Technical Contents

Engineering Guide: Standard Sheet Metal Sheet Sizes

Engineering Insight: Standard Sheet Metal Sheet Sizes and the Precision Imperative

In the realm of industrial manufacturing, standard sheet metal dimensions serve as the foundational framework upon which precision engineering is built. While nominal sizes such as 4 ft × 8 ft (1219 mm × 2438 mm) or 5 ft × 10 ft (1524 mm × 3048 mm) are widely adopted across global supply chains, it is the adherence to exact tolerances and material consistency that separates functional fabrication from exceptional performance. At Wuxi Lead Precision Machinery, we recognize that standardization without precision is a liability—not an asset. Our decades of experience in high-stakes environments, including components for Olympic-standard equipment and mission-critical military systems, have reinforced a core principle: dimensional accuracy is non-negotiable.

Sheet metal, whether steel, aluminum, or stainless alloy, begins as a standardized blank. However, the true value emerges in how that blank is transformed. Even minor deviations in thickness or flatness—measured in thousandths of an inch—can cascade into assembly misalignments, structural weaknesses, or compromised performance in final products. For industries such as aerospace, defense, and advanced automation, where Wuxi Lead operates regularly, these tolerances are governed by stringent international standards including ISO 9001 and MIL-STD-810.

Our engineering team prioritizes not only the selection of appropriate standard sizes but also the rigorous validation of material properties and dimensional consistency upon intake. This ensures downstream processes—laser cutting, CNC bending, welding, and surface treatment—proceed with maximum repeatability and minimal waste. We maintain tight control over tolerances across all production stages, routinely achieving ±0.1 mm on cut profiles and ±0.2° on bend angles, even in complex multi-stage fabrications.

The choice of starting sheet size also directly impacts yield efficiency and cost structure. Larger formats like 1500 mm × 3000 mm or 2000 mm × 4000 mm reduce the number of required joints in large enclosures or structural panels, enhancing both strength and aesthetic continuity. However, handling these larger sheets demands advanced equipment and expert process planning—capabilities we have refined through high-volume, high-precision contracts.

