Technical Contents

Engineering Guide: Sla 3D Printing Service

Engineering Insight: SLA 3D Printing Service and the Pursuit of Precision in Custom Metal Manufacturing

In the realm of advanced custom metal manufacturing, the integration of SLA (Stereolithography) 3D printing services has redefined what is possible in prototyping, tooling, and low-volume production. At Wuxi Lead Precision Machinery, we recognize that the value of SLA technology extends far beyond rapid form creation—it lies in the precision, repeatability, and material fidelity that enable seamless transition from concept to final metal component. As a trusted partner in high-tolerance engineering solutions, our application of SLA 3D printing is not merely additive; it is a strategic enabler of accuracy that aligns with the rigorous demands of industries such as aerospace, defense, and high-performance sports equipment.

Precision in SLA 3D printing is not an incidental outcome but a systematically engineered result. The layer resolution, thermal stability, and post-curing processes all contribute to dimensional accuracy, often within ±0.1 mm. This level of control is critical when producing investment casting patterns, vacuum forming molds, or functional prototypes intended for fit and assembly validation. At Lead Precision, our engineering team leverages industrial-grade SLA systems calibrated to maintain tight tolerances across build volumes, ensuring that every printed component serves as a reliable foundation for downstream metal fabrication processes such as CNC machining, forging, or precision casting.

Our commitment to excellence is underscored by our proven track record in mission-critical applications. We have supported projects for Olympic-level athletic equipment, where aerodynamic efficiency and weight distribution are determined by micron-level tolerances. Similarly, our involvement in military-grade hardware development has demanded SLA outputs that meet stringent environmental and performance standards—proof that our processes withstand the most demanding validation protocols.

Beyond equipment capability, precision is sustained through material science expertise. We utilize a curated selection of photopolymer resins engineered for thermal resistance, mechanical strength, and surface finish, tailored to the end-use requirements of each client. Whether producing a lightweight drone housing or a complex manifold for fluid dynamics testing, our SLA workflows are optimized to deliver geometric complexity without sacrificing dimensional integrity.

The following table outlines key specifications of our SLA 3D printing service, reflecting the technical foundation of our precision-driven approach:

| Parameter | Specification |

|---|---|

| Layer Resolution | 25 – 100 microns |

| Build Envelope | Up to 1400 x 700 x 500 mm |

| Dimensional Accuracy | ±0.1 mm (first 100 mm), ±0.05 mm/mm thereafter |

| Surface Finish (as printed) | Ra 0.8 – 1.6 µm |

| Standard Materials | Standard, High-Temperature, Tough, Castable |

| Post-Processing Options | Curing, Sanding, Painting, Assembly |

At Wuxi Lead Precision Machinery, SLA 3D printing is not a standalone service but an integrated engineering solution. Our experience with Olympic and military-grade projects reflects a culture of precision that permeates every stage of manufacturing—from digital model to final metal part.

