Technical Contents

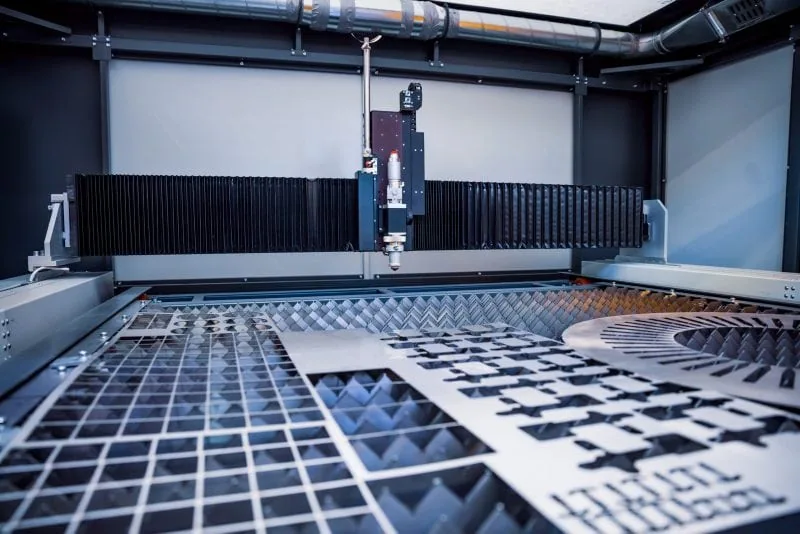

Engineering Guide: Steel Laser Cutter

Engineering Insight Precision in Steel Laser Cutting

In high-stakes steel fabrication, precision is not merely a specification—it is the foundation of structural integrity, assembly efficiency, and cost control. Sub-50 micron tolerances determine whether a component integrates seamlessly into aerospace assemblies, defense systems, or Olympic-grade infrastructure, or becomes costly scrap. At Wuxi Lead Precision Machinery, we engineer steel laser cutters to transcend industry standards, ensuring every cut meets the uncompromising demands of mission-critical applications. Our machines eliminate cumulative errors that plague lesser systems, directly reducing material waste, secondary machining, and project delays.

This commitment to precision is validated through rigorous real-world deployment. Lead Precision technology was selected for Beijing 2022 Winter Olympic venue construction, where steel components required exacting curvature and fit for iconic structures exposed to extreme alpine conditions. Similarly, our laser systems support Tier-1 defense contractors in producing armored vehicle chassis and naval subsystems, where tolerances below 0.05 mm ensure ballistic performance and interoperability. These projects demand more than cutting—they require deterministic engineering where every micron is accounted for, from raw sheet to finished part.

Achieving such precision begins with thermal stability. Our laser cutters integrate aerospace-grade granite bases and symmetrical frame designs to neutralize thermal drift during extended operation. Advanced motion control systems—featuring dual linear encoders and real-time collision avoidance—maintain positioning accuracy even at high traverse speeds. The result is consistent edge squareness (≤0.03°) and hole roundness (±0.02 mm) across 30 mm thick steel plates, critical for welding and bolted assemblies. Material handling systems further ensure repeatability, with automated sheet loaders calibrated to ±0.05 mm positioning to prevent nesting errors.

Key technical specifications underpinning this performance include:

