Technical Contents

Engineering Guide: Soft Sheet Metal

Engineering Insight: The Critical Role of Precision in Soft Sheet Metal Fabrication

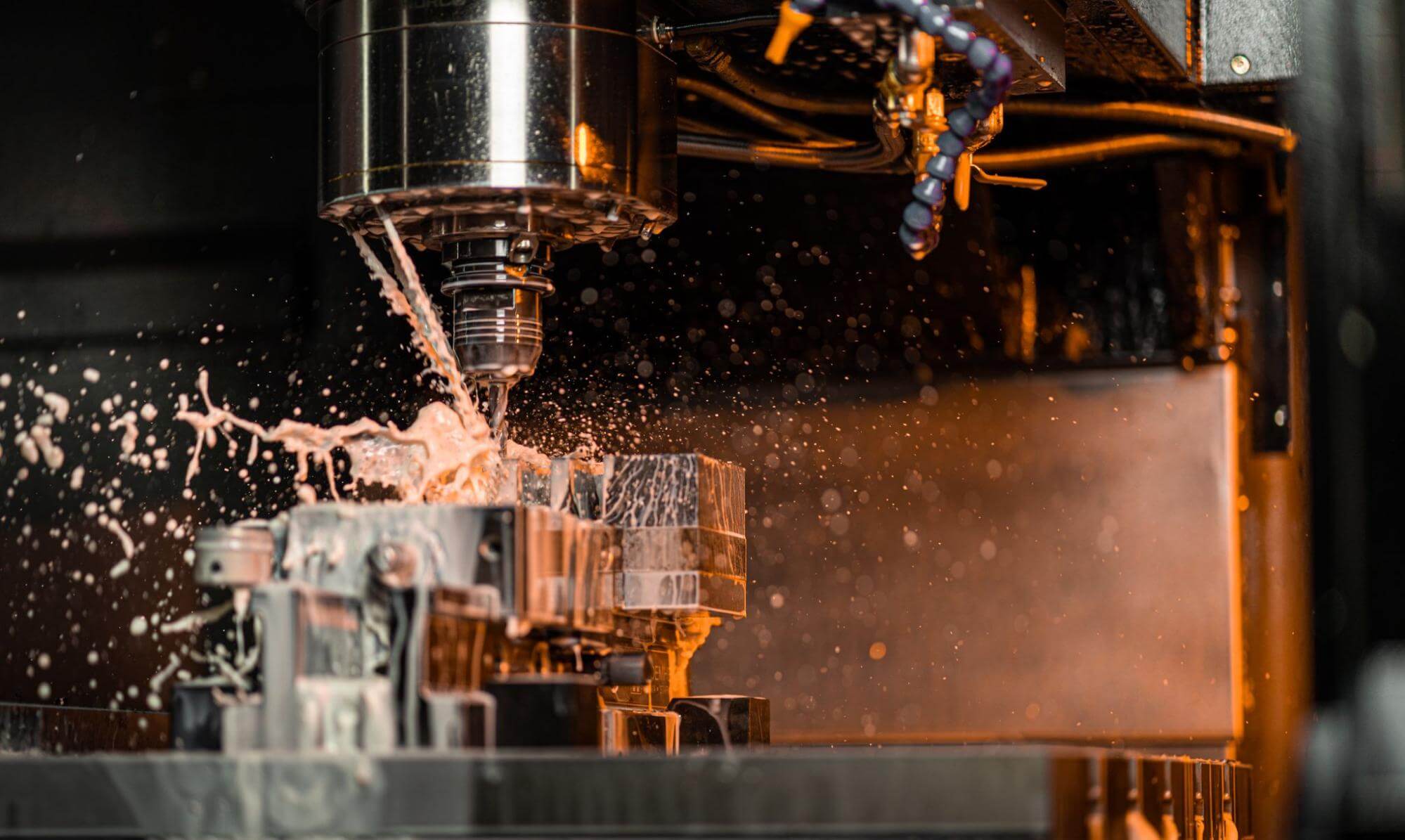

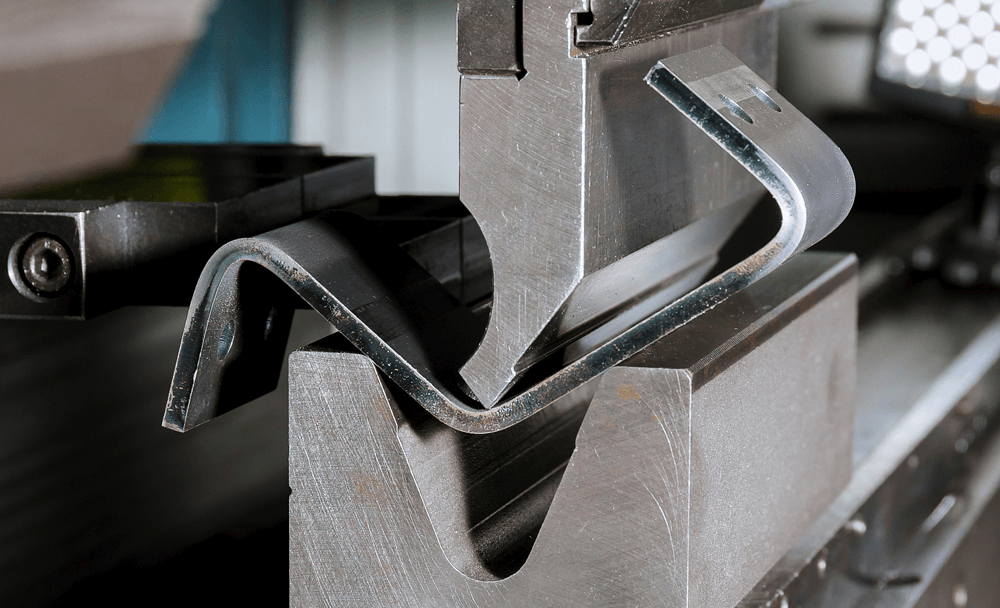

In the realm of sheet metal fabrication, soft sheet metals—such as aluminum alloys, mild steel, and select copper-based materials—present unique engineering challenges despite their apparent malleability. Their low yield strength and high ductility make them prone to deformation, warping, and dimensional inaccuracies during cutting, bending, and forming operations. At Wuxi Lead Precision Machinery, we understand that working with soft sheet metal is not simply a matter of handling thinner or more pliable material—it demands a refined approach rooted in precision engineering, advanced tooling, and decades of applied expertise.

