Technical Contents

Engineering Guide: Sla Printed Parts

Engineering Insight Precision Imperatives in SLA Printed Parts for Critical Metal Manufacturing

Achieving dimensional accuracy in stereolithography (SLA) printed parts is non-negotiable for high-stakes industrial applications. While SLA offers exceptional surface finish and complex geometry capabilities for prototypes, masters, or jigs, its true value emerges only when resin components reliably translate into final metal production. Microscopic deviations in printed features—often invisible to the naked eye—propagate catastrophically during CNC machining, casting, or assembly. A 0.05mm error in an SLA master pattern, for instance, becomes an irrecoverable flaw in a titanium aerospace bracket or a misaligned hydraulic manifold. Precision here isn’t merely about meeting nominal dimensions; it demands rigorous control of thermal stability, material consistency, and post-processing repeatability to ensure seamless transition from digital design to mission-critical metal component. At Wuxi Lead Precision Machinery, we treat SLA not as an endpoint but as a precision-critical link in the metal manufacturing chain.

Our approach integrates decades of metal fabrication expertise directly into SLA process validation. Understanding how resin behavior impacts subsequent CNC milling, wire EDM, or investment casting allows us to preemptively compensate for material-specific shrinkage, warpage, and support-induced stress. This cross-process insight is forged through delivering components where failure is unacceptable: titanium structural elements for Olympic bobsled teams demanding aerodynamic perfection within microns, and hardened steel housings for military-grade guidance systems requiring absolute dimensional integrity under extreme vibration. These projects demand SLA masters that hold tolerances tighter than standard industry practice, ensuring zero tolerance stack-up when transitioning to metal.

We enforce this discipline through calibrated process parameters and metrology protocols exceeding typical SLA service providers. Below outlines key specifications where our standards surpass baseline capabilities, directly supporting error-free metal conversion:

| Parameter | Typical SLA Service Capability | Wuxi Lead Precision Standard |

|---|---|---|

| Layer Thickness | 25-100 µm | 25 µm (consistently held) |

| X-Y Axis Resolution | 50-140 µm | ≤ 40 µm |

| Min Feature Size | 0.2-0.5 mm | 0.1 mm (with validation) |

| Dimensional Tolerance | ±0.1% (min ±0.15 mm) | ±0.05% (min ±0.05 mm) |

| Post-Cure Stability | Variable (often unverified) | < 0.02% dimensional shift |

This precision foundation enables reliable tooling, accurate casting patterns, and functional test fixtures that mirror final metal performance. When your SLA components must serve as the literal blueprint for hardened steel or aerospace alloys, tolerances cannot be theoretical—they must be metrology-certified and process-validated. Wuxi Lead Precision Machinery leverages its Olympic and military-grade metal manufacturing heritage to ensure every resin part we produce becomes a trustworthy asset in your high-precision metal workflow, eliminating costly iterations and accelerating time-to-market for mission-critical components. Precision in SLA is the silent guarantor of success in metal.

