Technical Contents

Engineering Guide: Sls 3D Printing Service

Engineering Insight: SLS 3D Printing Service – Precision as a Standard

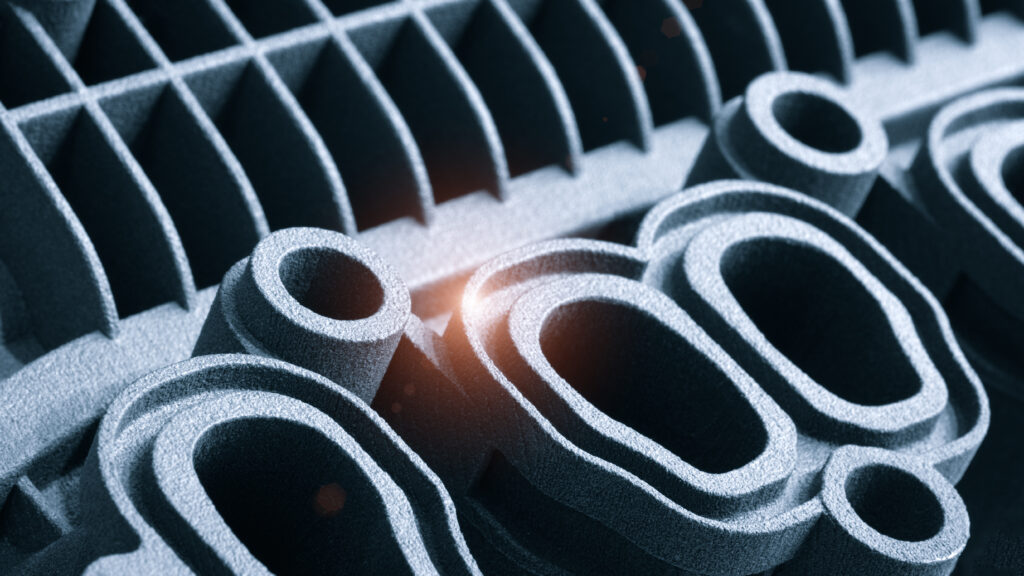

In the realm of custom metal manufacturing, Selective Laser Sintering (SLS) 3D printing has emerged as a transformative technology, enabling the production of complex, high-strength components with minimal material waste. At Wuxi Lead Precision Machinery, we recognize that the true value of SLS 3D printing lies not just in its design flexibility, but in its capacity to deliver repeatable, micron-level precision—especially critical in high-stakes industries such as aerospace, defense, and advanced sports engineering. Our engineering philosophy treats precision not as an outcome, but as a foundational requirement embedded in every stage of the SLS process.

Precision in SLS 3D printing begins with material control. We utilize only certified metal powders—primarily stainless steel, titanium, and nickel-based superalloys—subjected to rigorous pre-processing screening to ensure particle size distribution and flowability meet strict aerospace-grade standards. This consistency directly influences layer uniformity during sintering, reducing internal porosity and dimensional deviation. Our in-house metrology lab employs laser scanning and coordinate measuring machines (CMM) to validate part geometry both pre- and post-build, ensuring tolerances remain within ±0.1 mm for standard builds and as tight as ±0.05 mm for mission-critical applications.

Our experience in high-precision manufacturing has been tested on global stages. Wuxi Lead was commissioned to produce lightweight, load-optimized components for China’s Olympic bobsled development program, where aerodynamic integrity and structural reliability were non-negotiable. Similarly, our team has supported military-grade drone subsystems requiring thermal stability and impact resistance under extreme conditions. These projects demanded more than technical capability—they required a culture of precision that permeates design, simulation, build, and post-processing.

Each SLS build at Lead Precision undergoes a full digital twin workflow. Finite element analysis (FEA) and computational fluid dynamics (CFD) simulations guide topology optimization, ensuring that parts are not only lightweight but also functionally superior. Support structures are algorithmically generated to minimize warping and residual stress, while our proprietary thermal calibration routines adjust laser power and scan speed in real time based on chamber conditions.