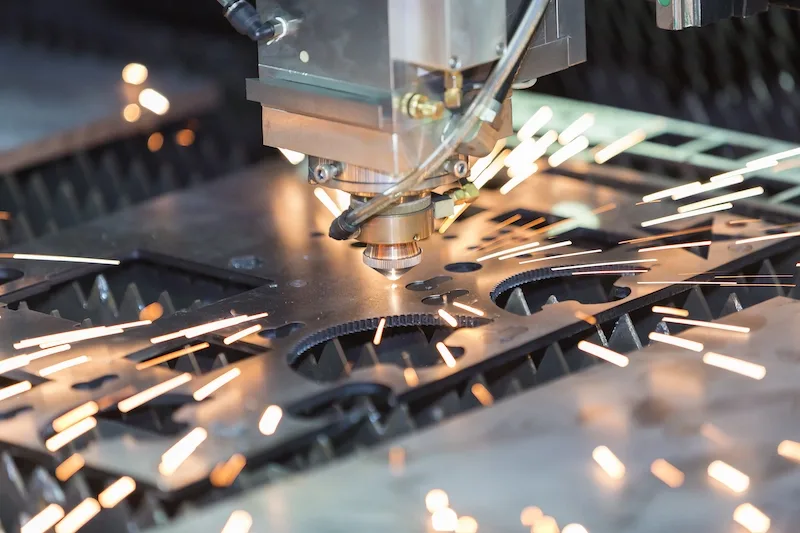

Precision in soft sheet metal fabrication begins with material behavior prediction. Unlike harder alloys, soft metals exhibit significant springback and can stretch unevenly under stress, leading to inconsistencies in final part geometry. This necessitates the use of high-resolution CNC-controlled press brakes with real-time feedback systems, laser-guided cutting platforms, and adaptive clamping mechanisms that minimize distortion during processing. At Lead Precision, our fabrication cells are calibrated to maintain tolerances within ±0.05 mm, ensuring repeatability across production runs—even for materials as sensitive as 0.5 mm aluminum 1100 or 0.8 mm low-carbon steel.

