Lead Stainless Steel CNC Machining Service in China

Tolerance: 0.005 mm maximum

Steel Grades: 1045, 1215, 4130, 4140, 4340, A514

Finishing: Powder Coating, Nickel Plating, Carburizing, Bead Blasting

Equipment: 5 Axis CNC Machinery

CNC Steel Machining Services You Can Get

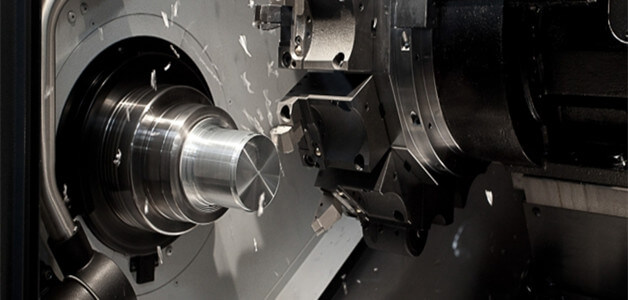

Steel CNC Turning

With our turning services, you can get precisely machined cylindrical and symmetrical components that are durable, and ready for immediate use.

Tolerance: ±0.005 inches

Applications: Cylindrical components like shafts, pins, and custom fasteners

Steel CNC Milling

We provide high speed milling services for your complex 2D or 3D shapes with our rotating multi point cutting tools that ensure precise dimensional accuracy.

Tolerance: ±0.01 inches

Applications: Components such as brackets, housings, and support structures

Steel CNC Grinding

For high-performance components, choose our grinding services that prepare steel parts for additional post-processing treatments and to meet precise tolerance requirements.

Tolerance: Surface finishes as fine as Ra 0.2 μm and dimensional tolerances of ±0.002 inches

Applications: For achieving ultra-smooth surfaces on machine tools, precision instruments, and molds

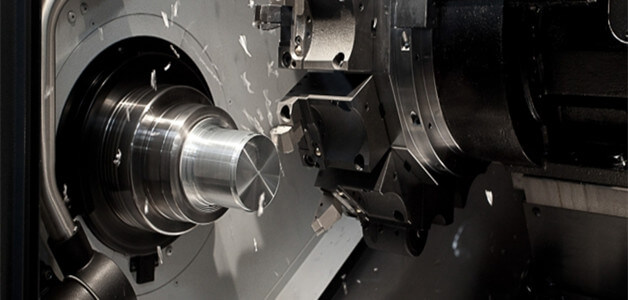

Multi Axis CNC Steel Machining

With our advanced 5 axis steel CNC machinery, we deliver components with highly complex geometries and intricate parts ensuring both efficiency and precision.

Tolerance: ±0.005 inches

Applications: For producing complex parts with multiple axes of movement, such as turbine components and medical implants

Steel Grades We Use for CNC Machining

Choose from our steel material range

Grade 1045 steel CNC machining for manufacturing parts such as shafts, bolts, and gears.

Yield Tensile Strength: 450 MPa

Hardness (Brinell): 170

Elongation at Break: 12%

Commonly used for high speed production of components like hose fittings, couplings, and studs.

Yield Tensile Strength: 415 MPa

Hardness (Brinell): 167

Elongation at Break: 10%

For critical components like aircraft engine parts and high-performance gears in the aerospace and automotive industries.

Yield Tensile Strength: 460 MPa

Hardness (Brinell): 217

Elongation at Break: 20%

Used for components such as spindles, gears, shafts, and bolts in high-stress applications in the aerospace, automotive, and oil and gas industries.

Yield Tensile Strength: 655 MPa

Hardness (Brinell): 197

Elongation at Break: 19%

Good for heavy-duty aircraft landing gear, high-stress engine components, and crankshafts in the aerospace and automotive industries.

Yield Tensile Strength: 710-930 MPa

Hardness (Brinell): 217-260

Elongation at Break: 18-20%

Used in the construction of cranes, mining equipment, and heavy-duty truck frames in the construction, mining, and freight transport industries.

Yield Tensile Strength: 690 MPa minimum

Hardness (Brinell): 235-293

Elongation at Break: 18%

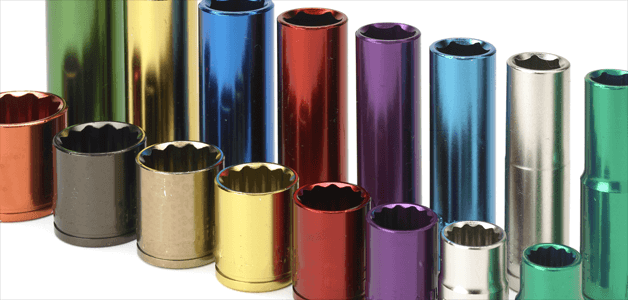

Surface Finishing and Post-Processing

Choose Lead Steel CNC Machining for the best post-processing treatments to enhance their durability, appearance, or performance.

Powder Coating

We use this technique to form a protective, durable layer ideal for harsh environments. It increases corrosion resistance and provides a smooth, attractive finish.

Carburizing

This process hardens the surface of steel parts, significantly increasing their wear resistance. Useful for components to be subjected to high levels of friction.

Nickel Plating

Electroplating a thin layer of nickel onto the surface to enhance resistance to corrosion and wear. It is suitable for both functional and decorative applications.

Bead Blasting

We use it to smooth the surface of steel parts, removing any burrs or sharp edges. It improves the surface quality for additional treatments or ensuring a uniform finish.

Where Our CNC Machined Steel Are Used

Automation

We machine 4140 steel into precision gears, shafts, and axles for high-performance engines and transmissions.

Aerospace

4340 steel components like landing gear and crankshafts meet exacting tolerances of ±0.003 inches for strength and reliability.

Construction & Mining

Using A514 steel, we produce heavy-duty structural parts like crane booms and mining equipment frames with tolerances up to ±0.01 inches.

Why Choose Lead Stainless Steel CNC Machining China

Advanced Equipment

We use the latest CNC technology to produce parts with unparalleled accuracy.

Precision

Our advanced CNC steel cutting machines and experienced technicians ensure that each part is manufactured with the highest level of accuracy.

Versatility

We work with a wide range of steel grades, offering solutions for industries ranging from automotive and aerospace to medical devices.

Efficiency

From prototyping to high-volume production, we deliver projects on time and within budget, ensuring minimal downtime for your operations.

Quality Assurance

Every part undergoes rigorous quality checks to ensure it meets your exact specifications before it leaves our facility.

Expert Support

Our team is here to provide guidance on material selection, machining processes, and finishing options to ensure your project’s success.

Contact

At Lead Precision Machinery, we deliver CNC machined steel components for professionals in the automotive, aerospace, medical, electronic, and other industries with precise CNC steel needs.

Our Steel CNC machining professionals are skilled in turning, milling, drilling, and grinding. We also provide small and large scale multi axis machining services along with top-notch surface finishing on demand.

FAQ

Can a CNC machine cut stainless steel?

Yes, CNC machining equipment is used all over the world to cut metal including steel for precise and accurate shapes.

What is the best steel for CNC machining?

That depends on your needs. 1045 steel is good for manufacturing, A514 is good for construction and mining, 4140 and 4340 are best for automotive and aerospace industries.

How thick or thin can steel CNC machines cut?

Our 5 axis CNC machinery can cut as thin as 0.06 inches. Other low cost machinery can cut steel at a 12 mm thickness or more depending on your needs.