Technical Contents

Engineering Guide: Steel 3D Printing Service

Engineering Insight: Steel 3D Printing Service – Precision as a Standard

In the realm of advanced manufacturing, steel 3D printing has evolved from a prototyping novelty into a cornerstone of high-performance, mission-critical production. At Wuxi Lead Precision Machinery, we treat steel additive manufacturing not merely as a fabrication method, but as an engineering discipline where precision defines success. Our approach integrates metallurgical science, computational modeling, and rigorous process control to deliver components that meet the exacting demands of aerospace, defense, and high-end industrial applications.

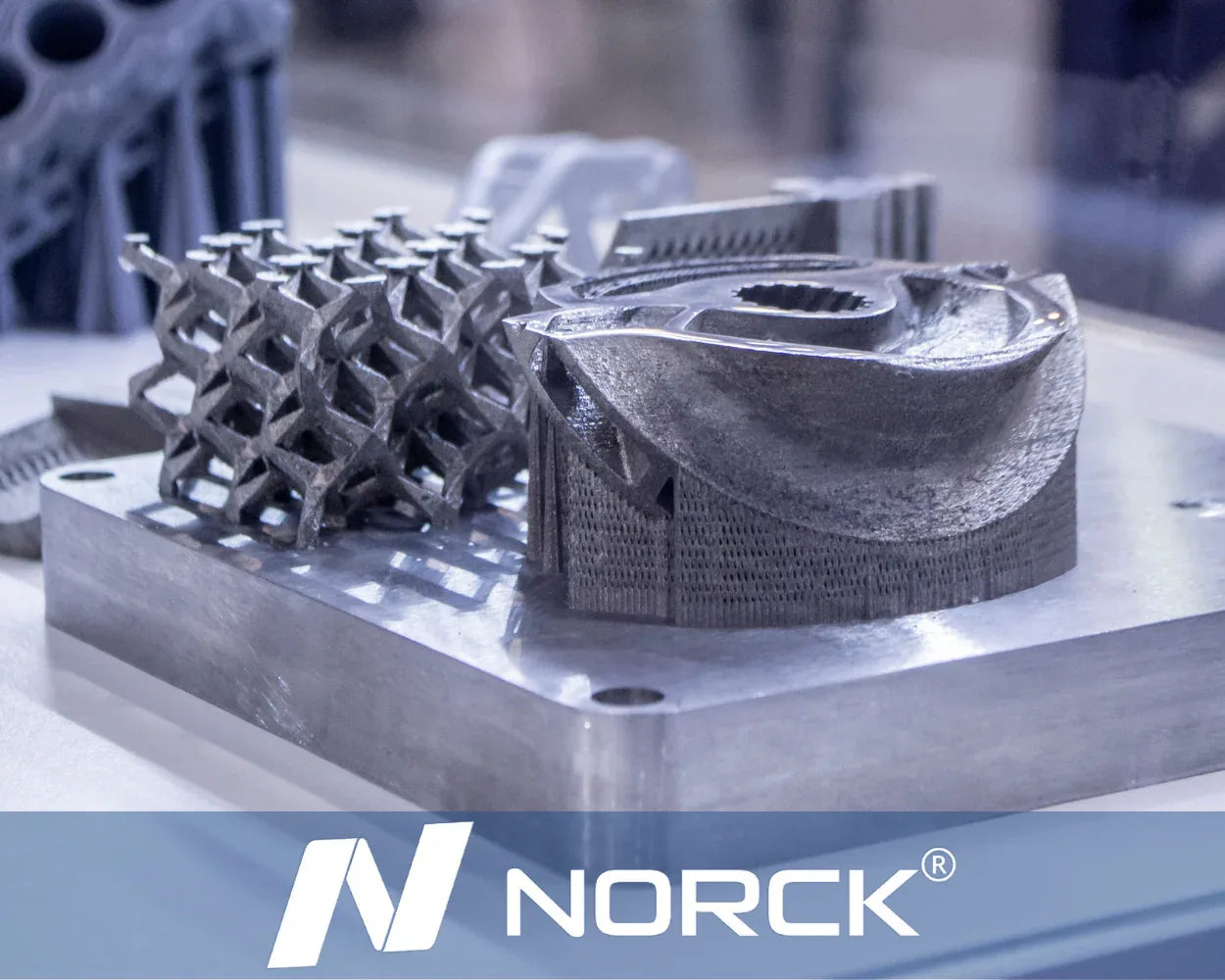

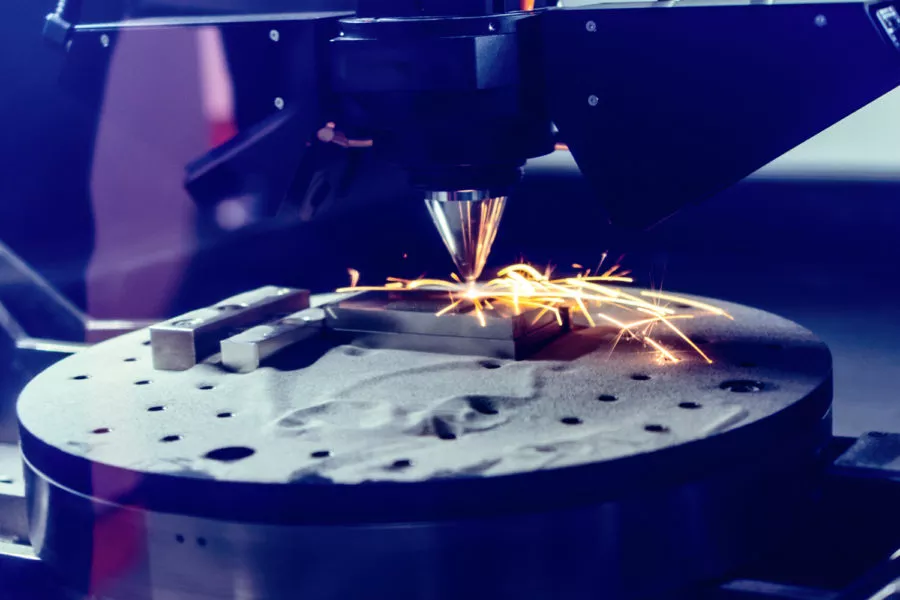

Precision in steel 3D printing extends beyond dimensional accuracy. It encompasses repeatability, material integrity, surface consistency, and geometric complexity—all of which are non-negotiable in sectors where failure is not an option. At Lead Precision, our in-house developed printing systems utilize laser powder bed fusion (LPBF) technology with real-time melt pool monitoring and adaptive layer correction. This ensures that each build adheres to micron-level tolerances and maintains mechanical properties consistent with forged equivalents.

Our expertise is validated through direct involvement in projects for the Chinese Olympic teams and military R&D units. For the Olympics, we engineered lightweight titanium and stainless steel components for high-speed sleds and training apparatuses, where every gram and micron impacted athlete performance. In military applications, we produced high-strength, corrosion-resistant steel parts for unmanned systems operating in extreme environments. These engagements demanded not only technical excellence but also full traceability, certification, and compliance with national defense standards.