Our commitment to precision is not theoretical. Over the past 18 years, Wuxi Lead has delivered mission-critical components for applications where failure is not an option. This includes structural enclosures for military communication systems requiring EMI shielding integrity and vibration resistance, as well as architectural paneling for Olympic-scale venues demanding flawless aesthetic alignment across thousands of units. These projects underscore our ability to balance the delicacy required for soft materials with the rigor expected in high-stakes industrial environments.

Beyond machinery, precision is sustained through process control. We employ in-process metrology, finite element analysis (FEA) for bend simulation, and proprietary stress-relief protocols to counteract micro-deformations inherent in soft sheet metal. Each stage—from nesting optimization to final deburring—is monitored to prevent cumulative error, ensuring that every component meets exacting specifications.

The following table outlines key fabrication parameters we optimize for soft sheet metal applications:

| Parameter | Typical Range | Control Method |

|---|---|---|

| Material Thickness | 0.3 – 3.0 mm | Laser micrometer verification |

| Bending Tolerance | ±0.1° angular, ±0.05 mm linear | CNC press brake with crowning compensation |

| Cutting Tolerance | ±0.03 mm | Fiber laser with adaptive focus |

| Surface Roughness (Ra) | 0.8 – 3.2 µm | Optimized gas pressure and nozzle selection |

| Springback Compensation | Material-specific algorithms | FEA-based tool path adjustment |

At Wuxi Lead Precision Machinery, our experience with soft sheet metal is forged in real-world, high-performance applications. We do not merely fabricate parts—we engineer reliability into every bend, cut, and finish, ensuring our clients receive components that perform as designed, every time.

Precision Specs & Tolerances

Technical Capabilities: Precision Fabrication for Soft Sheet Metal

Wuxi Lead Precision Machinery delivers industry-leading fabrication for soft sheet metal components, including aluminum alloys, copper, brass, and thin-gauge stainless steel. Our specialized 5-axis CNC milling and turning centers eliminate the deformation risks inherent in machining malleable materials. Unlike conventional 3-axis systems, our HAAS and DMG MORI platforms maintain consistent tool engagement and minimal clamping force, preventing warping during high-precision contouring. This capability ensures dimensional stability for complex geometries—such as enclosures, heat sinks, and fluidic manifolds—where tolerances below ±0.05 mm are non-negotiable.

Soft sheet metal presents unique challenges: low rigidity invites chatter, thermal expansion skews measurements, and burr formation compromises edge integrity. Our process counters these through adaptive toolpath strategies, cryogenic cooling, and custom vacuum-fixturing that distributes pressure evenly across the workpiece. Material-specific parameters are pre-validated in our digital twin simulation suite, reducing trial runs by 70% and guaranteeing first-article success. All operations adhere to ISO 1302 surface finish standards, with Ra values consistently held at 0.8 µm or better.

Quality assurance is anchored in Zeiss CONTURA CMM systems, providing full 3D traceability per AS9100 and ISO 17025 protocols. Every batch undergoes automated GD&T validation against CAD models, with real-time SPC data accessible via client dashboards. This closed-loop inspection prevents non-conformances from progressing to assembly, critical for aerospace and medical device partners where scrap costs exceed $5,000 per component.

Our tolerance benchmarks reflect material behavior under controlled conditions. The table below specifies achievable limits for soft sheet metal up to 3.0 mm thickness:

| Parameter | Material Thickness Range | Standard Tolerance | Precision Option |

|---|---|---|---|

| Linear Dimensions | 0.5–3.0 mm | ±0.05 mm | ±0.02 mm |

| Hole Positioning | 0.5–3.0 mm | ±0.08 mm | ±0.03 mm |

| Flatness | 0.5–2.0 mm | 0.10 mm/m² | 0.05 mm/m² |

| Edge Radius | All thicknesses | ±0.15 mm | ±0.05 mm |

| Angular Features | 0.8–3.0 mm | ±0.3° | ±0.1° |

These specifications assume standard annealed tempers; tighter tolerances are attainable with stress-relieved stock or post-machining stabilization. Crucially, our 5-axis workflow integrates milling, drilling, and chamfering in a single setup—eliminating secondary operations that introduce stack-up errors. This holistic approach reduces lead times by 40% while ensuring repeatability across 10,000+ part runs.

For clients in electric vehicle and semiconductor sectors, our capability translates to reliable supply chains. By mastering the interplay of machine dynamics, material science, and metrology, Wuxi Lead transforms soft sheet metal from a fabrication challenge into a competitive advantage. All deliverables include full inspection reports with CMM point-cloud overlays, providing auditable proof of conformance for your most demanding applications.

