Technical Contents

Engineering Guide: Sls Printing Services

Engineering Insight Precision in SLS Printing Services

Selective Laser Sintering (SLS) represents a cornerstone of advanced additive manufacturing for functional polymer and composite parts. While the technology offers significant design freedom and rapid prototyping advantages, its true industrial value in high-stakes applications hinges entirely on uncompromising precision. In sectors like aerospace, medical device manufacturing, and defense, dimensional accuracy, repeatability, and material integrity are not merely desirable; they are non-negotiable requirements dictating component performance, safety, and regulatory compliance. Achieving this level of precision demands far more than standard machine operation. It requires deep material science expertise, rigorous process control, sophisticated post-processing capabilities, and an ingrained engineering culture focused on metrology and validation at every stage. Sub-millimeter deviations can cascade into catastrophic system failures or costly production line stoppages. Therefore, selecting an SLS service provider necessitates evaluating their proven ability to deliver consistent, certified accuracy under real-world manufacturing constraints, not just theoretical machine specifications.

Wuxi Lead Precision Machinery understands this critical imperative. Our engineering team possesses extensive, battle-tested experience delivering SLS components where precision is paramount. We have successfully produced mission-critical polymer and composite parts for demanding applications, including components integrated into systems for the Beijing Winter Olympics infrastructure and specialized fixtures utilized within sensitive defense sector programs. These projects demanded adherence to stringent military-grade (MIL-STD) and aerospace standards, requiring not only exact dimensional conformance but also thorough documentation, traceability, and validation through advanced metrology. Our facility operates under certified quality management systems, ensuring every SLS build undergoes meticulous process monitoring and post-build verification using calibrated CMMs and optical scanning equipment. This commitment to precision engineering is woven into our operational DNA.

The following specifications reflect the precision benchmarks consistently achievable through our optimized SLS processes and rigorous quality protocols for standard industrial polymers like PA12:

| Parameter | Specification | Relevance to Precision |

|---|---|---|

| Layer Thickness | 50 – 100 μm | Directly impacts surface finish and feature resolution |

| Dimensional Accuracy | ±0.1% (min ±0.1 mm) | Critical for fit, function, and assembly tolerances |

| Feature Resolution | 0.3 mm (min) | Enables complex geometries and fine details |

| Surface Roughness (Ra) | 8 – 15 μm | Affects part performance and post-processing needs |

| Build Repeatability | < 0.05% variation | Ensures consistent quality across batches |

Partnering with a provider possessing demonstrable experience in high-precision, regulated environments transforms SLS from a prototyping tool into a reliable production solution. At Wuxi Lead Precision Machinery, our Olympic and defense project heritage provides concrete evidence of our capability to meet the most exacting precision demands. We translate this expertise into every customer project, guaranteeing SLS-printed components that perform reliably within your critical assemblies, backed by comprehensive metrology reports and unwavering engineering support. Precision isn’t just a specification we meet; it’s the foundation of our manufacturing promise.

