabilities that define our steel mold manufacturing process

| Specification | Detail |

|---|---|

| Maximum Part Size | 2,500 mm × 1,800 mm × 1,200 mm |

| Tolerance Range | ±0.002 mm to ±0.005 mm |

| Surface Finish | Ra 0.1 µm to Ra 0.8 µm (polished or textured) |

| Tool Steel Types | H13, P20, 1.2344, S136, SKD61, 718H |

| Machining Equipment | 5-axis CNC, EDM, CNC Grinding, CMM |

| Quality Standards | ISO 9001:2015, IATF 16949, RoHS |

| Lead Time | 4–12 weeks (based on complexity) |

| Finishing Options | Nitriding, Chrome Plating, PVD Coating, Texturing |

Elevate your production capabilities with steel molds engineered for performance and longevity. Contact us today at [email protected] to discuss your project requirements and receive a detailed technical proposal within 24 hours. Let Wuxi Lead Precision Machinery be your strategic partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.