Material & Finish Options

Material Selection in Precision Sheet Metal Fabrication

Selecting the appropriate soft sheet metal material is critical in high-performance manufacturing, particularly in industries such as aerospace, medical devices, and advanced electronics. At Wuxi Lead Precision Machinery, we emphasize material compatibility with fabrication processes, end-use environments, and performance requirements. Among the most widely used soft sheet metals are aluminum, steel, and titanium—each offering distinct mechanical, thermal, and chemical properties.

Aluminum stands out for its excellent strength-to-weight ratio, corrosion resistance, and electrical conductivity. It is particularly suitable for lightweight structural components and enclosures where weight reduction is a priority. Grade 6061-T6 is a common choice due to its weldability and machinability, while 5052-H32 is preferred for deep-drawing applications. Aluminum’s natural oxide layer provides inherent corrosion resistance, but for enhanced durability and aesthetic control, anodizing is recommended.

Steel, specifically low-carbon and stainless variants, offers superior tensile strength and formability. Mild steel (e.g., AISI 1008–1020) is cost-effective and ideal for enclosures, brackets, and chassis requiring high rigidity. Stainless steel grades such as 304 and 316 provide excellent resistance to oxidation and chemical exposure, making them suitable for harsh environments, including medical and food processing applications. While steel is heavier than aluminum, its mechanical robustness ensures long-term reliability under stress.

Titanium, though more expensive, delivers unmatched performance in extreme conditions. Its high strength-to-density ratio, exceptional corrosion resistance—even in saline environments—and biocompatibility make it indispensable in aerospace, defense, and implantable medical devices. Grade 2 and Grade 5 (Ti-6Al-4V) are commonly used in sheet form, though titanium’s low thermal conductivity and high reactivity require specialized tooling and handling during fabrication.

Surface finishing plays a vital role in both functionality and appearance. Anodizing, primarily applied to aluminum, enhances surface hardness, wear resistance, and corrosion protection. It also allows for color coding through dye integration, which is valuable for product identification and branding. Type II (sulfuric acid) and Type III (hardcoat) anodizing are the most prevalent, with Type III offering thicker, more durable coatings for industrial applications.

Below is a comparative overview of key material specifications relevant to soft sheet metal fabrication.

| Material | Common Grades | Thickness Range (mm) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|---|

| Aluminum | 5052-H32, 6061-T6 | 0.5 – 6.0 | 190 – 310 | High | Enclosures, heat sinks, aerospace |

| Mild Steel | AISI 1008, 1020 | 0.8 – 10.0 | 340 – 440 | Low (requires coating) | Industrial frames, brackets |

| Stainless Steel | 304, 316 | 0.5 – 8.0 | 505 – 620 | Very High | Medical devices, food processing |

| Titanium | Grade 2, Grade 5 | 0.5 – 5.0 | 345 – 1000 | Exceptional | Aerospace, defense, implants |

Understanding material behavior under load, temperature, and environmental exposure ensures optimal performance and cost efficiency. At Wuxi Lead Precision Machinery, we support clients in selecting the right combination of material and finish to meet exact engineering and aesthetic demands.

Manufacturing Process & QC

Soft Sheet Metal Fabrication: Precision Engineering from Concept to Volume

Wuxi Lead Precision Machinery delivers flawless soft sheet metal components through a rigorously controlled production sequence. Our process eliminates defects inherent in materials like aluminum 1100, copper C110, and brass C260, ensuring structural integrity and dimensional accuracy for demanding applications. This begins with integrated engineering during the Design phase. Material-specific behaviors—springback, grain direction sensitivity, and thermal expansion—are modeled using advanced FEA software. We collaborate with clients to optimize part geometry, selecting appropriate alloys and thicknesses while designing tooling paths that prevent burring, warping, or micro-cracking. Critical tolerances are validated against ASME Y14.5 standards before prototyping commences.

Prototyping transitions digital models into physical validation. Utilizing high-speed CNC punch presses and laser cutters with sub-10-micron repeatability, we produce functional prototypes within 72 hours. Each prototype undergoes comprehensive metrology: CMM scans verify flatness within ±0.05mm/m, surface profilometry checks for micro-scratches, and tensile testing confirms material properties remain uncompromised. Client feedback is incorporated iteratively, with design adjustments made in real-time via our PLM system. This phase identifies latent risks like stress concentrations or assembly interference, preventing costly errors in volume production.