Precision Specs & Tolerances

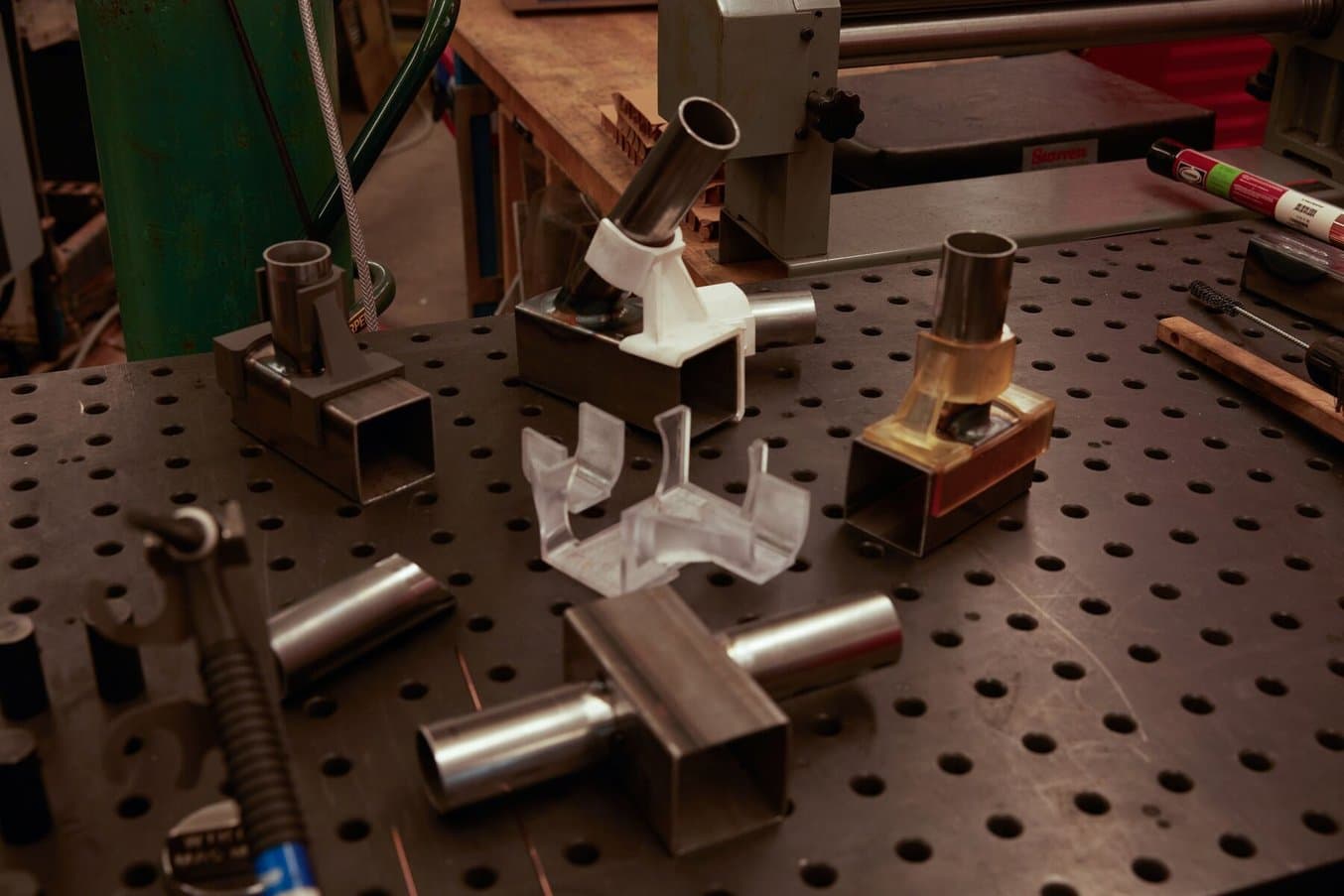

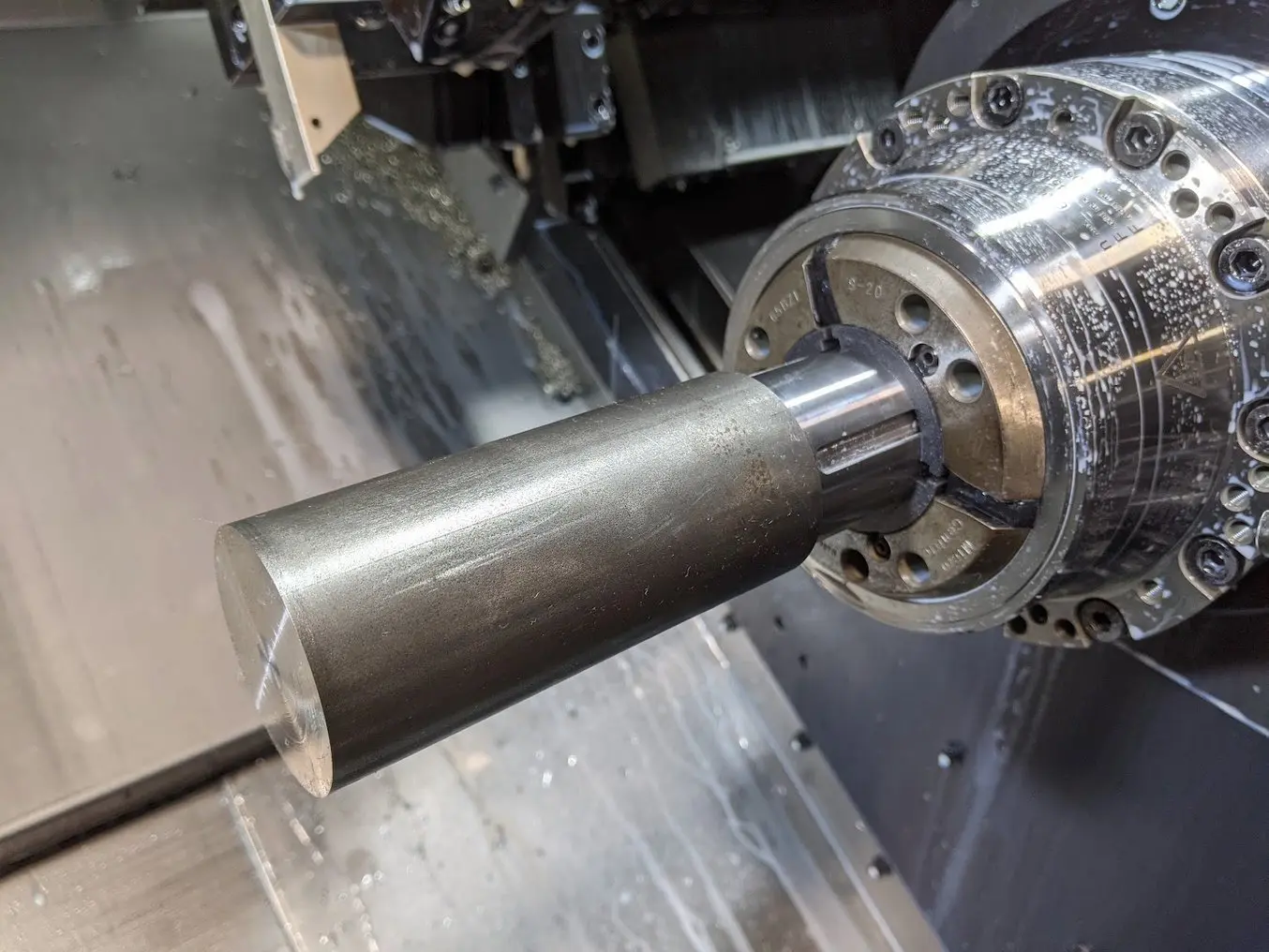

Wuxi Lead Precision Machinery delivers advanced manufacturing solutions tailored to the most demanding sectors, including aerospace, medical, energy, and high-performance automotive. Our technical capabilities are built around precision, repeatability, and material integrity, ensuring every component meets the highest global standards. At the core of our production floor is a fleet of state-of-the-art 5-axis CNC machining centers, enabling us to produce complex geometries with superior surface finishes and tight dimensional control. These machines allow simultaneous multi-axis movement, reducing setup times and improving accuracy by minimizing part repositioning. This capability is especially critical when integrating components initially produced via selective laser sintering (SLS), where post-processing is required to achieve functional tolerances and interface specifications.

Our integration of SLS printing services with precision CNC machining provides a hybrid manufacturing advantage. Additively manufactured metal parts often require critical feature finishing, thread creation, or surface refinement to meet functional requirements. We specialize in the precision machining of such components, particularly those made from Inconel, titanium, stainless steel, and aluminum alloys. The 5-axis platform allows us to access difficult-to-reach features, ensuring that even the most intricate internal channels or organic shapes are machined to exacting standards.

