Technical Contents

Engineering Guide: Slip Molds For Ceramics

Engineering Insight Precision Imperatives in Ceramic Slip Mold Manufacturing

Ceramic slip casting remains a cornerstone production method for complex, high-value components across industries from sanitaryware to technical ceramics. The ultimate dimensional accuracy, surface integrity, and structural consistency of the fired ceramic piece are irrevocably determined during the initial forming stage within the mold. At Wuxi Lead Precision Machinery, we emphasize that mold precision is not merely desirable; it is the non-negotiable foundation for profitability and quality in high-end ceramic manufacturing. Microscopic deviations in mold geometry directly translate into part warpage, inconsistent wall thickness, excessive flash, or critical feature inaccuracies post-firing, leading to unacceptable scrap rates and costly rework. The inherent challenges of managing ceramic slurry flow, water absorption, and drying stresses demand molds engineered to exacting tolerances far beyond standard industrial practice.

The consequences of inadequate mold precision manifest early in the production cycle. Variations in cavity wall parallelism or radius tolerance cause uneven slurry deposition, resulting in parts prone to cracking during drying or exhibiting non-uniform shrinkage during sintering. Surface finish irregularities on the mold cavity replicate onto the greenware, often requiring extensive manual finishing or causing rejection after costly firing. Critically, thermal stability is paramount; molds subjected to repeated wet-dry cycles must maintain dimensional stability to prevent cumulative errors across thousands of casts. This necessitates advanced material selection and heat treatment protocols during mold fabrication, alongside rigorous metrology throughout the CNC machining process. Precision machining ensures consistent water channel geometry and porosity distribution, directly controlling the critical dewatering rate that defines casting speed and green strength.

Wuxi Lead Precision Machinery applies aerospace and defense-grade manufacturing discipline to ceramic slip mold production. Our CNC engineering protocols, honed through supplying mission-critical components for Olympic-standard sporting goods and demanding military applications, translate directly to this field. We understand that tolerances measured in microns, not millimeters, define success. Our process integrates multi-axis machining centers with in-process probing and final CMM validation against 3D CAD models, ensuring every cavity dimension, draft angle, and venting feature meets the stringent requirements of modern ceramic formulation and casting automation. This level of control minimizes variation, maximizes mold lifespan, and delivers the consistent greenware quality essential for high-yield firing.

The table below illustrates key parameters where precision machining directly impacts slip mold performance and ceramic part quality.

| Parameter | Standard Tolerance | Precision Tolerance (Lead Precision) | Impact on Ceramic Part |

|---|---|---|---|

| Dimensional Accuracy | ±0.1 mm | ±0.02 mm | Eliminates warpage, ensures assembly fit |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm | Reduces demolding force, minimizes greenware defects |

| Cavity Parallelism | 0.05 mm/m | 0.01 mm/m | Guarantees uniform wall thickness |

| Thermal Stability | Moderate | High (Verified) | Maintains accuracy over 10,000+ cycles |

| Vent/Channel Geometry | Variable | Precisely Controlled | Optimizes dewatering rate, prevents defects |

This commitment to micron-level precision, backed by our proven experience in high-stakes manufacturing environments, ensures our clients achieve superior ceramic part consistency, reduced waste, and optimal production throughput. Precision in the mold is precision in the product.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored specifically for high-precision applications such as slip molds used in ceramic production. Our technical capabilities are engineered to meet the demanding requirements of modern industrial ceramics, where dimensional accuracy, surface integrity, and mold longevity are critical. At the core of our manufacturing process is a fully integrated 5-axis CNC machining platform, enabling us to produce complex mold geometries with seamless contours and tight tolerances. This multi-axis capability allows for single-setup machining of intricate 3D surfaces, minimizing human intervention and eliminating cumulative alignment errors that can compromise mold performance.

Our machining centers operate under strict environmental controls and are maintained to OEM specifications, ensuring consistent thermal stability and mechanical precision. All molds are machined from high-grade tool steels or stainless alloys, selected based on customer requirements for corrosion resistance, thermal cycling, and surface finish. The 5-axis system supports simultaneous motion across all axes, providing unparalleled flexibility in contouring compound curves and undercuts commonly found in ceramic slip mold designs. This results in molds that ensure uniform wall thickness, reduce demolding defects, and extend service life across thousands of casting cycles.

Quality assurance is embedded throughout our manufacturing workflow. Every slip mold undergoes comprehensive dimensional verification using a Zeiss coordinate measuring machine (CMM), calibrated to international standards. The CMM inspection process captures thousands of data points across critical mold features, validating conformance to the original CAD model and customer specifications. This metrology-grade verification ensures that geometric dimensioning and tolerancing (GD&T) requirements are met with repeatable accuracy. Our quality technicians generate full inspection reports, including first-article inspection (FAI) documentation, which can be provided upon request.