We understand that in custom manufacturing, a deviation of a few microns can compromise system performance. That is why our SLS 3D printing service integrates quality assurance into the build process—not as a final checkpoint, but as a continuous feedback loop. From initial CAD to final inspection, precision is monitored, measured, and guaranteed.

Technical Specifications – SLS 3D Printing Service

| Parameter | Specification |

|---|---|

| Build Volume | 250 × 250 × 300 mm |

| Layer Thickness | 20–60 μm (adjustable) |

| Typical Accuracy | ±0.1 mm (standard), ±0.05 mm (high-precision mode) |

| Surface Roughness (Ra) | 8–15 μm (as-built), down to 3 μm (post-processed) |

| Materials | 316L Stainless Steel, Ti6Al4V, Inconel 718, AlSi10Mg |

| Post-Processing Options | Stress relieving, HIP, CNC finishing, polishing, coating |

| Lead Time (Standard) | 7–12 days (including QA and reporting) |

At Wuxi Lead Precision Machinery, we don’t just meet industry standards—we help define them. Our SLS 3D printing service delivers precision-engineered metal components where performance, reliability, and repeatability are paramount.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing for Demanding Applications

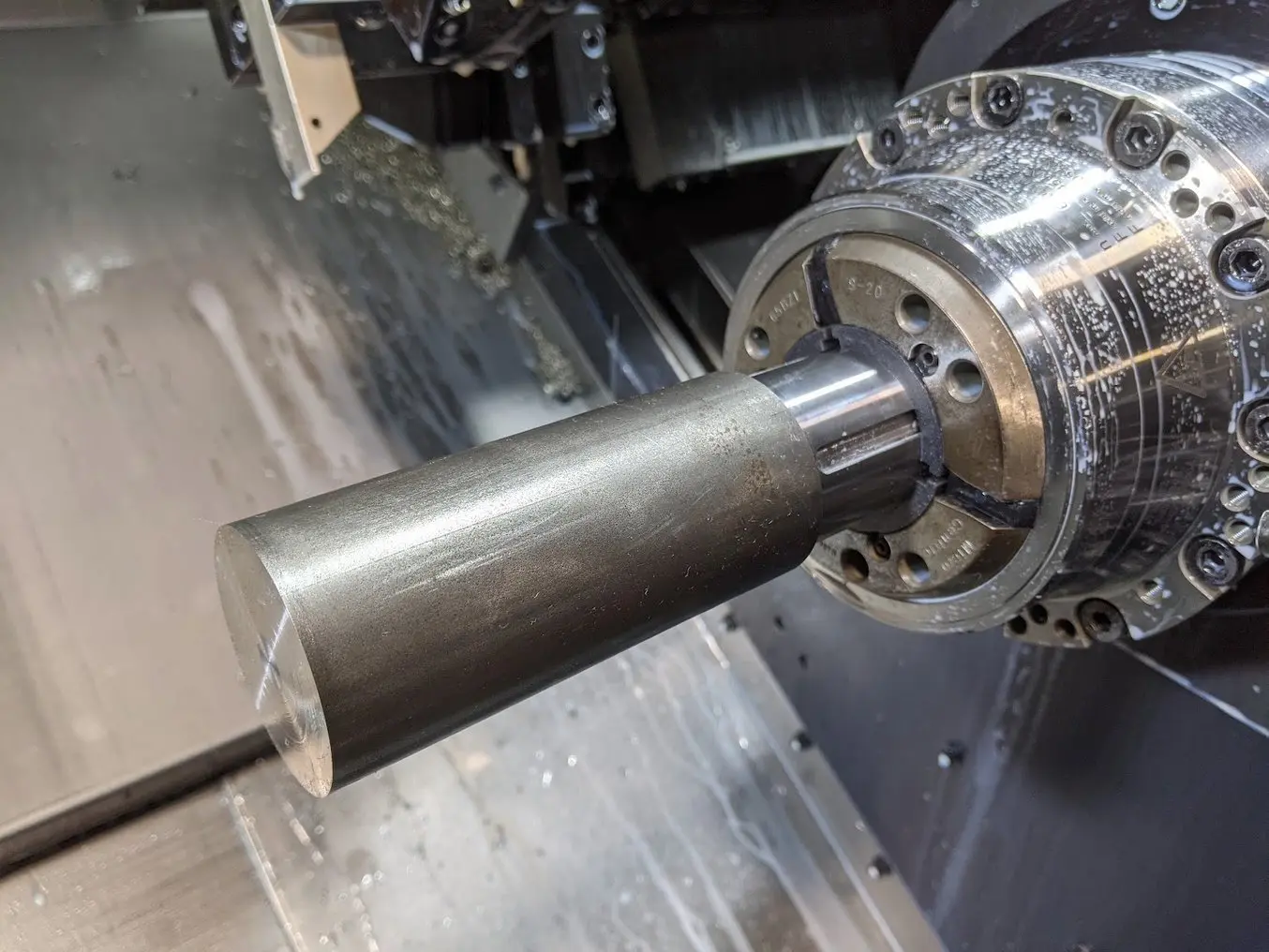

Wuxi Lead Precision Machinery delivers advanced metal component production through integrated subtractive manufacturing solutions. While industry terminology requires clarification—Selective Laser Sintering (SLS) is a polymer-based additive process—we specialize in high-precision metal part fabrication using complementary technologies. Our core strength lies in multi-axis CNC machining, which achieves superior dimensional accuracy, surface integrity, and material properties unattainable with polymer SLS for metal applications. This approach ensures components meet rigorous aerospace, medical, and energy sector requirements where structural reliability is non-negotiable.

Our facility operates state-of-the-art 5-axis CNC machining centers, enabling complex geometries in a single setup. This eliminates cumulative error from multiple fixtures, critical for turbine blades, hydraulic manifolds, and surgical instrument components. Capable of processing titanium alloys, Inconel, stainless steel, and aluminum, our systems maintain thermal stability during extended operations through closed-loop coolant management and rigid machine structures. Integrated probing systems perform in-process verification, adjusting for tool wear and material variance to sustain tolerances across production runs.