Quality assurance is non-negotiable in our process. Every component undergoes comprehensive inspection using a coordinate measuring machine (CMM) with probing accuracy down to ±0.0001 inches (2.5 µm). Our CMM systems are calibrated to ISO 17025 standards and operated by certified metrology technicians. Full first-article inspection (FAI) reports and production-level SPC data are available upon request, ensuring complete traceability and compliance with AS9100 and ISO 13485 requirements.

We maintain strict environmental controls in our metrology lab to eliminate thermal drift, ensuring measurement stability across long production runs. In addition to CMM inspection, we employ surface roughness testers, optical comparators, and hardness testing equipment to validate material and finish properties.

The following table outlines our standard machining tolerances for post-processed SLS components:

| Feature Type | Standard Tolerance | Precision Tolerance | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm | Up to 150 mm; tighter tolerances achievable with special process control |

| Hole Diameter | ±0.025 mm | ±0.012 mm | Reamed or precision bored |

| Positional Tolerance | ±0.030 mm | ±0.015 mm | Relative to datum; verified via CMM |

| Surface Roughness | Ra 3.2 µm | Ra 0.8 µm | As-machined; polished finishes available |

| Angular Features | ±0.05° | ±0.02° | Verified using optical CMM and digital angle gauges |

These capabilities position Wuxi Lead Precision Machinery as a trusted partner for high-integrity metal components where additive freedom meets machined precision.