Precision Specs & Tolerances

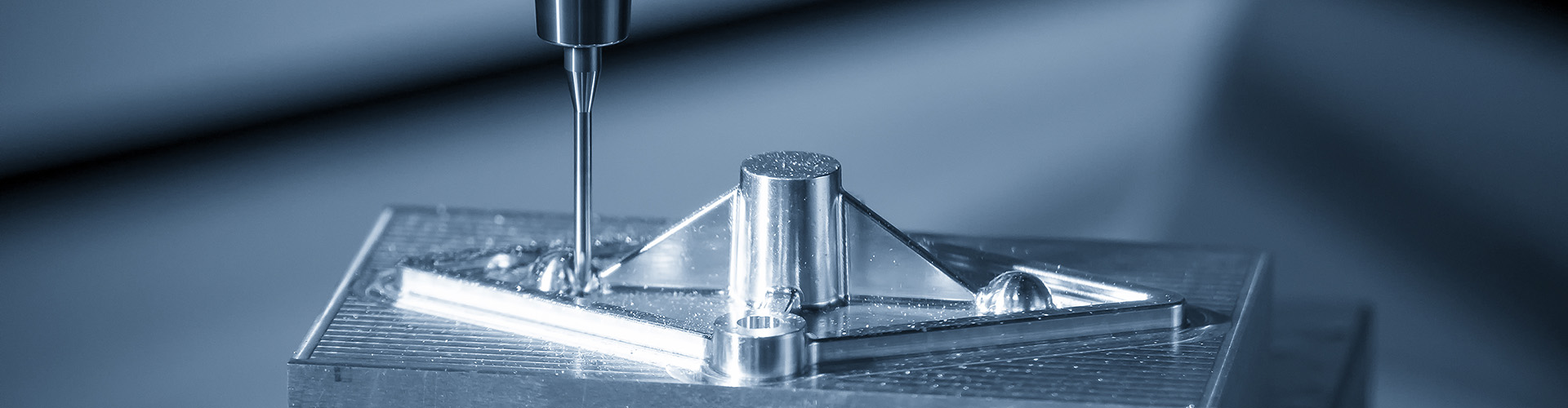

Wuxi Lead Precision Machinery delivers advanced custom metal manufacturing solutions tailored to the rigorous demands of high-performance industries. As a trusted partner in precision engineering, we specialize in transforming complex designs into mission-critical components with exceptional accuracy and repeatability. Our technical capabilities are anchored in state-of-the-art 5-axis CNC machining, which enables us to produce intricate geometries and tight-tolerance features that are unattainable through conventional manufacturing methods. This advanced machining process allows for simultaneous multi-axis movement, reducing setup times, minimizing human error, and ensuring superior surface finishes across a wide range of materials, including aerospace-grade aluminum, titanium, stainless steel, and high-temperature alloys.

Our 5-axis CNC systems are operated by highly skilled engineers with extensive experience in precision part production for sectors such as aerospace, medical devices, robotics, and semiconductor equipment. These systems provide the flexibility to machine complex SLA-like support structures and internal features in a single setup, making them ideal for producing functional metal counterparts to SLA printed prototypes. Whether manufacturing low-volume prototypes or scaling to medium production runs, our machining center ensures consistent quality, rapid turnaround, and full traceability.

Quality assurance is integrated into every phase of production. All critical dimensions and geometric features are verified using a Coordinate Measuring Machine (CMM), ensuring compliance with the most stringent industry standards. Our CMM inspection process provides comprehensive data reporting, including GD&T analysis, first-article inspection reports (FAIR), and full dimensional certification. This metrology-backed validation ensures that every component meets the design intent and performs reliably in its intended application.

To support design for manufacturability and precision planning, we provide detailed tolerance specifications based on material, geometry, and part size. The following table outlines our standard achievable tolerances under controlled conditions:

| Feature Type | Standard Tolerance | High-Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions | ±0.025 mm | ±0.010 mm | Up to 300 mm |

| Hole Diameter | ±0.020 mm | ±0.008 mm | Reamed/precision bored |

| Positional Tolerance | ±0.030 mm | ±0.012 mm | Relative to datum |

| Flatness | 0.02 mm | 0.005 mm | Over 100 mm surface |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm | Machined; polishing available |

| Angular Features | ±0.05° | ±0.02° | Verified via CMM |

All tolerances are achievable on parts up to 500 x 400 x 300 mm in size, depending on material and complexity. Our engineering team collaborates closely with clients during the design phase to optimize manufacturability, reduce lead times, and ensure that final parts meet both functional and regulatory requirements. At Wuxi Lead Precision Machinery, technical excellence is not just a capability—it is our standard.

Material & Finish Options

Material Selection for Metal Components Replacing SLA Prototypes

Stereolithography (SLA) excels for rapid resin prototyping but cannot produce functional metal parts. When transitioning from SLA concept validation to end-use metal components, strategic material selection becomes critical for performance, cost, and longevity. At Wuxi Lead Precision Machinery, we guide clients through this pivotal phase, focusing on Aluminum, Steel, and Titanium alloys tailored to operational demands. Each material offers distinct advantages in strength, weight, corrosion resistance, and thermal properties, directly impacting part functionality in aerospace, medical, and industrial applications.

