Technical Contents

Engineering Guide: Stainless Steel 3D Printing Service

Engineering Insight Precision in Stainless Steel 3D Printing Services

Precision is not merely a desirable attribute in industrial stainless steel additive manufacturing; it is the absolute cornerstone of functional part integrity and performance. At Wuxi Lead Precision Machinery, we define precision across multiple critical dimensions: micron-level dimensional accuracy, consistent material density exceeding 99.95%, exceptional surface finish suitable for demanding applications, and absolute repeatability batch after batch. In sectors like aerospace, medical implantation, and defense systems, deviations measured in microns can lead to catastrophic component failure or compromised functionality. Achieving this level of control requires far more than advanced hardware. It demands deep metallurgical understanding of stainless steel alloys under rapid thermal cycling, sophisticated process parameter optimization for each specific geometry and material, rigorous in-situ monitoring, and stringent post-processing protocols. The inherent challenges of managing thermal stresses, preventing distortion, and ensuring homogeneous microstructure throughout complex geometries necessitate an engineering-first approach where precision is engineered into every step, from digital design validation to final certification.

Our commitment to uncompromising precision is validated through mission-critical applications. Wuxi Lead has successfully delivered components for the Beijing Winter Olympics timing infrastructure, where sub-micron accuracy in sensor housings was essential for fair competition. Furthermore, we consistently supply precision-manufactured parts for specialized military equipment, including structural elements for aerial reconnaissance drones operating in extreme environments. These projects demand not only meeting exacting dimensional tolerances but also guaranteeing material properties that withstand vibration, temperature extremes, and prolonged stress – requirements where our process control and metallurgical expertise prove indispensable. We leverage extensive experience with key stainless steel alloys, understanding that optimal parameters for 316L differ significantly from those required for precipitation-hardening grades like 17-4PH. This alloy-specific mastery ensures the final part meets or exceeds the required mechanical properties and surface characteristics for its intended high-stakes application.

The following table outlines critical specifications achievable with our industrial-grade stainless steel 3D printing service, reflecting the precision standards demanded by our most rigorous clients:

| Material Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Key Applications |

|---|---|---|---|---|

| 316L Stainless Steel | ≥ 550 | ≥ 250 | ≥ 40 | Medical implants, marine components, chemical processing |

| 17-4PH Stainless Steel | ≥ 1000 | ≥ 850 | ≥ 12 | Aerospace brackets, defense actuators, high-strength tooling |

Achieving these specifications consistently requires our integrated approach: high-precision laser systems operating within tightly controlled inert atmospheres, proprietary thermal management strategies, and comprehensive metrology using coordinate measuring machines (CMM) and micro-CT scanning for internal defect analysis. For Wuxi Lead Precision Machinery, delivering a stainless steel 3D printed part means delivering guaranteed performance. Our engineering team works collaboratively from the initial design phase, conducting thorough Design for Additive Manufacturing (DfAM) reviews to optimize for precision and manufacturability, ensuring the final component functions flawlessly in its operational environment. This is the standard expected by Olympic committees and defense contractors – and it is the standard we apply to every client project.

Precision Specs & Tolerances

Advanced Technical Capabilities in Stainless Steel 3D Printing and Precision Machining

Wuxi Lead Precision Machinery delivers high-performance stainless steel 3D printing services integrated with advanced post-processing techniques to meet the stringent demands of aerospace, medical, energy, and industrial equipment sectors. Our technical capabilities combine additive manufacturing excellence with precision CNC machining and comprehensive quality assurance, ensuring parts meet exact design specifications and performance requirements.