Material & Finish Options

Material Selection for SLS Metal Printing

Selecting the optimal material for Selective Laser Sintering (SLS) metal printing is critical for achieving performance, durability, and cost efficiency in high-end applications. At Wuxi Lead Precision Machinery, we prioritize materials that align with aerospace, medical, and industrial demands while ensuring seamless integration with our precision post-processing capabilities. Aluminum, steel, and titanium dominate demanding sectors due to their distinct mechanical properties and compatibility with SLS technology.

Aluminum alloys, particularly AlSi10Mg, deliver an exceptional strength-to-weight ratio and thermal conductivity. This makes them ideal for lightweight structural components in aerospace and automotive industries. Post-print anodizing enhances surface hardness and corrosion resistance, while offering aesthetic customization through dye options. Steel variants like 316L stainless steel provide superior tensile strength and biocompatibility, essential for medical implants and marine hardware. Their inherent corrosion resistance ensures longevity in harsh environments without additional coatings. Titanium Ti6Al4V stands out for extreme strength-to-weight performance and biocompatibility, frequently specified in aviation and surgical tools. Its fatigue resistance and ability to withstand high temperatures make it indispensable for mission-critical parts.

Key mechanical properties guide material decisions based on application stressors. Refer to the comparative specifications below:

| Material | Tensile Strength (MPa) | Elongation (%) | Density (g/cm³) | Typical Applications |

|---|---|---|---|---|

| AlSi10Mg | 290–340 | 8–12 | 2.67 | Heat exchangers, drone frames |

| 316L Stainless | 500–650 | 35–45 | 8.00 | Surgical instruments, valve parts |

| Ti6Al4V | 880–950 | 10–15 | 4.43 | Aircraft brackets, orthopedic implants |

Anodizing remains a pivotal finish for aluminum SLS components, transforming surface durability. Our controlled anodizing process at Wuxi Lead creates a porous oxide layer that absorbs dyes for color coding or branding while significantly improving wear resistance. Type II (sulfuric acid) anodizing is standard for general use, whereas Type III (hard coat) suits high-abrasion scenarios. Crucially, anodizing must follow precision CNC machining to ensure uniform coating adhesion on complex geometries—a capability refined through our integrated manufacturing workflow.

Material choice directly impacts production yield, lifecycle costs, and functional reliability. Wuxi Lead Precision Machinery combines decades of metallurgical expertise with ISO-certified SLS printing to match your project requirements with the optimal alloy and finish. Our engineers collaborate closely with clients to navigate trade-offs between mechanical performance, regulatory compliance, and post-processing needs, ensuring every component meets stringent industry benchmarks. Partner with us to transform material potential into precision-engineered reality.

Manufacturing Process & QC

Design: The Foundation of Precision

At Wuxi Lead Precision Machinery, the production process for our selective laser sintering (SLS) printing services begins with a meticulously engineered design phase. This stage is critical to achieving zero-defect manufacturing outcomes. Our engineering team collaborates closely with clients to analyze part geometry, functional requirements, and material compatibility. Utilizing advanced CAD software and finite element analysis (FEA), we ensure that every design is optimized for structural integrity, thermal performance, and manufacturability. Design for additive manufacturing (DfAM) principles are applied rigorously to minimize material waste, reduce post-processing needs, and enhance part performance. Each design undergoes internal validation and client review before progression, ensuring alignment with technical and operational expectations.

Prototyping: Validating Performance Under Real Conditions

Once the design is finalized, we proceed to rapid prototyping using our high-precision SLS systems. This phase enables functional testing and dimensional verification without the tooling costs associated with traditional manufacturing. Prototypes are produced in the same high-performance metal alloys intended for final production—ensuring accurate representation of mechanical properties, surface finish, and thermal behavior. Our in-house metrology lab conducts comprehensive inspections using coordinate measuring machines (CMM), optical scanning, and metallurgical analysis to confirm compliance with ISO 9001 and AS9100 quality standards. Any deviations are addressed through iterative refinement, ensuring that the final design is not only functional but also scalable for mass production. This closed-loop validation process is central to our zero-defect philosophy.

