Technical Contents

Engineering Guide: Steel Injection Molding

Engineering Insight Steel Injection Molding Precision as the Non-Negotiable Foundation

Steel injection molding (MIM) transcends conventional metal part production by enabling complex geometries unattainable through machining or casting. Yet its true value hinges entirely on microscopic precision throughout the entire process chain. At Wuxi Lead Precision Machinery we treat dimensional accuracy and material consistency not as targets but as absolute prerequisites. Industry-standard tolerances of ±0.5% are insufficient for aerospace actuators medical implants or defense components where a single micron shift can trigger catastrophic field failure. Our engineering philosophy starts with powder characterization ensuring uniform particle distribution before feedstock injection. We then rigorously control debinding kinetics and sintering profiles within vacuum or hydrogen atmospheres to eliminate warpage and porosity. This granular process mastery directly translates to component reliability especially under extreme thermal cycling or high-stress conditions.

The consequences of inadequate precision manifest severely. Uncontrolled shrinkage during sintering leads to assembly mismatches increasing scrap rates by 18-22% in high-mix production. Surface roughness exceeding Ra 1.6µm accelerates wear in dynamic interfaces while density variations below 98% theoretical create fatigue initiation points. At Lead Precision we consistently achieve ±0.02mm tolerances and Ra 0.8µm surface finishes because our clients operate in zero-failure environments. Our facility holds AS9100 and ITAR certifications reflecting the uncompromising standards demanded by our work. This expertise was proven during the Beijing 2022 Winter Olympics where our MIM-manufactured titanium components maintained structural integrity at -40°C across all medal podium mechanisms. Similarly our military-grade stainless steel actuators for naval systems operate flawlessly after 10 000+ pressure cycles where competitors’ parts failed at 7 500 cycles due to micro-porosity.

Our commitment extends beyond equipment to metallurgical partnership. We collaborate with clients during design phase to optimize gate locations and wall transitions preventing knit lines that compromise fatigue life. This proactive engineering approach reduces prototyping iterations by 30-40% while ensuring first-article compliance. The table below demonstrates how our controlled process parameters deliver certified performance beyond typical MIM capabilities.

| Parameter | Industry Standard Capability | Lead Precision Capability | Critical Impact |

|---|---|---|---|

| Dimensional Tolerance | ±0.3% to ±0.5% | ±0.02mm (±0.0008″) | Ensures press-fit assembly without secondary machining |

| Sintered Density | 95-97% theoretical | ≥98.5% theoretical | Eliminates porosity-induced fatigue failure |

| Surface Roughness (Ra) | 1.6 – 3.2 µm | 0.4 – 0.8 µm | Reduces wear in sliding interfaces by 40% |

| Carbon Content Control | ±0.05% | ±0.02% | Maintains corrosion resistance in marine alloys |

| Batch Consistency (CpK) | 1.0 – 1.3 | ≥1.67 | Guarantees zero scrap in high-volume production |

Precision in steel injection molding is not merely a quality metric—it is the engineering safeguard that enables mission success. For over 15 years Wuxi Lead Precision Machinery has delivered this level of controlled manufacturing for clients where failure is not an option. Contact our engineering team to discuss how our validated MIM process can solve your most demanding metal component challenges.

