Technical Contents

Engineering Guide: Short Run Injection Molding

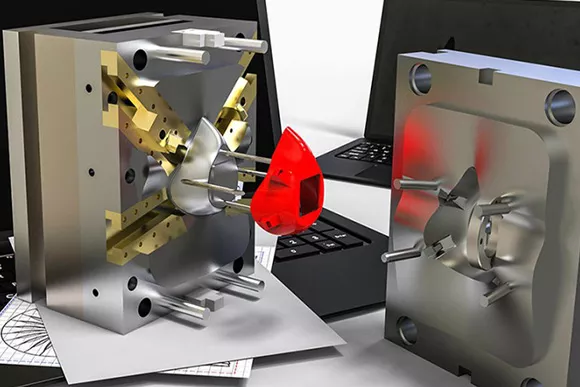

Engineering Insight: The Critical Role of Precision in Short Run Injection Molding

In the realm of custom metal manufacturing, short run injection molding stands as a strategic solution for prototyping, low-volume production, and rapid market entry. While often associated with plastics, the process is increasingly integrated with precision metal components—particularly in hybrid assemblies where metal inserts, overmolding, and tight-tolerance interfaces are essential. At Wuxi Lead Precision Machinery, we recognize that the success of short run injection molding hinges not on volume, but on uncompromising precision.

Precision in short run injection molding ensures dimensional accuracy, repeatability, and material integrity across every cycle. Unlike high-volume production, where tooling amortization drives cost efficiency, short runs demand immediate accuracy from the first shot. There is no room for iterative correction—each component must meet exacting specifications out of the gate. This is especially critical in industries such as aerospace, defense, and medical technology, where failure is not an option.

Our engineering team at Wuxi Lead Precision Machinery leverages decades of experience in high-precision metal fabrication to support injection molding applications requiring micron-level tolerances. Our involvement in mission-critical projects—including components for Olympic-standard equipment and military-grade systems—has honed our ability to deliver parts that perform under extreme conditions. These projects demanded flawless integration between metal and polymer elements, where thermal expansion, mechanical load, and environmental resistance were rigorously tested.

We apply this same rigor to short run injection molding tooling and component manufacturing. Our CNC-machined molds, insert cores, and overmolding fixtures are produced using advanced 5-axis machining centers and inspected via coordinate measuring machines (CMM), ensuring geometric accuracy within ±0.002 mm. This level of control directly translates to reduced flash, consistent wall thickness, and optimal gate performance in the molding process.

Material selection and thermal management are also central to our approach. We collaborate closely with molding partners to optimize cooling channels, ejection systems, and surface finishes—tailoring each element to the specific polymer and production timeline. Whether supporting rapid tooling for prototype validation or durable steel molds for limited series production, our focus remains on precision that enables performance.

The table below outlines key specifications achievable through our integrated manufacturing process:

| Specification | Capability |

|---|---|

| Dimensional Tolerance | ±0.002 mm |

| Surface Finish (Ra) | 0.1 – 0.8 µm |

| Maximum Part Weight (Metal Insert) | 500 g |

| Tooling Material Options | H13, P20, S136, 420 Stainless Steel |

| Machining Accuracy (CMM Verified) | ±0.0015 mm |

| Lead Time (Prototype Tooling Support) | 10–15 Days |

| Secondary Operations | Passivation, Anodizing, Laser Marking, Tumbling |

At Wuxi Lead Precision Machinery, we understand that short run injection molding is not a compromise—it is a precision-driven discipline. By integrating advanced metal manufacturing with engineering foresight, we ensure every component meets the highest standards of quality, reliability, and performance.

Precision Specs & Tolerances

Technical Capabilities for Precision Short Run Injection Molding Components

Wuxi Lead Precision Machinery delivers exceptional technical execution for short run injection molding applications requiring custom metal components. Our integrated manufacturing ecosystem, centered on advanced multi-axis CNC technology and rigorous quality control, ensures precision, repeatability, and rapid turnaround essential for low-volume, high-complexity production. We specialize in transforming intricate designs into fully functional, dimensionally stable parts where traditional high-volume tooling is impractical or cost-prohibitive.

The cornerstone of our capability is a modern fleet of high-precision 5-axis CNC machining centers. These systems provide simultaneous, coordinated motion across all five axes, enabling the complete machining of highly complex geometries—including deep cavities, undercuts, and organic contours—in a single setup. This eliminates cumulative errors from multiple fixtures, significantly reduces lead times by removing secondary operations, and ensures superior part integrity. Our machines utilize advanced thermal compensation systems and high-resolution encoders to maintain micron-level accuracy throughout extended production runs, even for challenging materials like hardened tool steels, stainless alloys, and high-temperature superalloys common in molding applications.

Quality assurance is non-negotiable. Every critical feature undergoes comprehensive verification using state-of-the-art Coordinate Measuring Machines (CMM) equipped with high-accuracy probes and advanced metrology software. Our CMM inspection protocols are designed specifically for the stringent requirements of injection molding components, verifying not only dimensional conformance but also critical form, position, and surface finish parameters that directly impact mold performance and part quality. This data-driven approach, integrated with statistical process control (SPC), provides full traceability and guarantees that every component meets or exceeds the specified tolerances before shipment. Our quality management system is ISO 9001 certified, ensuring consistent adherence to international standards.

