Technical Contents

Engineering Guide: Stainless Steel Machining Services

Engineering Insight Stainless Steel Machining Services

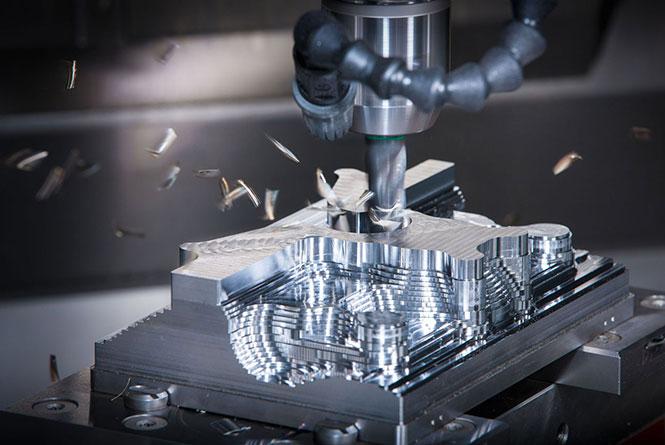

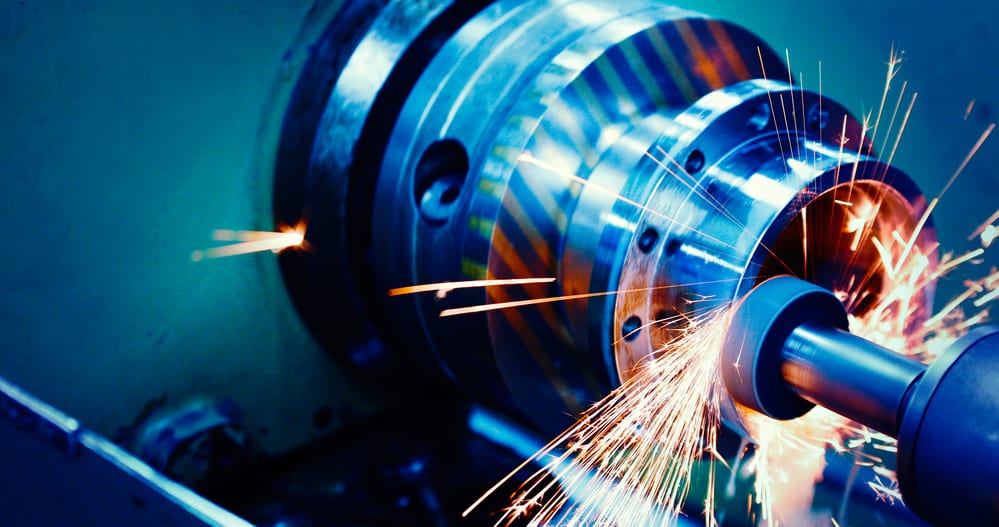

Precision in stainless steel machining transcends mere dimensional accuracy; it is the foundational requirement for functional integrity, longevity, and safety in critical applications. Stainless steel’s inherent properties – high strength, work hardening tendency, and thermal sensitivity – demand exceptional process control. Microscopic deviations during milling, turning, or grinding can induce residual stress, accelerate wear, compromise corrosion resistance at cut edges, or cause catastrophic failure in high-pressure or cyclic load environments. Achieving true precision requires not only state-of-the-art multi-axis CNC equipment with sub-micron repeatability but also deep metallurgical understanding. Material selection must align with the operational environment, coolant strategies must manage heat without inducing micro-cracks, and toolpath optimization is essential to minimize vibration and prevent built-up edge that degrades surface finish. For sectors like aerospace, medical implants, or semiconductor manufacturing, tolerances consistently held within ±0.005mm are non-negotiable, directly impacting system performance and regulatory compliance.

Wuxi Lead Precision Machinery has honed this precision capability over 15+ years, specifically addressing the stringent demands of mission-critical industries. Our engineering team possesses proven expertise in machining complex geometries from challenging grades like 17-4PH, 316LVM, and custom superalloys. This proficiency is validated through direct contributions to projects where failure is not an option. We supplied precision-machined structural components for the Beijing 2022 Winter Olympic Games infrastructure, meeting extreme fatigue and dimensional stability requirements under harsh environmental conditions. Furthermore, our facility consistently delivers parts certified to stringent military specifications (MIL-STD) for defense contractors, where traceability, material certification, and zero-defect performance are rigorously audited. This experience translates directly to our commercial clients, ensuring every component adheres to the highest standards of geometric accuracy and material integrity.