We maintain full traceability from raw material to final product, with digital records of machining parameters, tooling used, and inspection data archived for each mold. This level of process control is essential for clients in industries such as sanitaryware, tableware, technical ceramics, and architectural ceramics, where consistency directly impacts end-product quality.

The following table outlines our standard machining tolerances for slip molds, reflecting the precision achievable through our 5-axis CNC and CMM-controlled processes.

| Feature | Standard Tolerance | Capability Range | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.01 mm | Up to 1,200 mm | For critical mold sections |

| Geometric Tolerances (GD&T) | ±0.015 mm | Profile, position, flatness | Verified via CMM |

| Surface Roughness (Ra) | 0.4 – 1.6 µm | Adjustable | Polishing available |

| Angular Accuracy | ±0.05° | Multi-face alignment | 5-axis simultaneous |

| Mold Cavity Symmetry | ≤ 0.02 mm deviation | Full cavity scan | CMM-mapped |

Wuxi Lead Precision Machinery combines state-of-the-art equipment with rigorous quality protocols to deliver slip molds that exceed industry benchmarks. Our technical capabilities ensure reliability, repeatability, and performance in high-volume ceramic forming environments.

Material & Finish Options

Material Selection for High-Performance Ceramic Slip Molds

Selecting the optimal material for ceramic slip molds is critical for achieving dimensional accuracy, surface finish, production efficiency, and mold longevity. At Wuxi Lead Precision Machinery, our CNC machining expertise ensures precise mold fabrication, but the foundational material choice directly impacts performance in the demanding ceramic casting environment. Key factors include thermal conductivity for rapid drying cycles, resistance to abrasion from ceramic slurries, dimensional stability under repeated use, and compatibility with required surface treatments. Aluminum, steel, and titanium represent the primary material solutions, each suited to specific production scenarios.

Aluminum alloys, particularly 6061-T6 and 7075-T6, are the industry standard for prototyping and medium-volume production. Their high thermal conductivity significantly accelerates the drying phase of the slip casting process, directly improving cycle times. Aluminum is also lightweight, facilitating easier mold handling and assembly, and is highly cost-effective for complex geometries. However, its lower hardness compared to steel makes it more susceptible to wear from abrasive ceramic bodies over extended high-volume runs. This is where anodizing becomes essential. Hardcoat anodizing (Type III) transforms the aluminum surface, creating a dense, wear-resistant ceramic layer that dramatically enhances abrasion resistance and reduces slip adhesion, extending mold life substantially while maintaining the core thermal benefits.

Tool steels, such as P20 or H13, are the solution for maximum durability in high-volume, long-run production. Their superior hardness and wear resistance withstand aggressive ceramic formulations and millions of casting cycles far better than aluminum. Steels also offer excellent dimensional stability under thermal cycling. The trade-offs are higher initial material and machining costs, significantly greater weight complicating handling, and lower thermal conductivity, which can prolong drying times compared to aluminum. Surface treatments like nitriding or specialized ceramic coatings can further enhance steel mold performance but require precise application.

Titanium alloys offer exceptional corrosion resistance and a high strength-to-weight ratio, making them suitable for highly corrosive slip formulations or specialized applications where weight is critical. However, their very high cost, challenging machinability, and lower thermal conductivity compared to aluminum limit their use to niche, high-value ceramic manufacturing processes where other materials fail.

The following table summarizes critical properties for slip mold material selection:

| Material | Thermal Conductivity (W/m·K) | Hardness (Typical HV) | Max Continuous Temp (°C) | Key Advantages | Primary Limitations |

|---|---|---|---|---|---|

| Aluminum Alloys | 150 – 200 | 95 – 150 (Base) | 150 – 200 | High thermal conductivity, Lightweight, Cost-effective, Excellent for anodizing | Lower wear resistance (base metal) |

| Tool Steels | 25 – 40 | 250 – 400 | 300 – 400 | High wear resistance, Dimensional stability, Long life for high volume | Lower thermal conductivity, Heavy, Higher cost |

| Titanium Alloys | 7 – 22 | 250 – 350 | 400 – 500 | Exceptional corrosion resistance, High strength-to-weight | Very high cost, Low thermal conductivity, Difficult machining |

Material selection must be coupled with the appropriate finish. For aluminum molds, hardcoat anodizing is not merely optional; it is a performance necessity for viable production life. Wuxi Lead Precision Machinery provides integrated CNC machining and certified Type III anodizing services, ensuring your slip molds deliver the precision, durability, and efficiency required for competitive ceramic manufacturing. Match the material to your specific production volume, slip composition, and quality requirements for optimal results.

