Technical Contents

Engineering Guide: Sheet Metal Tube

Engineering Insight: Precision in Sheet Metal Tube Fabrication

In high-stakes manufacturing sectors, the dimensional accuracy of sheet metal tubes directly dictates system performance, safety, and longevity. A variance of mere microns can compromise structural integrity in aerospace assemblies, disrupt fluid dynamics in hydraulic systems, or induce catastrophic fatigue in load-bearing frameworks. Unlike standard tubing, precision-engineered sheet metal tubes demand absolute control over geometric tolerances, wall consistency, and surface integrity. This is non-negotiable where failure equates to operational downtime, regulatory non-compliance, or safety hazards. At Wuxi Lead Precision Machinery, we treat every tube as a mission-critical component—not a commodity—applying aerospace-grade methodologies honed through decades of delivering for Olympic infrastructure projects and classified defense applications.

Our process begins with material science rigor. We select alloys like 304/316 stainless steel and 6061-T6 aluminum based on end-use environmental stressors, then deploy multi-axis CNC laser cutting and robotic bending cells to achieve repeatability within ±0.05mm. Crucially, we eliminate cumulative error through in-process metrology: each bend sequence is validated via coordinate measuring machines (CMM) before progression, ensuring angular deviations never exceed 0.1°. This discipline stems from our work on Olympic stadium tensile structures—where tube alignment errors of 0.3° would have visibly distorted 500-ton roof geometries—and military-grade vehicle chassis, where vibration resistance hinges on perfect tube symmetry.

The following specifications reflect our standard production envelope for critical applications. Custom tolerances beyond these ranges are routinely achieved for defense and energy sector partners:

| Parameter | Standard Tolerance | Max Capacity | Notes |

|---|---|---|---|

| Outer Diameter | ±0.05 mm | 300 mm | Round/square/rectangular |

| Wall Thickness | ±0.03 mm | 12 mm | Consistency across full length |

| Straightness | 0.1 mm/m | 6,000 mm | Verified via laser interferometry |

| Angular Accuracy | ±0.1° | 180° bends | Multi-radius capabilities |

| Surface Roughness | Ra 0.8 µm | Full length | Deburred, oxide-free finish |

Precision tube fabrication transcends technical execution; it embodies risk mitigation. When Wuxi Lead engineered tubular components for a naval vessel’s sonar array housing, our ±0.02mm ovality control prevented acoustic signal scattering—a tolerance mandated by classified naval specifications. Similarly, for Beijing’s Olympic ice arena, our tubes’ thermal expansion coefficients were calibrated to 0.000011 µm/°C, ensuring zero structural drift across -30°C to 40°C swings. These projects underscore a core truth: in sheet metal tube production, precision isn’t a specification—it’s the foundation of trust.

For global OEMs, partnering with a fabricator that treats tolerances as inviolable commitments separates functional assemblies from卓越 engineering. Wuxi Lead’s ISO 9001:2015-certified workflow, coupled with direct experience in zero-failure environments, delivers tubes that perform exactly as simulated—every time. Your application’s reliability starts with the geometry of its core components.

