Technical Contents

Engineering Guide: Sla 3D Printing Services

Engineering Insight Precision in SLA 3D Printing Services for Advanced Manufacturing

Precision is not merely a desirable attribute in industrial additive manufacturing; it is the foundational requirement determining functional viability and integration within high-stakes production ecosystems. Stereolithography (SLA) 3D printing, while often associated with prototyping, delivers exceptional dimensional accuracy and surface finish critical for end-use components, tooling, and master patterns within custom metal manufacturing workflows. At Wuxi Lead Precision Machinery, we recognize that micron-level tolerances in SLA outputs directly impact the quality and performance of subsequent metal casting, machining, or assembly processes. Inferior precision leads to costly rework, material waste, and compromised part integrity – risks unacceptable in sectors demanding absolute reliability.

Our engineering approach treats SLA as an integral precision engineering process, not just rapid fabrication. We deploy industrial-grade SLA systems calibrated and maintained to stringent standards, ensuring consistent layer adhesion, minimal thermal distortion, and repeatability across builds. This rigor stems from our core competency in ultra-precision CNC machining for aerospace, defense, and high-performance applications, including components meeting Olympic infrastructure specifications and military-grade requirements. The same uncompromising focus on metrology, process control, and material science that governs our metal production defines our SLA service execution. We understand that a casting pattern deviating by 50 microns can propagate critical defects through an entire investment casting run, ultimately affecting the structural integrity of a finished titanium aerospace bracket. Precision in the digital model and its physical realization via SLA is therefore the first, non-negotiable step in a successful metal manufacturing chain.

Wuxi Lead leverages SLA specifically for applications where its unique precision advantages are paramount. This includes producing intricate investment casting patterns for complex turbine blades, creating low-friction jigs and fixtures for delicate assembly operations, and fabricating fluidic manifolds requiring smooth internal channels impossible via traditional methods. Our process integrates seamlessly with our metal capabilities, ensuring the SLA component functions as intended within the broader manufacturing sequence. Rigorous in-process inspection using coordinate measuring machines (CMM) validates every critical dimension against the original CAD model before parts proceed to metal processing stages.

The following specifications represent the precision benchmarks achievable with our industrial SLA systems under controlled manufacturing conditions:

| Parameter | Typical Performance | Industrial Standard Target |

|---|---|---|

| Layer Thickness | 25 – 100 microns | ≤ 50 microns |

| XY Resolution | 50 – 140 microns | ≤ 75 microns |

| Z Axis Accuracy | ±0.05 mm | ±0.025 mm |

| Build Volume | 145 x 145 x 175 mm | Custom configurations available |

| Surface Finish (As Printed) | Ra 0.8 – 1.6 µm | Ra ≤ 1.0 µm achievable |

| Material Types | Engineering-grade photopolymers (castable, high-temp, biocompatible) | ISO 10993 certified options |

This level of controlled precision transforms SLA from a prototyping tool into a certified manufacturing process. For Wuxi Lead clients, it means reduced time-to-market for complex metal assemblies, elimination of tooling costs for low-volume precision components, and guaranteed dimensional fidelity from digital design to final metal part. We apply the same engineering discipline honed on Olympic and military projects to every SLA build, ensuring your additive components meet the exacting demands of advanced metal manufacturing. Precision is the thread connecting every stage of production; we ensure it remains unbroken.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced SLA 3D printing services integrated with high-precision metal manufacturing to meet the rigorous demands of aerospace, medical, automotive, and industrial clients. Our technical capabilities combine state-of-the-art stereolithography with secondary precision machining and comprehensive quality assurance, enabling us to produce complex, high-fidelity prototypes and end-use components with exceptional surface finish and dimensional accuracy.

Our SLA 3D printing process utilizes industrial-grade resin systems, including standard, engineering-grade, biocompatible, and high-temperature formulations, allowing for functional testing, rapid prototyping, and low-volume production. Layer resolution as fine as 25 microns ensures smooth surface finishes and intricate detail reproduction, critical for applications requiring aesthetic precision or tight integration with mating components. Post-processing is performed in-house, including support removal, curing, and surface finishing options such as sanding, priming, and painting, tailored to customer specifications.