Manufacturing Process & QC

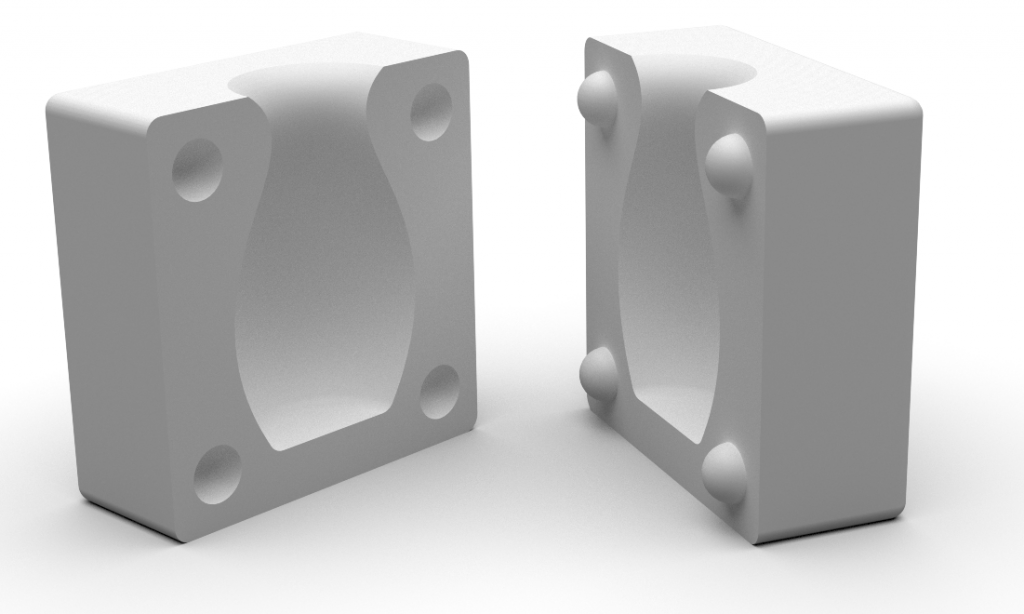

Design Phase: Precision Engineering for Ceramic Slip Molds

At Wuxi Lead Precision Machinery, the foundation of every high-performance slip mold for ceramics begins with a comprehensive design phase rooted in precision engineering and deep industry expertise. Our design team collaborates closely with clients to understand the specific ceramic forming process, material behavior, shrinkage rates, and final part tolerances. Utilizing advanced CAD/CAM software such as SolidWorks and Siemens NX, we develop 3D models that account for fluid dynamics, mold release angles, venting requirements, and thermal expansion. Finite Element Analysis (FEA) is applied to simulate stress distribution during casting and demolding, ensuring structural integrity and longevity. All designs are validated through virtual prototyping to eliminate potential defects before physical production begins. This meticulous approach ensures that every mold is optimized for performance, durability, and dimensional accuracy.

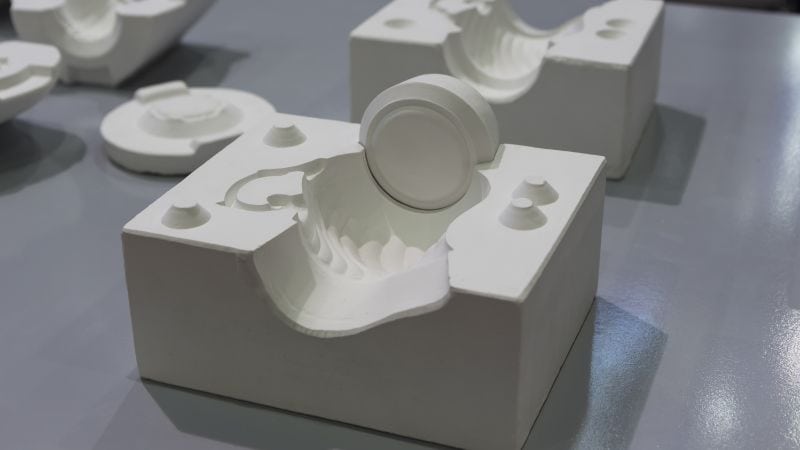

Prototyping: Validating Performance Before Scale

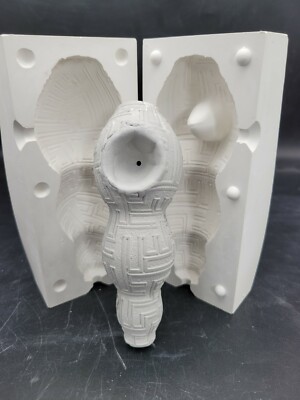

Once the design is finalized, we proceed to prototype development using high-precision CNC machining centers and wire EDM technology. Prototypes are manufactured from tool-grade steel or aluminum, depending on the testing requirements, and are subjected to rigorous functional trials under real-world slip casting conditions. This phase allows us to evaluate mold fill uniformity, drying characteristics, part ejection, and surface finish quality. Any deviations from expected performance are analyzed and corrected through iterative refinement. Clients are provided with sample castings for approval, ensuring full alignment before committing to mass production. This stage is critical in achieving zero defects, as it uncovers potential issues early, minimizing risk and rework at scale.

