Technical Contents

Engineering Guide: Sls Printed Parts

Engineering Insight: SLS Printed Parts and the Imperative of Precision

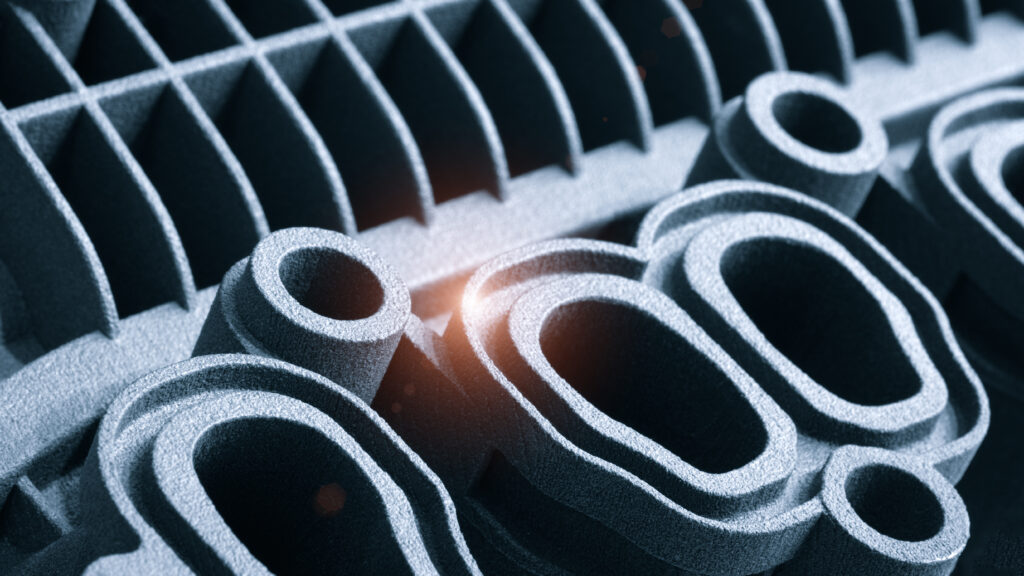

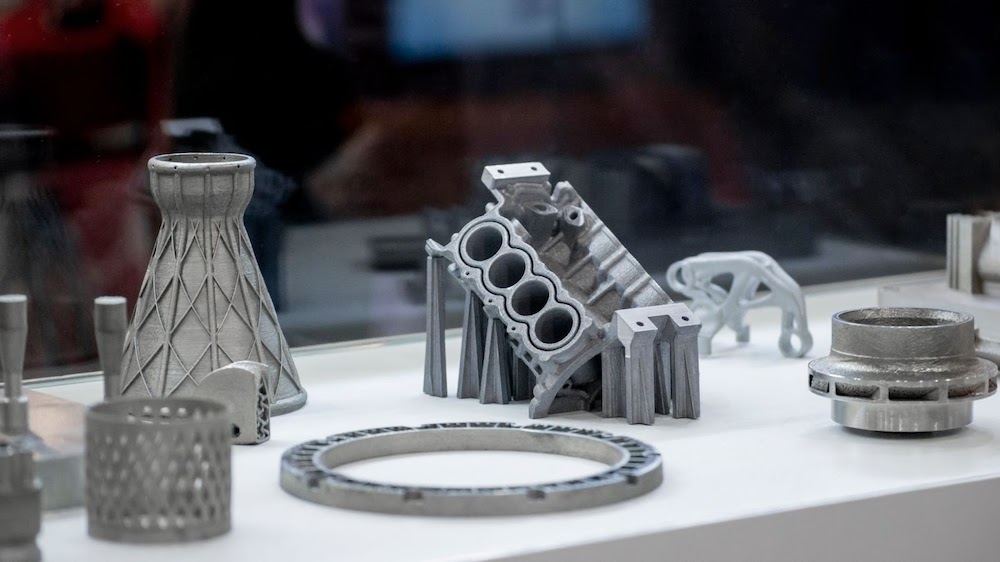

Selective Laser Sintering (SLS) has emerged as a transformative technology in custom metal manufacturing, enabling complex geometries, rapid prototyping, and low-volume production with exceptional material efficiency. At Wuxi Lead Precision Machinery, we recognize that the true value of SLS printed parts lies not just in their design flexibility, but in the precision with which they are manufactured. In high-stakes industries such as aerospace, defense, and elite sports equipment—sectors where we have delivered mission-critical components—dimensional accuracy, material consistency, and repeatability are non-negotiable.