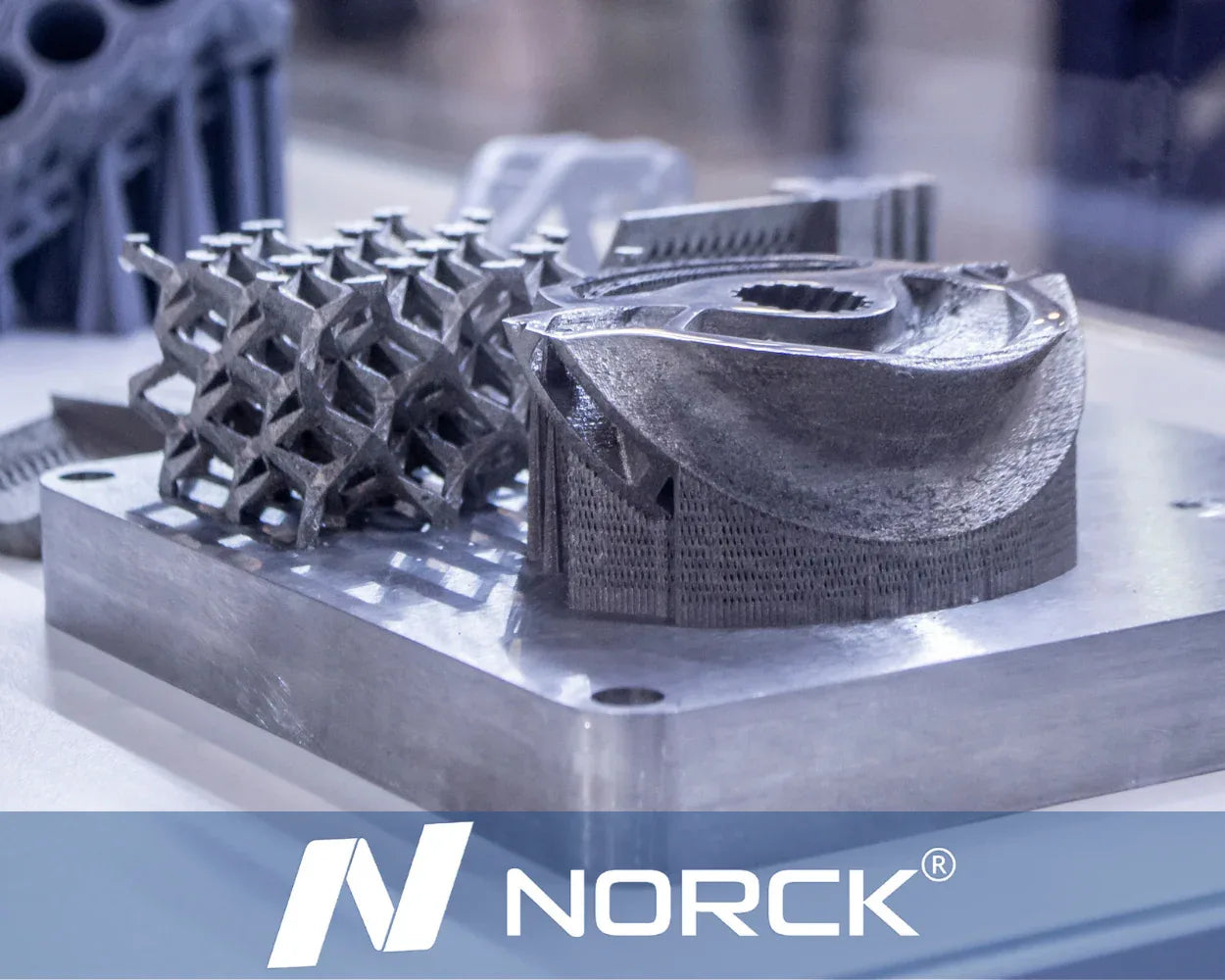

Our stainless steel 3D printing process leverages state-of-the-art metal additive systems capable of producing complex geometries with high density and excellent mechanical properties. We specialize in processing high-grade stainless steel alloys such as 316L, 17-4 PH, and 304, chosen for their corrosion resistance, strength, and suitability for harsh environments. The layer-by-layer fabrication enables internal channels, lattice structures, and topology-optimized designs that are unachievable through traditional methods.

Post-printing, components undergo precision finishing using our 5-axis CNC machining centers. These multi-axis systems provide unparalleled accuracy and surface integrity, allowing for tight-tolerance features, fine surface finishes, and complex contours. The integration of 5-axis technology ensures minimal setup changes, reduced risk of human error, and consistent dimensional accuracy across high-mix, low-volume production runs.

To guarantee compliance with international standards, every component passes through a rigorous quality control workflow. Our inspection suite includes a high-accuracy Coordinate Measuring Machine (CMM), enabling full 3D dimensional verification against CAD models. We perform geometric dimensioning and tolerancing (GD&T) analysis, surface roughness testing, and material certification as part of our standard QC protocol. This data is compiled into detailed inspection reports, traceable to each production batch.

Our facility supports end-to-end manufacturing—from design validation and rapid prototyping to full-scale production—ensuring scalability without compromise on quality. With in-house metallurgical analysis and environmental testing, we validate material properties including tensile strength, hardness, and corrosion resistance, ensuring long-term reliability in service.

The following table outlines the key technical specifications achievable through our integrated stainless steel 3D printing and precision machining workflow.

| Specification | Capability |

|---|---|

| Material Options | 316L, 304, 17-4 PH Stainless Steel |

| Build Envelope (Additive) | Up to Ø400 x 400 mm |

| Layer Thickness (Typical) | 20–50 µm |

| As-Built Surface Roughness (Sa) | 8–15 µm (Ra) |

| Post-Machined Surface Finish | As low as 0.8 µm (Ra) |

| Dimensional Tolerance (Machined) | ±0.010 mm |

| Geometric Tolerance (GD&T) | ±0.015 mm (Form & Position) |

| Feature Resolution | Down to 0.1 mm (internal channels, thin walls) |

| Heat Treatment Options | Solution annealing, H900/H1150 for 17-4 PH |

| Inspection Equipment | Zeiss CMM, OGP optical comparator, roughness testers |

Wuxi Lead Precision Machinery maintains ISO 9001-certified processes and supports full documentation, including First Article Inspection (FAI) and PPAP upon request. Our technical team collaborates closely with clients during design for manufacturability (DFM) reviews to optimize part performance and reduce lead times. This end-to-end control ensures that every stainless steel component we produce meets the highest standards of precision, durability, and repeatability.