Quality control is non-optional in mission-critical manufacturing. Every component undergoes comprehensive inspection via Zeiss CONTURA CMM systems with HP-O optical sensors. This provides traceable, full-spectrum validation against CAD models, including GD&T analysis, surface roughness mapping, and first-article reporting per AS9102 standards. Our metrology lab operates under ISO 17025 guidelines, with temperature-controlled environments ensuring measurement uncertainty below ±1.5μm. Statistical process control data is shared in real-time with clients via secure portals, enabling proactive adjustments before non-conformances occur.

The following table details achievable tolerances for machined metal components, reflecting our process capability after rigorous SPC validation:

| Tolerance Class | Dimensional Accuracy | Surface Finish (Ra) | Typical Applications |

|---|---|---|---|

| Standard | ±0.05 mm | 1.6 μm | Brackets, housings |

| Precision | ±0.01 mm | 0.8 μm | Valve bodies, seals |

| Micro-Precision | ±0.005 mm | 0.4 μm | Implants, optics mounts |

These specifications assume optimal material selection and geometric feasibility. Actual tolerances are co-engineered during Design for Manufacturability (DFM) reviews, where our engineering team identifies cost-saving opportunities without compromising performance. Unlike additive methods requiring secondary machining for critical features, our CNC-first strategy delivers net-shape metal parts with certified metallurgical properties—eliminating porosity risks inherent in powder-based metal processes. For clients requiring hybrid solutions, we partner with qualified metal AM providers while applying our QC protocols to post-processing stages. This ensures seamless transition from prototype to volume production with uncompromised quality documentation. Wuxi Lead’s capability portfolio bridges the gap between design ambition and field-proven reliability in metal component manufacturing.

Material & Finish Options

Material Selection for High-Performance SLS 3D Printing in Custom Metal Manufacturing

In selective laser sintering (SLS) 3D printing, material selection is a critical determinant of part performance, durability, and application suitability. At Wuxi Lead Precision Machinery, we specialize in advanced metal additive manufacturing, offering precision-engineered components in aluminum, steel, and titanium—each chosen for its unique mechanical properties and compatibility with industrial demands. Understanding the characteristics of these materials enables optimal design and functional performance in aerospace, automotive, medical, and energy sectors.