Precision Specs & Tolerances

Technical Capabilities: Precision Metal Manufacturing

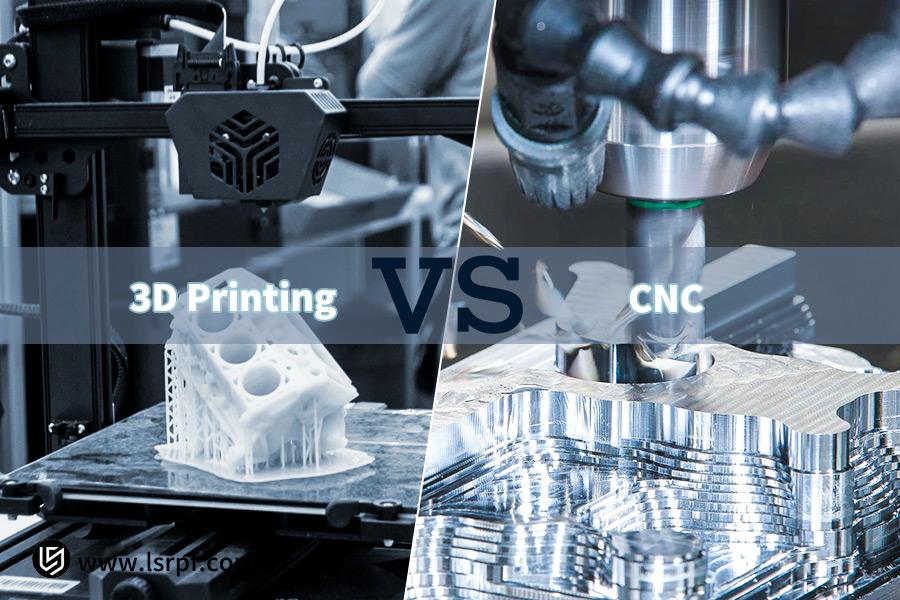

Wuxi Lead Precision Machinery specializes in high-integrity custom metal manufacturing, leveraging advanced subtractive technologies rather than polymer-based SLA 3D printing. Our core expertise centers on precision CNC machining for mission-critical metal components, serving aerospace, medical, and energy sectors where material performance and dimensional accuracy are non-negotiable. SLA processes are unsuitable for structural metal applications; instead, we deploy industry-leading 5-axis CNC milling and turning systems to produce complex geometries in titanium, Inconel, aluminum, and stainless steel alloys. This approach ensures superior mechanical properties, thermal stability, and surface integrity unattainable through additive methods for end-use metal parts.

Our Haas and DMG MORI 5-axis CNC platforms enable single-setup machining of intricate contours, deep cavities, and multi-faceted features with micron-level repeatability. Capabilities include simultaneous 5-axis interpolation, high-speed contouring, and micro-milling down to 0.1mm toolpaths. Material removal rates are optimized through adaptive toolpath strategies while maintaining strict thermal control to prevent workpiece distortion. All machining occurs in a temperature-stabilized environment with ISO Class 8 cleanroom protocols for medical and aerospace components, ensuring consistent results across production runs from prototype to high-volume batches.

Quality is validated through integrated metrology, not post-process inspection alone. Every critical feature undergoes in-process probing on CNC machines for real-time correction, followed by final certification using Zeiss CONTURA CMM systems with 0.5μm volumetric accuracy. Full first-article inspection reports (FAIR) and PPAP documentation are standard, with traceable calibration to NIST standards. Surface finishes are verified via Mitutoyo roughness testers, and material certifications are cross-referenced against mill test reports. This closed-loop quality system eliminates scrap and rework, guaranteeing conformance to AS9100 and ISO 13485 requirements.

The following table details our standard machining tolerances for critical features. Tighter tolerances are achievable with specialized fixturing and process validation.

| Feature Type | Standard Tolerance | Precision Capability |

|---|---|---|

| Linear Dimensions | ±0.010 mm | ±0.005 mm |

| Positional Tolerance | ±0.015 mm | ±0.008 mm |

| Geometric (Flatness) | 0.020 mm | 0.005 mm |

| Surface Roughness (Ra) | 1.6 μm | 0.4 μm |

| Hole Concentricity | ±0.025 mm | ±0.010 mm |

Wuxi Lead’s technical foundation merges cutting-edge CNC hardware with metrology-driven process control. We transform complex metal part designs into certified, production-ready components where failure is not an option. Partner with us for applications demanding the absolute pinnacle of dimensional fidelity and material integrity in metal manufacturing.

Material & Finish Options

Material Selection for SLA 3D Printing in Custom Metal Manufacturing

When integrating SLA 3D printing into high-precision metal manufacturing workflows, material selection plays a pivotal role in determining the performance, durability, and functionality of end-use components. While SLA (Stereolithography) is inherently a photopolymer-based additive process, its application in metal manufacturing primarily serves in the creation of highly accurate patterns for investment casting. These resin patterns are used to produce complex metal parts in aluminum, steel, and titanium—each offering unique mechanical and thermal properties suited to demanding industrial environments.