Our commitment to precision is quantifiable through controlled process parameters and rigorous inspection protocols utilizing coordinate measuring machines (CMMs) with nanometer-level resolution and in-process probing. The following specifications represent our standard high-precision stainless steel machining capability for demanding applications.

| Parameter | Specification |

|---|---|

| Material Grades | 303, 304/L, 316/L, 17-4PH, 440C, Custom Alloys |

| Standard Tolerance | ±0.005 mm (±0.0002″) |

| Tight Tolerance | ±0.002 mm (±0.00008″) achievable |

| Max Work Envelope | 800 x 500 x 400 mm (XYZ) |

| Surface Finish | Ra 0.4 μm (16 μin) standard; Ra 0.2 μm achievable |

| Certifications | ISO 9001, ISO 13485, NADCAP (pending) |

Achieving this level of precision requires integrating advanced technology with seasoned engineering judgment. At Wuxi Lead Precision Machinery, we do not merely machine parts; we solve complex manufacturing challenges inherent in high-performance stainless steel applications. Partner with our engineering team to ensure your critical components meet the uncompromising standards demanded by modern industry. Contact us for a detailed capability review and precision assessment specific to your project requirements.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced stainless steel machining services tailored for high-performance industries including aerospace, medical, energy, and precision automation. Our technical capabilities are built around a foundation of modern 5-axis CNC machining centers, enabling us to produce complex, high-precision components with superior surface finishes and dimensional accuracy. Stainless steel, known for its corrosion resistance, strength, and durability, presents unique challenges in machining due to work hardening, heat retention, and tool wear. Our engineering team applies material-specific cutting strategies, optimized toolpaths, and high-pressure coolant systems to ensure consistent part quality and extended tool life.

Our 5-axis CNC machining platforms provide simultaneous multi-directional cutting, allowing for complete part geometry in a single setup. This reduces cumulative errors, improves positional accuracy, and significantly shortens lead times. We work with a wide range of stainless steel alloys, including 304/L, 316/L, 17-4 PH, 420, and 440C, supporting both prototyping and high-volume production runs. Each machining operation is supported by in-house programming using advanced CAM software, ensuring optimal tool engagement, surface finish control, and efficient material removal rates.

Quality is embedded at every stage of production. All stainless steel components undergo rigorous inspection using a Zeiss DuraMax and Wenzel LH876 coordinate measuring machine (CMM), providing traceable, high-resolution metrology data. Our quality control process includes first-article inspection, in-process checks, and final validation against customer specifications. All inspection reports are documented and available in PDF or DMIS format, meeting ISO 9001 and industry-specific compliance standards.

We maintain tight tolerances across critical dimensions, surface finishes, and geometric features. Our machining capabilities are proven in applications requiring hermetic sealing, biocompatibility, and high-cycle reliability. With full traceability of materials and processes, Wuxi Lead ensures that every stainless steel component meets the exacting standards demanded by Tier 1 manufacturers.

The table below outlines our standard machining tolerances for stainless steel components under controlled production conditions.

| Feature Type | Standard Tolerance | Tight Tolerance Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.005 mm | Up to 300 mm |

| Hole Diameter | ±0.02 mm | ±0.01 mm | Reamed or honed |

| Positional Tolerance | ±0.02 mm | ±0.01 mm | Relative to datum |

| Flatness | 0.02 mm | 0.005 mm | Over 100 mm span |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Machined; 0.2 µm with polishing |

| Angular Features | ±0.05° | ±0.02° | 5-axis simultaneous |

Our technical team collaborates closely with design and engineering partners to review manufacturability, recommend material and tolerance optimization, and ensure seamless transition from prototype to production. With a focus on precision, consistency, and technical excellence, Wuxi Lead Precision Machinery is a trusted partner for mission-critical stainless steel components.