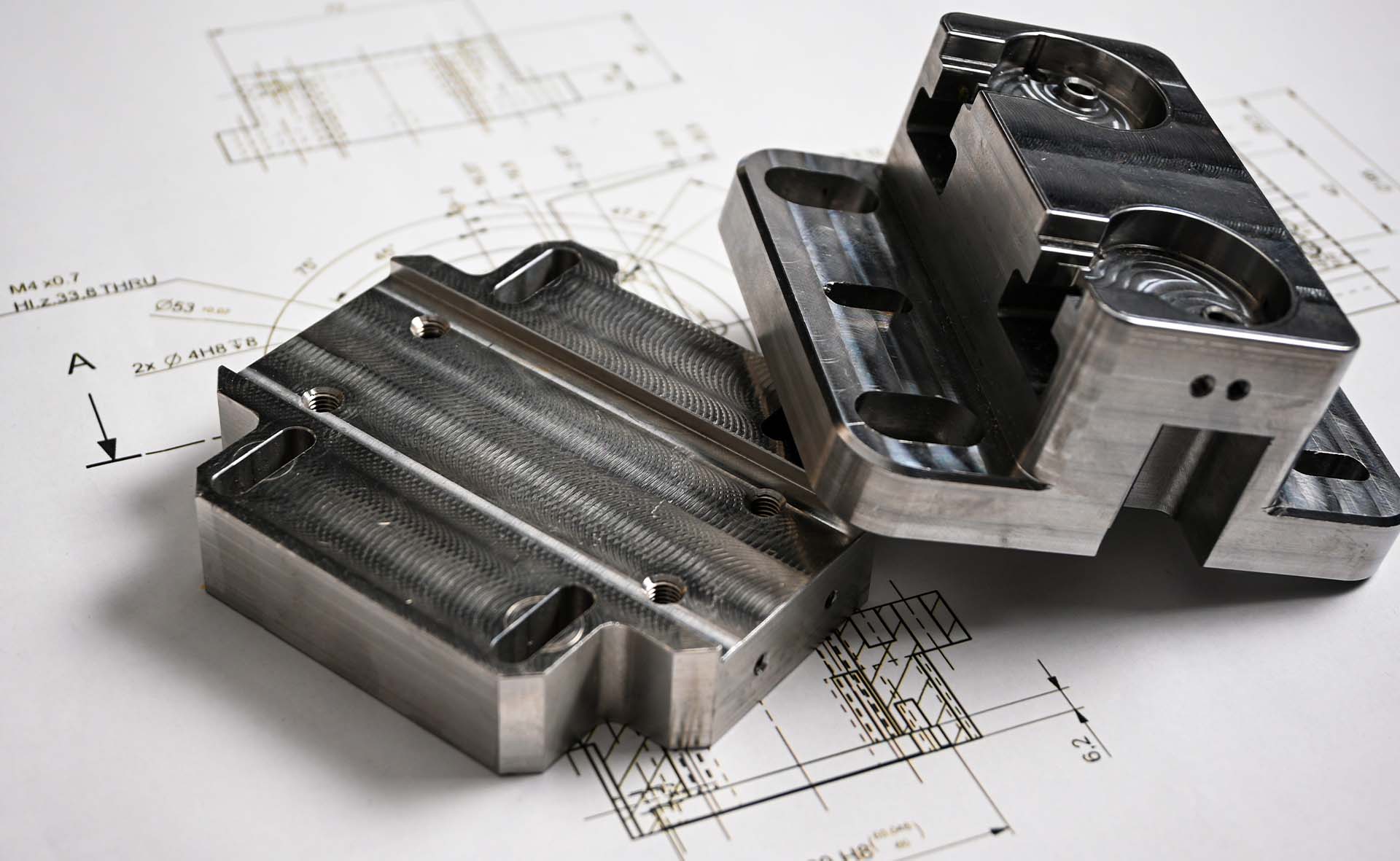

To ensure dimensional integrity and compatibility with metal components, all SLA parts undergo rigorous metrology and can be further enhanced using our 5-axis CNC machining centers. This hybrid approach enables us to machine critical features, refine tolerances, or prepare SLA components for overmolding, insert integration, or assembly with metal parts. The 5-axis CNC capability supports complex geometries with high repeatability, delivering ±0.005 mm accuracy on critical surfaces. Our machining centers are equipped with automated tool changers, high-speed spindles, and probing systems for in-process verification, minimizing setup time and maximizing precision.