SLS leverages high-powered lasers to fuse fine metallic powders layer by layer, building parts directly from 3D CAD data. While this process bypasses many limitations of traditional machining, it introduces unique challenges related to thermal distortion, residual stress, and surface finish. Without rigorous process control, even minor deviations can compromise structural integrity and functional performance. This is where precision engineering becomes paramount. Our in-house SLS systems are calibrated to maintain tight thermal gradients, and our proprietary post-processing protocols—including stress-relief annealing, precision machining, and surface treatment—ensure that every component meets exacting tolerances.

At Wuxi Lead, our experience extends to supplying precision-engineered components for Olympic-level equipment and military-grade systems. These applications demand parts that perform under extreme conditions—whether enduring repeated mechanical stress in high-performance machinery or operating in variable thermal environments. Our SLS printed components have been validated under ISO 13485 and AS9100 standards, reflecting our commitment to quality and traceability. Each build undergoes full metrological validation using coordinate measuring machines (CMM) and 3D scanning to verify compliance with design specifications.

We also emphasize material selection and microstructural optimization. Our SLS capabilities support a range of high-performance alloys, including Ti6Al4V, Inconel 718, and 17-4 PH stainless steel, all processed under controlled atmospheres to prevent oxidation and ensure homogeneity. The integration of simulation-driven design allows us to anticipate deformation and adjust scan strategies proactively, minimizing the need for rework and accelerating time-to-market.

Below are representative specifications for our SLS printed metal parts, reflecting our standard production capabilities under controlled conditions.

| Parameter | Typical Value | Notes |

|---|---|---|

| Layer Thickness | 20–50 µm | Adjustable based on resolution needs |

| Dimensional Accuracy | ±0.1 mm (for features < 100 mm) | Up to ±0.2% for larger geometries |

| Surface Roughness (as-built) | Ra 10–15 µm | Can be reduced to Ra 1–3 µm with finishing |

| Build Envelope | 250 x 250 x 300 mm | Custom configurations available |

| Supported Materials | Ti6Al4V, Inconel 718, 17-4 PH, AlSi10Mg | Full material certification provided |

| Post-Processing Options | CNC machining, HIP, polishing, coating | Application-specific customization |

Precision in SLS is not an outcome—it is a discipline. At Wuxi Lead Precision Machinery, we combine advanced equipment, deep metallurgical expertise, and a proven track record in high-reliability sectors to deliver SLS printed parts that perform.

Precision Specs & Tolerances

Technical Capabilities for Precision Metal Components Including SLS-Derived Parts

Wuxi Lead Precision Machinery delivers exceptional dimensional accuracy and surface integrity for complex metal components, including those originating from metal additive manufacturing processes such as Selective Laser Sintering (SLS). While SLS provides significant design freedom for intricate geometries, achieving the tight tolerances and surface finishes demanded by aerospace, medical, and high-performance industrial applications often requires precision post-processing. Our integrated manufacturing ecosystem bridges this gap, transforming near-net-shape SLS parts into fully mission-critical components.