The following table details our standard and achievable tolerance capabilities for critical features in precision-machined mold components:

| Feature Type | Standard Capability (mm) | Tight Tolerance Capability (mm) |

|---|---|---|

| Linear Dimensions | ± 0.05 | ± 0.005 |

| Hole Position | ± 0.03 | ± 0.01 |

| Flatness | 0.05 / 100mm | 0.01 / 100mm |

| Perpendicularity | 0.03 | 0.01 |

| Surface Roughness (Ra) | 1.6 µm | 0.4 µm |

| Bore Roundness | 0.01 | 0.003 |

This combination of advanced 5-axis CNC machining, meticulous CMM-based quality control, and demonstrable tight-tolerance performance allows Wuxi Lead to reliably produce the complex cores, cavities, inserts, and precision alignment features demanded by sophisticated short run injection molding projects. We provide the engineering rigor and manufacturing precision necessary to validate designs, support prototyping, and deliver low-volume production runs with the quality expected of high-end tooling. Partner with us to overcome the unique challenges of short-run metal component manufacturing for injection molding applications.

Material & Finish Options

Material Selection for Short Run Injection Molding: Precision in Every Component

In short run injection molding, material selection plays a pivotal role in determining part performance, tooling longevity, and overall production efficiency. At Wuxi Lead Precision Machinery, we specialize in custom metal manufacturing solutions tailored for low-volume, high-precision applications. Our expertise enables us to guide clients through informed decisions when selecting between aluminum, steel, and titanium for mold components, along with appropriate surface treatments such as anodizing.

Aluminum is often the preferred choice for short run tooling due to its excellent machinability, lightweight nature, and superior thermal conductivity. These properties allow for faster cycle times and reduced wear during production. While aluminum may not match the durability of steel or titanium, its performance is more than sufficient for low to medium production volumes, typically up to 10,000 cycles. It is particularly advantageous when rapid prototyping or iterative design changes are required.

Steel, particularly tool steel variants such as P20 or H13, offers exceptional hardness and wear resistance, making it ideal for longer service life under repeated thermal cycling. When higher production volumes are anticipated within the short run spectrum—especially above 50,000 shots—steel molds provide unmatched dimensional stability and surface finish retention. However, steel is heavier and more challenging to machine, which can extend lead times and increase initial costs.

Titanium stands at the high end of performance, offering an outstanding strength-to-density ratio and excellent corrosion resistance. While rarely used for full mold bases due to cost and machining complexity, titanium finds strategic application in critical mold inserts or cores where extreme durability and resistance to thermal fatigue are required. Its biocompatibility and non-reactive nature also make it suitable for medical or aerospace-grade components.

Surface treatment is equally critical in enhancing mold performance. Anodizing, particularly Type II (sulfuric acid) and Type III (hard coat), is widely applied to aluminum molds. This electrochemical process increases surface hardness, improves wear resistance, and provides a protective oxide layer that enhances corrosion protection. Anodized finishes also allow for color coding, aiding in mold identification and quality control.

Below is a comparative overview of key material properties relevant to short run injection molding applications.

| Material | Tensile Strength (MPa) | Hardness (HRC) | Thermal Conductivity (W/m·K) | Typical Mold Life (Cycles) | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061-T6 | 310 | 15–20 (HB) | 167 | 5,000 – 10,000 | Prototypes, low-volume production |

| P20 Tool Steel | 900–1100 | 28–32 | 30 | 50,000 – 100,000 | Medium to high-volume tooling |

| H13 Steel | 1,500 | 45–50 | 35 | 100,000+ | High-stress, high-temp molding |

| Titanium Grade 5 | 900 | 36 | 7 | 50,000+ (inserts only) | Aerospace, medical, corrosive env. |

At Wuxi Lead Precision Machinery, we integrate material science with precision engineering to deliver molds that meet exact functional and economic requirements. Whether you prioritize speed, durability, or environmental resistance, our team ensures optimal material and finish selection for your short run injection molding project.

Manufacturing Process & QC

Precision Short Run Injection Molding: The Zero Defect Path from Concept to Production

At Wuxi Lead Precision Machinery, we recognize that high-value, low-volume metal components demand an injection molding process engineered for uncompromising quality from the earliest design phase. Our specialized short run injection molding service eliminates the traditional trade-offs between small batch sizes and manufacturing perfection, delivering complex metal parts with the consistency required for aerospace, medical, and advanced industrial applications. The foundation of our Zero Defects philosophy is a rigorously controlled, three-stage production workflow designed to preempt errors and ensure first-time-right outcomes.

