Technical Contents

Engineering Guide: Ss Cycle Parts

Engineering Insight: Stainless Steel Cycle Parts – The Imperative of Precision in High-Performance Manufacturing

In the realm of high-performance cycling, every gram, every micron, and every mechanical interface contributes to the final outcome: speed, reliability, and safety. Stainless steel (SS) cycle parts—ranging from cranksets and bottom brackets to derailleur components and fasteners—demand a level of precision that transcends standard manufacturing tolerances. At Wuxi Lead Precision Machinery, we understand that the integrity of a cyclist’s performance hinges on the exactness of each machined component. This is not merely about aesthetics or fit; it is about ensuring mechanical harmony, fatigue resistance, and long-term durability under dynamic stress.

Stainless steel, while prized for its corrosion resistance and strength-to-weight ratio, presents unique machining challenges. Its work-hardening characteristics, thermal conductivity, and abrasive nature require advanced CNC techniques, specialized tooling, and real-time process control. Even minor deviations in thread pitch, bore concentricity, or surface finish can lead to premature wear, increased friction, or catastrophic failure under load. This is why precision engineering is non-negotiable in the production of SS cycle parts.

Our experience at Wuxi Lead Precision Machinery extends beyond commercial cycling applications. We have supplied mission-critical components for Olympic-level athletes and defense-grade systems where failure is not an option. These high-stakes environments have refined our approach to tolerancing, material science, and quality assurance. For instance, our CNC-machined stainless steel components consistently achieve tolerances within ±0.005 mm, with surface finishes as fine as Ra 0.4 µm—standards that align with aerospace and military specifications.

The integration of multi-axis machining, in-process metrology, and automated inspection ensures repeatability across production runs. Each component undergoes rigorous testing for dimensional accuracy, microstructure integrity, and corrosion resistance. This disciplined approach guarantees that every SS cycle part not only meets but exceeds the functional demands of elite cycling applications.

Whether for time-trial framesets or endurance drivetrains, the performance of stainless steel components is directly proportional to the precision of their manufacture. At Wuxi Lead, we bring military-grade discipline and Olympic-level attention to detail into every part we produce—ensuring that when performance matters most, our components deliver without compromise.

Typical Specifications for Precision-Machined Stainless Steel Cycle Components

| Parameter | Standard Specification | Tolerance/Range |

|---|---|---|

| Material Grade | AISI 304, 316, 17-4 PH | As per customer requirement |

| Machining Tolerance | Dimensional | ±0.005 mm |

| Surface Roughness (Ra) | Critical interfaces | 0.4 – 1.6 µm |

| Concentricity | Bearing seats, bores | ≤ 0.01 mm |

| Runout | Rotating components | ≤ 0.015 mm |

| Thread Accuracy | ISO Metric, UNF | 6H/6g Class |

| Heat Treatment | As required (solution anneal, H1150) | Certified per batch |

| Inspection Method | CMM, Optical Comparator, Roughness Tester | 100% critical features |