Precision Specs & Tolerances

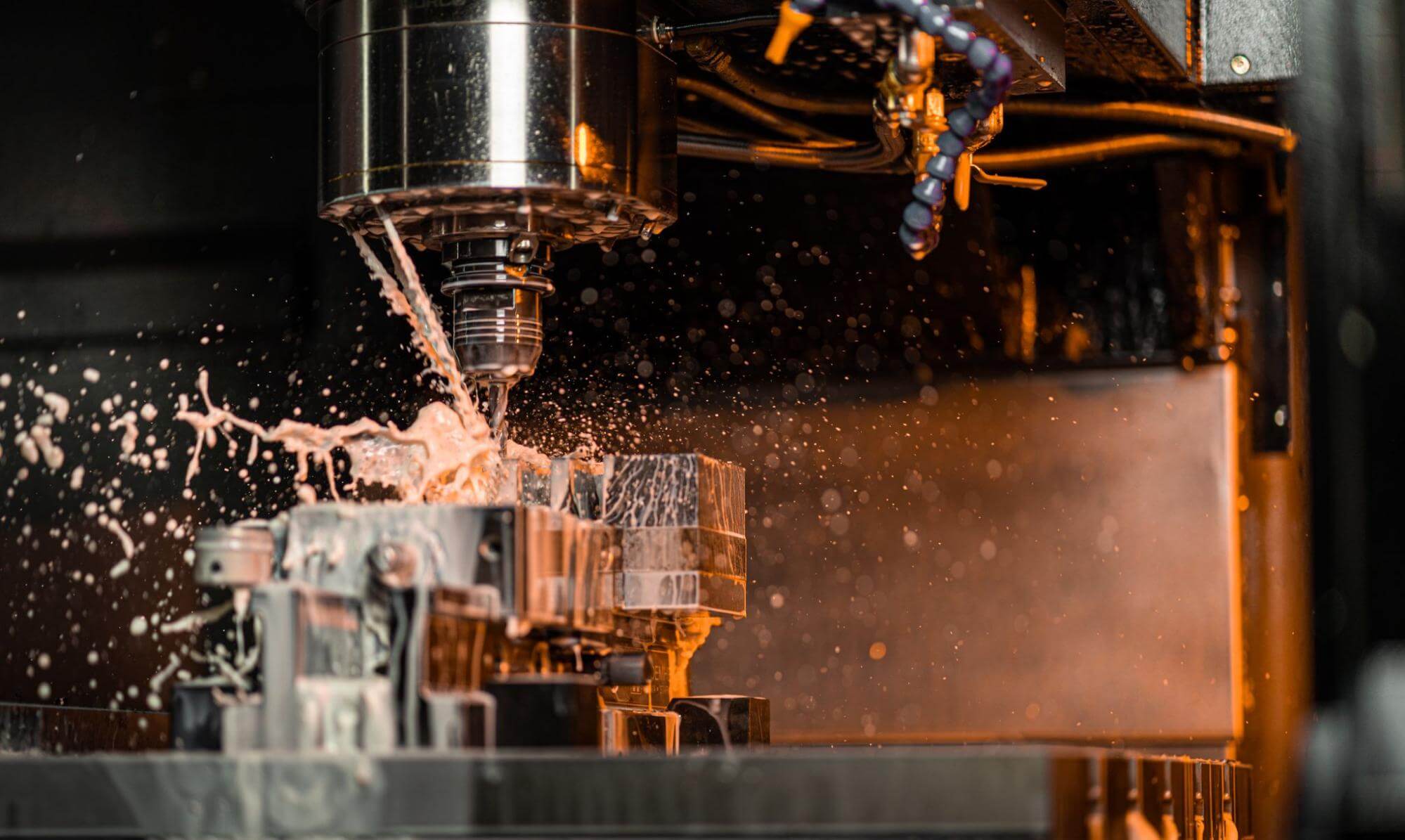

Wuxi Lead Precision Machinery delivers advanced sheet metal tube fabrication through precision engineering and state-of-the-art manufacturing technologies. Our technical capabilities are built around high-performance 5-axis CNC machining systems, enabling complex geometries, tight tolerances, and seamless integration of multi-faceted features on tubular sheet metal components. These systems provide simultaneous multi-directional cutting and forming, allowing for intricate contours, angled cuts, and precise hole patterns that are unattainable with conventional 3-axis platforms. This level of control ensures superior part accuracy and consistency across both prototyping and high-volume production runs.

All fabrication processes are supported by a rigorous quality control framework centered on Coordinate Measuring Machine (CMM) inspection. Each component undergoes comprehensive dimensional verification to ensure compliance with international standards and customer-specific engineering drawings. Our CMM systems provide micron-level measurement accuracy, validating critical features such as hole placement, angular alignment, wall thickness uniformity, and overall form. Data from each inspection is documented and traceable, supporting full quality assurance reporting for regulated industries including aerospace, medical device manufacturing, and high-end industrial equipment.

Our facility specializes in processing a wide range of sheet metal materials, including cold-rolled steel, stainless steel, aluminum, and copper alloys. Material thicknesses from 0.5 mm to 6.0 mm are routinely handled, with adaptive tooling and fixturing designed to maintain rigidity and minimize deformation during high-speed machining. Advanced nesting software optimizes material utilization, reducing waste and improving cost efficiency without compromising part integrity.

The integration of 5-axis CNC technology with in-process and post-process CMM validation ensures that every sheet metal tube component meets the highest standards of precision and repeatability. Whether producing lightweight structural tubes for automation systems or corrosion-resistant enclosures for harsh environments, our process delivers consistent results with minimal variation.