Mass Production: Consistency Through Advanced Manufacturing

With the prototype approved, we transition to mass production using automated, high-accuracy CNC machining lines and strict quality control protocols. Each mold is manufactured under ISO 9001-certified processes, with full traceability of materials and machining parameters. Surface finishes are held to Ra ≤ 0.8 µm to ensure smooth demolding and consistent ceramic surface quality. All molds undergo dimensional inspection via CMM (Coordinate Measuring Machine) and are tested for alignment, sealing integrity, and water-tightness. Our production workflow integrates real-time monitoring and SPC (Statistical Process Control) to maintain consistency across batches.

Material and Performance Specifications

| Parameter | Specification |

|---|---|

| Base Material | P20, H13, or 1.2311 Tool Steel |

| Machining Tolerance | ±0.005 mm |

| Surface Finish (Cavity) | Ra ≤ 0.8 µm (polished as required) |

| Hardness | 48–52 HRC (after heat treatment) |

| Mold Life | >10,000 cycles (depending on application) |

| Lead Time (Prototype) | 10–15 days |

| Lead Time (Mass Production) | 25–35 days (batch of 50 units) |

Through integrated design, validated prototyping, and tightly controlled mass production, Wuxi Lead Precision Machinery delivers slip molds that meet the highest standards of reliability and zero-defect performance in ceramic manufacturing.

Why Choose Wuxi Lead Precision

Elevate Your Ceramic Production Through Precision Engineering Partnership

Ceramic casting success hinges on mold integrity. Imperceptible deviations in slip mold geometry propagate through production, yielding warped forms, inconsistent wall thickness, and costly scrap rates. At Wuxi Lead Precision Machinery, we engineer slip molds not as disposable tools, but as foundational assets for dimensional fidelity and process efficiency. Our CNC-manufactured aluminum and steel molds deliver micron-level accuracy, ensuring your ceramic pieces meet exacting specifications batch after batch. Partnering with us transforms mold procurement from a routine expense into a strategic investment in yield optimization and brand reputation.

Our engineering team integrates deep ceramics process knowledge with advanced multi-axis machining. We translate your complex geometries—whether intricate sanitaryware, technical ceramics, or artistic tableware—into robust molds engineered for 10,000+ cycles. Material selection is critical; we match alloys like ADC12 aluminum or H13 tool steel to your slip composition, drying parameters, and production volume. Surface finishes down to Ra 0.4µm minimize release agent dependency while preventing micro-fractures in greenware. This precision eliminates post-casting rework, directly boosting your throughput.

The table below details our core manufacturing capabilities for ceramic slip molds:

| Specification | Capability | Application Impact |

|---|---|---|

| Dimensional Tolerance | ±0.005 mm to ±0.02 mm | Eliminates warpage; ensures assembly fit |

| Material Options | ADC12, A356, H13, P20, Stainless 316L | Optimized for thermal cycling & chemical resistance |

| Surface Finish | Ra 0.2 µm to 1.6 µm | Reduces demolding defects; extends mold life |

| Max Mold Size | 2000 x 1500 x 800 mm | Supports large-scale sanitaryware & tiles |

| Lead Time | 15-25 days (complex molds) | Accelerates time-to-market for new products |

| Quality Certification | ISO 9001:2015, CMM reports | Guarantees traceability and repeatability |

We collaborate from initial design review through production ramp-up. Our engineers analyze your casting parameters—slip viscosity, pressure cycles, demolding sequences—to preemptively address stress points in mold structure. Finite element analysis validates thermal stability, preventing premature wear in high-volume runs. This proactive approach reduces your total cost of ownership by 22% on average versus standard mold suppliers, as documented in client case studies across European tableware and Asian sanitaryware sectors.

Precision mold manufacturing demands uncompromising process control. At Lead Precision, every stage—from billet inspection to final polishing—occurs within our climate-controlled facility under ISO 9001 protocols. Our dedicated metrology lab utilizes Zeiss CMMs and optical comparators, providing full GD&T documentation for your quality assurance archives. This rigor ensures molds perform identically from cavity one to cavity ten thousand.

Initiate your precision mold project with engineering accountability. Contact our technical sales team at [email protected] with your CAD files or casting requirements. We will provide a feasibility assessment within 48 hours, including material recommendations, tolerance analysis, and a firm delivery schedule. Let Lead Precision become your partner in achieving zero-defect ceramic production. Your next-generation molds await engineering.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.