The process begins with intensive collaborative Design for Manufacturability (DFM) analysis. Our engineering team dissects your CAD model, scrutinizing geometry, wall thickness transitions, gate locations, and material flow dynamics specific to metal injection molding (MIM) feedstocks. We identify potential porosity zones, shrinkage risks, or ejection challenges before tooling commences, providing actionable feedback to optimize the design for flawless producibility. This proactive step is non-negotiable for eliminating costly redesigns and scrap later. Following DFM validation, we proceed to precision prototyping using production-intent tooling. Unlike rapid prototyping methods, our short-run molds replicate the exact cavity pressure, temperature profiles, and ejection sequences of full production. Each prototype undergoes comprehensive metrology, including CMM verification against critical dimensions and material property testing, ensuring the part meets all functional and regulatory requirements. Only when the prototype batch achieves certified Zero Defects status do we authorize full-scale production.

Mass production leverages our advanced, climate-controlled molding cells equipped with real-time process monitoring. Every cycle parameters—pressure, temperature, fill speed—are continuously tracked against the validated prototype baseline using Statistical Process Control (SPC). Automated vision systems perform 100% inline dimensional and surface defect inspection on critical features, rejecting non-conforming units before they proceed. Rigorous material traceability and batch-controlled sintering ensure metallurgical properties meet exact specifications. This closed-loop system, combined with our stringent operator training protocols, guarantees that every component in your short run batch adheres to the Zero Defects standard, protecting your downstream assembly and end-product reliability.

The following table outlines key performance specifications achievable through our controlled short run process:

| Parameter | Capability Range | Typical Application Target |

|---|---|---|

| Dimensional Tolerance | ±0.02 mm to ±0.05 mm | Critical sealing surfaces, bearing interfaces |

| Surface Roughness (Ra) | 0.8 µm to 3.2 µm (as-molded) | Cosmetic parts, fluid contact areas |

| Material Options | 17-4PH, 316L, 15-5PH, Inconel 718, Custom Alloys | High-strength, corrosion-resistant components |

| Batch Size Flexibility | 50 to 5,000 parts | Low-volume production, bridge tooling |

| Prototype Lead Time | ≤ 15 working days (incl. validation) | Accelerated design validation |

| Production Lead Time | ≤ 25 working days (after approval) | Responsive supply chain execution |

This integrated approach transforms short run metal injection molding from a perceived risk into a strategic advantage. By embedding quality at every phase—Design, Prototyping, Mass Production—we deliver not just parts, but guaranteed performance and supply chain resilience for your most demanding applications. Partner with Wuxi Lead to manufacture with absolute precision, on time, every time.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Precision-Driven Short Run Injection Molding Solutions

At Wuxi Lead Precision Machinery, we understand that in high-end custom metal manufacturing, agility, precision, and reliability are non-negotiable. When your project demands short run injection molding that combines rapid turnaround with uncompromising quality, partnering with a trusted expert is essential. We specialize in delivering tailored manufacturing solutions for low to medium volume production, enabling innovation without the burden of high tooling costs or extended lead times.

Our advanced short run injection molding services are engineered for clients in aerospace, medical devices, automation, and high-performance industrial sectors. Whether you are prototyping a new component or scaling up for limited production, our capabilities ensure dimensional accuracy, material integrity, and repeatable consistency—critical for mission-critical applications.

What sets Wuxi Lead Precision Machinery apart is our integration of in-house tooling design, precision CNC machining, and real-time quality monitoring. We utilize high-grade steel and aluminum molds, fabricated with micron-level precision, to support complex geometries and tight tolerances. Our molding machines are calibrated for optimal pressure and temperature control, ensuring minimal warpage and maximum repeatability across every batch.

We recognize that every client’s needs are unique. That’s why we offer full project collaboration—from initial design review and material selection to mold flow analysis and final inspection. Our engineering team works closely with yours to optimize part design for manufacturability, reduce cycle times, and eliminate potential defects before production begins.

By choosing to partner with us, you gain access to a vertically integrated manufacturing ecosystem based in Wuxi, China, with global export compliance and logistics support. Our facility is ISO 9001 certified, and we maintain rigorous quality control protocols, including first article inspection (FAI), statistical process control (SPC), and full traceability for every component produced.

Below are key technical specifications for our short run injection molding capabilities:

| Specification | Detail |

|---|---|

| Shot Weight Range | 10 g – 1200 g |

| Clamping Force | 80 Ton – 1200 Ton |

| Tolerance | ±0.02 mm |

| Materials Supported | ABS, PC, POM, PA6/PA66, PBT, PPS, LCP, PEEK, and filled variants |

| Mold Material | H13, S136, 718H, 2738, 420 Stainless |

| Surface Finishes | SPI #A1, #B2, #C3, Textured, Polished, Coated |

| Secondary Operations | CNC trimming, ultrasonic welding, insert molding, labeling, packaging |

We are committed to accelerating your time-to-market while maintaining the highest standards of engineering excellence. Whether you require 100 or 10,000 precision-molded components, our short run injection molding services deliver speed, scalability, and superior part quality.

For expert consultation and a tailored quote, contact us today at [email protected]. Let Wuxi Lead Precision Machinery be your strategic partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.