Quality control is integral to our manufacturing workflow. Every SLA and machined component undergoes full inspection using a Zeiss DuraMax Bridge-type CMM, ensuring compliance with ISO 10360 standards. Our inspection protocols include first-article inspection (FAI), production part approval (PPAP), and comprehensive dimensional reports with GD&T analysis. All inspection data is documented and archived for full traceability, supporting regulatory compliance in highly controlled industries.

The following table outlines key technical specifications for our SLA 3D printing and precision machining services:

| Parameter | Specification |

|---|---|

| Build Envelope (SLA) | 140 x 140 x 175 mm |

| Layer Resolution | 25 – 100 microns |

| Standard Materials | Standard, Tough, Flexible, Castable, Dental, High-Temp Resins |

| Surface Finish (as printed) | Ra ≤ 0.8 µm |

| Post-Processing Options | Support Removal, Curing, Sanding, Priming, Painting, Metallization |

| Secondary Machining | 5-Axis CNC Milling and Drilling |

| Machining Tolerance (CNC) | ±0.005 mm |

| Feature Accuracy (SLA) | ±0.1 mm (first 100 mm), +0.05 mm per additional 100 mm |

| Inspection Equipment | Zeiss DuraMax CMM, Optical Comparator, Calipers, Micrometers |

| Quality Standards | ISO 9001:2015, PPAP, FAI, Full GD&T Reporting |

At Wuxi Lead Precision Machinery, we bridge the gap between rapid prototyping and precision manufacturing, delivering SLA 3D printed components that meet the exacting standards of modern engineering.

Material & Finish Options

Material Selection Guidance for Metal Additive Manufacturing

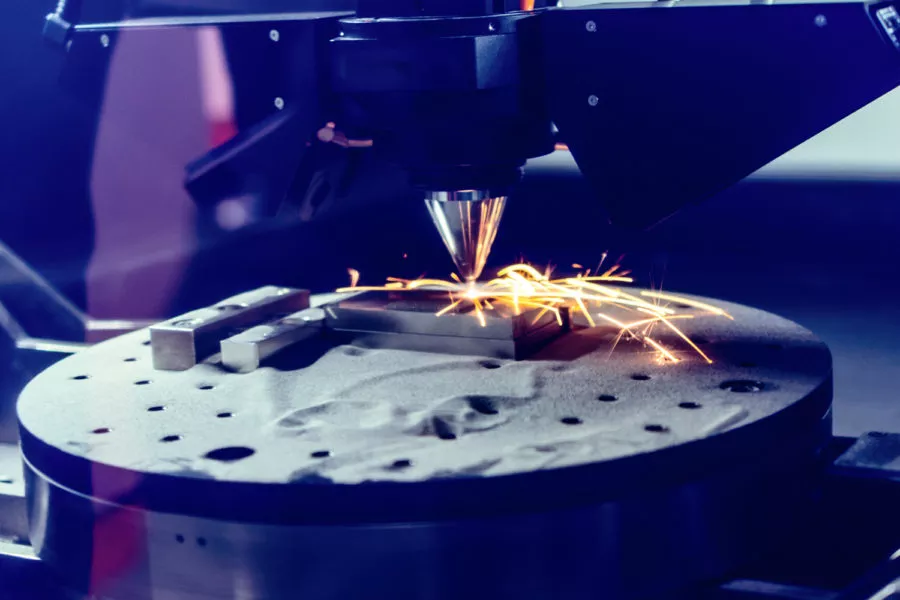

While SLA 3D printing utilizes photopolymer resins for prototyping, Wuxi Lead Precision Machinery specializes in metal additive manufacturing (e.g., SLM, DMLS) for end-use industrial components. Material selection directly impacts part performance, cost, and post-processing requirements. Below we clarify critical considerations for Aluminum, Steel, and Titanium alloys—common in high-strength applications—and address surface finishing constraints.