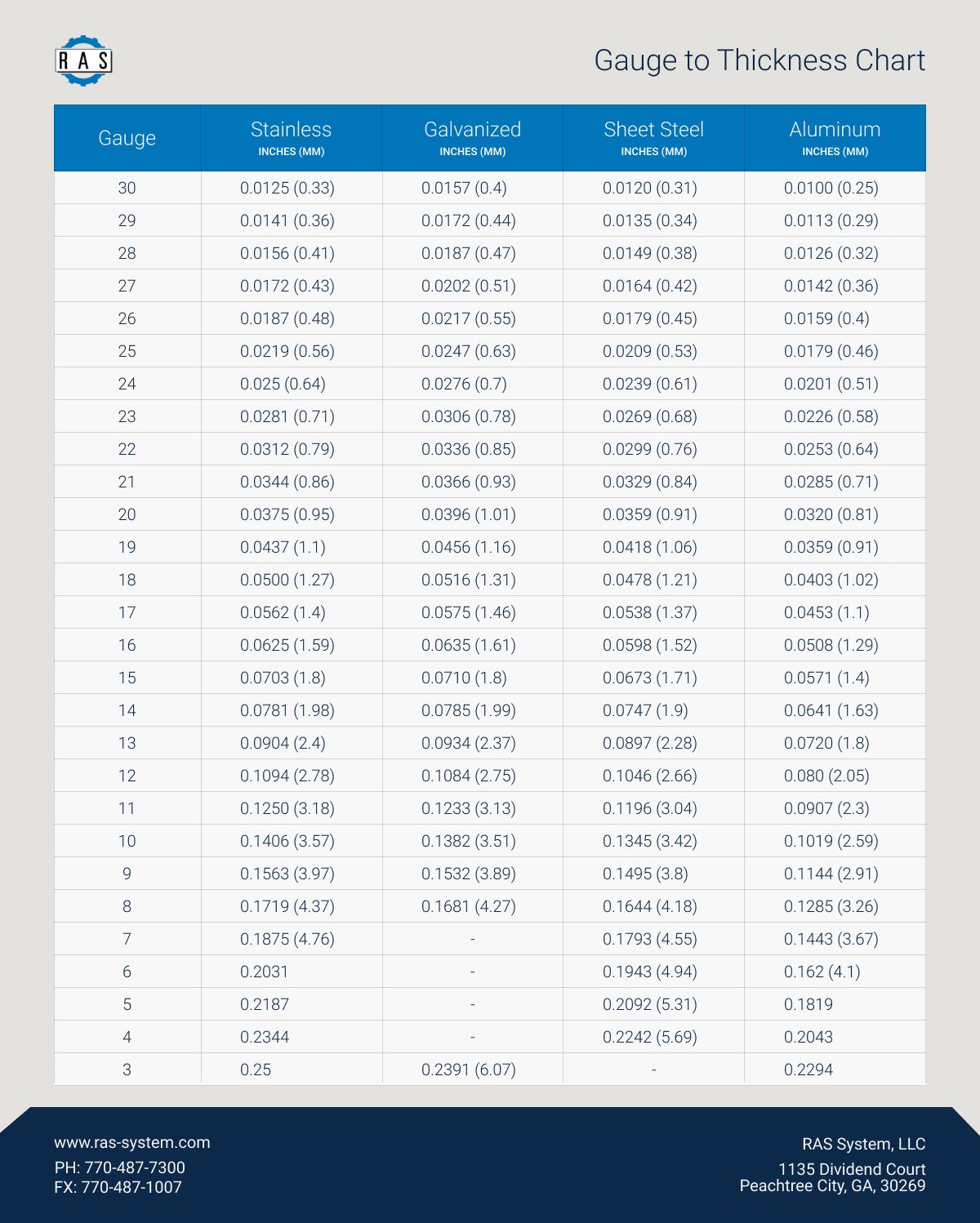

Below is a reference table outlining commonly used standard sheet sizes and their typical applications within our production environment.

| Material Type | Standard Size (mm) | Thickness Range (mm) | Common Applications |

|---|---|---|---|

| Cold Rolled Steel | 1219 × 2438 | 0.5 – 6.0 | Enclosures, chassis, industrial frames |

| Aluminum 5052/6061 | 1524 × 3048 | 1.0 – 10.0 | Aerospace components, heat shields |

| Stainless Steel 304 | 1000 × 2000 | 0.8 – 8.0 | Medical devices, food processing |

| Galvanized Steel | 1250 × 2500 | 0.6 – 5.0 | Outdoor cabinets, automotive parts |

| Expanded Metal | 2000 × 4000 | 1.0 – 3.0 (strand) | Architectural grilles, safety guards |

At Wuxi Lead Precision Machinery, we combine adherence to global standards with a commitment to micron-level precision. Our work on Olympic-grade mechanical systems and defense logistics platforms underscores our capability to deliver not just metal, but engineered reliability. When selecting standard sheet sizes, we do not default—we deliberate.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication

Wuxi Lead Precision Machinery delivers engineered sheet metal solutions meeting the most demanding global industrial standards. Our core strength lies in mastering both standard and custom sheet metal dimensions while maintaining exceptional geometric accuracy and process control. We routinely process standard sheet sizes ranging from 1000 x 2000 mm up to 3000 x 15000 mm across common thicknesses of 0.5 mm to 25.4 mm (1 inch). Material versatility is critical; we expertly handle cold-rolled steel (CRS), stainless steel (304, 316, 430), aluminum (5052, 6061), galvanized steel (G60, G90), and copper alloys within these standard formats. Crucially, our infrastructure supports non-standard sheet dimensions and exotic materials upon engineering review, ensuring flexibility without compromising our precision mandate.

The foundation of our dimensional accuracy is a modern fleet of 5-axis CNC machining centers and fiber laser cutting systems. These platforms enable complex, single-setup fabrication of intricate sheet metal components, significantly reducing cumulative error from multiple handling operations. Our 5-axis CNC bending cells, featuring high-tonnage press brakes with automatic tool changers and real-time angle feedback systems, produce consistent bends across large sheets and complex geometries. This integrated approach minimizes secondary operations and ensures critical features maintain positional integrity relative to the primary datum structure.

Rigorous quality assurance is non-negotiable. Every critical dimension undergoes verification using calibrated Coordinate Measuring Machines (CMM) operating under ISO 17025 guidelines. Our CMM inspection protocols validate flatness, hole patterns, feature locations, and critical form tolerances against client CAD models and Geometric Dimensioning & Tolerancing (GD&T) callouts. Statistical Process Control (SPC) data is maintained for high-volume runs, providing traceability and enabling proactive process refinement. Surface finish and material integrity are confirmed through standardized visual and metrological checks at defined process stages.

