Technical Contents

Engineering Guide: Sls 3D Printing Services

Engineering Insight: The Role of Precision in SLS 3D Printing Services

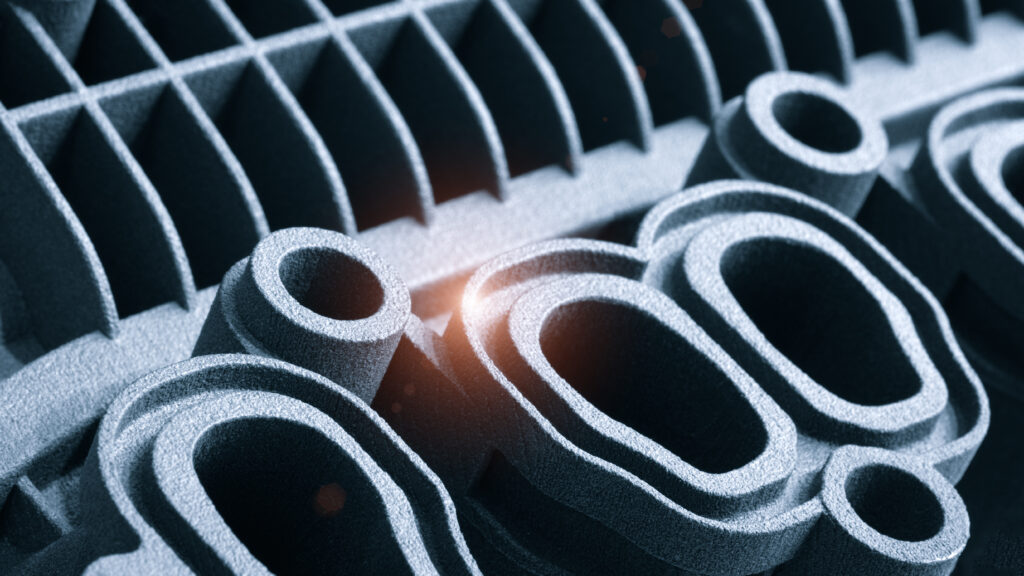

In the realm of advanced manufacturing, Selective Laser Sintering (SLS) 3D printing has emerged as a transformative technology, particularly in custom metal fabrication. At Wuxi Lead Precision Machinery, we recognize that the true value of SLS lies not just in its ability to produce complex geometries, but in its capacity to deliver repeatable, high-precision components suitable for mission-critical applications. Precision in SLS 3D printing is not an optional enhancement—it is the foundation upon which reliability, performance, and compliance are built.

SLS operates by using a high-powered laser to fuse fine particles of metal powder, layer by layer, into fully dense components based on digital 3D models. The accuracy of this process depends on multiple interdependent factors: laser calibration, thermal management, powder quality, and post-processing controls. Even minor deviations in any of these parameters can result in dimensional inaccuracies, surface defects, or compromised mechanical properties—issues that are unacceptable in high-stakes industries such as aerospace, defense, and elite sports engineering.

Our experience at Wuxi Lead Precision Machinery has been shaped by projects demanding the highest standards of quality and consistency. We have supplied precision-engineered components for Olympic-level athletic equipment, where marginal gains are measured in milliseconds, and for military-grade systems, where failure is not an option. These applications require not only adherence to tight tolerances but also rigorous material certification, traceability, and in-process inspection. Our SLS 3D printing services are engineered to meet and exceed these demands, integrating ISO-compliant quality systems with real-time monitoring and post-build metrology.

Precision also extends beyond physical dimensions. It encompasses repeatability across production batches, consistency in material properties, and the ability to maintain design intent from prototype to full-scale production. Our in-house engineering team works closely with clients to optimize part orientation, support structures, and thermal profiles—ensuring that every component meets exacting performance criteria. This level of control is only possible through a combination of advanced machinery, deep process knowledge, and a culture of continuous improvement.