The following table outlines the standard technical specifications and achievable tolerances for our sheet metal tube fabrication services.

| Parameter | Specification |

|---|---|

| Material Types | Mild Steel, Stainless Steel, Aluminum, Copper |

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Maximum Working Envelope | 1200 mm × 800 mm × 500 mm |

| Machining Axes | 5-Axis Simultaneous CNC |

| Positional Accuracy | ±0.01 mm |

| Repeatability | ±0.005 mm |

| Angular Tolerance | ±0.1° |

| Hole Position Tolerance | ±0.02 mm |

| Surface Finish (Typical) | Ra ≤ 1.6 µm |

| Quality Inspection | CMM-Based Full Dimensional Reporting |

Wuxi Lead Precision Machinery is committed to technical excellence in every stage of production. Our capabilities in 5-axis CNC fabrication and precision metrology position us as a trusted partner for high-complexity sheet metal tube solutions in demanding industrial applications.

Material & Finish Options

Material Selection for Precision Sheet Metal Tubes

Selecting the optimal material for sheet metal tube fabrication is critical for performance, longevity, and cost efficiency in demanding industrial applications. At Wuxi Lead Precision Machinery, we prioritize material properties that align with your operational environment, mechanical requirements, and regulatory standards. Aluminum, steel, and titanium dominate high-end tube fabrication, each offering distinct advantages for aerospace, medical, automotive, and energy sectors.

Aluminum alloys, particularly 6061-T6 and 7075-T6, deliver an exceptional strength-to-weight ratio and inherent corrosion resistance. These grades are ideal for weight-sensitive applications like drone frames or heat exchangers. Aluminum’s machinability allows for complex geometries with tight tolerances, though it requires protective finishes for harsh environments. Steel remains the backbone for structural integrity. Carbon steel (A36, 1018) provides high tensile strength at economical costs for general industrial use, while stainless steel grades 304 and 316 offer superior corrosion and heat resistance for medical devices or marine hardware. Titanium Grade 2 and 5 (Ti-6Al-4V) excel in extreme conditions—resisting oxidation up to 600°C and withstanding saltwater immersion—making them indispensable for aerospace hydraulics and surgical implants. However, titanium’s hardness demands specialized CNC tooling and slower machining rates.

The following table summarizes key properties to guide your selection:

| Material | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Typical Applications |

|---|---|---|---|---|

| Aluminum 6061-T6 | 2.7 | 310 | Moderate | Aerospace ducts, Robotics |

| Stainless 316 | 8.0 | 570 | Excellent | Medical instruments, Marine |

| Titanium Grade 5 | 4.4 | 900 | Exceptional | Jet engine components, Implants |

Anodizing: Essential Protection for Aluminum Tubes

Anodizing is non-negotiable for aluminum sheet metal tubes exposed to abrasion, chemicals, or outdoor elements. This electrochemical process thickens the natural oxide layer, enhancing surface hardness by up to 65 HRC and providing a porous base for dyeing. Type II (sulfuric acid) anodizing suits general corrosion protection, while Type III (hardcoat) delivers 25–50 µm thickness for extreme wear resistance in hydraulic systems. At Wuxi Lead, we control anodizing parameters to ensure uniform coating adhesion and dimensional stability, preventing micro-cracking that compromises tube integrity. Note that anodizing cannot be reapplied without stripping the base material—specify finish requirements upfront during design.

Material choice directly impacts manufacturability and lifecycle costs. While titanium offers unparalleled performance, its machining complexity increases lead times and costs by 3–5x versus aluminum. Conversely, uncoated carbon steel may require frequent maintenance in corrosive settings, offsetting initial savings. Partner with Wuxi Lead early in your design phase; our engineering team analyzes your load conditions, environmental exposure, and volume needs to recommend the most economical material-finish combination. We validate selections through in-house salt spray testing and FEA simulation, ensuring your sheet metal tubes meet mission-critical precision and durability standards.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the production process for sheet metal tubes begins with meticulous design engineering. Our in-house team of mechanical and structural engineers collaborates closely with clients to translate conceptual requirements into manufacturable designs. Utilizing advanced 3D CAD software such as SolidWorks and AutoCAD, we develop detailed models that incorporate precise dimensions, material specifications, and geometric tolerances. Finite Element Analysis (FEA) is applied to simulate stress, load, and thermal behavior, ensuring structural integrity under operational conditions. Design for Manufacturability (DFM) principles are rigorously applied to eliminate potential production bottlenecks, reduce material waste, and enhance overall efficiency. Every design undergoes internal peer review and client validation before moving to the next phase, establishing a foundation for zero-defect manufacturing.