What sets our steel 3D printing service apart is our closed-loop quality assurance system. From raw material sourcing to final post-processing—including hot isostatic pressing (HIP), precision CNC machining, and surface finishing—every stage is monitored and documented. We conduct comprehensive mechanical testing, metallographic analysis, and non-destructive inspection (NDT) using industrial CT scanning to ensure internal and external integrity.

Our facility operates under ISO 9001 and AS9100 certifications, with dedicated cleanrooms for powder handling and climate-controlled build environments. This level of control allows us to consistently produce complex geometries such as conformal cooling channels, lattice structures, and integrated assemblies—features that traditional manufacturing cannot replicate.

Below are key technical specifications for our steel 3D printing capabilities:

| Parameter | Specification |

|---|---|

| Build Volume | 250 × 250 × 300 mm |

| Layer Thickness | 20–60 μm |

| Positional Accuracy | ±0.02 mm |

| Surface Roughness (as-built) | Ra 8–12 μm |

| Post-processed Surface Finish | Ra 1–3 μm (with polishing/machining) |

| Materials | 316L Stainless Steel, 17-4PH, 15-5PH, Maraging Steel, Tool Steel (H13) |

| Density | >99.95% (HIP-treated) |

| Support Structure Strategy | Optimized auto-generation with minimal contact |

At Wuxi Lead Precision Machinery, we understand that in high-stakes industries, precision is not a feature—it is the foundation. Our steel 3D printing service delivers not just parts, but engineered solutions where performance, reliability, and accuracy are guaranteed.