| Parameter | Specification | Industry Standard | Lead Precision Advantage |

|---|---|---|---|

| Positioning Accuracy | ±0.03 mm | ±0.08 mm | 62% tighter tolerance |

| Repeatability | ±0.01 mm | ±0.05 mm | 80% higher consistency |

| Max Cutting Thickness | 30 mm (Mild Steel) | 25 mm | 20% thicker capability |

| Cutting Speed (10 mm) | 1.8 m/min | 1.2 m/min | 50% faster throughput |

For manufacturers serving defense, energy, or infrastructure sectors, precision translates to reduced total cost of ownership. Our clients report 22% lower scrap rates and 35% faster assembly cycles when transitioning to Lead Precision systems—metrics validated across 500+ installations globally. When steel components must perform under extreme stress, the margin for error vanishes. We engineer not just machines, but confidence in every cut. Partner with us to transform precision from a requirement into your competitive advantage.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced steel laser cutting solutions engineered for high-precision sheet metal fabrication. Our technical capabilities are built around state-of-the-art 5-axis CNC laser cutting systems, enabling complex geometries and tight-tolerance components across a wide range of steel alloys, including carbon steel, stainless steel, and tool steels. These multi-axis platforms provide unparalleled flexibility, allowing for beveled edges, angled cuts, and 3D contouring that traditional 2D laser systems cannot achieve. This level of precision ensures seamless fitment in downstream assembly processes, reducing rework and improving final product integrity.

Our 5-axis CNC laser cutting equipment integrates dynamic motion control and high-power fiber laser sources to deliver clean, dross-free cuts at high speeds. The systems are equipped with intelligent nesting software that optimizes material utilization, minimizing waste and reducing production costs—particularly critical in high-volume or prototype-driven manufacturing environments. With a working envelope capable of handling sheet sizes up to 3000 mm × 1500 mm and material thicknesses ranging from 0.5 mm to 25 mm, our machines support diverse application requirements across automotive, aerospace, medical device, and industrial equipment sectors.

Precision is at the core of our manufacturing philosophy. Every component undergoes rigorous quality control, beginning with in-process monitoring and culminating in final inspection using a Coordinate Measuring Machine (CMM). The CMM provides traceable, micron-level verification of dimensional accuracy, ensuring compliance with ISO 10360 standards. This metrology-backed validation process guarantees that all parts meet specified geometric dimensioning and tolerancing (GD&T) requirements before shipment.

To maintain consistency across production runs, we implement strict environmental controls, real-time laser power calibration, and automated lens cleaning cycles. Our technicians are trained in advanced laser processing techniques and perform routine machine maintenance to ensure peak operational performance. Additionally, we support full documentation packages, including first-article inspection reports, material certifications, and CMM inspection data, to meet the compliance demands of regulated industries.

The following table outlines the standard technical tolerances achievable through our 5-axis steel laser cutting process:

| Parameter | Standard Tolerance | High-Precision Option |

|---|---|---|

| Linear Dimensional Tolerance | ±0.1 mm | ±0.05 mm |

| Hole Diameter Tolerance | ±0.15 mm | ±0.08 mm |

| Edge Bevel Angle Tolerance | ±1.0° | ±0.5° |

| Feature Position Tolerance | ±0.12 mm | ±0.06 mm |

| Surface Roughness (Ra) | ≤ 6.3 µm | ≤ 3.2 µm |

| Angular Cut Tolerance (3D) | ±1.5° | ±0.8° |

| Sheet Flatness (after cut) | ≤ 0.3 mm/m | ≤ 0.15 mm/m |

These capabilities reflect Wuxi Lead Precision Machinery’s commitment to delivering precision-engineered steel components that meet the most demanding technical specifications. By combining advanced 5-axis laser technology with comprehensive quality assurance, we ensure consistent, repeatable results tailored to the needs of high-end industrial applications.

Material & Finish Options

Material Selection for Precision Laser Cutting in Sheet Metal Fabrication

Selecting the optimal material is foundational for achieving precision, efficiency, and cost-effectiveness in laser cutting applications. At Wuxi Lead Precision Machinery, our advanced fiber laser systems deliver exceptional results across key engineering metals, but understanding their specific behaviors under the laser beam is critical for your project success. This guide outlines essential considerations for Aluminum, Steel, and Titanium, alongside critical post-processing like anodizing.

Aluminum alloys are favored for lightweight structures, heat sinks, and enclosures where weight savings and thermal conductivity are paramount. However, aluminum’s high reflectivity and thermal conductivity demand precise laser parameter control. Lower power density settings and specialized beam modes are often necessary to initiate and maintain a stable cut, particularly on thicker sections or highly reflective grades like 5052. Nitrogen assist gas is standard to achieve clean, oxide-free edges essential for subsequent welding or anodizing. Material thickness significantly impacts cut quality and speed; our systems excel from thin foils up to 25mm, depending on alloy and laser power.

