Technical Contents

Engineering Guide: Standard Cnc

Engineering Insight: The Non-Negotiable Imperative of Precision in Standard CNC Machining

Precision is not merely a desirable attribute in CNC machining; it is the absolute foundation upon which functional, reliable, and high-performance components are built. In industries where failure carries catastrophic consequences – aerospace, defense, medical, and high-end automation – tolerances measured in microns directly translate to system integrity, safety, and operational lifespan. Standard CNC machining, often perceived as a baseline capability, demands extraordinary control to consistently achieve the dimensional accuracy, geometric perfection, and surface finish required by mission-critical applications. The cost of deviation extends far beyond scrap; it encompasses assembly failures, field malfunctions, reputational damage, and potential liability. True precision engineering requires moving beyond basic machine capability to encompass rigorous process control, advanced metrology, material science understanding, and unwavering commitment to repeatability.

At Wuxi Lead Precision Machinery, our 20+ years of experience, particularly in supplying components for Olympic-standard sporting equipment and stringent military programs, underscores this reality. These sectors operate under zero-defect mandates where every micron matters. Olympic components must deliver flawless performance under extreme stress, demanding absolute consistency. Military hardware operates in unforgiving environments where a single out-of-tolerance feature can compromise an entire system. This experience has ingrained a culture where precision is systemic – from initial material certification and thermal stability management to in-process gauging and final inspection protocols traceable to national standards. We understand that achieving nominal dimensions is insufficient; geometric tolerances (flatness, cylindricity, positional) and surface integrity are equally critical for part function and longevity.

Our standard CNC machining processes are engineered to deliver exceptional results consistently. This capability is built on a foundation of high-rigidity machine tools maintained to exacting standards, coupled with sophisticated toolpath strategies that minimize deflection and thermal drift. Continuous investment in multi-sensor CMMs, optical comparators, and surface roughness testers ensures verification at every critical stage. The following table outlines the core precision capabilities achievable within our standard CNC machining framework for critical applications:

| Specification Category | Capability | Measurement Standard |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm (±0.0002″) | ISO 2768-mK / Custom |

| Geometric Tolerance (Flatness/Cylindricity) | 0.003 mm (0.0001″) per 100mm | ASME Y14.5 / ISO 1101 |

| Surface Roughness (Ra) | 0.4 µm (16 µin) | ISO 4287 / ASME B46.1 |

| Repeatability (CpK) | ≥ 1.67 | Statistical Process Control |

| Material Compliance | Full Mill Certificates | ASTM, AMS, MIL Spec |

Achieving this level of precision in standard CNC operations requires more than advanced equipment; it demands deep engineering expertise applied to every stage of the manufacturing journey. It means understanding how material properties interact with cutting parameters, how fixturing influences distortion, and how environmental factors impact final dimensions. At Lead Precision, our engineers collaborate closely with clients from the design phase, offering DFM insights specifically focused on manufacturability at the required precision level. We translate complex engineering requirements into robust, repeatable machining processes. When your application demands reliability under extreme conditions, proven precision isn’t optional – it’s the only acceptable standard. Demand machining where tolerance stacks are engineered, not endured.