Precision Specs & Tolerances

Technical Capabilities for Precision Stainless Steel Cycle Components

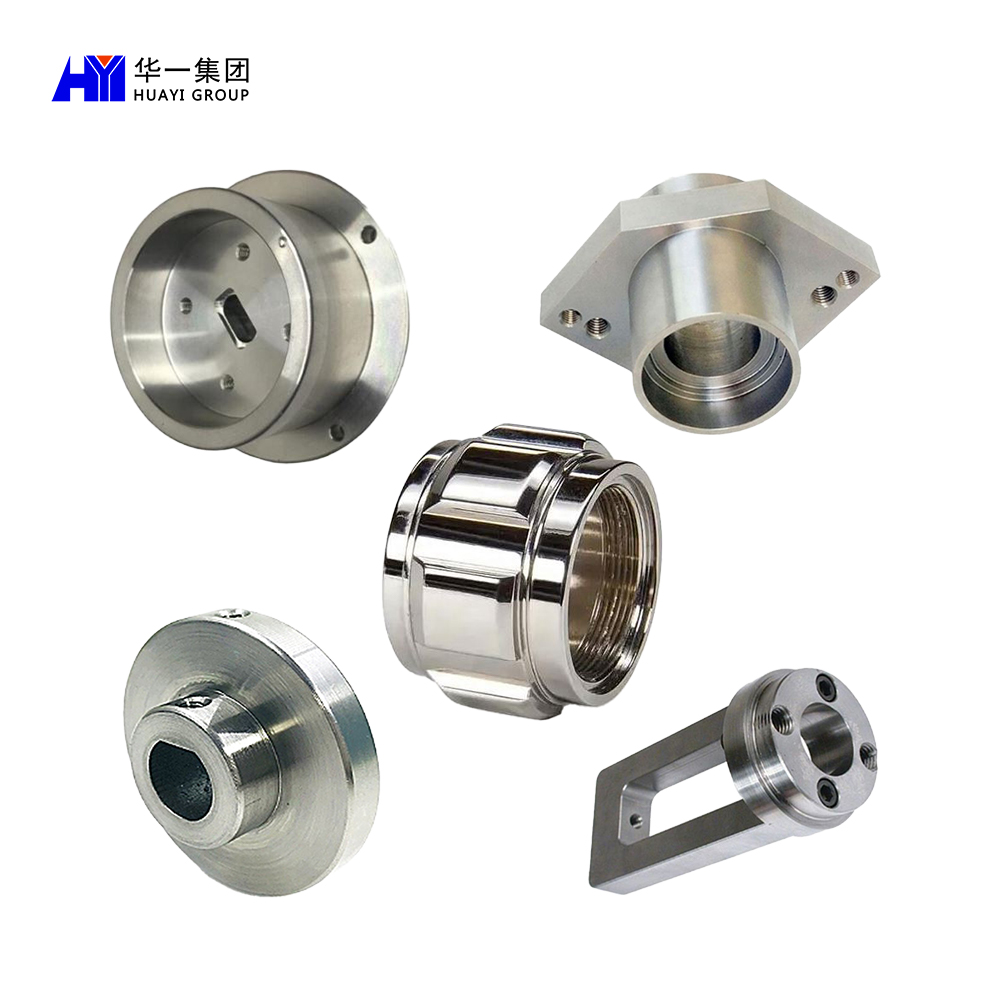

Wuxi Lead Precision Machinery delivers uncompromising precision for high-performance stainless steel bicycle components. Our advanced manufacturing ecosystem is engineered specifically for the demanding geometries and material properties inherent in critical cycle parts, where safety, weight, and fatigue resistance are non-negotiable. Central to our capability is a dedicated fleet of state-of-the-art 5-axis CNC machining centers. These systems enable the complete machining of complex, three-dimensional components—such as integrated headset cups, hollow crank arms, suspension linkages, and custom hub shells—in a single setup. This eliminates cumulative error from multiple fixturing operations, ensuring superior dimensional integrity and surface finish consistency across high-value production runs. Material efficiency is maximized through optimized toolpaths that minimize waste in premium stainless alloys like 17-4 PH and 316L, crucial for balancing strength-to-weight ratios in performance cycling applications.

Rigorous quality assurance is embedded at every stage, anchored by our comprehensive Coordinate Measuring Machine (CMM) inspection protocol. Every critical feature of finished components undergoes 100% verification against CAD nominal data using calibrated Zeiss and Hexagon CMM systems. This includes full geometric dimensioning and tolerancing (GD&T) validation for profile, position, runout, and surface texture. Our inspection regime extends beyond final part verification; pre-production material certification, in-process checks during long runs, and statistical process control (SPC) data analysis are standard practice. This proactive approach ensures zero non-conformances reach the customer, mitigating risk for safety-critical assemblies where micro-defects can lead to catastrophic failure. All inspection reports are digitally archived and provided with shipments, offering full traceability for your quality documentation.

Our commitment to micron-level accuracy is quantified in the tolerance standards we consistently achieve across production batches. These benchmarks reflect our mastery of stainless steel machining dynamics, thermal compensation techniques, and environmental controls within our ISO 9001-certified facility.

| Feature Category | Standard Capability | Tight Tolerance Option | Applicable Standard |

|---|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm | ISO 2768-mK |

| Angular Dimensions | ±0.05° | ±0.02° | ISO 2768-c |

| Geometric Position | ±0.015 mm | ±0.008 mm | ISO 1101 |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm | ISO 1302 |

| Concentricity/Runout | 0.010 mm | 0.005 mm | ISO 1101 |

This precision foundation allows us to transform intricate stainless steel cycle part designs into reality without compromising structural integrity or performance. We partner with engineering teams to optimize manufacturability early in the design phase, leveraging our CNC expertise to suggest geometry refinements that enhance strength while reducing cycle time. For OEMs and tier suppliers demanding flawless execution on mission-critical components, Wuxi Lead provides the technical depth and quality rigor to exceed the highest industry expectations. Contact our engineering team to discuss tolerance validation for your specific application requirements.

