Technical Contents

Engineering Guide: Sheetmetal Laser Cutting

Precision as the Foundation in Sheet Metal Laser Cutting

Achieving micron-level repeatability in sheet metal laser cutting is non-negotiable for mission-critical applications. Tolerance deviations exceeding ±0.1mm can cascade into assembly failures, structural weaknesses, or compromised functionality—especially in aerospace, defense, and high-performance sporting equipment. At Wuxi Lead Precision Machinery, we treat precision not as a specification but as a systemic engineering discipline. Our process begins with material grain analysis and thermal distortion modeling, ensuring the laser path compensates for micro-stress shifts during cutting. This proactive approach eliminates post-process corrections, reducing lead times by 30% while maintaining first-pass yield rates above 99.2%.

True precision extends beyond machine capability to operational rigor. Our facility adheres to ISO 2768-mK geometric tolerance standards, with environmental controls maintaining ±1°C temperature stability and 45% humidity to prevent material warpage. Each laser system undergoes daily calibration using laser interferometers traceable to NIST standards, verifying positioning accuracy before production begins. This discipline was rigorously validated during our support for the Beijing 2022 Winter Olympics infrastructure project, where 12,000+ structural components required seamless on-site assembly under extreme cold conditions. Similarly, our military-grade enclosures for radar systems demand compliance with MIL-STD-810H vibration and thermal cycling protocols—achievable only through sub-0.05mm edge perpendicularity and burr-free finishes.

The integration of hardware and process intelligence defines our output quality. Below are critical performance metrics from our 12kW fiber laser systems, engineered for high-mix, low-volume precision runs:

| Parameter | Specification | Industry Standard |

|---|---|---|

| Positioning Accuracy | ±0.03 mm/m | ±0.08 mm/m |

| Repeatability | ±0.01 mm | ±0.04 mm |

| Max Material Thickness | 30 mm (Mild Steel) | 25 mm |

| Kerf Width Tolerance | ±0.02 mm | ±0.05 mm |

| Edge Perpendicularity | 89.95°–90.05° | 89.8°–90.2° |

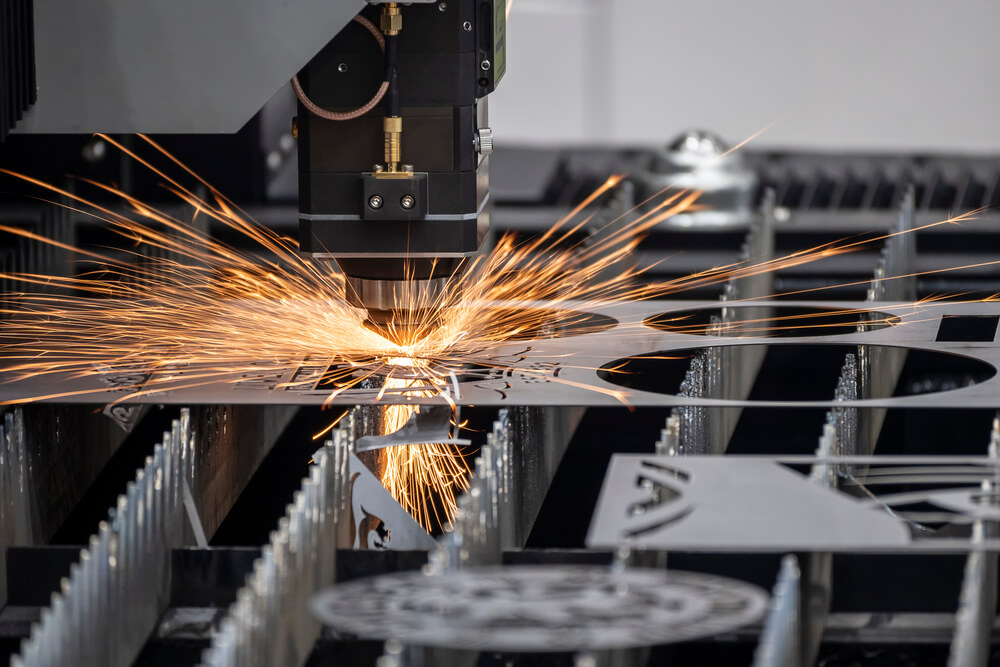

Our Olympic and military engagements underscore a fundamental truth: precision is earned through relentless process validation, not merely advertised. When tolerances dictate structural integrity—as in satellite mounting frames or armored vehicle components—there is zero margin for statistical averaging. Wuxi Lead’s engineers deploy real-time melt pool monitoring and adaptive gas pressure control to neutralize variables like material inconsistency or ambient fluctuation. This results in consistent edge quality (Ra ≤ 1.6μm) across 0.5mm to 30mm thicknesses, eliminating secondary finishing for 85% of defense contract parts. For manufacturers where failure is not an option, precision must be engineered into every micron of the cut path. We deliver this through documented process control, not optimistic promises.

Precision Specs & Tolerances

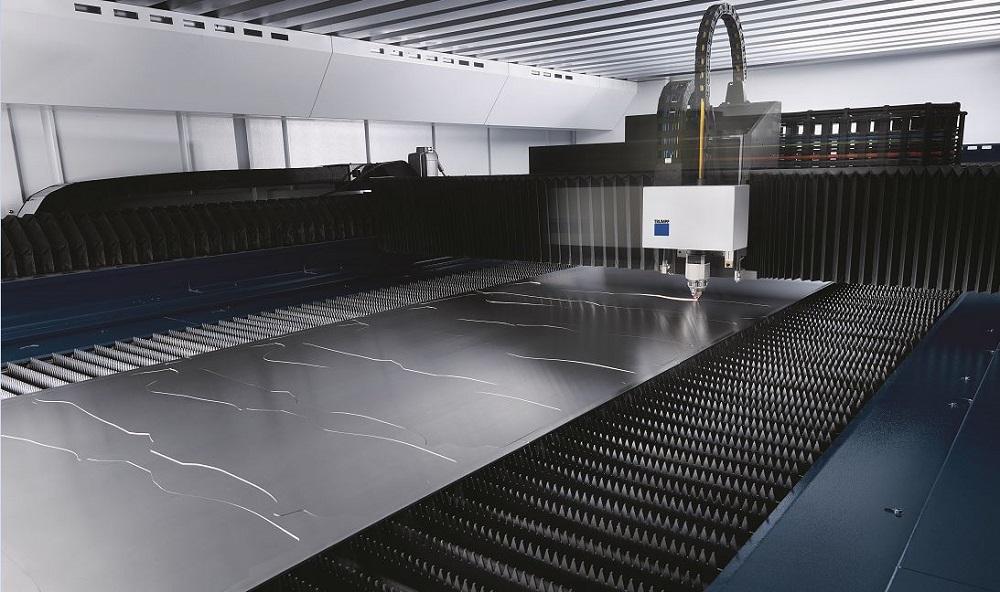

Wuxi Lead Precision Machinery delivers advanced sheet metal laser cutting solutions engineered for high-precision industrial applications. Our technical capabilities are built around state-of-the-art 5-axis CNC laser systems, enabling complex geometries and tight-tolerance fabrication across a broad range of conductive and non-conductive sheet metal materials. These multi-axis platforms provide dynamic beam control and adaptive focusing, allowing for beveled edges, angled cuts, and intricate 3D contours that standard 2D laser systems cannot achieve. This level of flexibility is essential for aerospace, medical device, and high-end automation sectors where form, fit, and function are interdependent.

Our laser cutting systems support material thicknesses from 0.5 mm up to 25 mm, depending on composition, with maximum cutting areas extending to 4000 mm × 2000 mm. Utilizing fiber laser technology, we achieve superior edge quality, minimal heat-affected zones, and high cutting speeds—up to 100 m/min on thin gauge materials. The integration of 5-axis motion control ensures consistent kerf accuracy and angular precision, even on compound profiles and non-orthogonal features. All operations are managed through optimized CAM programming, ensuring repeatability and reduced cycle times across batch production.