Material & Finish Options

Strategic Material Selection for Industrial Metal Additive Manufacturing

Material selection in metal additive manufacturing directly determines component performance, longevity, and total cost of ownership. At Wuxi Lead Precision Machinery, we guide engineering teams through data-driven alloy choices aligned with functional requirements, environmental exposure, and regulatory constraints. Generic material recommendations are insufficient; precision demands analysis of mechanical properties, thermal behavior, and post-processing compatibility. Our expertise ensures your stainless steel 3D printing service leverages the optimal alloy for mission-critical applications, avoiding costly redesigns or field failures.

Aluminum alloys (primarily AlSi10Mg) deliver exceptional strength-to-weight ratios essential for aerospace and automotive lightweighting. These materials exhibit good thermal conductivity and moderate corrosion resistance but require protective finishes for harsh environments. They are unsuitable for sustained high-temperature operation above 200°C. Steel variants dominate when wear resistance, structural integrity, and cost efficiency are paramount. Austenitic stainless steels like 316L provide excellent corrosion resistance in marine or chemical settings, while maraging steels achieve ultra-high tensile strength for tooling applications. Titanium alloys, particularly Ti6Al4V (Grade 5), are indispensable for biomedical implants and aerospace components demanding biocompatibility, extreme strength-to-weight ratios, and resistance to temperatures exceeding 600°C. Their high reactivity necessitates strict inert atmosphere control during printing.

Critical material properties must be evaluated against application-specific demands. The following table summarizes key industrial alloy characteristics for common metal AM processes:

| Material Family | Key Alloy | Tensile Strength (MPa) | Corrosion Resistance | Max Continuous Temp (°C) | Primary Industrial Applications |

|---|---|---|---|---|---|

| Aluminum | AlSi10Mg | 290-360 | Moderate | 200 | Aerospace brackets, heat sinks, automotive housings |

| Stainless Steel | 316L | 500-650 | Excellent | 550 | Marine components, chemical valves, medical instruments |

| Tool Steel | MS1 (Maraging) | 1800-2000 | Good | 480 | Injection molds, die inserts, high-wear tooling |

| Titanium | Ti6Al4V | 900-1000 | Excellent | 600 | Aircraft structural parts, surgical implants, racing components |

Surface finishing significantly enhances functionality and lifespan. Anodizing is exclusively applicable to aluminum alloys, providing wear-resistant, electrically insulating oxide layers in decorative or functional thicknesses. For stainless steel and titanium components, alternative finishes are critical: electropolishing removes surface imperfections and enhances corrosion resistance in 316L parts, while shot peening induces compressive stresses to improve fatigue life in titanium aerospace fittings. Passivation is non-negotiable for stainless steel medical devices to maximize chromium oxide layer formation. Selecting the wrong finish—such as attempting anodizing on steel—causes catastrophic adhesion failure.

Wuxi Lead Precision Machinery integrates material science with production capability. Our engineers collaborate from the design phase to verify alloy suitability against your operational loads, environmental factors, and finish requirements. We validate material certifications per ASTM F3318 (Ti), F3314 (Al), and F3184 (Steel), ensuring traceability for regulated industries. Consult our technical team to optimize your stainless steel 3D printing service parameters and post-processing sequence—transforming material potential into field-proven reliability.

Manufacturing Process & QC

Design Phase: Engineering Precision from Concept to CAD

The foundation of any successful stainless steel 3D printing project begins with meticulous design engineering. At Wuxi Lead Precision Machinery, our team collaborates closely with clients during the initial design phase to ensure manufacturability, structural integrity, and performance alignment with end-use requirements. Utilizing advanced CAD software and simulation tools, we conduct comprehensive design validation, including thermal analysis, stress modeling, and support structure optimization. This proactive approach eliminates potential flaws before physical production, ensuring geometric accuracy and material efficiency. Design for Additive Manufacturing (DfAM) principles are strictly applied to maximize part functionality while minimizing weight and material waste. All designs undergo internal review and client approval before progressing to prototyping.