Material & Finish Options

Material selection is a critical decision in the production of high-performance SS cycle parts, directly influencing strength, weight, durability, and overall functionality. At Wuxi Lead Precision Machinery, we specialize in precision manufacturing for demanding applications, offering expert guidance in selecting the optimal metal and finish for your specific cycling components. The three primary materials used in high-end cycle part fabrication—aluminum, steel, and titanium—each present unique advantages depending on performance requirements, environmental exposure, and design constraints.

Aluminum is widely favored in the cycling industry for its excellent strength-to-weight ratio and corrosion resistance. 6061 and 7075 aluminum alloys are particularly common in structural and non-load-bearing components such as brackets, housings, and linkage systems. These alloys are easily machinable and respond well to heat treatment, allowing for enhanced mechanical properties. However, aluminum’s lower hardness compared to steel makes it more susceptible to wear under high friction conditions.

Steel remains the material of choice when maximum strength and wear resistance are required. Alloy steels such as 4140 and 1045 offer high tensile strength and excellent fatigue resistance, making them ideal for crank arms, bottom brackets, and other high-stress drivetrain components. While steel is heavier than aluminum and titanium, its durability and cost-effectiveness for high-load applications make it indispensable in performance cycling systems. Proper surface finishing and protective coatings are essential to prevent corrosion, especially in outdoor or wet environments.

Titanium alloys, particularly Grade 5 (Ti-6Al-4V), deliver an outstanding balance of strength, low density, and exceptional corrosion resistance. Though more expensive and challenging to machine, titanium is increasingly used in premium cycle parts where weight savings and longevity are paramount. Components such as seatposts, handlebars, and fasteners benefit from titanium’s fatigue resistance and ability to withstand extreme conditions without degradation.

For aluminum components, anodizing is the recommended surface treatment to enhance durability and appearance. Anodizing creates a controlled oxide layer that improves wear and corrosion resistance while allowing for color customization through dye integration. Type II (sulfuric acid) anodizing is standard for most cycle parts, offering a balance of protection and aesthetics, while Type III (hardcoat) anodizing provides superior surface hardness for high-wear applications.

The following table summarizes key mechanical and physical properties of the materials discussed:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Corrosion Resistance | Typical Applications in Cycling |

|---|---|---|---|---|---|

| 6061 Aluminum | 2.7 | 310 | 276 | High | Brackets, housings, linkages |

| 7075 Aluminum | 2.8 | 572 | 503 | Moderate | High-strength structural components |

| 4140 Steel | 7.85 | 655 | 415 | Low (with coating) | Crank arms, bottom brackets, axles |

| 1045 Steel | 7.85 | 570 | 310 | Low (with coating) | Shafts, bolts, high-wear fittings |

| Ti-6Al-4V (Gr 5) | 4.43 | 900 | 830 | Very High | Seatposts, handlebars, fasteners |

At Wuxi Lead Precision Machinery, we support material and finish selection with in-depth engineering consultation, ensuring your SS cycle parts meet both performance targets and production efficiency.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: Precision Manufacturing Process for SS Cycle Parts

Achieving flawless performance in stainless steel cycle components demands an uncompromising production methodology. At Wuxi Lead Precision Machinery, our integrated process from initial concept to full-scale manufacturing is engineered specifically for zero-defect outcomes in demanding applications. We understand that even microscopic deviations in critical cycle parts can lead to catastrophic field failures or premature wear, directly impacting your product’s reliability and safety. Our systematic approach eliminates guesswork and ensures every component meets the most stringent aerospace and high-performance cycling standards.

The journey begins with collaborative design engineering. Our CNC specialists work directly with your technical team to translate functional requirements into optimized, manufacturable CAD models. This phase focuses on material selection (primarily 304/316L SS), geometric feasibility, and critical tolerance allocation. We perform rigorous DFMA analysis to identify potential stress points, machining challenges, and opportunities for weight reduction without sacrificing structural integrity, ensuring the design is inherently robust before any metal is cut.