For industries where performance is non-negotiable, partnering with a manufacturer that understands the engineering nuances of SLS 3D printing is essential. At Wuxi Lead, we bring proven expertise, cutting-edge technology, and a commitment to precision that has been validated on global stages.

SLS 3D Printing Technical Specifications – Wuxi Lead Precision Machinery

| Parameter | Specification |

|---|---|

| Build Volume | 250 x 250 x 300 mm |

| Layer Thickness | 20–50 µm |

| Positional Accuracy | ±0.1 mm per 100 mm |

| Surface Roughness (as-built) | Ra 8–12 µm |

| Common Materials | Stainless Steel 316L, Inconel 718, Ti6Al4V |

| Post-Processing Options | CNC Machining, Heat Treatment, Polishing, Passivation |

| Quality Standards | ISO 9001:2015, Full Material Certification, First Article Inspection (FAI) |

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing at Wuxi Lead

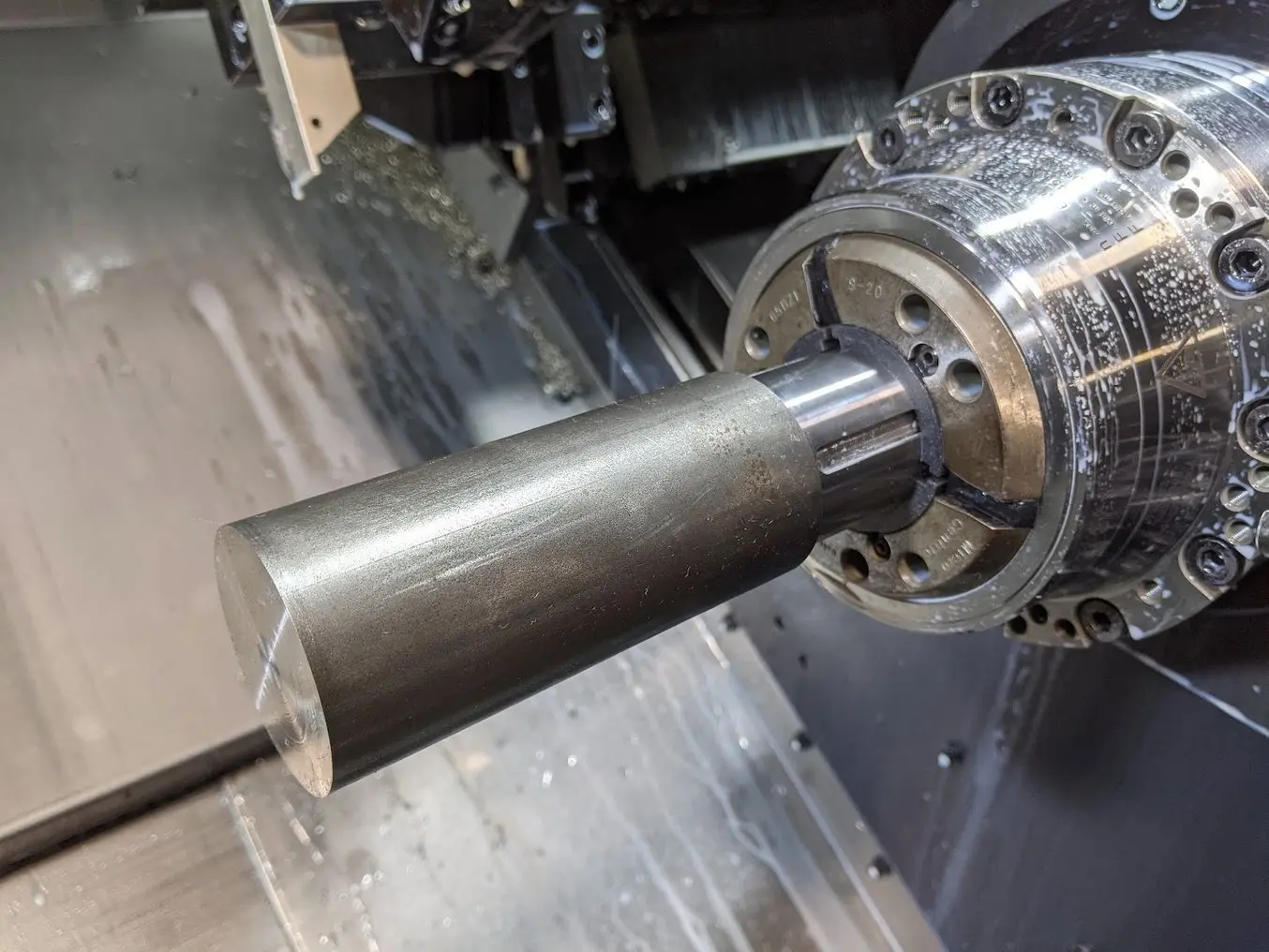

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions engineered for the most demanding industrial applications. While selective laser sintering (SLS) serves specific polymer prototyping needs, our core expertise and facility investment focus on high-precision subtractive manufacturing for mission-critical metal components. We specialize in transforming complex metal designs into reality using state-of-the-art multi-axis CNC machining centers, ensuring exceptional dimensional accuracy, surface integrity, and material performance for aerospace, medical, energy, and automation sectors.

Our technical foundation rests upon a comprehensive fleet of modern 5-axis CNC machining centers. These systems provide unparalleled flexibility for machining intricate geometries in a single setup, minimizing handling errors and significantly enhancing part accuracy and repeatability. Capable of processing a wide range of engineering metals including titanium alloys, Inconel, stainless steels, aluminum alloys, and hardened tool steels, our equipment handles both prototyping and low-to-medium volume production runs with equal rigor. The integration of high-speed machining (HSM) strategies and advanced toolpath optimization software ensures efficient material removal while maintaining stringent surface finish requirements critical for functional performance.