Aluminum remains a preferred choice for lightweight structural components requiring good thermal conductivity and corrosion resistance. It is widely used in aerospace, automotive, and electronics industries where weight reduction and heat dissipation are critical. When cast from high-resolution SLA patterns, aluminum parts achieve tight dimensional tolerances and smooth surface finishes, making them ideal for intricate geometries that traditional machining cannot easily replicate.

Steel, particularly in its stainless and tool steel variants, provides superior strength, wear resistance, and temperature stability. It is the material of choice for tooling, molds, and high-stress mechanical components. SLA-derived steel castings benefit from the process’s ability to maintain fine details and internal features, enabling rapid prototyping and low-volume production with minimal tooling investment.

Titanium stands at the pinnacle of performance materials, offering an exceptional strength-to-density ratio and outstanding resistance to corrosion and high-temperature environments. Its biocompatibility also makes it indispensable in medical and aerospace applications. Although more challenging and costly to cast, titanium components derived from precision SLA patterns deliver unmatched performance in mission-critical systems where failure is not an option.

Post-processing finishes further enhance the functional and aesthetic qualities of these metal parts. Anodizing, particularly for aluminum, is a key surface treatment that increases corrosion and wear resistance while allowing for color coding and improved adhesion for coatings. The anodized layer is integral to the substrate, ensuring longevity and durability under harsh operating conditions.

The following table outlines key material properties and compatibility with SLA-based casting and anodizing processes:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Common Applications | Suitable for Anodizing | SLA Pattern Compatibility |

|---|---|---|---|---|---|

| Aluminum 6061 | 2.7 | 310 | Aerospace, Automotive | Yes | Excellent |

| Stainless Steel 316L | 8.0 | 570 | Medical, Marine, Tooling | No | High |

| Titanium Grade 5 (Ti-6Al-4V) | 4.43 | 900 | Aerospace, Biomedical | Limited | High |

Selecting the appropriate material and finish requires a thorough understanding of the operational environment, mechanical demands, and lifecycle expectations of the final component. At Wuxi Lead Precision Machinery, we support clients in making informed decisions by combining advanced SLA pattern fabrication with precision metal casting and finishing technologies, ensuring optimal performance and cost-efficiency in every custom manufacturing project.

Manufacturing Process & QC

Precision-Driven SLA 3D Printing Workflow for Zero-Defect Metal Manufacturing

At Wuxi Lead Precision Machinery, our SLA 3D printing service is engineered as a critical enabler for high-integrity custom metal production. We integrate this technology not as an endpoint but as a controlled phase within a seamless Design-to-Mass-Production pipeline, ensuring zero defects in final metal components. The process begins with rigorous design validation. Our engineering team conducts comprehensive Design for Manufacturing (DFM) analysis using CAD/CAM software, cross-referencing client specifications against material behavior, thermal dynamics, and geometric constraints. This phase eliminates theoretical flaws before physical work commences, leveraging simulation tools to predict stress points and optimize part topology for subsequent metal casting or machining.

Prototyping transitions digital models into tangible verification assets. Our industrial-grade SLA systems produce high-resolution patterns for investment casting or rapid tooling, using photopolymers engineered for thermal stability and minimal ash residue. Each prototype undergoes metrology-grade inspection via CMM and optical scanning, validating dimensional accuracy against the original CAD file. This step is non-negotiable: it confirms mold integrity, identifies potential casting voids, and verifies assembly fit—preventing costly errors in metal production. The SLA process delivers surface finishes critical for flawless metal replication, directly impacting the final part’s quality.