Material & Finish Options

Material Selection for Precision Machined Components

Material selection fundamentally determines the performance, longevity, and cost-effectiveness of precision machined components. At Wuxi Lead Precision Machinery, our engineering team emphasizes that the optimal choice aligns with the part’s functional requirements, environmental exposure, and manufacturing constraints. While our core expertise lies in high-precision stainless steel machining services, understanding the broader landscape of aluminum, steel, and titanium is critical for informed decision-making in demanding aerospace, medical, and industrial applications. Each material offers distinct advantages and machining considerations that directly impact final part quality and project timelines.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are favored for applications requiring a high strength-to-weight ratio, excellent thermal conductivity, and good machinability. They are ideal for structural components, heat sinks, and housings where weight reduction is paramount. However, aluminum lacks the inherent corrosion resistance of stainless steel in harsh environments and requires protective finishes like anodizing for enhanced surface durability and wear resistance. Anodizing creates a hard, non-conductive oxide layer, available in clear, colored, or hard coat variants, significantly improving surface properties without dimensional compromise when controlled precisely.

Carbon and alloy steels provide high strength, toughness, and cost efficiency for structural and mechanical parts subjected to heavy loads. Yet, for critical applications demanding superior corrosion resistance alongside strength, stainless steel is the definitive solution. Grades like 304/L and 316/L offer excellent resistance to oxidation, chemicals, and moisture, making them indispensable in medical devices, food processing, and marine environments. Our advanced CNC centers achieve exceptional surface finishes and tight tolerances on stainless alloys, though their work-hardening tendency necessitates specialized tooling and cutting strategies.

Titanium, especially Grade 5 (Ti-6Al-4V), delivers an unmatched combination of high strength, low density, and extraordinary corrosion resistance, even in highly aggressive conditions. It is the material of choice for critical aerospace components, biomedical implants, and chemical processing equipment. Machining titanium presents significant challenges due to its low thermal conductivity and high chemical reactivity, requiring rigid setups, specific cutting parameters, and dedicated tool paths to prevent galling and ensure dimensional accuracy. Passivation is essential for stainless steel to maximize corrosion resistance, while titanium typically requires specialized cleaning or acid etching rather than anodizing.

The following table summarizes key properties and applications for common precision machining materials:

| Material Family | Key Grades | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating | Typical Applications |

|---|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 2.7 | 310-570 | Moderate (Anodized) | Excellent | Aerospace brackets, heat sinks, enclosures |

| Stainless Steel | 304/L, 316/L | 8.0 | 515-690 | Excellent | Moderate | Medical instruments, valves, marine hardware |

| Titanium | Gr 2, Gr 5 | 4.5 | 345-900 | Exceptional | Challenging | Aircraft components, surgical implants |

Selecting the right material requires balancing performance needs with manufacturability. Wuxi Lead Precision Machinery provides expert consultation to navigate these complexities, ensuring your stainless steel, aluminum, or titanium components meet the highest standards of precision and reliability from prototype through volume production. Our process expertise minimizes risk and optimizes total cost.

Manufacturing Process & QC

Design: Engineering Precision from Concept to Blueprint

At Wuxi Lead Precision Machinery, the foundation of flawless stainless steel machining begins with precision-driven design engineering. Our process integrates client specifications with advanced CAD/CAM software to develop optimized 3D models and technical drawings. Every design is rigorously reviewed for manufacturability, material compatibility, and performance under real-world conditions. We collaborate closely with engineering teams and end-users to ensure dimensional accuracy, tolerance alignment, and compliance with international standards such as ISO 2768 and ASME Y14.5. Finite element analysis (FEA) and design for manufacturability (DFM) protocols are applied to preempt structural weaknesses and machining challenges, ensuring that every component is engineered for both function and process efficiency.

Prototyping: Validating Performance Before Scale

Once the design is finalized, we proceed to prototype development—a critical phase in our zero-defect strategy. Using high-precision CNC machining centers, we produce functional prototypes from the same grade of stainless steel intended for full-scale production, such as 304, 316, 17-4 PH, or custom alloys. These prototypes undergo comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to verify dimensional integrity and surface finish. We conduct performance testing for corrosion resistance, mechanical strength, and fitment in assembly environments. Client feedback is incorporated at this stage, enabling iterative refinement without impacting production timelines. This validation loop ensures that design intent is fully realized and any potential issues are resolved before mass production begins.