Aluminum alloys, particularly AlSi10Mg, are widely used for lightweight structural components requiring high strength-to-density ratios and excellent thermal conductivity. This material is ideal for heat exchangers, engine parts, and drone components where weight reduction without sacrificing integrity is essential. Its inherent corrosion resistance and weldability further enhance versatility in complex assemblies.

Stainless steel, especially grades such as 316L and 17-4 PH, delivers superior mechanical strength, wear resistance, and performance in aggressive environments. These steels are commonly selected for hydraulic manifolds, tooling inserts, and marine components due to their excellent resistance to oxidation and chloride-induced stress corrosion cracking. The high density and hardness of steel make it suitable for load-bearing applications requiring long-term reliability.

Titanium, primarily Ti6Al4V (Grade 5), stands at the forefront of high-performance materials in SLS printing. Renowned for its exceptional strength-to-weight ratio, biocompatibility, and resistance to extreme temperatures and corrosive media, titanium is the material of choice for aerospace structural elements, medical implants, and high-end racing components. Its ability to maintain strength under thermal stress ensures reliability in mission-critical environments.

Post-processing finishes further enhance material performance. Anodizing, while most commonly applied to aluminum, improves surface hardness, wear resistance, and corrosion protection. This electrochemical process creates a controlled oxide layer that can also be dyed for identification or aesthetic purposes. For steel and titanium, alternative surface treatments such as passivation, polishing, or coating may be recommended based on environmental exposure and functional requirements.

Below is a comparative overview of key material properties relevant to SLS 3D printing:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation at Break (%) | Common Applications |

|---|---|---|---|---|---|

| AlSi10Mg | 2.67 | 400–450 | 280–320 | 8–12 | Lightweight structures, heat sinks |

| 316L Stainless Steel | 7.98 | 550–600 | 250–300 | 35–45 | Marine, chemical processing, tooling |

| 17-4 PH Steel | 7.75 | 950–1050 | 750–850 | 12–15 | Aerospace, high-strength fixtures |

| Ti6Al4V | 4.43 | 900–950 | 800–850 | 10–12 | Medical implants, jet engines, racing |

At Wuxi Lead, we support material certification, mechanical testing, and tailored finishing to ensure every component meets stringent industry standards. Our engineering team collaborates with clients to select the optimal material and post-treatment process, ensuring performance, longevity, and compliance.

Manufacturing Process & QC

SLS 3D Printing Production Process: Precision from Concept to Volume

At Wuxi Lead Precision Machinery, our Selective Laser Sintering (SLS) service delivers complex, high-performance metal components through a rigorously controlled production sequence. We integrate advanced engineering with stringent quality protocols to achieve true zero-defect manufacturing for demanding industrial applications. This process begins with collaborative design validation and culminates in seamless volume production.