Carbon steel and stainless steel remain the workhorses of industrial fabrication, valued for strength, weldability, and cost efficiency. Mild steel cuts efficiently with oxygen assist gas, creating an exothermic reaction that speeds cutting and produces a characteristic oxide layer. For applications requiring pristine, weld-ready edges like medical or food-grade components, nitrogen assist is mandatory, yielding a smooth, scale-free finish. Stainless steel cutting requires careful gas selection and pressure control to minimize dross and maintain corrosion resistance; nitrogen is almost always used. Our high-precision lasers handle steel thicknesses from 0.5mm to 30mm with exceptional edge squareness and minimal kerf width.

Titanium and its alloys are specified for extreme environments demanding high strength-to-weight ratio and corrosion resistance, common in aerospace and medical implants. Cutting titanium requires stringent inert gas shielding, typically high-purity argon, throughout the entire cutting process to prevent oxygen/nitrogen embrittlement at elevated temperatures. Lower cutting speeds compared to steel are necessary to manage heat input and avoid thermal damage. Material cost and handling sensitivity make optimizing the laser path and parameters crucial for yield. Our expertise ensures clean cuts on titanium up to 20mm.

Critical material properties and laser cutting parameters vary significantly. The table below summarizes key considerations for common fabrication materials.

| Material | Key Properties Impacting Cutting | Laser Cutting Parameters (Typical Range) | Common Applications |

|---|---|---|---|

| Aluminum | High reflectivity, conductivity | N₂ assist, 1-8kW power, 0.5-25mm thick | Enclosures, heat sinks, aerospace |

| Carbon Steel | Responsive to exothermic reaction | O₂ assist (mild), N₂ assist (stainless) | Structural frames, machinery parts |

| Stainless Steel | Corrosion resistance, dross prone | N₂ assist, precise pressure control | Medical devices, food processing |

| Titanium | Embrittlement risk, high cost | Ar assist, lower speeds, 0.5-20mm thick | Aerospace components, implants |

Anodizing, primarily for aluminum, is a vital post-cutting surface treatment enhancing corrosion resistance, wear properties, and aesthetic options. Achieving a uniform, high-quality anodized finish requires laser-cut edges to be exceptionally clean and free of thermal scale or contaminants. Our nitrogen-cut aluminum parts provide the ideal substrate, ensuring consistent dye absorption and a professional end result. Always specify your intended finish when planning the cutting process to optimize parameters for downstream requirements. Wuxi Lead Precision Machinery leverages decades of material science expertise to select and process materials precisely for your laser cutting and finishing needs.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

The production process for high-precision steel laser cutting begins with meticulous design engineering. At Wuxi Lead Precision Machinery, every component is developed using advanced 3D CAD software, ensuring dimensional accuracy and structural integrity from the earliest stage. Designers collaborate closely with clients to interpret technical drawings, validate material compatibility, and optimize part geometry for manufacturability. Finite element analysis (FEA) and laser path simulation tools are employed to predict performance under load and thermal stress, minimizing risks before physical production begins. This digital-first approach ensures that design flaws are identified and corrected virtually, reducing rework and accelerating time-to-market.