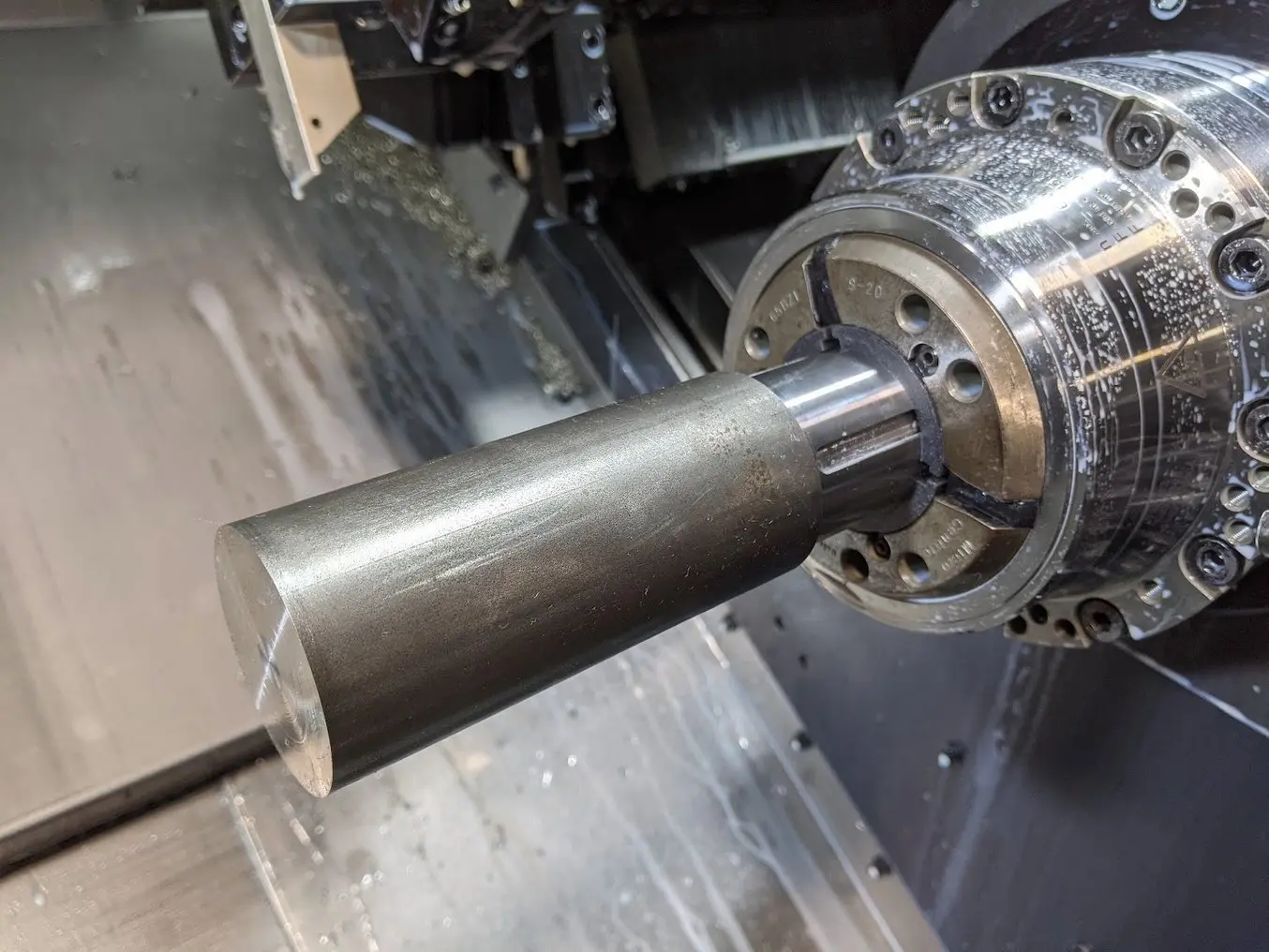

Our core capability centers on advanced 5-axis CNC machining centers, featuring sub-micron repeatability and rigid thermal compensation systems. These machines handle a comprehensive range of engineering alloys, including titanium, inconel, stainless steels, and aluminum, commonly used in metal SLS. The simultaneous 5-axis motion allows for complete part accessibility in a single setup, eliminating cumulative errors from multiple fixturing operations. This is particularly critical for the complex internal channels, organic forms, and thin-walled structures typical of SLS-produced metal parts, ensuring geometric accuracy that additive processes alone cannot consistently achieve. Our machining processes meticulously refine critical sealing surfaces, bearing journals, and mating interfaces to meet stringent functional requirements.

Rigorous quality control is non-negotiable. Every component undergoes comprehensive inspection using state-of-the-art Coordinate Measuring Machines (CMM) equipped with high-precision probes and advanced metrology software. Our AS9100-certified quality management system mandates full first-article inspection reports (FAIR) and statistical process control (SPC) for high-volume runs. For SLS-derived parts, this includes verifying dimensional stability post-heat treatment and stress relief, critical steps often required after the additive phase. Our CMMs validate not only linear dimensions but also complex geometries, profile tolerances, and surface texture parameters essential for part functionality and assembly. Material certification and traceability are fully documented throughout the process.

The synergy between our precision machining and metrology capabilities ensures SLS-produced metal parts meet the most demanding specifications. We understand the unique characteristics of additive-manufactured materials and tailor machining strategies to address potential porosity, surface roughness, and residual stress, delivering components with guaranteed dimensional stability, superior surface finish, and long-term reliability. This integrated approach transforms the design potential of SLS into robust, high-performance metal hardware.

Standard Machining Tolerances for Precision Metal Components

| Feature | Standard Capability | Precision Capability |

|---|---|---|

| Linear Dimension (mm) | ±0.010 | ±0.005 |

| Angular Tolerance (°) | ±0.05 | ±0.02 |

| Flatness (mm per 100mm) | 0.015 | 0.005 |

| True Position (mm) | ±0.015 | ±0.008 |

| Surface Roughness (Ra) | 0.8 µm | 0.4 µm |

Partnering with Wuxi Lead ensures your SLS metal components transcend prototype status, achieving the certified precision and reliability required for end-use applications in the most critical environments. Our technical expertise guarantees seamless transition from additive near-net-shape to fully qualified precision hardware.