Our commitment to precision is quantifiable through the achievable tolerances listed below. These represent standard production capabilities under controlled conditions for typical geometries; tighter tolerances are attainable through dedicated process optimization for mission-critical features.

| Process | Standard Tolerance | Measurement Method |

|---|---|---|

| Laser Cutting | ±0.1 mm | CMM / Optical Comparator |

| CNC Punching | ±0.15 mm | CMM / Calipers |

| CNC Bending (Flat) | ±0.2° / ±0.25 mm | CMM / Angle Gauge |

| CNC Bending (Formed) | ±0.5° / ±0.5 mm | CMM / Profile Projector |

| Welding (Post-Machined) | ±0.1 mm (Machined Features) | CMM |

| Hole Position (Pattern) | ±0.1 mm | CMM |

| Overall Flatness (Per Sq. Meter) | 0.5 mm | Surface Plate / CMM |

Wuxi Lead Precision Machinery transcends basic sheet metal processing. We provide a certified, data-driven manufacturing environment where standard sheet sizes become the starting point for achieving exceptional component precision. Partner with us for fabrication where tolerances are guaranteed, not guessed.

Material & Finish Options

Material Selection in Sheet Metal Fabrication: Aluminum, Steel, and Titanium

Selecting the appropriate material is a critical step in precision sheet metal fabrication, directly influencing product performance, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in high-tolerance fabrication across a range of industrial-grade metals, with aluminum, steel, and titanium being the most widely used for advanced manufacturing applications. Each material offers distinct mechanical properties, weight characteristics, and corrosion resistance, making them suitable for different operational environments.

Aluminum is favored in industries requiring lightweight yet strong components, such as aerospace, electronics, and transportation. Its excellent strength-to-weight ratio, combined with natural corrosion resistance and high thermal conductivity, makes it ideal for heat sinks, enclosures, and structural parts. Aluminum 5052 and 6061 are among the most commonly specified alloys due to their weldability and formability. When enhanced surface protection is required, aluminum is often anodized—a process that increases surface hardness and wear resistance while allowing for color coding and improved aesthetics.

Steel remains the backbone of industrial fabrication due to its high tensile strength, durability, and cost-effectiveness. Cold-rolled steel (CRS) and galvanized steel are frequently used in machinery frames, electrical cabinets, and automotive components. While steel offers superior strength, it is prone to oxidation; thus, protective finishes such as powder coating or zinc plating are typically applied. Stainless steel, particularly grades 304 and 316, provides inherent corrosion resistance and is widely used in medical devices, food processing equipment, and outdoor applications.

Titanium is selected for extreme environments where strength, temperature resistance, and corrosion performance are paramount. With a strength-to-density ratio exceeding both aluminum and steel, titanium is ideal for aerospace, defense, and high-performance automotive sectors. Though more expensive and challenging to machine, its ability to withstand high stress and temperatures up to 600°C ensures reliability in mission-critical systems.

The choice of finish further enhances material performance. Anodizing, primarily applied to aluminum, creates a durable oxide layer that improves wear and corrosion resistance. Type II (sulfuric acid) anodizing is standard for most industrial uses, while Type III (hardcoat) anodizing delivers enhanced surface hardness for high-wear components.

Below is a comparative overview of key material specifications:

| Material | Common Grades | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 5052, 6061 | 2.7 | 200–310 | High (with anodizing) | Enclosures, heat sinks, aerospace |

| Steel | CR1018, 304, 316 | 7.8 | 370–700 | Moderate (stainless: high) | Machinery frames, cabinets |

| Titanium | Grade 2, Grade 5 | 4.5 | 345–1000 | Excellent | Aerospace, medical, defense |

Understanding the interplay between material properties, fabrication techniques, and surface finishes ensures optimal performance in end-use applications. At Wuxi Lead Precision Machinery, we support clients in selecting the right combination of material and finish to meet technical requirements and production scalability.

Manufacturing Process & QC

Sheet Metal Fabrication Production Process: Achieving Zero Defects

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered for uncompromising quality and efficiency, directly supporting the goal of Zero Defects in final components. This structured approach spans Design, Prototyping, and Mass Production, ensuring every stage actively prevents errors rather than merely detecting them. Success hinges on precise adherence to standard sheet metal specifications from the outset, eliminating dimensional mismatches and material incompatibilities that cause downstream failures.

The Design phase integrates strict adherence to globally recognized sheet size standards and material properties. Our engineers utilize advanced CAD/CAM software with built-in DFMA (Design for Manufacturability and Assembly) rules, specifically calibrated for common sheet formats. This prevents designs requiring non-standard blank sizes or thicknesses that introduce handling errors and waste. Critical verification occurs during this stage, confirming that the design aligns with available coil or sheet stock dimensions, material grades, and inherent fabrication tolerances. Material selection is validated against project requirements for strength, corrosion resistance, and formability, ensuring suitability before any physical work begins. This foundational step eliminates the most common root causes of defects related to material specification and geometric feasibility.