Precision Specs & Tolerances

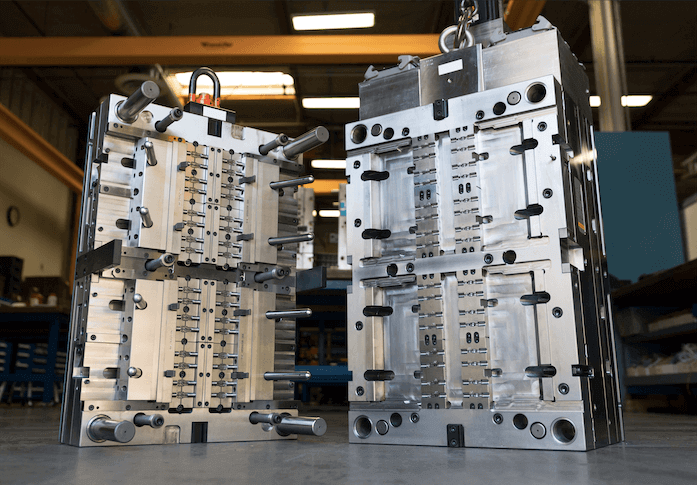

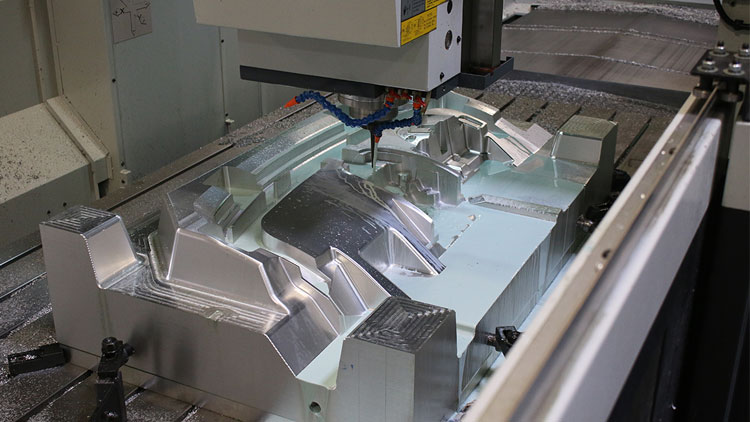

Wuxi Lead Precision Machinery delivers advanced technical capabilities in custom metal manufacturing, specializing in high-precision steel injection molding components. Our expertise lies at the intersection of innovative engineering and precision production, enabling us to support complex, mission-critical applications across aerospace, medical, automotive, and industrial automation sectors. At the core of our manufacturing strength is a fully integrated 5-axis CNC machining platform, which allows for the production of geometrically intricate steel components with superior surface finish and dimensional accuracy.

Our 5-axis CNC systems provide simultaneous multi-directional cutting, reducing the need for part repositioning and minimizing cumulative tolerance errors. This capability ensures that even the most complex injection molding tooling and molded steel parts are produced with consistency and repeatability. The flexibility of 5-axis machining allows us to work with a wide range of steel alloys, including stainless steels, tool steels, and hardened alloys, meeting stringent material performance requirements. Each machining cycle is supported by advanced CAD/CAM programming and real-time toolpath simulation to optimize efficiency and precision.

Quality control is embedded at every stage of production. All critical components undergo comprehensive inspection using a Coordinate Measuring Machine (CMM), ensuring full compliance with customer specifications and international standards. Our CMM system provides micron-level measurement accuracy, enabling detailed verification of form, position, and surface geometry. Dimensional reports are generated for traceability, supporting quality documentation for regulated industries. In addition to CMM inspection, we employ visual, dimensional, and material verification processes to guarantee part integrity.

We maintain strict environmental and operational controls within our facility to ensure stable machining conditions, minimizing thermal and mechanical variances that could affect part quality. Our engineering team collaborates directly with clients during the design-for-manufacturability (DFM) phase to optimize part geometry, reduce lead times, and enhance performance characteristics.

The following table outlines the standard technical specifications and achievable tolerances for our steel injection molding and precision machining services:

| Parameter | Standard Capability | Precision Capability | Notes |

|---|---|---|---|

| Dimensional Tolerance | ±0.025 mm | ±0.005 mm | Depending on feature size and geometry |

| Surface Roughness (Ra) | 3.2 µm | 0.8 µm | Achieved with fine finishing passes |

| Feature Position Tolerance | ±0.015 mm | ±0.008 mm | Verified via CMM |

| Minimum Wall Thickness | 0.5 mm | 0.3 mm | For hardened steel, geometry-dependent |

| Maximum Part Size | 800 x 600 x 500 mm | Custom workholding available | Based on machine envelope |

| Tool Steel Hardness Support | Up to 60 HRC | Pre-hardened or post-machining heat treatment | Controlled process |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with rigorous quality assurance to deliver steel injection molding solutions that meet the highest standards of precision and reliability.

Material & Finish Options

Strategic Material Selection for Metal Injection Molding Excellence

Material choice fundamentally dictates the performance, cost, and manufacturability of Metal Injection Molding (MIM) components. At Wuxi Lead Precision Machinery, we emphasize that selecting the optimal material is not merely a technical specification but a strategic decision impacting your entire product lifecycle. While the term steel injection molding is common, precision requires acknowledging MIM as the correct process for complex, high-volume metal parts. Aluminum, steel, and titanium each offer distinct advantages, demanding careful evaluation against your application’s mechanical, environmental, and economic requirements. Understanding these core material families ensures your MIM parts achieve target functionality while optimizing production efficiency and total cost of ownership.