Quality assurance is not a final step but an integrated process throughout manufacturing at Wuxi Lead. Every critical dimension and feature undergoes rigorous validation using calibrated Coordinate Measuring Machines (CMMs). Our metrology lab, operating under strict environmental controls, utilizes both touch-trigger and optical scanning probes to verify complex contours, positional tolerances, and geometric dimensioning and tolerancing (GD&T) callouts against the original CAD model. This systematic CMM inspection protocol provides documented, traceable evidence of conformance, delivering the confidence our global clients require for components operating in high-stakes environments. Material certifications and in-process inspections further guarantee compliance with specified material properties and process parameters.

Achieving micron-level precision consistently requires mastery of both machine capability and process control. The following table details representative tolerance capabilities achievable across common feature types on our precision CNC platforms, validated through our CMM inspection regime. These values reflect standard production capabilities for qualified materials and geometries under controlled conditions; specific project requirements are always evaluated during the quoting and process planning phase.

| Feature Type | Tolerance Range | Measurement Method |

|---|---|---|

| Linear Dimensions | ±0.005 mm | CMM |

| Hole Diameter (Reamed) | +0.005 / -0.000 mm | CMM / Air Gage |

| Positional Tolerance | ±0.010 mm | CMM |

| Flatness | 0.005 mm | CMM |

| Surface Roughness (Ra) | 0.4 – 0.8 µm | Profilometer |

| Thread Fit (Metric) | 6H / 6g | Go/No-Go Gages |

Wuxi Lead Precision Machinery combines cutting-edge 5-axis CNC technology with metrology-grade quality control to consistently produce metal components meeting the highest global standards. Our commitment to technical excellence ensures your most complex metal parts are manufactured with the precision, reliability, and documentation demanded by advanced engineering applications. Partner with us for manufacturing solutions where accuracy is non-negotiable.

Material & Finish Options

Material Selection for SLS 3D Printing Services in Custom Metal Manufacturing

When leveraging Selective Laser Sintering (SLS) 3D printing services for high-performance industrial applications, material selection is a critical determinant of part functionality, durability, and cost-efficiency. At Wuxi Lead Precision Machinery, we specialize in precision metal manufacturing using advanced SLS technology, offering clients a strategic advantage through optimized material and finish combinations. The most widely used metals in our SLS processes are aluminum, steel, and titanium—each selected for distinct mechanical properties and operational suitability.