Prototyping serves as the definitive quality gate. Using the exact materials and standard sheet sizes designated for production, we fabricate initial units on our high-precision CNC punch presses, lasers, and brake presses. Each prototype undergoes rigorous dimensional inspection against the CAD model using CMM (Coordinate Measuring Machine) technology, verifying critical features within tight tolerances. Simultaneously, we perform comprehensive process validation, including FMEA (Failure Mode and Effects Analysis), to identify and mitigate any potential production variances. This phase confirms that the chosen standard sheet size and thickness perform as expected during bending, cutting, and forming, catching subtle issues like springback or distortion early. Only prototypes meeting all specifications with documented process capability indices (Cp/Cpk > 1.67) are approved for mass production.

Mass Production leverages the validated process parameters and tooling. Our automated lines operate under strict SPC (Statistical Process Control) protocols, continuously monitoring key variables like laser power, punch force, and bend angle. Real-time data feeds into our quality management system, triggering immediate corrective actions if deviations approach tolerance limits. Every sheet is traced from certified material stock, and final inspection employs AQL sampling plans alongside 100% critical feature checks. This closed-loop system, built upon the precision established in Design and Prototyping, ensures consistent output where defects are physically impossible under controlled conditions, fulfilling our Zero Defects commitment.

Standard Sheet Metal Specifications for Precision Fabrication

| Material | Thickness Range (mm) | Standard Sheet Sizes (mm) | Typical Tolerances (mm) |

|---|---|---|---|

| Cold Rolled Steel | 0.5 – 6.0 | 1000×2000, 1250×2500 | ±0.05 (Flatness) |

| Aluminum 5052/6061 | 0.8 – 4.0 | 1220×2440, 1500×3000 | ±0.03 (Thickness) |

| Stainless Steel 304 | 0.5 – 3.0 | 1000×2000, 1250×2500 | ±0.1° (Bend Angle) |

| Galvanized Steel | 0.6 – 5.0 | 1000×2000, 1220×2440 | ±0.5 (Punch Feature) |

This systematic progression, grounded in standard material specifications and enforced by rigorous process control at every step, is how Wuxi Lead delivers flawless sheet metal components for demanding industrial applications.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Unmatched Expertise in Sheet Metal Fabrication

At Wuxi Lead Precision Machinery, we understand that precision, consistency, and material efficiency are the foundation of high-performance sheet metal fabrication. As a trusted leader in advanced manufacturing solutions based in China, we specialize in delivering custom sheet metal components that meet the exacting standards of industries ranging from aerospace and automotive to medical devices and industrial automation. When you partner with us, you gain more than a supplier — you gain a strategic manufacturing ally committed to quality, on-time delivery, and engineering excellence.

One of the critical elements in optimizing fabrication efficiency is understanding standard sheet metal dimensions. Utilizing standard sheet sizes minimizes material waste, reduces lead times, and lowers production costs. At Lead Precision, we maintain an extensive inventory of metal sheets in globally recognized standard sizes across a range of materials, including cold-rolled steel, stainless steel, aluminum, and galvanized steel. Our CNC punching, laser cutting, bending, and welding capabilities are fine-tuned to maximize yield from these standard formats, ensuring your parts are produced with both precision and cost-efficiency.

Below are the most commonly used standard sheet metal sizes we work with, tailored to support high-volume and prototype production runs:

| Material Type | Standard Sheet Size (mm) | Thickness Range (mm) | Common Grades |

|---|---|---|---|

| Cold-Rolled Steel | 1000 x 2000, 1219 x 2438 | 0.5 – 6.0 | SPCC, DC01, Q235 |

| Stainless Steel | 1000 x 2000, 1219 x 2438 | 0.5 – 5.0 | SUS304, SUS316, AISI 304 |

| Aluminum | 1200 x 2400, 1500 x 3000 | 0.8 – 6.0 | 5052, 6061, 1060 |

| Galvanized Steel | 1000 x 2000, 1219 x 2438 | 0.6 – 4.0 | SGCC, DX51D |

Our engineering team collaborates closely with clients during the design phase to ensure optimal nesting, grain direction, and bend allowances — all while leveraging standard sheet formats to enhance manufacturability. Whether you’re scaling a prototype or managing large-batch production, our ISO-certified facility combines state-of-the-art machinery with rigorous quality control to deliver components that meet tight tolerances and superior finish requirements.

We invite global manufacturers to experience the Lead Precision advantage. Our commitment to innovation, transparency, and responsive service ensures your sheet metal projects are executed flawlessly from concept to completion. For technical consultations, material recommendations, or project quotations, contact us today.

Email us at [email protected] and let our team of experts help you optimize your fabrication process with precision-engineered solutions built to last.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.