Precision Specs & Tolerances

Technical Capabilities: Precision Integration of Additive and Subtractive Manufacturing

Wuxi Lead Precision Machinery delivers certified high-integrity steel components through a rigorously controlled hybrid manufacturing process. Our core strength lies in seamlessly integrating metal additive manufacturing (specifically Laser Powder Bed Fusion for steel alloys) with advanced 5-axis CNC machining and comprehensive metrology. Pure additive processes often fall short of the stringent geometric and surface finish requirements demanded by aerospace, medical, and energy sectors. We address this critical gap by employing additive manufacturing for complex near-net-shape fabrication, followed immediately by precision CNC operations to achieve final part specifications. This integrated workflow ensures dimensional stability, critical feature accuracy, and superior surface quality unattainable through additive methods alone.

Our facility houses state-of-the-art 5-axis CNC machining centers, essential for finishing intricate geometries produced via steel 3D printing. These systems provide simultaneous multi-axis motion, enabling the precise machining of internal channels, undercuts, and complex organic shapes inherent in optimized AM designs. This capability eliminates the need for multiple setups, minimizing cumulative error and ensuring exceptional part consistency. Material removal is performed with micron-level control, transforming the as-built AM part into a dimensionally perfect component meeting the most exacting engineering drawings. The 5-axis platform is fundamental to achieving true geometric accuracy across complex surfaces and tight internal features.

Quality control is not a final step but an embedded process throughout production. Every critical steel component undergoes rigorous inspection using calibrated Coordinate Measuring Machines (CMM). Our CMM protocols validate all specified dimensions, geometric tolerances (GD&T), and critical datums against the original CAD model and customer requirements. This metrology-driven approach provides full traceability and documented evidence of conformance, essential for regulated industries. We adhere strictly to international quality standards, ensuring every shipped part meets or exceeds specified tolerances with statistical process control data available upon request.

The table below details the achievable precision for steel components (316L, 17-4PH, 304L) following our integrated AM + 5-axis CNC process. These tolerances represent our standard production capability under controlled conditions for qualified geometries and are validated through CMM inspection.

| Parameter | Dimension Range | Linear Tolerance | Geometric Tolerance (e.g., Position, Flatness) | Surface Roughness (Ra) |

|---|---|---|---|---|

| Small Features | < 25 mm | ±0.010 mm | 0.015 mm | 0.8 – 1.6 μm |

| Medium Features | 25 – 100 mm | ±0.015 mm | 0.025 mm | 1.6 – 3.2 μm |

| Large Features | 100 – 300 mm | ±0.025 mm | 0.050 mm | 3.2 – 6.3 μm |

| Critical Datums | Any Size | ±0.005 mm | 0.010 mm | 0.4 – 0.8 μm |

Notes: Tolerances assume optimized part orientation during AM build and appropriate CNC fixturing. Surface finish values are achievable on machined surfaces; as-built AM surfaces will be rougher and require machining for critical applications. Actual capability may vary based on specific part geometry, material, and thermal history; pre-production tolerance analysis is standard practice. All tolerances are verified via CMM per ISO 10360 standards.

This commitment to measurable precision, combining the design freedom of steel 3D printing with the unwavering accuracy of 5-axis CNC and CMM validation, defines Wuxi Lead’s technical capability. We partner with clients from initial design for manufacturability through final inspection to deliver components where dimensional integrity is non-negotiable.

Material & Finish Options

Material Selection for High-Performance Steel 3D Printing Services

When selecting materials for precision 3D printed components, especially in industrial and high-performance applications, understanding the mechanical, thermal, and environmental properties of available alloys is critical. At Wuxi Lead Precision Machinery, our steel 3D printing services are engineered to deliver exceptional dimensional accuracy and structural integrity, but optimal results depend on the right material choice. The most widely used metal families in additive manufacturing—aluminum, steel, and titanium—each offer distinct advantages depending on application demands such as strength-to-weight ratio, corrosion resistance, and operating temperature.