Aluminum alloys like AlSi10Mg offer an optimal strength-to-weight ratio and thermal conductivity, ideal for aerospace brackets or automotive heat exchangers. However, raw 3D-printed aluminum surfaces exhibit porosity and roughness, making them incompatible with standard anodizing. Achieving anodized finishes requires CNC-machined secondary operations to create a uniform substrate. Steel variants—316L stainless for corrosion resistance in marine environments and 17-4PH for high tensile strength in tooling—provide durability but necessitate stress-relief heat treatment post-printing to prevent warpage. Titanium Ti6Al4V delivers exceptional biocompatibility and fatigue resistance for medical implants or aerospace components, though its reactive nature demands inert atmosphere processing during printing. Crucially, anodizing is not applicable to titanium or steel; alternatives like passivation (for steel) or plasma electrolytic oxidation (for titanium) are used instead.

Material properties must align with functional demands. Refer to the comparative specifications below:

| Material | Key Properties | Typical Applications | Post-Processing Requirements |

|---|---|---|---|

| AlSi10Mg | Density: 2.68 g/cm³; UTS: 290-360 MPa | Lightweight structural parts | CNC machining, heat treatment |

| 316L Stainless | Density: 8.0 g/cm³; UTS: 550-650 MPa | Marine, chemical equipment | Stress relief, electropolishing |

| 17-4PH Steel | Density: 7.75 g/cm³; UTS: 1000-1300 MPa | High-stress tooling | Solution aging, precision grinding |

| Ti6Al4V | Density: 4.43 g/cm³; UTS: 900-950 MPa | Medical implants, aerospace | Hot isostatic pressing (HIP), shot peening |

Anodizing remains exclusive to aluminum and requires a smooth, defect-free base—unattainable on as-printed additive surfaces due to layer lines and micro-porosity. For functional aluminum parts requiring corrosion resistance or electrical insulation, we recommend full CNC finishing prior to Type II (sulfuric acid) or Type III (hardcoat) anodizing. Steel and titanium demand alloy-specific treatments: 316L benefits from nitric acid passivation, while titanium often receives laser polishing or chemical etching for biocompatibility.

At Wuxi Lead, we integrate metal AM with precision CNC capabilities to deliver finished components meeting ISO 2768-mK tolerances. Always involve manufacturing engineers early to evaluate material-process-finish interdependencies. Contact our technical team to optimize your design for performance, cost, and surface integrity.

Manufacturing Process & QC

Design: Engineering Precision from Concept to CAD

At Wuxi Lead Precision Machinery, the foundation of flawless custom metal manufacturing begins with precision-driven design. Our engineering team collaborates closely with clients to transform conceptual ideas into detailed 3D CAD models, optimized for structural integrity, manufacturability, and performance. Utilizing advanced simulation software, we conduct thermal, stress, and flow analyses to validate designs before any physical work commences. This digital validation ensures that every component meets exact functional requirements while minimizing material waste and production risk. Design for manufacturability (DFM) principles are integrated at this stage to preempt potential issues, aligning geometry, tolerances, and material selection with downstream SLA 3D printing and post-processing capabilities. All designs undergo rigorous internal review and client approval, ensuring full transparency and alignment with project goals.

Prototyping: Validating Performance with SLA 3D Printing

Once the design is finalized, we transition to rapid prototyping using high-resolution Stereolithography (SLA) 3D printing. SLA technology enables us to produce highly accurate, isotropic prototypes with fine details and smooth surface finishes—ideal for functional testing and form-fit validation. These prototypes are not merely visual aids; they serve as engineering-grade models for assembly trials, airflow testing, and ergonomic evaluation. Our SLA systems use industrial-grade photopolymers that simulate the mechanical properties of final metal components, allowing clients to assess performance under real-world conditions. Each prototype is inspected using coordinate measuring machines (CMM) and optical scanners to verify dimensional accuracy against the original CAD file. Feedback from this phase is systematically incorporated, ensuring that the final design is optimized for mass production with zero deviation risk.