Aluminum alloys, particularly AlSi10Mg, are favored for applications requiring a high strength-to-weight ratio, excellent thermal conductivity, and good corrosion resistance. This makes aluminum ideal for aerospace components, automotive heat exchangers, and lightweight structural parts. Its low density contributes to fuel and energy efficiency without compromising structural integrity under moderate loads and temperatures.

Stainless steel, especially grades such as 316L and 17-4 PH, delivers superior mechanical strength, wear resistance, and performance in corrosive or high-pressure environments. These properties make steel a preferred choice for medical devices, fluid system components, and industrial tooling. The dense microstructure achieved through SLS processing ensures leak-tight performance and long service life in demanding operational conditions.

Titanium alloys, notably Ti6Al4V (Grade 5), represent the pinnacle of performance in extreme environments. With exceptional strength-to-density ratio, biocompatibility, and resistance to oxidation at elevated temperatures, titanium is extensively used in aerospace, defense, and biomedical implants. Its ability to maintain mechanical integrity under thermal stress and exposure to aggressive chemicals justifies its use in mission-critical applications.

Post-processing finishes further enhance part performance and longevity. Anodizing, while more commonly associated with aluminum, can be applied to improve surface hardness, wear resistance, and aesthetic consistency. In SLS-produced aluminum components, anodizing creates a protective oxide layer that increases corrosion resistance and allows for color coding or branding. However, due to the porous nature of as-printed metal parts, secondary treatments such as hot isostatic pressing (HIP) or machining may be required prior to anodizing to ensure surface uniformity and sealing.

Below is a comparative overview of key material properties relevant to SLS 3D printing:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 400–450 | 280–320 | 8–12 | Aerospace, Automotive, Heat Sinks |

| 316L Steel | 7.98 | 590–690 | 300–350 | 35–45 | Medical, Marine, Chemical Processing |

| 17-4 PH Steel | 7.75 | 1000–1300 | 850–1000 | 10–15 | Aerospace, Tooling, Defense |

| Ti6Al4V | 4.43 | 900–950 | 800–850 | 10–12 | Biomedical, Jet Engines, Drones |

Selecting the appropriate material and finish requires a thorough understanding of operational demands, environmental exposure, and lifecycle requirements. At Wuxi Lead Precision Machinery, we support clients through material consultation, prototyping, and full-scale production to ensure optimal performance in every custom metal component.

Manufacturing Process & QC

Wuxi Lead Precision Machinery: SLS 3D Printing Production Process for Zero Defect Metal Components

Our Selective Laser Sintering (SLS) production process delivers uncompromising quality for custom metal manufacturing, engineered from initial concept to high-volume output with a foundational commitment to zero defects. This rigorous methodology ensures every component meets exacting aerospace, medical, and industrial specifications.