Precision Specs & Tolerances

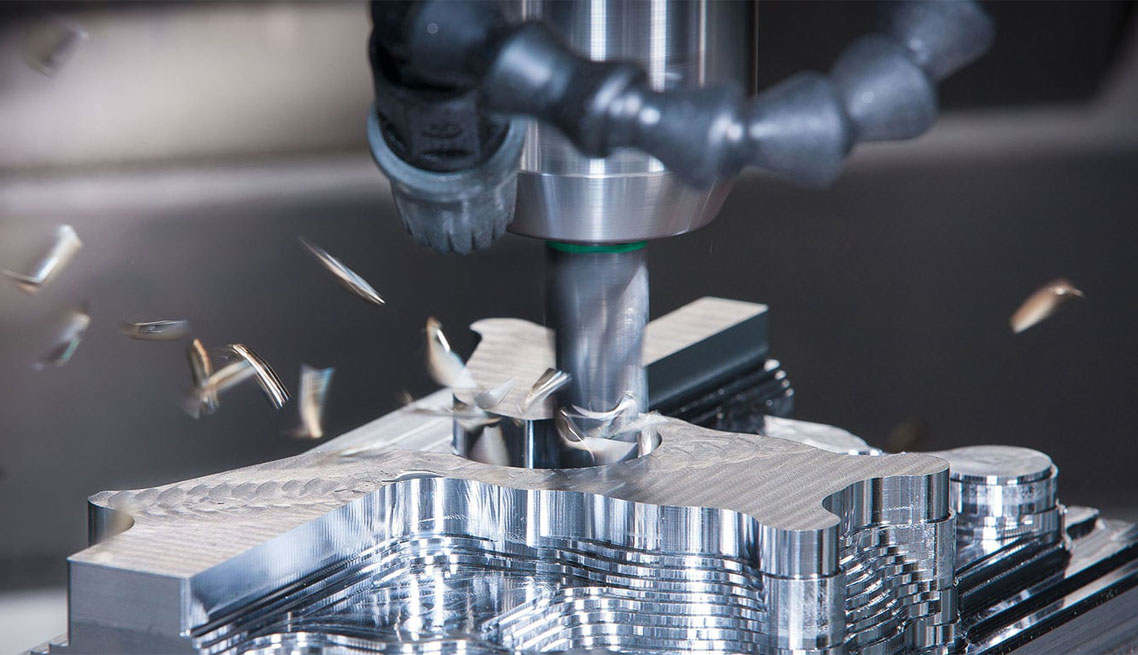

At Wuxi Lead Precision Machinery, our technical capabilities are engineered to meet the most demanding requirements in precision CNC machining. As a leader in advanced manufacturing solutions, we specialize in high-accuracy production using state-of-the-art 5-axis CNC machining centers. These systems enable us to execute complex geometries with superior surface finishes and tight tolerances, essential for industries such as aerospace, medical, automotive, and industrial automation.

Our 5-axis CNC machines provide simultaneous multi-directional cutting, allowing for intricate part features that would be unattainable with traditional 3-axis technology. This dynamic capability reduces the need for multiple setups, minimizing human error and significantly improving repeatability and throughput. The integration of high-speed spindles and advanced toolpath strategies ensures optimal material removal rates while maintaining micron-level precision across diverse materials, including aluminum alloys, stainless steel, titanium, and engineering plastics.

To guarantee the integrity and consistency of every component, we implement a rigorous quality control protocol centered around Coordinate Measuring Machine (CMM) inspection. Each critical dimension is verified using Zeiss and Mitutoyo CMM systems, ensuring full compliance with ISO 10360 standards. Our inspection process is not limited to final part validation; it extends throughout production via in-process checks, statistical process control (SPC), and first-article inspection reports (FAIR). This proactive approach allows real-time correction and continuous process optimization.

All CNC programs are developed using industry-leading CAD/CAM software, enabling simulation-driven machining strategies that enhance tool life, reduce cycle times, and prevent collisions. Our engineering team works closely with clients during the design for manufacturability (DFM) phase to identify potential improvements in geometry, material selection, and tolerance specifications—ensuring that every part is both high-performing and cost-efficient to produce.

Our facility operates under ISO 9001:2015 certification, reflecting our commitment to quality management and continuous improvement. From prototype to high-volume production, we maintain complete traceability of materials, processes, and inspection data, providing full documentation with every shipment.

The following table outlines our standard machining tolerances and capabilities:

| Parameter | Standard Capability | High-Precision Capability |

|---|---|---|

| Linear Tolerance | ±0.005 mm | ±0.002 mm |

| Angular Tolerance | ±0.05° | ±0.02° |

| Surface Roughness (Ra) | 0.8 μm | 0.4 μm |

| Positional Accuracy | ±0.003 mm | ±0.001 mm |

| Repeatability | ±0.002 mm | ±0.001 mm |

| Maximum Work Envelope (XYZ) | 1200 x 800 x 650 mm | 800 x 600 x 500 mm |

| Materials | Aluminum, Steel, Stainless, Titanium, Plastics | Same, with tighter process control |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with metrology-grade inspection to deliver components that meet the highest standards of precision and reliability. Our technical expertise ensures that every project, regardless of complexity, is executed with consistency, accuracy, and full traceability.