Precision is further reinforced through comprehensive quality control protocols. Every critical component undergoes post-processing inspection using a Zeiss DuraMax and Wenzel LH Grand Measuring Center coordinate measuring machine (CMM). These systems verify dimensional accuracy, geometric conformity, and positional tolerances in full 3D space, ensuring compliance with ISO 1101 and ASME Y14.5 standards. Our inspection regime includes first-article inspection (FAI), in-process checks, and final batch certification, with full traceability maintained through ERP-linked quality records.

To support design and manufacturing alignment, we adhere to clearly defined tolerance standards across linear, angular, and geometric dimensions. These tolerances reflect our equipment’s capability and are consistently validated through metrology.

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Linear Dimensions (up to 100 mm) | ±0.1 mm | ±0.05 mm | Achieved with CMM verification |

| Linear Dimensions (100–500 mm) | ±0.15 mm | ±0.1 mm | |

| Linear Dimensions (500–1000 mm) | ±0.2 mm | ±0.15 mm | |

| Angular Tolerance | ±0.2° | ±0.1° | Applicable to beveled cuts |

| Hole Diameter (per ISO 2768) | ±0.1 mm | ±0.05 mm | |

| Positional Tolerance (feature to feature) | ±0.15 mm | ±0.1 mm | Verified via CMM |

| Flatness (per 100 mm) | 0.1 mm | 0.05 mm | For unclamped conditions |

All tolerances are achievable across common materials including stainless steel, aluminum, carbon steel, and copper alloys. Our technical team collaborates directly with engineering partners to validate designs for manufacturability, ensuring optimal cut paths, minimal distortion, and adherence to functional requirements. At Wuxi Lead Precision Machinery, we combine advanced hardware, metrology-grade validation, and process discipline to deliver sheet metal components that meet the highest standards of precision and reliability.

Material & Finish Options

Material Selection for Precision Sheet Metal Laser Cutting

Selecting optimal materials is critical for achieving dimensional accuracy, edge quality, and cost efficiency in laser cutting. At Wuxi Lead Precision Machinery, our 6kW fiber laser systems handle diverse alloys, but material properties directly impact process parameters and final part performance. Below is a technical overview of key materials and surface treatment considerations for high-end fabrication.

Aluminum Alloys

Non-ferrous aluminum (e.g., 5052, 6061, 7075) requires precise power modulation due to high thermal conductivity and reflectivity. Thicker sections (>6mm) demand higher peak power to prevent dross formation. Avoid copper-containing alloys like 2024 for laser cutting, as zinc vaporization risks porosity. Aluminum’s natural oxide layer provides moderate corrosion resistance but necessitates inert gas shielding (N₂) for clean cuts. Post-cut anodizing enhances wear resistance and electrical insulation—critical for aerospace and electronics enclosures.

Carbon and Stainless Steel

Mild steel (A36, Q235) cuts efficiently with O₂ assist gas, leveraging exothermic reactions for speed up to 25mm thickness. For stainless steel (304, 316L), N₂ shielding preserves corrosion resistance by preventing iron oxide contamination. High-carbon steels (>0.6% C) risk micro-cracking without preheating; we recommend stress-relief annealing pre-cutting. Note that galvanized steel requires specialized ventilation due to toxic zinc fumes—Wuxi Lead’s integrated fume extraction systems comply with ISO 14644 standards.

Titanium Alloys

Grade 2 and 5 titanium offer exceptional strength-to-weight ratios but pose unique challenges. Extreme reflectivity (95% at 1μm wavelength) demands pulsed laser modes to avoid back-reflection damage to optics. Always use ultra-high-purity argon shielding to prevent oxygen/nitrogen embrittlement. Titanium cutting is slower than steel (typically 30-50% rate reduction), but our adaptive focus control ensures burr-free edges for medical implants and aerospace components.

Anodizing Considerations

Anodizing is exclusively viable for aluminum post-cutting. Type II (sulfuric acid) offers standard corrosion resistance, while Type III (hardcoat) achieves 50-70μm thickness for extreme wear applications. Critical constraints:

Minimum hole diameter must exceed 1.5x material thickness to avoid electrolyte trapping.