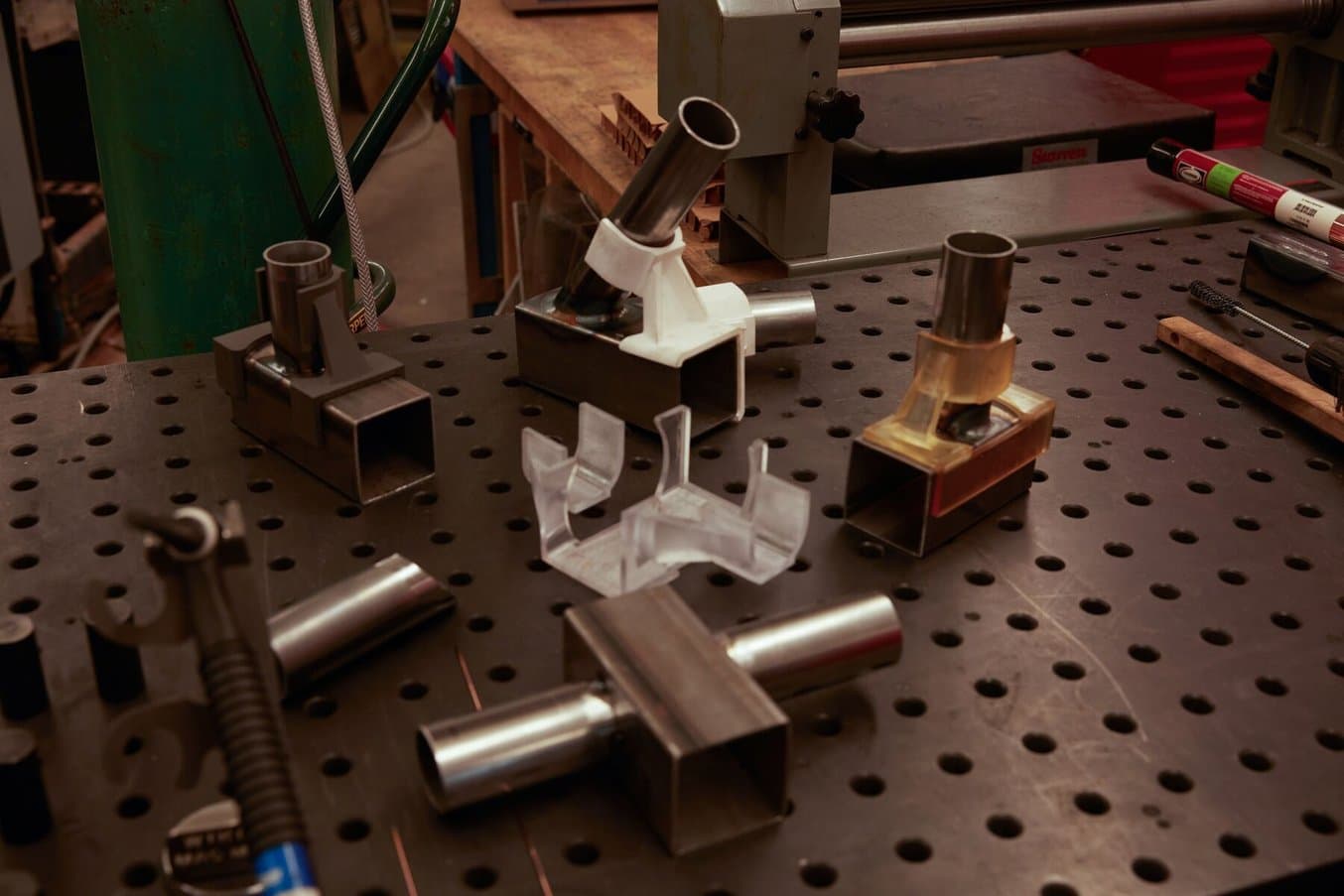

The process begins with collaborative design refinement. Our engineering team works directly with client CAD data, applying deep expertise in Design for Additive Manufacturing (DfAM). We rigorously analyze part geometry, thermal stress points, and support structure requirements using advanced simulation software. This critical phase identifies potential weaknesses early, optimizing the design for structural integrity, material efficiency, and seamless manufacturability. Material selection—primarily high-performance alloys like Inconel 718, Titanium Ti6Al4V, and Stainless Steel 17-4 PH—is validated against application demands for strength, corrosion resistance, and thermal stability before proceeding.

Prototyping transitions the validated design into tangible form under controlled production conditions. We produce functional prototypes using the exact SLS parameters and material lots designated for final production. These prototypes undergo comprehensive metrology, including full 3D laser scanning against nominal CAD and destructive mechanical testing per ASTM/ISO standards. Dimensional accuracy, surface finish, and material properties are meticulously verified. Client feedback and test results drive any necessary micro-adjustments to the build strategy or post-processing, ensuring the prototype is a true representation of the final part’s quality and performance. This phase eliminates design risks and confirms process capability.