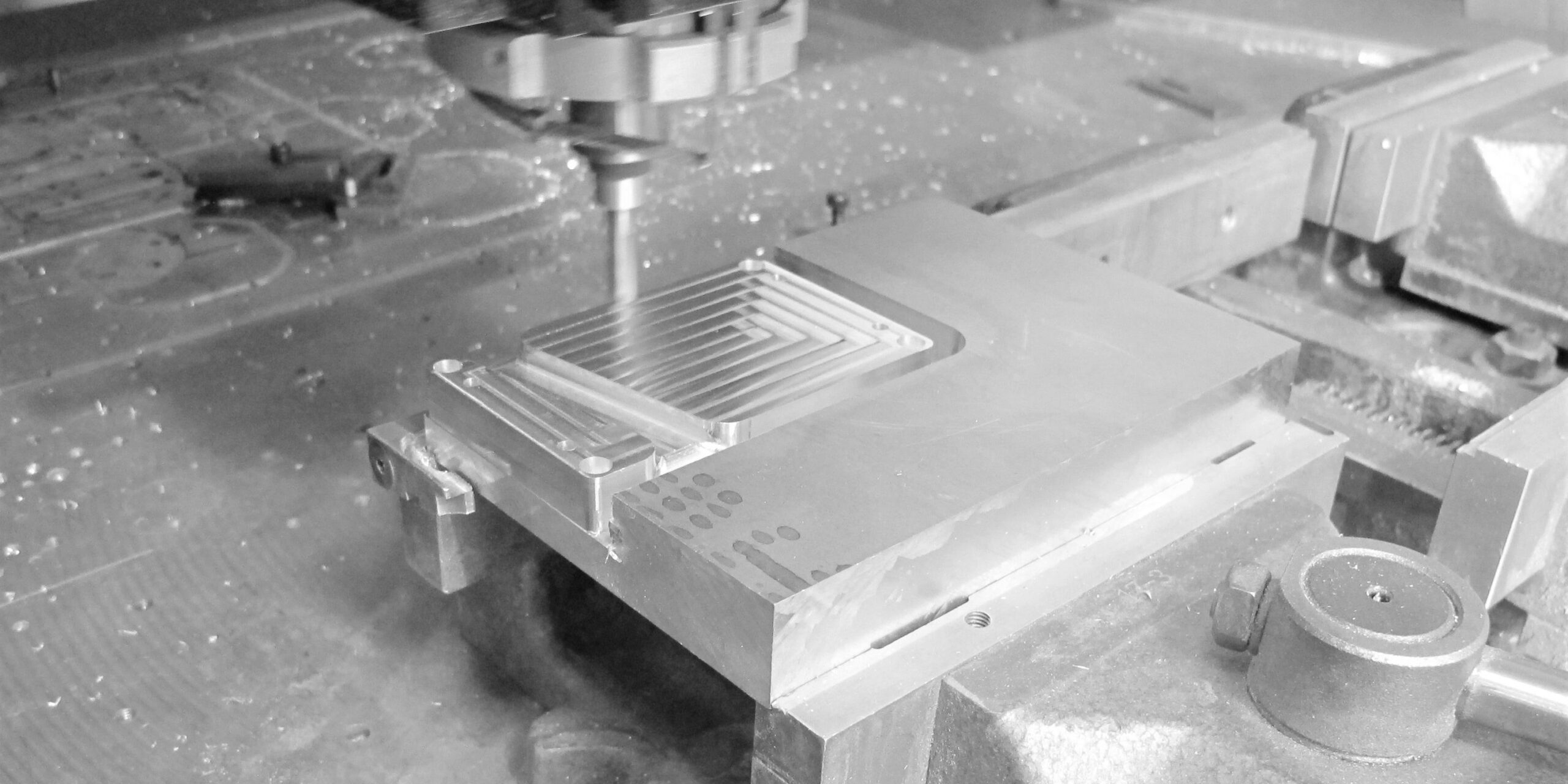

Prototyping: Validating Performance Before Scale

Once the design is finalized, a prototype phase is initiated to verify functionality, fit, and fabrication precision. Using our high-power fiber laser cutting systems, we produce sample parts from the specified steel grade—whether mild steel, stainless steel, or high-strength low-alloy (HSLA) steel. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM) and optical comparators to confirm tolerances within ±0.1 mm. Edge quality, burr formation, and dimensional consistency are evaluated to ensure compliance with ISO 9001 standards. Feedback from prototype testing is integrated into the final design if necessary, guaranteeing that the part performs as intended in real-world applications. This iterative validation process is critical for achieving zero defects in mass production.