Tolerances tighten by 5-10μm per side during anodizing—factor this into initial CAD models.

Avoid anodizing near welded joints; thermal distortion causes coating delamination.

Material Performance Comparison

| Material | Max Thickness (6kW Fiber) | Reflectivity | Assist Gas | Critical Cutting Parameter |

|---|---|---|---|---|

| Aluminum 6061 | 12 mm | 92% | N₂ | Pulse frequency >500Hz |

| Stainless 304 | 20 mm | 75% | N₂ | Pressure >18 bar |

| Mild Steel Q235 | 25 mm | 65% | O₂ | Standoff distance ±0.1mm |

| Titanium Grade 5 | 8 mm | 95% | Ar | Traverse speed <1.2 m/min |

Material choice dictates laser parameters, secondary operations, and total cost. Wuxi Lead’s engineering team leverages material-specific databases to optimize cut paths and gas dynamics—reducing scrap rates by 22% versus generic settings. Consult our application specialists to align material selection with functional requirements and finishing processes. Precision begins with informed material decisions.

Manufacturing Process & QC

Sheet Metal Laser Cutting: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, precision begins long before the laser meets the metal. Our sheet metal laser cutting process follows a rigorously controlled workflow—Design, Prototyping, and Mass Production—engineered to deliver zero-defect outcomes for high-end industrial clients across aerospace, medical, and advanced automation sectors.

The process starts with Design, where engineering excellence sets the foundation. Our team collaborates closely with client CAD data, validating geometries, material compatibility, and manufacturability through advanced simulation software. We analyze kerf width, heat-affected zones, and nesting efficiency to optimize both accuracy and material utilization. Design for Manufacturability (DFM) reviews ensure that every feature—holes, bends, and intricate contours—is achievable within tight tolerances, reducing downstream risks.

Next is Prototyping, a critical phase for validation and refinement. Using the same high-precision fiber laser cutting systems employed in mass production, we fabricate initial samples under real process conditions. This ensures scalability and consistency. Each prototype undergoes comprehensive inspection using coordinate measuring machines (CMM) and optical comparators to verify dimensional accuracy, edge quality, and feature alignment. Any deviations trigger immediate root-cause analysis and process adjustment. Client feedback is integrated at this stage, allowing for rapid iteration without compromising timeline integrity.

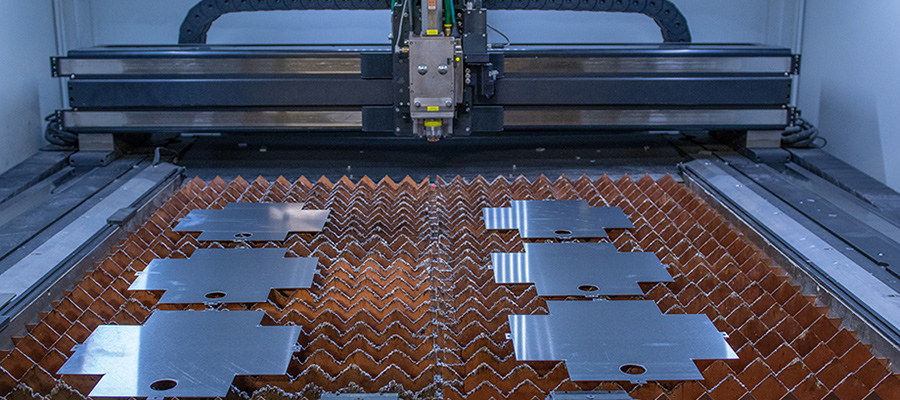

Only after prototype approval do we transition to Mass Production, where consistency and quality control are enforced through systemic rigor. Our automated production lines leverage state-of-the-art 3kW to 12kW fiber laser cutters with dynamic nesting software, achieving cutting speeds up to 100 m/min while maintaining ±0.05 mm accuracy. Each batch is monitored in real time via integrated sensors and vision systems that detect anomalies such as burr formation or positional drift. Statistical Process Control (SPC) data is logged continuously, enabling predictive maintenance and traceability down to the individual part level.