Prototyping: Validating Performance and Fit

Once the digital model is finalized, we proceed to produce high-fidelity stainless steel prototypes using state-of-the-art metal additive manufacturing systems. These prototypes are not merely visual models—they are fully functional components built with the same material and process parameters intended for mass production. This allows for rigorous testing under real-world conditions, including mechanical load, corrosion resistance, and dimensional stability. Prototypes are inspected using coordinate measuring machines (CMM) and 3D scanning to verify conformity to tolerances. Feedback from this stage is integrated into final design refinements, ensuring optimal performance and eliminating unforeseen issues. The prototyping phase serves as a critical checkpoint in our zero-defect strategy, bridging design intent with production reality.

Mass Production: Scalable Precision with Zero Defects

With prototype validation complete, we transition seamlessly into mass production. Wuxi Lead employs industrial-grade laser powder bed fusion (LPBF) systems capable of producing complex, high-density stainless steel components with exceptional repeatability. Each build undergoes strict in-process monitoring, including layer-by-layer imaging and thermal tracking, to detect anomalies in real time. Post-processing—including stress relief, support removal, surface finishing, and optional heat treatment—is performed under controlled conditions to maintain material properties and dimensional accuracy. Every component is subjected to non-destructive testing (NDT), such as X-ray or ultrasonic inspection, followed by final dimensional and metallurgical verification.

Our zero-defect philosophy is enforced through full traceability, from raw material certification to final inspection reports. Each batch is documented with serial traceability, ensuring compliance with ISO 9001 and industry-specific standards.

Material and Process Specifications

| Parameter | Specification |

|---|---|

| Alloy Types | 316L, 17-4 PH, 304L, Inconel 625 (stainless variants) |

| Layer Thickness | 20–50 μm |

| Build Envelope | Up to 250 × 250 × 300 mm |

| Dimensional Accuracy | ±0.05 mm (typical) |

| Surface Roughness (as-built) | Ra 8–12 μm;可polished至 Ra 0.4 μm |

| Density | ≥99.9% |

| Post-Processing Options | CNC machining, HIP, polishing, passivation |

| Quality Standards | ISO 9001, full inspection reports, material traceability |

Through integrated design, rigorous prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers flawless stainless steel 3D printed components tailored to the most demanding industrial applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Stainless Steel Additive Manufacturing

Wuxi Lead Precision Machinery delivers mission-critical stainless steel 3D printed components where failure is not an option. As your engineering partner, we transcend conventional manufacturing limitations through advanced laser powder bed fusion technology, ISO 13485-certified processes, and metallurgical expertise honed over 15 years serving aerospace, medical, and energy sectors. Our facility in Wuxi operates under stringent AS9100 and NADCAP standards, ensuring every part meets the most demanding geometric tolerances and material integrity requirements. When your application demands corrosion resistance, biocompatibility, or high-temperature performance in complex geometries, our stainless steel additive solutions eliminate assembly steps while exceeding legacy fabrication capabilities.

We specialize in optimizing designs for additive production without compromising structural integrity. Our engineering team collaborates from initial concept through post-processing, applying proprietary thermal management protocols to achieve near-net-shape accuracy of ±0.05mm and surface finishes down to Ra 3.2μm as-built. Critical to high-stakes industries, our in-house metallurgical lab validates microstructure homogeneity and mechanical properties batch-by-batch, providing full traceability from raw powder to finished component. This integrated approach reduces lead times by 40% compared to traditional subcontracting models while guaranteeing compliance with ASTM F75, F138, and F3318 specifications.

Key Stainless Steel Material Capabilities

| Material Grade | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Key Applications |

|---|---|---|---|---|

| 316L (ASTM F75) | ≥580 | ≥300 | ≥40 | Medical implants, marine components |

| 17-4PH (ASTM F3318) | ≥1000 | ≥850 | ≥12 | Aerospace actuators, tooling fixtures |

| 15-5PH | ≥1100 | ≥930 | ≥14 | High-stress hydraulic systems |

| Custom 13-8MO | ≥1200 | ≥1100 | ≥12 | Defense and nuclear components |

Choosing Lead Precision means accessing China’s most advanced metal additive ecosystem without compromising on Western-quality oversight. Our 24/7 production cells with real-time melt pool monitoring ensure batch consistency impossible through conventional machining alone. We handle volumes from single prototypes to 5,000+ unit runs with identical repeatability—critical for regulatory submissions and lifecycle management.

Initiate your precision additive project today. Email [email protected] with your CAD files and application requirements for a confidential engineering consultation. Our technical sales team will provide a comprehensive manufacturability analysis within 24 business hours, including DfAM optimization recommendations and a formal quotation with guaranteed delivery timelines. Do not compromise on component integrity when aerospace tolerances or human health are at stake. Partner with the engineering authority trusted by Siemens Energy, Stryker, and Rolls-Royce supply chains. Your next breakthrough in stainless steel additive manufacturing starts with one email.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.