Material & Finish Options

Material Selection for Precision CNC Machining

Selecting appropriate materials is critical for achieving optimal performance, durability, and cost-efficiency in CNC-machined components. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with functional requirements, environmental exposure, and post-processing needs. This guide outlines key considerations for aluminum, steel, and titanium alloys, alongside anodizing finishes essential for high-end applications.

Aluminum Alloys

Aluminum remains the preferred choice for lightweight structural components requiring excellent machinability and thermal conductivity. Alloys like 6061-T6 offer balanced strength and weldability for aerospace brackets, while 7075-T6 delivers superior strength for high-stress military or automotive parts. Its natural corrosion resistance reduces secondary treatment needs, though anodizing enhances surface hardness and wear resistance. Machinability is excellent, enabling tight tolerances and complex geometries with minimal tool wear.

Steel Variants

Steel alloys provide unmatched strength and wear resistance for demanding industrial applications. 4140 chromoly steel excels in high-torque shafts and tooling due to its hardenability, while 304 stainless steel dominates medical and food-processing equipment for its corrosion resistance and biocompatibility. Machining steel requires rigid CNC setups and specialized tooling to manage heat generation and chip control. Post-machining heat treatments like nitriding are often necessary to achieve final mechanical properties.

Titanium Alloys

Titanium, particularly Grade 5 (Ti-6Al-4V), is indispensable in aerospace and biomedical sectors where strength-to-weight ratio and biocompatibility are non-negotiable. Its exceptional corrosion resistance in saline environments justifies higher material and machining costs. However, low thermal conductivity demands slower cutting speeds and rigid toolpaths to prevent work hardening and tool deflection. We recommend dedicated CNC parameters and sharp carbide tools to maintain precision.

Anodizing Finishes

Anodizing is a critical electrochemical process for aluminum components, enhancing surface durability without dimensional compromise. Type II (sulfuric acid) anodizing provides standard corrosion and wear resistance with dye compatibility for identification. For extreme environments, Type III (hardcoat) anodizing delivers 50–100 μm thickness with Rockwell hardness up to 70 HRc, ideal for hydraulic pistons or aerospace fittings. Note that anodizing requires precise masking of critical tolerances and threaded features to maintain functional integrity.

Material specifications directly impact CNC programming, tool selection, and throughput. Our engineering team collaborates with clients to validate material-finish combinations against application stressors, ensuring compliance with ISO 2768 or customer-specific standards. Below is a comparative overview of key properties:

| Material | Key Alloys | Tensile Strength (MPa) | Common Applications |

|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 310–570 | Aerospace frames, heat sinks |

| Steel | 4140, 304 SS | 655–965 | Shafts, surgical instruments |

| Titanium | Ti-6Al-4V (Gr5) | 900–1000 | Aircraft landing gear, implants |

At Wuxi Lead, we leverage 5-axis CNC machining centers and in-house metallurgical analysis to optimize material utilization and finish quality. Partner with us to transform material specifications into precision-engineered solutions meeting AS9100 and ISO 13485 requirements. Contact our engineering team for alloy-specific machining protocols and finish validation testing.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, every successful CNC production cycle begins with meticulous design engineering. We collaborate closely with clients to transform conceptual ideas into manufacturable, high-precision components. Our engineering team leverages advanced CAD/CAM software—such as SolidWorks, AutoCAD, and Mastercam—to develop 3D models that meet exact dimensional, functional, and material requirements. Tolerance analysis, material selection, and manufacturability assessments are conducted in parallel to ensure optimal performance and cost-efficiency. Finite Element Analysis (FEA) is applied where necessary to validate structural integrity under operational loads. This phase establishes the blueprint for zero-defect manufacturing, ensuring every downstream step adheres to the highest standards of accuracy and repeatability.

Prototyping: Validation Before Scale

Once the design is finalized, we proceed to rapid prototyping using state-of-the-art 3-, 4-, and 5-axis CNC machining centers. Prototyping serves as a critical validation stage, allowing us to test form, fit, and function before full-scale production. Each prototype is machined from the intended production material—be it aluminum, stainless steel, titanium, or engineering plastics—to ensure real-world performance accuracy. Our quality control team conducts dimensional inspections using Coordinate Measuring Machines (CMM), optical comparators, and surface roughness testers. Feedback from this stage is integrated into final toolpath optimization and fixture design, minimizing variability and eliminating potential defects early. This iterative verification process ensures that only fully validated designs advance to mass production.