Material & Finish Options

Material Selection for SLS Printed Metal Parts: A Precision Engineering Guide

When producing high-performance components via Selective Laser Sintering (SLS), material selection is a critical decision that directly impacts mechanical performance, environmental resistance, and end-use functionality. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing using advanced SLS technologies, enabling the production of complex, high-strength parts tailored to aerospace, automotive, and industrial applications. The most widely used materials in metal SLS—aluminum, steel, and titanium—each offer distinct advantages depending on application demands.

Aluminum alloys, particularly AlSi10Mg, are favored for applications requiring a high strength-to-weight ratio and excellent thermal conductivity. This material is ideal for lightweight structural components, heat exchangers, and housings in automotive and aerospace systems. Its low density reduces overall component mass without sacrificing durability, making it a strategic choice for performance-driven industries.

Stainless steel, especially grades such as 316L and 17-4 PH, delivers superior mechanical strength, corrosion resistance, and temperature stability. These properties make steel suitable for harsh environments, including marine, chemical processing, and high-pressure systems. 316L is particularly valued for its weldability and resistance to chloride-induced corrosion, while 17-4 PH offers excellent hardness and can be precipitation-hardened post-printing for enhanced performance.

Titanium, specifically Ti6Al4V (Grade 5), stands at the pinnacle of high-performance SLS materials. Renowned for its exceptional strength-to-density ratio and biocompatibility, titanium is the material of choice for aerospace structural components, medical implants, and high-stress performance parts. Its resistance to extreme temperatures and corrosive environments further broadens its application scope in mission-critical systems.

Surface finishing plays a vital role in optimizing both performance and aesthetics. Anodizing is a widely adopted post-processing technique, particularly for aluminum parts. This electrochemical process enhances surface hardness, improves wear resistance, and allows for color coding through dye integration. While anodizing does not typically apply to steel or titanium in the same way, these materials benefit from alternative surface treatments such as passivation, polishing, or coating, depending on operational requirements.

Understanding the interplay between material properties and finishing options ensures optimal part performance. Below is a comparative overview of key SLS metal materials offered by Wuxi Lead Precision Machinery.

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 400–450 | 250–300 | 8–12 | Lightweight structures, heat sinks |

| 316L Stainless Steel | 8.0 | 550–600 | 300–350 | 35–45 | Marine components, chemical valves |

| 17-4 PH Steel | 7.8 | 950–1200 | 750–900 | 10–15 | High-strength fittings, tooling |

| Ti6Al4V | 4.43 | 880–950 | 830–880 | 10–12 | Aerospace, medical implants |

At Wuxi Lead Precision Machinery, we support clients in selecting the optimal material and finish combination to meet exacting engineering standards. Our expertise in SLS printed metal parts ensures precision, reliability, and performance in every component we manufacture.

Manufacturing Process & QC

SLS Printed Parts: Precision Manufacturing Process for Zero Defects

At Wuxi Lead Precision Machinery, we execute a rigorously controlled Selective Laser Sintering (SLS) production process specifically engineered for zero-defect metal components in precision-critical applications. Our integrated workflow ensures seamless transition from concept to certified production, eliminating traditional prototyping gaps and guaranteeing manufacturability from the outset. This methodology is fundamental to delivering the aerospace, medical, and industrial clients who demand absolute reliability in every part.

The process commences with collaborative Design for Additive Manufacturing (DfAM). Our engineering team works directly with your specifications to optimize geometry, material selection, and support structures, ensuring the design leverages SLS capabilities while meeting stringent functional requirements. We conduct comprehensive thermal and structural simulations to predict behavior during sintering, proactively identifying and resolving potential weaknesses or distortion risks before physical production begins. This phase is critical for achieving first-time-right outcomes and establishing the foundation for zero defects.

Prototyping transitions directly into production validation. Unlike conventional approaches, our initial SLS builds serve dual purposes: functional verification and process qualification. Each prototype undergoes full metrology against CAD data using calibrated CMMs and CT scanning, alongside rigorous mechanical and material property testing per ASTM F3301/F3318 standards. Crucially, we validate the entire production workflow – including build parameters, post-processing sequences, and final inspection protocols – during this stage. This eliminates the costly and risky “re-qualification” often required when moving from prototype to mass production.