Mass Production leverages fully automated cells monitored by our proprietary LeadQAI system. Stamping, bending, and forming operations occur under constant environmental control (20±1°C, 45% RH) to negate thermal drift. In-process sensors measure force distribution and part deflection 1,000 times per second, automatically adjusting press tonnage and bend angles. Every component passes through inline optical inspection stations detecting surface defects as small as 10µm. Statistical process control (SPC) tracks critical dimensions with real-time X-bar R charts, triggering immediate process correction if CpK falls below 1.67. Final assemblies undergo 100% functional testing against client-specific performance criteria.

Our Zero Defects commitment is non-negotiable. It is engineered into every stage through predictive analytics, closed-loop process control, and material traceability down to the ingot lot. The result is soft metal components that consistently meet aerospace, medical, and semiconductor industry requirements—delivered on schedule with zero concessions to quality.

| Material | Thickness Range (mm) | Tensile Strength (MPa) | Key Fabrication Challenges | Wuxi Lead Precision Solutions |

|---|---|---|---|---|

| Aluminum 1100 | 0.5 – 3.0 | 90 – 110 | Springback, surface marring | Adaptive bending algorithms, polymer-coated tooling |

| Copper C110 | 0.3 – 2.5 | 210 – 240 | Work hardening, oxidation | Oxygen-free laser cutting, cryogenic forming |

| Brass C260 | 0.4 – 2.0 | 340 – 420 | Galling, dimensional instability | Diamond-coated dies, real-time thermal compensation |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Expertise in Soft Sheet Metal Fabrication

At Wuxi Lead Precision Machinery, we specialize in high-precision manufacturing solutions tailored to the demanding requirements of modern industrial applications. When it comes to soft sheet metal fabrication, our engineering excellence, advanced CNC technology, and deep material science understanding set us apart as a trusted partner for global OEMs, aerospace firms, and high-tech equipment manufacturers. Whether you’re working with aluminum alloys, copper, brass, or low-carbon steel, our processes are designed to maintain material integrity while achieving tight tolerances and flawless surface finishes.

Soft sheet metals present unique challenges—material deformation, warping during cutting, and edge quality degradation are common issues that can compromise final product performance. At Lead Precision, we address these challenges with proprietary tooling strategies, adaptive clamping systems, and real-time process monitoring. Our state-of-the-art fiber laser cutting systems, combined with automated bending cells and robotic handling, ensure consistent repeatability down to ±0.05 mm. We also offer in-house material testing and first-article inspection reports to guarantee compliance with ISO 9001:2015 and customer-specific standards.

Our facility in Wuxi, China, spans over 12,000 square meters and operates under a lean manufacturing framework, enabling rapid prototyping, low-to-high volume production, and just-in-time delivery. We support international clients with full project lifecycle management—from DFM analysis and material sourcing to finishing, assembly, and logistics coordination. Every component is traceable, and every process is optimized for quality, speed, and cost-efficiency.

Below are key technical capabilities for soft sheet metal fabrication at Lead Precision:

| Specification | Detail |

|---|---|

| Material Thickness Range | 0.5 mm – 3.0 mm |

| Maximum Sheet Size | 1500 mm × 3000 mm |

| Tolerance Accuracy | ±0.05 mm (cutting), ±0.1° (bending) |

| Laser Cutting Power | Up to 6 kW (fiber) |

| Bending Press Tonnage | Up to 100 tons with CNC backgauging |

| Supported Materials | Aluminum (1050, 3003, 5052, 6061), Copper (C11000), Brass (H62, H68), SPCC, SECC |

| Surface Treatments | Deburring, grinding, polishing, anodizing, powder coating (partner network) |

| Quality Standards | ISO 9001:2015, RoHS compliant, First Article Inspection (FAI), PPAP Level 3 available |

We invite engineering teams, procurement managers, and product developers to contact us directly to discuss your next soft sheet metal project. Our technical sales engineers are available to provide detailed process recommendations, material selection guidance, and competitive quotations within 24 hours.

For partnership inquiries, technical collaboration, or sample requests, email us at [email protected]. Let Wuxi Lead Precision Machinery be your strategic manufacturing partner—where precision meets performance.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.