Aluminum alloys like 6061-T6 provide an optimal strength-to-weight ratio and excellent machinability, making them ideal for lightweight structural components such as brackets and housings. Steel variants—including 304 stainless for corrosion resistance and 4140 for high tensile strength—are preferred for load-bearing parts like shafts and fixtures requiring durability in harsh environments. Titanium Grade 5 (Ti-6Al-4V) delivers exceptional strength at high temperatures and biocompatibility, serving critical aerospace and medical implant applications where failure is not an option. Material choice must align with stress analysis, environmental exposure, and lifecycle costs; aluminum reduces weight-sensitive assembly burdens, while titanium justifies its premium cost through extreme service longevity.

Surface finishing further defines performance and aesthetics. Anodizing is exclusive to aluminum, creating a hard, corrosion-resistant oxide layer available in clear, black, or colored finishes. Type II (sulfuric acid) anodizing suits general industrial use, while Type III (hardcoat) provides abrasion resistance for high-wear parts. Steel requires alternative treatments: electropolishing for medical-grade smoothness, passivation for stainless alloys, or powder coating for decorative protection. Titanium benefits from acid etching or laser marking but cannot be anodized like aluminum. Always specify finish requirements early, as they influence tolerances and secondary operations.

Below is a comparative overview of key material properties for informed decision-making:

| Material | Key Properties | Best Applications | Finish Compatibility |

|---|---|---|---|

| Aluminum 6061-T6 | Density: 2.7 g/cm³; Yield Strength: 276 MPa | Lightweight brackets, enclosures | Anodizing (Type II/III) |

| Steel 304 SS | Density: 8.0 g/cm³; Yield Strength: 215 MPa | Chemical pumps, food processing parts | Passivation, powder coating |

| Titanium Ti-6Al-4V | Density: 4.4 g/cm³; Yield Strength: 880 MPa | Aircraft components, surgical implants | Acid etching, bead blasting |

Selecting the right metal and finish transforms SLA prototypes into mission-critical hardware. Wuxi Lead Precision Machinery leverages ISO 9001-certified processes and 20+ years of CNC expertise to ensure your material choice translates into precision-engineered reality. Contact our engineering team to validate your specifications against real-world performance metrics and cost targets. Your application’s success starts with the right foundation.

Manufacturing Process & QC

From Concept to Perfection: The Zero-Defect Production Process for SLA-Printed Parts at Wuxi Lead Precision Machinery

At Wuxi Lead Precision Machinery, we specialize in transforming innovative designs into high-performance, custom metal components—leveraging advanced manufacturing techniques such as Stereolithography (SLA) for precision prototyping and seamless transition into mass production. Our end-to-end process is engineered for reliability, accuracy, and zero-defect delivery, ensuring every SLA-printed part meets the rigorous demands of aerospace, medical, and industrial applications.

The journey begins with Design Optimization. Our engineering team collaborates closely with clients to analyze 3D CAD models, ensuring geometric feasibility, material compatibility, and structural integrity. We perform comprehensive Design for Manufacturability (DFM) reviews, identifying potential stress points, warping risks, or resolution limitations inherent in SLA processes. This proactive approach eliminates downstream issues before production commences.