Mass Production: Precision at Scale

With prototype approval, Wuxi Lead initiates high-volume CNC manufacturing under a rigorously controlled environment. Our production floor is equipped with automated CNC cells, robotic part handling, and real-time process monitoring systems. Each machine runs pre-validated G-code with tool wear compensation and in-process probing to maintain micron-level accuracy across thousands of parts. Statistical Process Control (SPC) is implemented at every stage, with continuous data logging and immediate alerting for any deviation from set parameters. All components undergo 100% visual inspection and sample-based metrology testing per ISO 9001 standards. Our zero-defect philosophy is enforced through traceability—each batch is serialized, and material certifications, inspection reports, and process logs are archived for full auditability.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Machining Tolerances | ±0.005 mm (standard), down to ±0.001 mm (precision) |

| Surface Roughness | Ra 0.4 µm to Ra 3.2 µm (adjustable per requirement) |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Brass, PEEK, Delrin |

| Max Work Envelope | 1200 x 800 x 600 mm (5-axis), 2000 x 1000 x 800 mm (3-axis) |

| Spindle Speed | Up to 24,000 RPM (high-speed machining) |

| Positioning Accuracy | ±0.003 mm per axis |

| Quality Standards | ISO 9001:2015, ISO 13485 (medical), RoHS compliant |

Through integrated design, rigorous prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers defect-free CNC components that meet the most demanding industrial requirements.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising CNC Excellence

In high-stakes manufacturing, standard CNC machining is never truly standard. It demands precision engineered to your exact specifications, relentless process control, and a partner who treats your project as mission-critical. At Wuxi Lead Precision Machinery, we redefine expectations for CNC production in aerospace, medical, energy, and advanced industrial sectors. Our German-engineered standards, ISO 9001:2015-certified workflows, and mastery of complex geometries ensure your components meet the most stringent global requirements—on time, every time.

We operate beyond basic machining. Our 5-axis milling and turning centers achieve micron-level tolerances while maintaining repeatability under serial production conditions. This capability stems from rigorous environmental controls, real-time in-process metrology, and a engineering team trained in failure-mode analysis for critical applications. When your design requires materials like Inconel 718, titanium alloys, or high-strength composites, our optimized toolpaths and coolant strategies prevent thermal distortion and surface integrity issues that compromise performance.

Core Technical Capabilities

| Parameter | Specification | Industry Benchmark |

|---|---|---|

| Positioning Accuracy | ±0.002 mm | ±0.005 mm |

| Repeatability | ±0.001 mm | ±0.003 mm |

| Max Work Envelope | 1,200 x 800 x 650 mm | 1,000 x 600 x 500 mm |

| Spindle Speed Range | 20 – 24,000 RPM | 20 – 15,000 RPM |

| Surface Finish (Ra) | 0.2 – 0.8 µm | 0.8 – 1.6 µm |

| Typical Lead Time | 15–25 days (complex assemblies) | 30–45 days |

This technical foundation is paired with proactive engineering collaboration. From DFM analysis to first-article inspection reports, we integrate with your R&D and quality teams to eliminate rework cycles. Our digital workflow provides live production tracking, material traceability down to the heat number, and full compliance documentation for regulated industries. We don’t just manufacture parts—we secure your supply chain resilience.

The cost of precision failure in mission-critical components is incalculable. Delays, scrap, or non-conformances erode margins and reputation. Partnering with Lead Precision mitigates these risks through transparent processes, engineering accountability, and capacity reserved for strategic clients. Our facility in Wuxi operates 24/7 with dedicated cells for high-priority programs, ensuring your production rhythm never falters.

Initiate your precision journey with a technical consultation. Email [email protected] with your component drawings and requirements. Our application engineers will respond within 24 hours with a detailed capability assessment, process validation plan, and actionable timeline. For urgent RFQs, include “Priority Engineering Review” in the subject line. Let us prove why global leaders trust Lead Precision for CNC machining where perfection is non-negotiable. Your next breakthrough begins with a single email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.