Aluminum alloys, particularly AlSi10Mg, are favored in aerospace and automotive sectors where lightweight design and thermal conductivity are paramount. This material provides excellent castability and fatigue resistance, making it ideal for complex geometries that benefit from reduced mass without sacrificing performance. However, aluminum’s lower hardness and wear resistance may limit its use in high-stress mechanical environments.

Stainless steel variants such as 316L and 17-4 PH dominate applications requiring durability, corrosion resistance, and high tensile strength. 316L stainless steel is especially suited for marine, chemical, and medical environments due to its outstanding resistance to chloride-induced pitting. In contrast, 17-4 PH offers superior strength through precipitation hardening, making it a preferred choice for tooling, valves, and high-stress components. Our steel 3D printing processes ensure dense, fully fused structures with mechanical properties that meet or exceed industry standards.

Titanium, specifically Grade 5 (Ti-6Al-4V), delivers an exceptional strength-to-density ratio and outstanding biocompatibility, positioning it as the material of choice for aerospace, defense, and medical implant applications. Its high resistance to oxidation and performance under extreme temperatures further enhance its utility in mission-critical systems. While titanium requires stringent process control during printing due to its reactivity, our advanced inert-gas chamber systems ensure consistent, high-quality builds.

Post-processing, including surface finishing, plays a pivotal role in final component performance. Anodizing, while more commonly associated with aluminum, enhances surface hardness and corrosion resistance and allows for color coding in assembly processes. For steel and titanium components, alternative surface treatments such as passivation, polishing, or coating are typically employed to achieve desired functional and aesthetic outcomes.

The following table summarizes key properties of commonly used materials in our steel 3D printing services:

| Material | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Density (g/cm³) | Key Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 400–440 | 280–320 | 5–8 | 2.67 | Aerospace, automotive lightweighting |

| 316L SS | 550–650 | 350–450 | 30–45 | 8.00 | Medical, marine, chemical processing |

| 17-4 PH SS | 950–1300 | 750–1100 | 10–15 | 7.80 | Tooling, aerospace, industrial parts |

| Ti-6Al-4V | 900–1050 | 800–900 | 10–14 | 4.43 | Aerospace, medical implants, defense |

Selecting the appropriate material and finish requires a holistic understanding of operational conditions and performance criteria. Wuxi Lead Precision Machinery supports clients in this decision with expert consultation, material testing, and full traceability to ensure every component meets the highest standards of quality and reliability.

Manufacturing Process & QC

Steel 3D Printing Production Process: Precision from Concept to Volume

At Wuxi Lead Precision Machinery, our steel 3D printing service delivers mission-critical components through a rigorously controlled, zero-defect production process. We integrate advanced additive manufacturing with decades of precision engineering expertise, ensuring every part meets stringent aerospace, medical, and industrial specifications. Our methodology eliminates waste and rework by embedding quality at every stage: Design, Prototyping, and Mass Production.

The process begins with collaborative Design optimization. Our engineering team works directly with your CAD models, applying Design for Additive Manufacturing (DfAM) principles specific to steel alloys like 17-4PH, 316L, and Inconel 718. We conduct comprehensive thermal and structural simulations to predict part behavior, optimizing support structures, orientation, and scan strategies. This phase identifies potential stress points, distortion risks, and material inconsistencies before printing, ensuring the digital blueprint is flawless and manufacturable. Material certification and traceability are established here, meeting AMS, ASTM, or client-specific standards.

Prototyping transitions the validated design into physical form for critical verification. Using identical production-grade EOS or SLM machines and parameters, we produce functional prototypes under controlled atmosphere conditions. Each prototype undergoes non-destructive testing (NDT) including high-resolution CT scanning and dye penetrant inspection, alongside mechanical property validation through tensile and fatigue testing. Dimensional accuracy is verified against the original CAD using CMM and optical metrology, typically achieving ±0.05 mm tolerance. This stage confirms performance, fit, and function, allowing for rapid, data-driven iterations if required – all documented for full traceability.