Mass production leverages the validated parameters within our controlled environment. Builds occur in inert gas atmospheres with real-time melt pool monitoring and layer-wise in-process metrology. Every build undergoes 100% dimensional verification against critical features, followed by proprietary stress-relief and surface enhancement post-processing tailored to the material and application. Final inspection includes non-destructive testing (NDT) where specified and comprehensive material certification. Our integrated quality management system, certified to ISO 9001:2015 and AS9100D, mandates traceability for every part batch, ensuring complete process control and defect elimination.

Key SLS Process Specifications

| Parameter | Standard Specification | Wuxi Lead Precision Standard |

|---|---|---|

| Material Options | Stainless Steel 316L, 17-4PH, Inconel 718, Titanium Ti6Al4V | Full aerospace-grade material certification with lot traceability |

| Layer Thickness | 20-50 µm | Optimized 30 µm standard; 20 µm available for high-detail features |

| Build Volume | Up to Ø250 x 325 mm | Ø300 x 400 mm capacity with multi-laser systems |

| Dimensional Accuracy | ±0.1% (min ±0.1 mm) | ±0.05% (min ±0.05 mm) verified by in-process CMM |

| Surface Roughness (As-Built) | Ra 15-25 µm | Ra 12-18 µm standard; Ra <5 µm achievable with post-processing |

| Post-Processing | Stress Relief, Bead Blasting | Proprietary HIP, precision machining, and surface treatments integrated |

| Quality Assurance | Final inspection report | Full traceability, 100% critical feature check, NDT options |

This closed-loop process, spanning validated design through certified production, is how Wuxi Lead delivers SLS metal parts with uncompromising quality. We transform complex geometries into mission-critical components where zero defects are not a target, but a baseline requirement. Partner with us to eliminate production risk and accelerate time-to-market for your most demanding applications.

Why Choose Wuxi Lead Precision

Partner with Wuxi Lead Precision Machinery for Advanced SLS Printed Metal Components

When precision, reliability, and innovation define your production standards, partnering with a leader in custom metal manufacturing becomes essential. At Wuxi Lead Precision Machinery, we specialize in delivering high-performance SLS (Selective Laser Sintering) printed metal parts tailored to the exacting demands of aerospace, medical, automotive, and industrial automation sectors. Our integration of cutting-edge additive manufacturing with decades of precision engineering expertise ensures your components meet the highest benchmarks for strength, complexity, and dimensional accuracy.

SLS printing enables the creation of intricate geometries that traditional machining methods cannot achieve. At Lead Precision, we leverage state-of-the-art metal SLS systems, advanced post-processing techniques, and rigorous quality control to transform your digital designs into fully functional metal components. Whether you require low-volume prototypes or high-integrity production parts, our facility in Wuxi, China, operates under ISO 9001-certified processes, ensuring consistency and compliance across every project.

Our engineering team collaborates closely with clients from concept through completion, offering DFM analysis, material selection guidance, and rapid iteration support. This consultative approach minimizes lead times and reduces development costs while maximizing part performance. With in-house capabilities spanning laser sintering, heat treatment, CNC finishing, and surface treatment, we maintain full control over quality and delivery timelines.

We understand that in high-end manufacturing, specifications matter. Below are the key technical capabilities of our SLS metal printing services:

| Parameter | Specification |

|---|---|

| Material Options | Stainless Steel 316L, Inconel 718, Titanium Ti6Al4V, Aluminum AlSi10Mg, Tool Steel (Maraging Steel) |

| Layer Thickness | 20–50 μm |

| Build Envelope | Up to 250 x 250 x 300 mm |

| Typical Accuracy | ±0.1 mm (depending on geometry and size) |

| Surface Roughness (as-built) | Ra 10–15 μm |

| Post-Processing Options | Stress Relieving, Hot Isostatic Pressing (HIP), CNC Machining, Polishing, Passivation |

| Quality Standards | ISO 9001:2015, Full Material Certification, 3D Scanning Inspection Reports |

Partnering with Wuxi Lead Precision Machinery means gaining a strategic manufacturing ally committed to technical excellence and responsive service. Our global logistics network ensures seamless delivery to North America, Europe, and Asia, while our multilingual engineering support team provides clear, real-time communication throughout your project lifecycle.

For your next advanced metal SLS project, contact us today. Send your design files and requirements to [email protected] and receive a detailed technical evaluation and quotation within 24 hours. Let Lead Precision bring your most demanding metal additive applications to life—efficiently, accurately, and with uncompromising quality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.