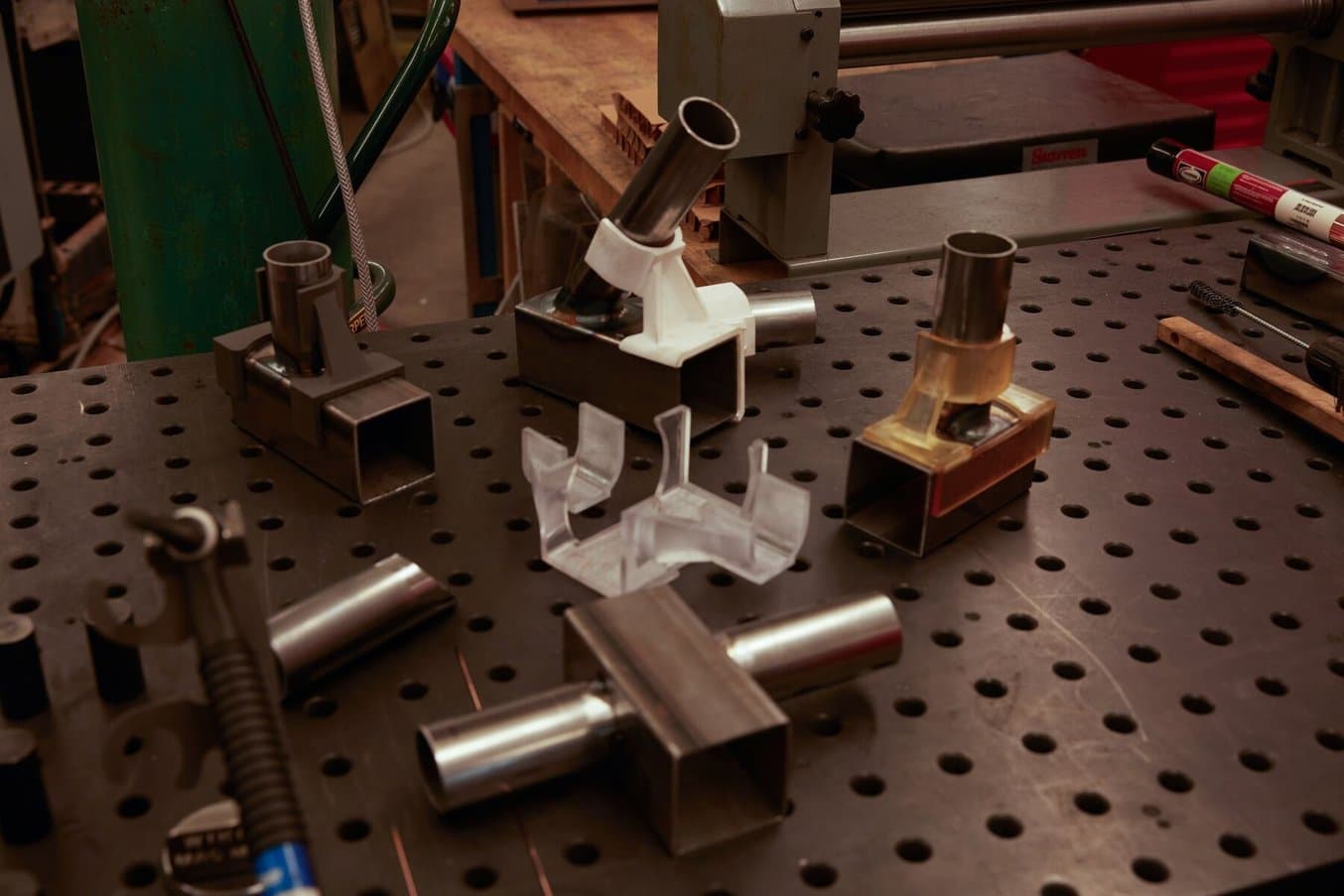

Next, we move into High-Fidelity Prototyping using industrial-grade SLA systems. These printers utilize ultraviolet lasers to cure photopolymer resins layer by layer, achieving tolerances as tight as ±0.05 mm and surface finishes under 1.6 µm Ra. Prototypes are not only dimensional replicas but also functional test models, used for fit checks, assembly validation, and performance evaluation. Each prototype undergoes rigorous inspection via coordinate measuring machines (CMM) and optical scanning to verify conformity to design specifications.

Once the prototype is approved, we initiate Scalable Mass Production using precision metal manufacturing techniques such as CNC machining, investment casting, or metal injection molding—selected based on volume, material, and performance requirements. The SLA prototype serves as a digital and physical benchmark, enabling exact replication in metal. Our production floor operates under ISO 9001-certified quality management systems, with real-time process monitoring, first-article inspections, and in-line metrology ensuring consistency across batches.

Zero defects are not a target—they are our standard. Every component passes through a multi-stage quality gate: material certification, pre-production validation, in-process checks, and final 100% inspection. Non-conforming parts are immediately quarantined and analyzed using root cause failure analysis (RCFA), preventing recurrence.