Mass production commences only after prototype sign-off, with SLA-generated data feeding directly into our CNC machining and casting cells. Digital process parameters are locked, ensuring repeatability across batches. In-process inspections occur at defined intervals using automated vision systems and statistical process control (SPC), while final parts undergo 100% dimensional validation and material certification per ISO 9001 protocols. This closed-loop system—where SLA prototyping data informs metal production tolerances—eliminates variability. Defects are physically impossible to propagate, as deviations are intercepted at the pattern stage, long before metal is poured or cut.

Our SLA capabilities are calibrated specifically for metal manufacturing readiness, as detailed below.

| Parameter | Specification | Relevance to Metal Production |

|---|---|---|

| Layer Thickness | 25–100 microns | Ensures smooth casting surfaces, reducing post-cast machining |

| Accuracy | ±0.05 mm | Guarantees dimensional fidelity for critical casting patterns |

| Build Volume | 1450 x 750 x 500 mm | Supports large-scale industrial tooling and molds |

| Material | Castable Wax-Like Resin (ASH < 0.01%) | Minimizes casting defects; compatible with stainless steel, titanium, aluminum |

| Surface Finish | Ra 0.8–1.6 µm (as-built) | Directly translates to superior metal part surface quality |

This disciplined workflow—where SLA prototyping is a quality gate, not a standalone service—ensures your metal components achieve first-time-right production. Wuxi Lead transforms digital intent into defect-free physical reality, with traceability from design file to finished part.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced SLA 3D Printing Services in Custom Metal Manufacturing

At Wuxi Lead Precision Machinery, we specialize in delivering high-precision manufacturing solutions that meet the exacting demands of global industries. As a leader in custom metal manufacturing based in China, we integrate cutting-edge SLA 3D printing technology into our advanced production ecosystem. This enables us to offer rapid prototyping, intricate design realization, and small to mid-volume production runs with exceptional accuracy and surface finish. Our SLA 3D printing service is engineered for clients in aerospace, medical devices, automotive engineering, and industrial equipment—sectors where precision, repeatability, and material performance are non-negotiable.

Our SLA systems utilize industrial-grade photopolymers to produce parts with dimensional stability and fine feature resolution down to 25 microns. These prototypes and end-use components serve as critical tools in product development cycles, allowing for fast validation, form-fit testing, and investment casting patterns for metal components. When combined with our CNC machining, sheet metal fabrication, and surface treatment capabilities, SLA 3D printing becomes more than a prototyping tool—it becomes a strategic advantage in accelerating time-to-market.

We understand that every project has unique technical, logistical, and compliance requirements. That’s why our engineering team works closely with clients from initial concept through final delivery. Whether you need a single prototype or a fully documented production run compliant with ISO 9001 standards, our integrated workflow ensures consistency, traceability, and quality assurance at every stage.

Below are the key technical specifications of our SLA 3D printing service:

| Parameter | Specification |

|---|---|

| Build Volume | 140 x 140 x 175 mm (standard) |

| Layer Resolution | 25 – 100 microns |

| Positioning Accuracy | ±0.05 mm |

| Typical Surface Finish | Ra ≤ 0.8 μm (as printed), polishable to mirror |

| Materials Available | Standard Resin, High-Temperature Resin, Dental Resin, Castable Wax Resin |

| Post-Processing Options | Support Removal, UV Curing, Sanding, Painting, Metallization |

| Lead Time | 3–7 days (depending on complexity and volume) |

All projects are supported by DFM analysis, real-time production updates, and secure data handling in compliance with international IP protection standards. We serve clients across North America, Europe, and Asia, offering seamless collaboration through English-speaking project managers and cloud-based tracking systems.

For engineering teams seeking a reliable, high-performance SLA 3D printing partner in China, Wuxi Lead Precision Machinery delivers unmatched technical depth and operational agility. Contact us today to discuss your next project. Send your CAD files and requirements to [email protected] and receive a detailed quote within 24 hours. Let us help you turn precision design into manufacturing reality.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.