Prototyping: Validating Performance and Fit

Once the design is finalized, we proceed to prototyping— a critical step in our zero-defect strategy. Using high-precision laser cutting, CNC bending, and automated welding systems, we fabricate functional prototypes that mirror the final product in material and construction. These prototypes are subjected to comprehensive quality checks, including dimensional inspection via Coordinate Measuring Machines (CMM), weld integrity testing, and assembly fit verification. We also conduct environmental and mechanical stress tests when required, particularly for applications in aerospace, automotive, or industrial equipment. Client feedback is integrated at this stage, allowing for design refinement without impacting mass production timelines. This iterative validation ensures that all functional, aesthetic, and performance criteria are met before full-scale manufacturing commences.

Mass Production: Consistency Through Automation and Control

With prototype approval, we transition to mass production under a tightly controlled manufacturing environment. Our facility in Wuxi employs automated sheet metal processing lines, including robotic bending cells and fiber laser cutting systems, ensuring repeatability and micron-level accuracy. Each production batch follows standardized work instructions derived from the approved prototype, with real-time monitoring through integrated Manufacturing Execution Systems (MES). Statistical Process Control (SPC) is used to track key parameters, enabling immediate corrective action if deviations occur. Every sheet metal tube undergoes 100% visual inspection and selective metrology sampling, with full traceability from raw material to finished product. This closed-loop quality system is certified under ISO 9001:2015 and supports our commitment to zero-defect delivery.

Key Production Specifications

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Tolerance (Bending) | ±0.1 mm |

| Tolerance (Cutting) | ±0.05 mm |

| Minimum Bend Radius | 1.0 x material thickness |

| Surface Roughness (Laser Cut) | Ra ≤ 3.2 μm |

| Welding Methods | TIG, MIG, Spot Welding |

| Max Part Length | 3000 mm |

| Coating Options | Powder Coating, Zinc Plating, Anodizing (Aluminum) |

Through integrated design, rigorous prototyping, and disciplined mass production, Wuxi Lead Precision Machinery delivers sheet metal tubes that meet the highest standards of precision, durability, and consistency.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Uncompromising Sheet Metal Tube Excellence

In high-stakes industrial applications, the integrity of sheet metal tube components directly impacts system performance, safety, and lifecycle costs. Generic fabrication solutions introduce unacceptable risks of dimensional drift, weld failure, or material inconsistency. At Wuxi Lead Precision Machinery, we engineer sheet metal tubes to the exacting standards demanded by aerospace, medical device, and advanced energy sectors—where microns define success. Our integrated approach merges German-engineered CNC bending cells with ISO 9001-certified quality protocols, ensuring every tube meets your geometric and functional requirements on the first iteration.

We eliminate the friction of offshore manufacturing through proactive engineering collaboration. Our technical team engages during your design phase to optimize manufacturability, identifying potential stress points or assembly conflicts before metal is cut. This DFM partnership reduces prototyping cycles by up to 40% and prevents costly downstream rework. Real-time production tracking via our client portal provides transparency into material certifications, in-process inspections, and delivery milestones—no time zone barriers, no communication gaps. With dedicated English-speaking project managers and 72-hour rapid quoting, we operate as a seamless extension of your engineering department.

Critical specifications define our capability ceiling. The table below reflects our standard production envelope for precision sheet metal tubes, achievable without custom tooling investment:

| Parameter | Capability Range | Tolerance Control |

|---|---|---|

| Material Thickness | 0.5 mm – 6.0 mm | ±0.05 mm |

| Tube Diameter | Ø10 mm – Ø300 mm | ±0.1 mm (round) |

| Bend Angles | 0° – 180° | ±0.1° |

| Straightness | ≤ 0.5 mm per 1000 mm | Measured via CMM |

| Surface Finish | Ra ≤ 0.8 µm (as-formed) | ISO 1302 compliant |

These metrics are not theoretical maximums but routinely achieved production standards, validated through our in-house metrology lab equipped with Zeiss coordinate measuring machines and laser trackers. For mission-critical applications, we implement 100% first-article inspection and batch traceability down to the coil level.

Your next-generation product deserves a fabrication partner who treats dimensional stability as non-negotiable. We do not merely supply tubes—we guarantee geometric certainty. Contact our engineering team to schedule a technical consultation and receive a capability assessment for your specific component. Provide your CAD file and requirements, and we will deliver a feasibility analysis with process recommendations within 72 hours.

Initiate precision collaboration today. Email [email protected] with subject line Sheet Metal Tube Engineering Review to connect with our application specialists. Let us demonstrate how Wuxi Lead Precision Machinery becomes the silent force behind your product’s reliability. Your specifications define our output—nothing less.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.