Mass Production leverages the perfected parameters from prototyping, scaled for volume without compromising integrity. Our factory operates under ISO 9001 and IATF 16949 certified workflows. Each build is monitored in real-time via integrated sensors tracking melt pool dynamics, oxygen levels, and layer adherence. Statistical Process Control (SPC) charts analyze critical parameters like laser power stability and layer thickness deviation, triggering automatic process corrections. Post-build, components undergo stress relief, precision machining (if required), and a final multi-stage inspection protocol: dimensional verification, surface roughness measurement (Ra ≤ 3.2 µm achievable), and 100% part-specific NDT. Material certificates and full build reports accompany every shipment.

This closed-loop process, governed by our Zero Defects philosophy, ensures consistent output where failure is not an option. By eliminating defects at the source through predictive design, validated prototyping, and intelligent production control, we deliver steel AM parts that perform reliably in the most demanding applications.

| Key Production Specification | Value | Application Impact |

|---|---|---|

| Build Volume (Max) | 500 x 500 x 500 mm | Accommodates complex industrial tooling & structural components |

| Layer Thickness Range | 20 – 60 µm | Balances surface finish, build speed, and feature resolution |

| Supported Steel Alloys | 17-4PH, 316L, 15-5PH, Inconel 625/718, Maraging Steel | Meets aerospace, medical implant, and high-wear industrial requirements |

| As-Built Density | ≥ 99.95% | Ensures mechanical properties match wrought material specifications |

| Typical Surface Roughness (As-Built) | Ra 12 – 25 µm | Provides optimal base for precision post-machining or coating |

| In-Process Monitoring Points | 12,000+ per build layer | Enables real-time defect detection and automatic process correction |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Steel 3D Printing Services

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision-engineered solutions tailored to the most demanding industrial applications. As a leader in custom metal manufacturing, we specialize in advanced steel 3D printing services that combine cutting-edge technology with decades of engineering excellence. Whether you’re developing mission-critical aerospace components, high-performance automotive systems, or complex industrial tooling, our team is equipped to bring your most ambitious designs to life.

Our steel additive manufacturing capabilities are built on a foundation of precision, repeatability, and material integrity. Utilizing state-of-the-art metal laser powder bed fusion (LPBF) systems, we produce fully dense, high-strength steel components with exceptional dimensional accuracy and surface finish. From initial design consultation to final post-processing, we ensure every part meets or exceeds international quality standards, including ISO 9001:2015 certification protocols.

We understand that in high-end manufacturing, performance is non-negotiable. That’s why we use premium-grade steel alloys such as 17-4 PH stainless steel, 316L stainless steel, and maraging steel, all processed under strictly controlled environments to ensure mechanical consistency. Our in-house metallurgical analysis and non-destructive testing (NDT) capabilities allow us to validate material properties and structural integrity at every stage of production.

Our engineering team collaborates directly with clients to optimize designs for additive manufacturing, reducing weight, consolidating assemblies, and improving functional performance—all while minimizing material waste and lead times. With rapid prototyping, low-volume production, and scalable batch manufacturing options, we support your project from concept to full-scale deployment.

Choose a partner who understands the complexities of modern metal 3D printing. At Wuxi Lead Precision Machinery, we combine advanced technology with deep process knowledge to deliver steel components that perform under the most rigorous conditions.

| Specification | Detail |

|---|---|

| Material Options | 17-4 PH Stainless Steel, 316L Stainless Steel, Maraging Steel, Tool Steel (H13, M2) |

| Build Volume | Up to 250 x 250 x 300 mm (standard), custom configurations available |

| Layer Thickness | 20–60 μm (adjustable for resolution vs. speed) |

| Dimensional Accuracy | ±0.05 mm for features under 100 mm |

| Surface Roughness | As-built: Ra 10–15 μm; Post-processed: Ra < 3.2 μm |

| Post-Processing | Stress relief, HIP, CNC machining, polishing, coating, heat treatment |

| Quality Standards | ISO 9001:2015, full material traceability, NDT (CT scanning, X-ray) |

| Lead Time | Prototype: 7–10 days; Production: 10–20 days (varies by complexity) |

Contact us today to discuss your next project. Send your CAD files and requirements to [email protected] and receive a detailed quote within 24 hours. Let Wuxi Lead Precision Machinery be your trusted partner in steel 3D printing—where innovation meets industrial precision.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.