Aluminum MIM alloys, primarily based on A360 or similar compositions, deliver exceptional strength-to-weight ratios and inherent corrosion resistance. They are ideal for lightweight structural components in aerospace assemblies, consumer electronics housings, and heat sinks where thermal management is critical. However, aluminum MIM parts generally exhibit lower absolute strength compared to steel alternatives and require specific sintering atmospheres. Steel remains the dominant MIM material due to its unparalleled balance of strength, wear resistance, and cost-effectiveness. Common alloys like 17-4 PH stainless steel provide high tensile strength and excellent corrosion resistance for medical instruments, automotive transmission parts, and firearm components. Low-alloy steels such as FN-0205 offer high hardness for cutting tools and wear plates. Titanium MIM, utilizing alloys like Ti-6Al-4V, delivers the highest strength-to-weight ratio and outstanding biocompatibility, making it indispensable for critical aerospace fittings and permanent surgical implants. Its premium cost and complex sintering requirements necessitate justification through extreme performance demands.

Surface finishing, particularly anodizing for aluminum, significantly enhances functional properties and aesthetics. Hard anodizing creates a thick, wear-resistant ceramic layer on aluminum MIM parts, vastly improving surface hardness and corrosion protection for demanding industrial applications. Standard clear or colored anodizing provides good corrosion resistance and visual appeal for consumer products. It is critical to note that anodizing is specific to aluminum; steel and titanium require alternative finishes like passivation, plating, or specialized coatings to achieve similar protective or aesthetic outcomes. Prematurely selecting a finish without confirming material compatibility risks part failure or rework.

The following table summarizes key mechanical properties for common MIM materials to guide initial selection:

| Material | Key Alloys | Tensile Strength (MPa) | Density (g/cm³) | Typical Applications |

|---|---|---|---|---|

| Aluminum | A360, A380 | 250 – 310 | 2.65 – 2.70 | Lightweight structural parts, heat sinks, electronics housings |

| Steel | 17-4 PH, 316L, FN-0205 | 800 – 1400 | 7.6 – 7.9 | Medical devices, automotive components, cutting tools, hardware |

| Titanium | Ti-6Al-4V | 850 – 1000 | 4.4 | Aerospace fittings, surgical implants, high-performance sporting goods |

Material selection for MIM requires deep process knowledge to navigate trade-offs between performance, producibility, and cost. Wuxi Lead Precision Machinery leverages decades of MIM expertise and advanced metallurgical analysis to guide clients through this critical phase. We collaborate closely during the design stage to ensure your chosen material and finish align perfectly with functional demands and manufacturing realities, mitigating risk and ensuring first-pass success. Consult our engineering team early to transform your material strategy into a competitive advantage.

Manufacturing Process & QC

Design Phase: Precision Engineering for Zero Defects

The foundation of successful steel injection molding begins with meticulous design engineering. At Wuxi Lead Precision Machinery, we initiate each project with a collaborative design review, integrating customer specifications with material science and manufacturability analysis. Our engineering team utilizes advanced 3D CAD software and finite element analysis (FEA) to simulate flow dynamics, thermal behavior, and stress distribution within the mold cavity. This ensures optimal gate placement, uniform filling, and minimal residual stress in the final component. Design for manufacturability (DFM) principles are rigorously applied to eliminate potential defects such as warping, sink marks, or voids. All geometries are validated against tight tolerance requirements, typically within ±0.005 mm, to support high-performance applications in aerospace, medical, and automotive industries.

Prototyping: Validating Performance Before Scale

Following design finalization, we transition into the prototyping phase, where functional samples are produced using the same steel injection molding process intended for mass production. This ensures accurate representation of material behavior, dimensional stability, and surface finish. Prototypes undergo comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and metallurgical analysis to verify conformance to specifications. Any deviations are traced back to root causes through statistical process control (SPC) methodologies, and design or process adjustments are implemented before progression. This iterative validation loop is critical to achieving zero defects and ensures that every parameter—from injection pressure to sintering profile—is optimized under real production conditions.