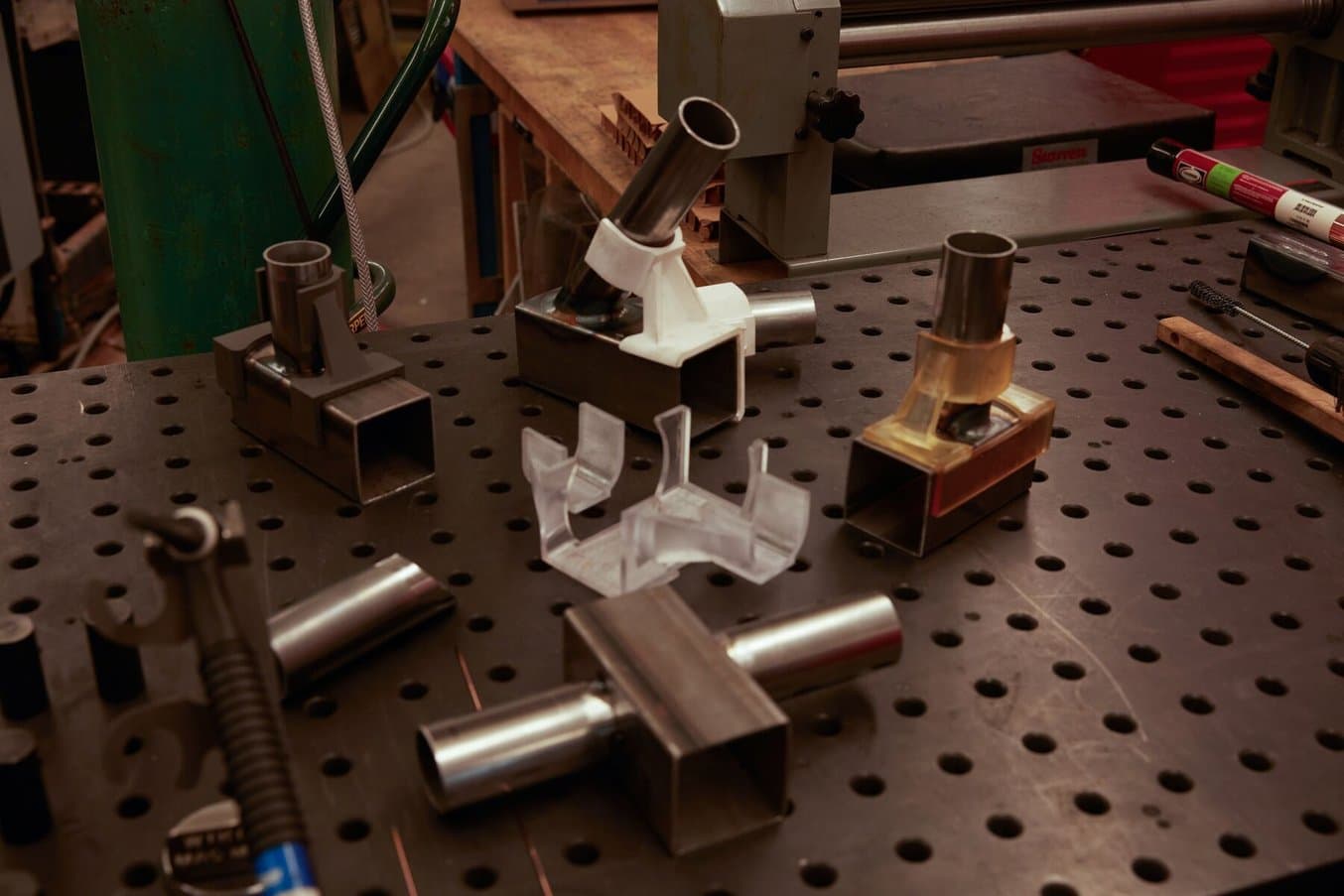

The foundation is meticulous Design for Additive Manufacturing (DfAM) analysis. Our engineering team works directly with client CAD data, scrutinizing geometry for optimal sintering performance, material behavior, and functional requirements. Critical factors like thermal stress distribution, support structure necessity, and surface finish targets are resolved before machine time is committed. This proactive DfAM stage prevents downstream errors and ensures the digital model is inherently manufacturable to specification. Only designs passing our internal tolerance and structural integrity checks proceed.

Prototyping is not merely a checkpoint but an integral validation loop within our zero-defect framework. Utilizing the exact production SLS systems and certified materials, we produce functional prototypes for rigorous client testing. Dimensional accuracy, mechanical properties, and assembly fit are verified against the original intent using CMM and metrology equipment. Any deviations trigger immediate design or parameter refinement. This iterative phase, often completed in days, de-risks the final production run and guarantees the process is locked before volume manufacturing begins.

Mass production leverages our industrial-scale SLS infrastructure under continuous statistical process control. Builds occur within Class 8 cleanrooms using calibrated EOS or Farsoon systems. Real-time monitoring of laser power, chamber temperature, and oxygen levels ensures consistent thermal profiles critical for material density and part integrity. Every layer is validated; no compromised build progresses. Post-processing, including precise depowdering, thermal stress relief, and optional media blasting or machining, adheres to documented procedures. Final inspection employs 100% first-article inspection protocols and AQL sampling per ISO 9001, with full traceability from raw powder lot to finished component. Defects are physically impossible to ship because our process control identifies and corrects anomalies at the source.