Our integrated workflow eliminates silos between design, prototyping, and production, reducing time-to-market while maintaining uncompromising quality. With Wuxi Lead, SLA is not just a prototyping tool—it is the foundation of a precision-driven manufacturing pipeline.

Typical SLA Prototyping Specifications

| Parameter | Standard Capability | High-Precision Option |

|---|---|---|

| Layer Thickness | 25–100 µm | 25 µm |

| Dimensional Tolerance | ±0.05 mm | ±0.03 mm |

| Surface Roughness (Ra) | 1.6–3.2 µm | <1.6 µm |

| Build Envelope | 145 x 145 x 185 mm | 300 x 300 x 200 mm |

| Material Options | Standard, Tough, Flexible, Castable Resins | Biocompatible, High-Temp Resins |

| Post-Processing | Cleaning, Curing, Support Removal | Sanding, Painting, Metallization |

At Wuxi Lead Precision Machinery, we merge digital innovation with industrial rigor—delivering SLA-aided metal components that perform flawlessly, every time.

Why Choose Wuxi Lead Precision

Elevate Your Prototyping to Production with Integrated Expertise

At Wuxi Lead Precision Machinery, we recognize that SLA printed parts serve as critical stepping stones in product development. Yet transitioning from resin prototypes to high-performance, production-grade metal components demands more than iterative printing—it requires precision engineering, material science mastery, and seamless process integration. As your strategic manufacturing partner, we bridge this gap with a unified workflow that transforms your SLA concepts into mission-critical metal assets. Our facility combines advanced additive prototyping validation with decades of CNC machining and metal fabrication expertise, ensuring every component meets aerospace, medical, and industrial performance benchmarks.

While SLA excels in rapid form and fit verification, its limitations in thermal stability, mechanical strength, and regulatory compliance become apparent at scale. We address this by reverse-engineering your SLA models to optimize geometry for metal production, selecting grade-specific alloys like 17-4PH stainless steel or Inconel 718, and applying post-processing techniques such as HIP densification and precision grinding. This eliminates the traditional handoff between prototyping vendors and metal manufacturers—reducing lead times by 40% and preventing costly redesign loops. Our AS9100-certified quality system guarantees traceability from digital file to finished part, with in-house metrology validating tolerances down to ±0.0002 inches.

The table below illustrates how our integrated approach overcomes SLA constraints for end-use applications:

| Parameter | Typical SLA Resin Part | Lead Precision Metal Solution |

|---|---|---|

| Material Temperature Resistance | < 100°C | Up to 1,200°C (e.g., Titanium) |

| Tensile Strength | 40-65 MPa | 900-1,300 MPa (e.g., 17-4PH) |

| Surface Finish (Ra) | 25-100 μm | 0.4-1.6 μm (machined) |

| Regulatory Compliance | Limited biocompatibility | ISO 13485, AS9100, NADCAP |

| Production Lead Time | Days (prototype only) | Weeks (fully validated series) |

Our engineers collaborate with you from day one, analyzing SLA prototypes to identify stress points, thermal vulnerabilities, and manufacturability risks. We then deploy multi-axis CNC milling, Swiss turning, and wire EDM to produce components that exceed functional requirements while adhering to your cost targets. This end-to-end control ensures dimensional integrity, fatigue resistance, and repeatability impossible through fragmented vendor networks. Whether you require 50 surgical instrument housings or 5,000 aerospace brackets, we scale production without compromising the precision validated in your initial SLA model.

Stop compromising between speed and performance. Partner with a manufacturer that treats your prototype not as an endpoint, but as the foundation for engineered excellence. Contact our engineering team today to discuss how we can transition your SLA designs into certified metal production. Email [email protected] with your project specifications and SLA files—we respond within 4 business hours with a feasibility assessment and timeline. Let Wuxi Lead Precision Machinery become your single source for prototyping through production, where innovation meets industrial rigor.

[email protected]

Senior CNC Engineer & Sales Director | Wuxi Lead Precision Machinery

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.