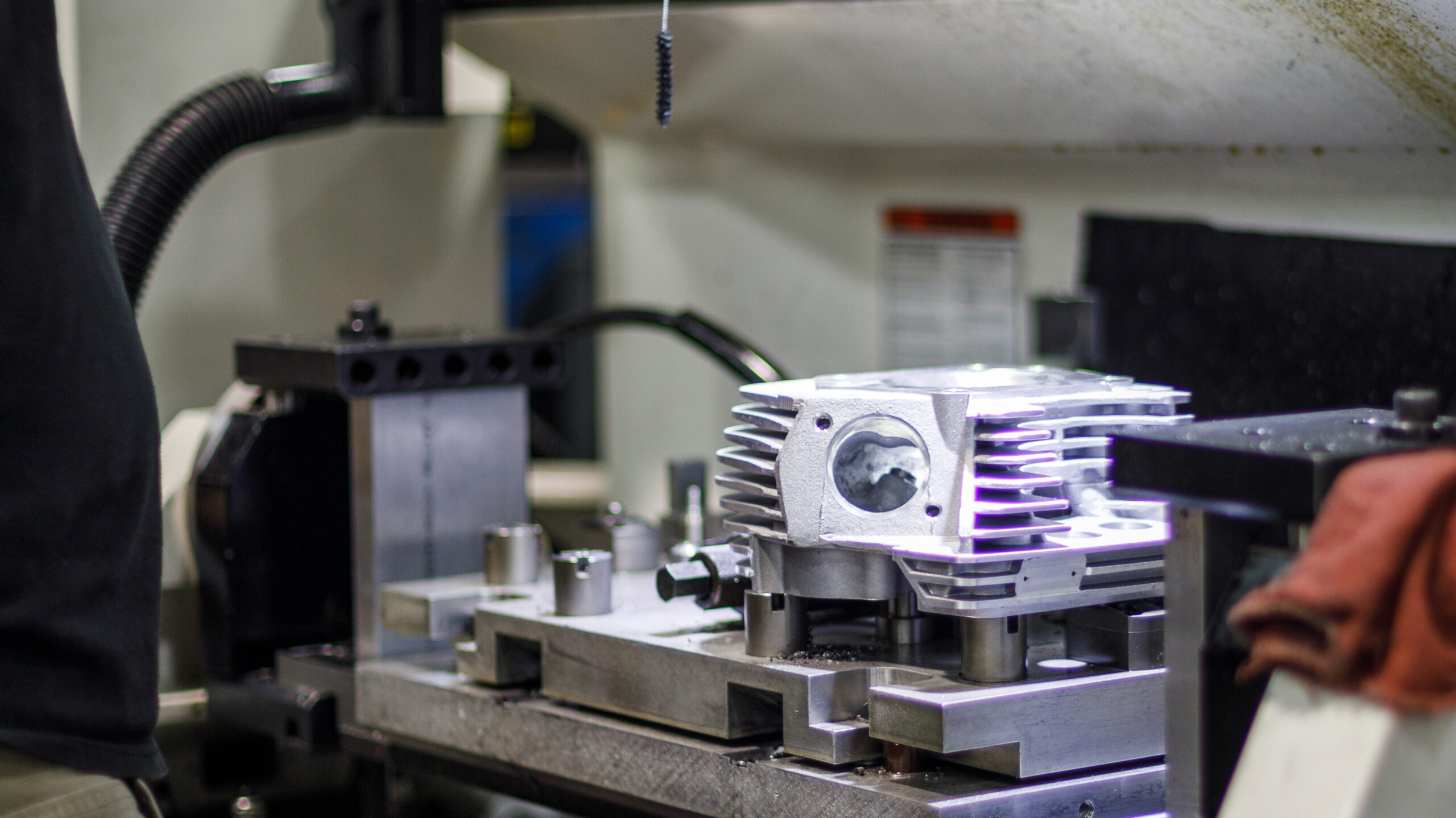

Prototyping is where theoretical precision becomes tangible reality. Utilizing our advanced 5-axis CNC milling and turning centers, we produce initial functional prototypes under full production conditions. Each prototype undergoes exhaustive metrology: CMM inspection against full GD&T callouts, surface roughness validation, and non-destructive testing where required. This phase is iterative; dimensional data feeds directly back to refine the CAM program and fixturing, guaranteeing the production process is validated and stabilized. Only after achieving consistent conformance to all specifications do we authorize mass production.