Mass Production: Precision, Consistency, Zero Defects

With prototype validation complete, we scale to high-precision mass production using advanced CNC machining, metal injection molding, and additive manufacturing where applicable. While SLA serves as the prototyping backbone, the final metal components are produced using processes tailored to material, volume, and performance needs—always maintaining the geometric accuracy established in the prototype phase. Our production floor operates under ISO 9001-certified quality management systems, with in-line inspection at every stage. Automated optical inspection (AOI), real-time process monitoring, and statistical process control (SPC) ensure consistency across batches. The result is a zero-defect manufacturing outcome, where every component meets stringent tolerance and reliability standards.

| Specification | Detail |

|---|---|

| SLA Layer Resolution | 25 – 100 μm |

| Prototype Accuracy | ±0.1 mm |

| Build Envelope (SLA) | 140 × 140 × 175 mm |

| Material Options (Prototyping) | Standard Resin, Tough Resin, High-Temperature Resin, Castable Resin |

| Lead Time (Prototype) | 3–5 days |

| Post-Processing | Cleaning, Curing, Support Removal, Surface Finishing |

| Quality Standards | ISO 9001:2015, Full Dimensional Reporting, First Article Inspection |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising SLA 3D Printing in Metal Manufacturing Workflows

Achieving dimensional accuracy and surface integrity in custom metal components demands flawless upstream processes. At Wuxi Lead Precision Machinery, we specialize in high-resolution Stereolithography (SLA) 3D printing engineered explicitly for mission-critical metal manufacturing applications. Our service is not a generic prototyping solution but a precision-engineered link in your production chain, producing investment casting patterns, master patterns for silicone molding, and functional prototypes that directly enable tight-tolerance metal castings. We understand that resin artifacts or dimensional drift in your pattern translate directly into costly scrap rates and rework in final metal parts. Our industrial-grade SLA systems operate within ISO 9001-certified environmental controls, ensuring thermal stability and material consistency impossible in standard service bureaus.

Our technical edge lies in material science integration and metrology-driven validation. We deploy advanced ceramic-filled and high-temperature resins specifically formulated for burnout compatibility in investment casting, minimizing ash residue and dimensional shift during shell processing. Every build undergoes in-process laser calibration and post-cure dimensional verification against your CAD nominal using calibrated CMM equipment. This eliminates the guesswork common in offshore SLA services, guaranteeing patterns that deliver as-cast metal tolerances within ±0.1% of nominal dimensions. For aerospace, medical implant, and energy sector clients, this precision translates to reduced machining time, higher yield rates, and accelerated time-to-assembly.

The following specifications define our production SLA capability for metal manufacturing support:

| Parameter | Specification | Relevance to Metal Manufacturing |

|---|---|---|

| Build Volume | 140 x 140 x 175 mm | Accommodates complex turbine blades, valve bodies, and orthopedic implant patterns |

| Layer Resolution | 25–100 microns | Enables smooth surface finishes (Ra ≤ 1.6 µm) critical for defect-free metal casting |

| XY Accuracy | ±0.05 mm | Ensures pattern fidelity for critical metal casting interfaces and sealing surfaces |

| Material Portfolio | Castable Wax, High-Temp Ceramic, Engineering Resins | Optimized for low-ash burnout and thermal stability during shell firing |

| Post-Processing | Automated Support Removal, UV Curing, Vapor Smoothing | Delivers consistent, ready-for-investment patterns with minimal manual intervention |

Partnering with Lead Precision means integrating a single source for precision pattern fabrication into your metal component supply chain. We collaborate from CAD validation through first-article inspection, providing material certificates, process documentation, and dimensional reports aligned with your PPAP requirements. Our engineering team speaks the language of metallurgists and foundry managers, focusing on how pattern quality impacts your metal pour outcomes.

Do not let substandard patterns compromise your metal casting yield or component performance. Submit your CAD file to [email protected] for a technical assessment and formal quotation within 24 hours. Our application engineers will specify the optimal resin, orientation, and support strategy to ensure your pattern delivers flawless metal results. For urgent projects requiring certified patterns for aerospace or medical validation, contact our technical sales team directly to discuss expedited workflows with full traceability. Precision in metal starts with precision in your pattern—partner with the SLA specialist who engineers for metal manufacturing reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.