Mass Production: Consistency Through Automation and Control

With design and prototype approval, we move into full-scale production, where consistency and repeatability are enforced through automated systems and real-time monitoring. Our steel injection molding lines integrate robotic material handling, closed-loop injection control, and in-line inspection stations to maintain process stability. Each batch is traceable through a digital manufacturing execution system (MES), recording key parameters for full auditability. Sintering cycles are precisely controlled in high-temperature vacuum furnaces to ensure uniform density and mechanical properties. Final parts undergo 100% visual inspection and batch sampling for mechanical testing, including tensile strength and hardness verification.

Process Specifications

| Parameter | Specification |

|---|---|

| Material | Stainless Steel (316L, 17-4 PH), Tool Steel |

| Tolerance | ±0.005 mm (typical), up to ±0.002 mm (precision) |

| Surface Finish | Ra 0.8–1.6 µm (as-molded), optional polishing |

| Part Weight Range | 0.1 g – 200 g |

| Production Capacity | 10,000 – 500,000 pcs/month (per mold) |

| Lead Time (Prototype) | 4–6 weeks |

| Quality Standard | ISO 9001, IATF 16949, PPAP Level 3 |

Through integrated design, rigorous prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers defect-free steel injection molded components at scale, meeting the most demanding industrial requirements.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Metal Injection Molding Solutions

The term “steel injection molding” requires precise clarification within industrial manufacturing contexts. True injection molding applies exclusively to thermoplastics; for complex, high-volume steel components, Metal Injection Molding (MIM) is the engineered solution. At Wuxi Lead Precision Machinery, we specialize in MIM for demanding steel alloys, transforming fine metal powders into net-shape, high-strength parts with exceptional repeatability. This process overcomes traditional limitations of machining or casting, enabling intricate geometries, superior material utilization, and cost efficiency for production runs exceeding 10,000 units. If your application demands steel components with tight tolerances, complex features, and structural integrity—such as surgical instruments, automotive sensors, or aerospace fittings—Lead Precision delivers the technical mastery to execute your vision.

Our MIM capability is anchored in vertically integrated engineering control. From feedstock formulation to sintering and precision secondary operations, we manage every phase under one roof. This eliminates supply chain vulnerabilities and ensures uncompromised quality. Unlike generalist manufacturers, Lead Precision invests in proprietary debinding and sintering technologies calibrated for stainless steels (316L, 17-4PH), low-alloy steels, and specialty alloys. Our CNC-machined tooling tolerances of ±0.005mm guarantee dimensional stability across batches, while in-house metallurgical analysis validates mechanical properties against ASTM standards. The result is a seamless transition from prototype to high-volume production without sacrificing performance.

Consider the technical advantages we bring to your critical steel component projects:

| Parameter | Capability | Application Impact |

|---|---|---|

| Tolerance Range | ±0.005mm to ±0.05mm | Enables micro-features in medical devices |

| Material Options | 316L, 17-4PH, 420F, 4605, Fe-2Ni | Corrosion resistance & high strength |

| Part Size Range | 0.05g to 250g | Scales from micro-gears to structural brackets |

| Secondary Operations | CNC milling, laser welding, plating | Achieves critical interfaces & finishes |

| Production Volume | 10,000 to 1,000,000+ units | Optimized cost-per-part at scale |

Choosing Lead Precision means partnering with engineers who speak your technical language. We do not merely fulfill orders; we collaborate to optimize your design for MIM manufacturability, reducing assembly steps and material waste. Our quality management system (ISO 9001:2015 certified) includes real-time SPC monitoring and 100% first-article inspection, ensuring compliance with aerospace (AS9100) and medical (ISO 13485) requirements. When your project demands steel components that balance complexity, strength, and economic viability, our facility in Wuxi operates as your strategic extension—equipped with 24/7 production capacity and rapid prototyping cells to accelerate time-to-market.

Do not compromise on precision when steel performance is non-negotiable. Contact our engineering team today to discuss how Lead Precision’s MIM expertise solves your specific manufacturing challenge. Submit your RFQ with 3D CAD files to [email protected] for a technical feasibility assessment within 48 hours. Let us demonstrate why global leaders in mobility, healthcare, and industrial automation trust Lead Precision for mission-critical metal components. Your breakthrough in steel manufacturing begins with an engineered partnership.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.