Mass production leverages our fully automated, lights-out capable manufacturing cells. Every component is machined under controlled environmental conditions with real-time process monitoring. Our Zero Defects commitment is operationalized through 100% in-process inspection of critical dimensions using integrated probes and vision systems, coupled with rigorous final inspection protocols exceeding standard AQL sampling. Statistical process control (SPC) data is continuously analyzed, enabling immediate corrective action. This closed-loop system, combined with our certified ISO 9001:2015 quality management framework, ensures batch-to-batch consistency and eliminates escape defects, minimizing your downstream assembly issues and field failures.

Critical SS Cycle Part Production Specifications

| Parameter | Capability Range | Measurement Standard | Process Control Level |

|---|---|---|---|

| Dimensional Tolerance | ±0.005 mm (critical) | ISO 2768-mK / GD&T | 100% In-Process SPC |

| Surface Roughness | Ra 0.2 µm – Ra 1.6 µm | ISO 1302 | Per Feature Sampling |

| Material Compliance | ASTM A276 304/316L | Mill Cert + In-House | Lot Traceability |

| Geometric Accuracy | < 0.01 mm Form Dev. | ASME Y14.5 | CMM Verification |

| Production Volume | 1 – 50,000+ units | Client Schedule | Automated Cell Ready |

This disciplined progression from validated design through rigorously tested prototyping to tightly controlled mass production forms the bedrock of Wuxi Lead’s zero-defect promise for your stainless steel cycle components. We deliver not just parts, but guaranteed performance and peace of mind.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we understand that in high-performance industries, every component matters. Whether you’re in aerospace, automotive, medical devices, or advanced industrial equipment, the integrity, precision, and repeatability of your metal parts directly impact your product’s success. That’s why forward-thinking manufacturers choose to partner with us—not just as a supplier, but as an engineering extension of their team.

Our specialization in custom metal manufacturing is built on over a decade of precision CNC machining, advanced material processing, and rigorous quality control. We don’t just meet specifications—we anticipate challenges, optimize designs for manufacturability, and deliver solutions that enhance performance while reducing long-term costs. From prototype development to high-volume production, our facility in Wuxi, China, is equipped with state-of-the-art multi-axis CNC centers, Swiss-type lathes, and automated inspection systems to ensure every part is produced to micron-level accuracy.

What sets us apart is our commitment to partnership. We work closely with your engineering team to review designs, suggest material improvements, and streamline production workflows. Our engineers are fluent in global standards including ISO 9001, AS9100, and IATF 16949, ensuring compliance across regulated industries. With in-house capabilities spanning milling, turning, grinding, and surface treatment, we offer a single-source solution that reduces supply chain complexity and accelerates time to market.

Below are key technical specifications that define our manufacturing capabilities:

| Capability | Specification |

|---|---|

| Machining Tolerances | ±0.005 mm (±0.0002″) |

| Maximum Work Envelope | 2000 x 1200 x 1000 mm (78.7 x 47.2 x 39.4 in) |

| Materials Processed | Aluminum Alloys, Stainless Steel, Titanium, Inconel, Brass, Tool Steels, Plastics |

| CNC Equipment | 3-axis to 5-axis milling, CNC turning, Swiss machining |

| Surface Finishes | As-machined, Anodizing, Passivation, Powder Coating, Polishing |

| Quality Assurance | CMM, Optical Comparator, Surface Roughness Tester, First Article Inspection (FAI) |

| Production Volume | Prototypes to 500,000+ units annually |

| Lead Times | From 7 days for prototypes, scalable for production runs |

We serve global clients with full traceability, real-time project updates, and dedicated account management. Our facility is export-ready, with extensive experience shipping to North America, Europe, and Asia under strict compliance protocols.

When you partner with Wuxi Lead Precision Machinery, you gain more than precision parts—you gain reliability, innovation, and a commitment to excellence that aligns with your highest standards.

Contact us today to discuss your next project. Email us at [email protected] and let our engineering team help you turn design challenges into manufacturing successes.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.