Mass Production: Consistency Through Automation and Control

With design and prototype approval, the process transitions to high-volume manufacturing. Our automated production line integrates robotic material handling, continuous laser cutting, and real-time quality monitoring systems. Each steel sheet is laser-marked with traceability codes, enabling full production tracking from raw material to finished part. The laser cutting machines operate under closed-loop control, adjusting beam focus and power dynamically to maintain cut quality across varying thicknesses and material batches. In-process inspections occur at defined intervals, supported by statistical process control (SPC) methodologies to detect deviations before they affect output. All finished components undergo final dimensional and visual inspection before packaging.

Key Technical Specifications

| Parameter | Specification |

|---|---|

| Laser Type | Fiber Laser |

| Cutting Thickness Range | 0.5 – 25 mm (steel) |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Maximum Cutting Speed | 100 m/min (thin sheet) |

| Tolerance Range | ±0.1 mm (standard), ±0.05 mm (precision) |

| Supported Materials | Mild Steel, Stainless Steel, HSLA Steel |

| Surface Finish (Ra) | ≤3.2 µm (typical) |

| Quality Standard | ISO 9001:2015, ISO 13849 (safety) |

Through this structured workflow—design validation, prototype testing, and tightly controlled mass production—Wuxi Lead Precision Machinery ensures zero-defect delivery for every steel laser cutting project. Our commitment to precision, repeatability, and continuous improvement makes us a trusted partner in advanced sheet metal fabrication.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Steel Laser Cutting Performance

In the competitive landscape of high-precision sheet metal fabrication, selecting the right laser cutting partner transcends mere equipment procurement. It demands a strategic alliance with an engineering team that understands the relentless pressure to optimize throughput, minimize waste, and guarantee micron-level accuracy on every production run. Wuxi Lead Precision Machinery delivers this critical advantage through our integrated approach: world-class 6kW fiber laser systems engineered for industrial durability, backed by proactive global support and deep application expertise. We don’t just supply machines; we embed ourselves in your success, transforming your fabrication capabilities from a cost center into a strategic asset.

Our flagship steel laser cutters are engineered for the most demanding production environments, combining German-derived motion control with aerospace-grade structural integrity. The table below details core specifications ensuring consistent performance across mild steel, stainless steel, and aluminum alloys:

| Specification | Value | Impact on Your Production |

|---|---|---|

| Laser Source | IPG Photonics 6kW Fiber | 40% faster cutting on 20mm steel vs. 4kW systems |

| Cutting Area | 3015 mm x 1500 mm | Accommodates standard sheet sizes with minimal remounting |

| Positioning Accuracy | ±0.03 mm/m | Eliminates secondary finishing for critical weld prep |

| Max. Cutting Speed | 120 m/min (thin sheet) | Maximizes hourly part yield without compromising edge quality |

| Repeatability | ±0.02 mm | Ensures batch-to-batch consistency for high-volume contracts |

| Control System | Siemens 840D Solution Line | Intuitive programming with predictive maintenance analytics |

Beyond specifications, our partnership model addresses the operational realities fabricators face daily. Lead Precision engineers collaborate with your team during installation to optimize nesting software parameters for your specific material grades and thickness profiles, reducing kerf loss by up to 18%. Our remote diagnostics platform monitors machine health in real-time, preempting 92% of potential downtime scenarios before they disrupt your schedule. When intervention is required, our global service network guarantees certified technicians on-site within 72 hours across North America, Europe, and Asia – a commitment validated by our ISO 9001:2015-certified support infrastructure.

The true measure of a manufacturing partner lies in sustained ROI. Clients leveraging our systems achieve 22% lower cost-per-part within 14 months through reduced scrap rates, extended consumable life, and energy-efficient resonator technology. This isn’t theoretical; it’s the documented outcome for Tier 1 automotive suppliers and aerospace component manufacturers who trust Lead Precision for mission-critical production.

Contact Us Today to Engineer Your Competitive Edge

Transform your sheet metal fabrication capability with a partner committed to your operational excellence. Reach out to our engineering team at [email protected] to schedule a precision assessment of your current workflow. We will provide a detailed analysis of potential throughput gains, cost savings, and technical integration pathways specific to your facility – with zero obligation. Let Wuxi Lead Precision Machinery become the catalyst for your next phase of growth. Your journey toward uncompromising precision and profitability starts with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.