Mass production leverages the perfected process parameters within our AS9100-certified facility. Production builds are executed on industrial-grade SLS systems operating within strict environmental controls. Real-time monitoring tracks laser power, chamber atmosphere, and thermal profiles for every layer. Crucially, our integrated quality management system enforces zero-defect protocols: 100% in-process dimensional checks via inline sensors, full batch material traceability from certified mills, and final inspection using CMMs and industrial CT scanning for internal defect detection. Every part receives a unique identifier linking it to its complete manufacturing and inspection history. Post-processing—including precision machining, HIP, heat treatment, and surface finishing—is performed to stringent tolerances, ensuring final components meet all geometric and functional requirements. This closed-loop system, validated through prototyping and sustained by rigorous process control, guarantees consistent, defect-free output at scale.

Key SLS production specifications maintained throughout this process are detailed below:

| Parameter | Capability | Tolerance/Detail |

|---|---|---|

| Material Options | Inconel 718, Ti6Al4V, SS 17-4 PH | AMS/ASTM certified, full traceability |

| Layer Thickness | 20 – 50 µm | Optimized per part geometry |

| Build Volume | Up to Ø 250 x 350 mm | Scalable for strategic components |

| Dimensional Accuracy | ± 0.1% (min ± 0.05 mm) | Verified via CMM & laser scanning |

| Surface Roughness (As-Built) | Ra 12 – 25 µm | Adjustable via parameter tuning |

| Post-Processing Options | Precision CNC, HIP, Heat Treat, Coating | Integrated in-house capability |

Wuxi Lead’s end-to-end SLS process transforms complex metal designs into flawless, high-integrity production parts. By embedding zero-defect principles from design validation through final inspection, we deliver guaranteed performance for the most demanding applications.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced SLS 3D Printing Services in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision Selective Laser Sintering (SLS) 3D printing services tailored to the evolving demands of modern industrial manufacturing. As a trusted leader in China’s custom metal production sector, we combine cutting-edge additive technology with decades of engineering expertise to support global clients across aerospace, automotive, medical, and energy industries. Our SLS 3D printing capabilities enable rapid prototyping, low-volume production, and complex component fabrication with exceptional repeatability and material integrity.

Choosing the right manufacturing partner is critical when precision, reliability, and innovation are non-negotiable. At Lead Precision, we go beyond standard service offerings by integrating full-process quality control, advanced post-processing techniques, and material traceability into every project. Our certified engineering team collaborates closely with clients from design optimization through final inspection, ensuring that every component meets stringent performance and regulatory requirements.

Our state-of-the-art SLS systems operate under controlled environments to maintain dimensional accuracy and surface consistency. We support a wide range of high-performance metal alloys, including stainless steel, titanium, aluminum, and nickel-based superalloys, enabling us to meet diverse application needs—from lightweight structural components to high-temperature resistant parts.

Below are key technical specifications that define our SLS 3D printing capabilities:

| Parameter | Specification |

|---|---|

| Build Envelope | Up to 250 x 250 x 300 mm |

| Layer Thickness | 20–60 µm |

| Positional Accuracy | ±0.1 mm over 100 mm |

| Surface Roughness (as-built) | Ra 8–12 µm |

| Supported Materials | 316L Stainless Steel, Ti6Al4V (Grade 5), AlSi10Mg, Inconel 718, CoCrMo |

| Post-Processing Options | Stress relieving, HIP, CNC finishing, polishing, coating |

| Quality Standards | ISO 9001:2015, Full material certification available |

We understand that each client faces unique engineering challenges. That’s why we offer fully customizable workflows, rapid turnaround times, and scalable production solutions designed to align with your project timelines and technical specifications. Whether you require a single prototype or a batch of mission-critical components, Lead Precision ensures unmatched consistency and technical support throughout the manufacturing cycle.

To begin a partnership built on precision, innovation, and reliability, contact us today. Our engineering team is ready to review your designs, provide expert feedback, and deliver prototypes or production parts with speed and accuracy.

For technical inquiries, project submissions, or collaboration opportunities, email us at [email protected]. Let Wuxi Lead Precision Machinery be your trusted partner in advanced SLS 3D printing for custom metal manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.