Mass Production: Scalable Precision with Full Traceability

With prototype approval, we transition seamlessly into high-volume SLS production. Our automated build chambers and controlled inert gas environments ensure consistent layer fusion and material homogeneity across large batch runs. Each production cycle is monitored in real time using integrated sensors and process control software that track laser power, scan speed, bed temperature, and atmospheric conditions. Post-build, parts undergo stress relieving, precision machining (if required), and surface treatments such as shot peening or polishing—all performed within our certified cleanroom facilities. Full material traceability, batch documentation, and 100% inspection of critical dimensions guarantee repeatability and compliance. Our production workflow is designed for scalability, supporting runs from hundreds to tens of thousands of components annually, all maintained to the same exacting standard.

Key SLS Production Specifications

| Parameter | Specification |

|---|---|

| Build Volume | Up to 250 x 250 x 300 mm |

| Layer Thickness | 20–50 μm |

| Material Options | Stainless Steel 316L, Inconel 718, Ti6Al4V, AlSi10Mg |

| Dimensional Accuracy | ±0.1 mm (typical) |

| Surface Roughness (as-built) | Ra 8–12 μm |

| Post-Processing Capabilities | CNC Machining, Heat Treatment, HIP, Polishing |

| Quality Standards | ISO 9001, AS9100, ISO 13485 (medical-grade) |

| Lead Time (Prototype) | 5–7 days |

| Lead Time (Mass Production) | 10–15 days (depending on volume) |

At Wuxi Lead Precision Machinery, we integrate engineering excellence with industrial-scale additive manufacturing to deliver SLS-printed metal components that meet the most demanding performance and quality requirements.

Why Choose Wuxi Lead Precision

Elevate Your Production Capabilities Through Strategic Partnership

Wuxi Lead Precision Machinery delivers more than SLS printing services; we provide engineered solutions for mission-critical metal components. Our facility in Wuxi, China, operates under stringent ISO 9001 and AS9100 quality management systems, ensuring every part meets aerospace, medical, and industrial sector requirements. We understand that precision manufacturing demands absolute reliability in material integrity, dimensional accuracy, and supply chain continuity. By partnering with us, you mitigate production risks while accelerating time-to-market for complex geometries impossible with traditional methods. Our engineering team collaborates from initial design validation through serial production, applying decades of metal additive expertise to optimize your parts for performance and cost efficiency.

Technical Specifications for SLS Metal Production

| Parameter | Capability | Industry Relevance |

|---|---|---|

| Materials | 316L Stainless Steel, Inconel 718, Ti6Al4V | Corrosion resistance, high-temp strength |

| Build Volume | 250 x 250 x 300 mm | Accommodates industrial-scale components |

| Dimensional Accuracy | ±0.1 mm | Ensures seamless assembly integration |

| Surface Finish (As-Built) | Ra 12.5 μm | Reduces secondary machining needs |

| Lead Time | 7-10 days (prototyping), 15 days (batch) | Accelerates development cycles |

| Post-Processing | HIP, CNC finishing, stress-relieving | Achieves aerospace-grade material properties |

Why Global Leaders Choose Lead Precision

We eliminate the guesswork in metal additive manufacturing through rigorous in-process monitoring and NDT validation. Our facility features calibrated EOS M 290 systems with argon-inerted chambers, guaranteeing repeatable microstructure density exceeding 99.95%. Unlike generic service bureaus, we specialize in production-intent parts—not just prototypes. This means implementing statistical process control (SPC) for batch consistency and full traceability from powder lot to finished component. Our quality documentation package includes material certs, CT scan reports, and first-article inspection (FAI) per AS9102 standards. For industries where failure is not an option, our zero-defect culture provides operational confidence.

Initiate Your Precision Manufacturing Workflow

Contact our engineering team to discuss how SLS printing can solve your most demanding manufacturing challenges. Share your CAD files or application requirements with [email protected] for a confidential feasibility assessment and quotation within 24 business hours. Our specialists will analyze part geometry, material suitability, and cost drivers to propose an optimized production strategy. Wuxi Lead Precision Machinery maintains dedicated logistics channels for seamless global delivery, with customs documentation handled in-house to prevent border delays. Do not compromise on quality for cost savings—demand both through a partner invested in your long-term success.

Reach out today to transform complex metal component production from a bottleneck into your competitive advantage. All technical consultations include a no-obligation manufacturability report detailing potential yield improvements and lead time reductions specific to your project.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.