Mass Production: Consistency Through Automation and Quality Control

With the approved prototype, we transition seamlessly into high-volume manufacturing. Our facility in Wuxi operates a fleet of multi-axis CNC lathes, milling centers, and automated transfer lines, all calibrated for continuous, repeatable performance. Each production run is governed by standardized work instructions and real-time process monitoring systems that detect deviations in tool wear, cutting parameters, or thermal expansion. In-process inspections occur at defined intervals, and final products undergo 100% visual inspection alongside random sampling per ANSI/ASQ Z1.4 standards. Our quality management system is ISO 9001:2015 certified, and we maintain full traceability for material batches, tooling, and inspection records.

| Parameter | Specification |

|---|---|

| Material Grades | 304, 316, 316L, 17-4 PH, 440C, Custom Alloys |

| Dimensional Tolerance | ±0.005 mm (tight-tolerance up to ±0.001 mm) |

| Surface Finish | Ra 0.4 µm to Ra 3.2 µm (custom finishes available) |

| Maximum Part Size | 800 mm × 600 mm × 500 mm |

| Production Capacity | Up to 50,000 units/month (varies by complexity) |

| Quality Standards | ISO 9001:2015, ISO 2768, ASME Y14.5 |

| Inspection Equipment | CMM, Optical Comparator, Roughness Tester, Hardness Tester |

Through seamless integration of design, prototyping, and production, Wuxi Lead delivers stainless steel components with uncompromising quality—ensuring zero-defect performance for aerospace, medical, semiconductor, and high-end industrial applications.

Why Choose Wuxi Lead Precision

Elevate Your Stainless Steel Manufacturing Partnership

Selecting the right precision machining partner for critical stainless steel components demands more than technical capability—it requires a strategic alliance built on reliability, engineering collaboration, and uncompromising quality control. At Wuxi Lead Precision Machinery, we engineer partnerships that transform complex design challenges into mission-critical solutions for aerospace, medical, and energy sectors. Our ISO 9001:2015 and IATF 16949-certified facility in Wuxi, China, operates as a seamless extension of your engineering team, ensuring every component meets stringent global standards while accelerating your time-to-market.

Technical Capabilities for Demanding Applications

Our advanced CNC infrastructure supports the full spectrum of stainless steel machining requirements. The following specifications reflect our operational excellence for high-integrity components:

| Parameter | Capability | Industry Relevance |

|---|---|---|

| Material Grades | 303, 304/L, 316/L, 17-4PH, 440C | Corrosion resistance, strength |

| Tolerance Range | ±0.005 mm (±0.0002″) | Aerospace sealing surfaces |

| Surface Finish | Ra 0.2 µm (8 µin) to Ra 1.6 µm (63 µin) | Medical implant biocompatibility |

| Max Part Dimensions | Ø 500 mm x 1000 mm (20″ x 39″) | Industrial valve bodies |

| Secondary Operations | Passivation, CIP cleaning, laser marking | FDA/ASME compliance |

This precision is sustained through real-time process monitoring, 100% first-article inspection via Zeiss CMMs, and material traceability from mill certificate to finished part. We mitigate supply chain risks through dual-sourcing of raw materials and strategic inventory buffers for recurring production runs.

Your Assurance in Every Partnership

Unlike transactional suppliers, we embed engineering accountability into every phase. Our technical team collaborates during DFM analysis to optimize manufacturability—reducing costs without sacrificing performance. All communications occur through dedicated project managers fluent in English and German, with responses guaranteed within 4 business hours. Intellectual property remains protected under NDA-secured workflows and segregated production cells. When your project demands zero-defect delivery for safety-critical applications, our corrective action protocols (root-cause analysis within 24 hours) ensure continuous compliance.

Initiate your project with a partner who treats your specifications as non-negotiable imperatives. Contact our engineering team directly at [email protected] to submit prints for a feasibility assessment and timeline-accurate quotation. Include your target tolerance class and volume requirements to receive a tailored process plan within 72 hours. For urgent RFQs, reference code LEAD-SS24 in your subject line to prioritize technical review.

Wuxi Lead Precision Machinery operates where precision meets partnership—transforming stainless steel challenges into competitive advantages. Your next breakthrough component begins with an email.

Senior CNC Engineer & Sales Director

Wuxi Lead Precision Machinery

[email protected]

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.