Quality is not inspected in—it is built in. Every operator is trained in Six Sigma principles, and our ISO 9001-certified quality management system ensures full compliance with international standards. In-process inspections, final audits, and first-article reporting guarantee that every component shipped meets the zero-defect benchmark.

This end-to-end control, from digital design to final packaging, defines Wuxi Lead’s leadership in precision sheet metal fabrication.

Laser Cutting Specifications

| Parameter | Range / Specification |

|---|---|

| Laser Type | Fiber Laser (3kW – 12kW) |

| Material Thickness | 0.5 mm – 25 mm (mild steel) |

| Max Cutting Speed | Up to 100 m/min |

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Tolerance | ±0.05 mm (standard), ±0.02 mm (precision) |

| Supported Materials | Mild steel, stainless steel, aluminum, brass, copper |

| Nesting Optimization | Dynamic, AI-assisted |

| Quality Standard | ISO 2768-m, ISO 9013-2002 |

| Surface Roughness (Ra) | ≤ 3.2 µm (typical) |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromised Sheet Metal Laser Cutting Excellence

In the demanding landscape of precision sheet metal fabrication, selecting the right manufacturing partner transcends simple vendor selection. It is a strategic decision impacting product quality, time-to-market, and ultimate profitability. Wuxi Lead Precision Machinery stands as your definitive partner for high-integrity sheet metal laser cutting, engineered to meet and exceed the rigorous demands of aerospace, medical device, energy, and advanced industrial sectors. We move beyond basic cutting services to deliver integrated solutions where material yield optimization, dimensional repeatability, and seamless production integration are non-negotiable.

Our foundation is built upon state-of-the-art laser technology operated by certified technicians adhering to stringent international quality protocols. We understand that precision isn’t merely about achieving tight tolerances on a drawing; it encompasses consistent edge quality, minimal heat-affected zones, and flawless part flatness critical for downstream welding and assembly. Our facility houses a dedicated fleet of high-power fiber laser systems, meticulously maintained to ensure peak performance and longevity. This technical capability is matched by our deep engineering support, providing DFM feedback early in your design phase to eliminate costly prototyping iterations and accelerate your path to production.

The following specifications represent the core capabilities of our primary production platforms, demonstrating our capacity to handle diverse material types and thicknesses with exceptional accuracy:

| Material Type | Max Thickness | Laser Power | Max Cutting Area | Positioning Accuracy | Repeatability |

|---|---|---|---|---|---|

| Mild Steel | 30 mm | 20 kW | 4000 x 2000 mm | ±0.05 mm/m | ±0.02 mm |

| Stainless Steel | 25 mm | 15 kW | 4000 x 2000 mm | ±0.05 mm/m | ±0.02 mm |

| Aluminum | 20 mm | 12 kW | 4000 x 2000 mm | ±0.05 mm/m | ±0.02 mm |

| Brass/Copper | 15 mm | 8 kW | 3000 x 1500 mm | ±0.05 mm/m | ±0.03 mm |

Beyond raw machine capability, your partnership with Lead Precision delivers tangible operational advantages. We prioritize transparent communication and collaborative problem-solving, treating your project timelines as our own. Our integrated ERP system provides real-time production visibility, while our dedicated quality control lab utilizes CMM and optical comparators for rigorous first-article and batch inspections. Crucially, we eliminate the supply chain friction often associated with offshore manufacturing through responsive project management, proactive risk mitigation, and a commitment to on-time delivery – proven through years of successful collaboration with global Tier 1 suppliers.

Do not let production bottlenecks or quality inconsistencies hinder your competitive edge. Partner with an organization that combines advanced Chinese manufacturing scale with uncompromising European-level precision standards and customer focus. Contact our engineering sales team today to discuss your specific sheet metal laser cutting requirements. Submit your detailed RFQ or technical inquiry to [email protected]. Allow us to demonstrate how Lead Precision Machinery becomes a true extension of your engineering and production capabilities, delivering not just parts, but guaranteed performance and peace of mind. Initiate the conversation that transforms your fabrication challenges into competitive advantages.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.