Key SLS Production Specifications

| Parameter | Standard Capability | Precision Option | Material Compatibility |

|---|---|---|---|

| Build Volume | 250 x 250 x 300 mm | 300 x 300 x 400 mm | PA11 PA12 GF-PA12 |

| Layer Thickness | 0.100 mm | 0.080 mm | Alumide |

| Dimensional Tolerance | ±0.3% (min ±0.2 mm) | ±0.2% (min ±0.1 mm) | Custom Composites |

| Surface Roughness (as-built) | Ra 12-15 µm | Ra 8-10 µm | Certified Aerospace |

| Lead Time (Prototype) | 5-7 Business Days | 3-5 Business Days | Medical Grade |

This end-to-end methodology, combining deep materials expertise with closed-loop quality management, transforms SLS from a prototyping tool into a reliable engine for certified production. Wuxi Lead ensures every component shipped meets the uncompromising standards required for aerospace, medical, and high-end industrial systems—delivering not just parts, but guaranteed performance. Trust precision-engineered components, manufactured without compromise.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced SLS 3D Printing Services in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision, industrial-grade Selective Laser Sintering (SLS) 3D printing services tailored to the exacting demands of modern manufacturing. As a trusted leader in custom metal fabrication from China, we combine cutting-edge additive technology with decades of engineering expertise to support global industries—from aerospace and automotive to medical devices and energy systems. When you partner with Lead Precision, you gain more than a supplier; you gain a strategic manufacturing ally committed to innovation, speed, and uncompromising quality.

Our SLS 3D printing service is engineered for performance-critical applications where dimensional accuracy, material integrity, and complex geometries are non-negotiable. Utilizing high-power fiber lasers and inert gas-controlled build chambers, we produce fully dense metal components with excellent mechanical properties, minimal porosity, and superior surface finish. Whether you require rapid prototyping, low-volume production, or full-scale serial manufacturing, our facility in Wuxi is equipped to scale with your project needs while maintaining strict adherence to international quality standards.

We understand that every client faces unique engineering challenges. That’s why our team of CNC engineers and additive manufacturing specialists works closely with you from design validation through post-processing and final inspection. Our in-house capabilities include support structure optimization, thermal distortion compensation, heat treatment, CNC milling for hybrid finishing, and comprehensive metrology using coordinate measuring machines (CMM). This end-to-end control ensures that every part meets your technical specifications and delivery timelines.

Below are the key technical specifications of our SLS 3D printing service:

| Parameter | Specification |

|---|---|

| Build Envelope | 250 x 250 x 325 mm |

| Layer Thickness | 20 – 50 µm |

| Positional Accuracy | ±0.05 mm |

| Repeatability | ±0.1 mm |

| Supported Materials | Stainless Steel 316L, Inconel 718, Titanium Ti6Al4V, Aluminum AlSi10Mg, Tool Steel (Maraging Steel MS1) |

| Surface Roughness (as-built) | Ra 10–15 µm (can be reduced to Ra 1–3 µm with polishing) |

| Post-Processing Options | Stress relief, Hot Isostatic Pressing (HIP), CNC machining, bead blasting, passivation, anodizing (for aluminum) |

| Quality Standards | ISO 9001:2015, full material traceability, first-article inspection reports (FAIR), PPAP documentation available |

All materials are certified and batch-tested to ensure compliance with ASTM F75, F138, F1713, and other relevant industry standards. We also offer design-for-additive-manufacturing (DfAM) consultations to help you optimize part topology, reduce weight, and eliminate assembly steps—delivering functional advantages and cost savings over traditional manufacturing.

For engineering teams seeking a reliable, responsive, and technically advanced SLS 3D printing partner in Asia, Wuxi Lead Precision Machinery stands ready to support your success. Contact us today at [email protected] to discuss your project requirements, request a quote, or receive sample parts for evaluation. Let’s build the future of manufacturing—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.