Technical Contents

Engineering Guide: Sheet Metal Systems

Engineering Insight: Precision as the Non-Negotiable Core of Sheet Metal Systems

In high-stakes sheet metal fabrication, precision transcends mere specification; it is the fundamental determinant of system integrity, performance, and longevity. Minute deviations in flatness, hole placement, or bend angles cascade into critical failures during assembly or operation. Misaligned components induce stress points, accelerate wear, compromise structural stability, and ultimately jeopardize the entire product lifecycle. For industries like aerospace, defense, and advanced medical equipment, where Wuxi Lead Precision Machinery operates daily, tolerances measured in thousandths of an inch are not aspirational targets but absolute prerequisites. The cost of imprecision extends far beyond scrap material – it encompasses delayed project timelines, costly rework, reputational damage, and potential safety hazards. True precision engineering demands an integrated approach, marrying advanced CNC technology with meticulous material science understanding and rigorous process control from the initial flat pattern through final finishing.

Wuxi Lead Precision Machinery embodies this precision imperative, forged through decades of solving the most demanding fabrication challenges. Our engineering team possesses deep expertise in managing the inherent variables of sheet metal – grain direction, springback, thermal distortion – ensuring predictable, repeatable results. This capability is proven not just in standard industrial applications, but on projects where failure is inconceivable. We have delivered critical structural and enclosure components for Olympic venue infrastructure, meeting the exacting aesthetic and functional demands of global events under intense scrutiny. Furthermore, our processes consistently satisfy stringent defense-grade specifications, producing mission-critical parts where dimensional accuracy directly impacts operational reliability and safety. This experience instills a culture where precision is not inspected in, but engineered in at every process stage.

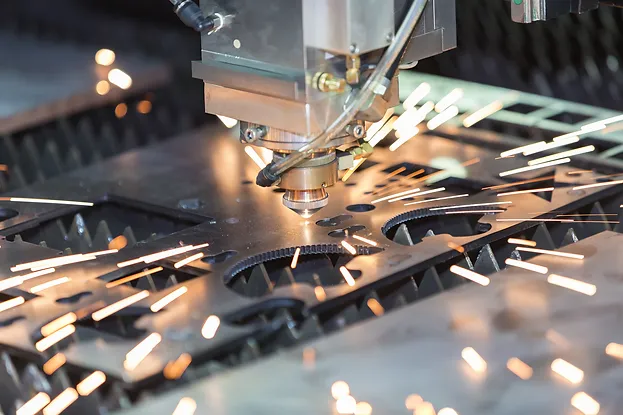

The technical foundation for this reliability lies in our controlled manufacturing environment and advanced equipment suite. We leverage state-of-the-art CNC punching, laser cutting, and press brake technologies, all operating within tightly monitored thermal and calibration regimes. Our proprietary process validation protocols ensure that every bend, cut, and form adheres to the specified tolerance, batch after batch. The table below outlines the core precision capabilities consistently achieved across our sheet metal systems production:

| Specification Category | Capability Range | Measurement Standard |

|---|---|---|

| Linear Dimensional Tolerance | ±0.05 mm to ±0.1 mm | ISO 2768-mK |

| Hole Positional Tolerance | ±0.03 mm (critical areas) | ASME Y14.5 GD&T |

| Bend Angle Accuracy | ±0.25° | In-process laser verification |

| Flatness Tolerance | 0.1 mm per 300 mm | Precision granite surface plate |

| Material Thickness Range | 0.5 mm to 6.0 mm | Cold Rolled Steel, Stainless, Aluminum |

This unwavering commitment to dimensional integrity translates directly into tangible client value: seamless assembly, reduced field failures, extended product service life, and significant total cost of ownership savings. When your sheet metal system forms the backbone of critical infrastructure or advanced machinery, partnering with a fabricator whose precision is validated by Olympic and military-grade projects is not merely an advantage – it is an operational necessity. Wuxi Lead Precision Machinery delivers the engineering rigor to ensure your systems perform flawlessly, exactly as designed, every time.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced technical capabilities in sheet metal fabrication, engineered to support high-precision industrial demands across aerospace, medical, automation, and energy sectors. Our integrated manufacturing ecosystem combines state-of-the-art 5-axis CNC machining with comprehensive sheet metal processing, enabling complex geometries and tight-tolerance components from a single source. This synergy ensures dimensional accuracy, structural integrity, and repeatability across both prototyping and high-volume production runs.

At the core of our precision sheet metal systems is a fleet of 5-axis CNC machining centers, equipped with high-speed spindles and dynamic tool changers. These systems allow for simultaneous multi-directional cutting, minimizing setup changes and eliminating cumulative alignment errors. This capability is critical when producing intricate housings, brackets, and enclosures with compound angles and internal features. By leveraging 5-axis technology, we achieve superior surface finishes and reduce secondary operations, accelerating time-to-market without compromising quality.

Sheet metal processing is supported by advanced laser cutting, precision bending with CNC-controlled press brakes, and automated welding stations. Our laser systems handle materials from 0.5 mm to 12 mm in thickness, with edge quality optimized for minimal burr and thermal distortion. CNC press brakes utilize real-time feedback systems to maintain angular accuracy within ±0.2°, even in high-repetition bending sequences. All processes are governed by digital work instructions derived from 3D CAD models, ensuring consistency from design to final part.

Quality assurance is integral to every stage of production. Each component undergoes rigorous inspection using a Zeiss DuraMax and Contura G2 Coordinate Measuring Machine (CMM), providing metrology-grade verification of geometric dimensions and tolerances. The CMM system is programmed to execute full-spectrum GD&T analysis, including position, flatness, concentricity, and profile tolerances. Data from inspections is documented and traceable, meeting ISO 9001 and customer-specific quality requirements.

Our technical capabilities are defined by measurable precision. The following table outlines standard and achievable tolerances across key fabrication processes:

| Process | Dimensional Tolerance | Angular Tolerance | Feature Position Tolerance | Surface Finish (Ra) |

|---|---|---|---|---|

| 5-Axis CNC Machining | ±0.005 mm | ±0.1° | ±0.01 mm | 0.8 – 3.2 µm |

| Laser Cutting (Steel) | ±0.1 mm | N/A | ±0.15 mm | 6.3 – 12.5 µm |

| CNC Bending | ±0.1 mm (length) | ±0.2° | ±0.2 mm | N/A |

| TIG/MIG Welding | ±0.3 mm (post-weld) | ±0.5° | ±0.3 mm | 12.5 – 25 µm |

| CMM Inspection Accuracy | ±0.003 mm (probe) | N/A | Full GD&T validation | N/A |

Wuxi Lead Precision Machinery maintains technical readiness for next-generation sheet metal systems, combining multi-axis precision, material versatility, and metrology-backed quality control to meet the evolving demands of global OEMs and Tier-1 suppliers.

Material & Finish Options

Material Selection for Precision Sheet Metal Systems

Selecting the optimal material is foundational to achieving performance, longevity, and cost efficiency in sheet metal fabrication. At Wuxi Lead Precision Machinery, we prioritize material properties aligned with your application’s mechanical, environmental, and aesthetic demands. Below, we detail critical considerations for aluminum, steel, and titanium, alongside essential finishing insights for aluminum components.

Aluminum Alloys

Aluminum dominates aerospace, electronics, and transportation sectors due to its exceptional strength-to-weight ratio and corrosion resistance. Grade 6061-T6 offers weldability and moderate strength for structural frames, while 5052-H32 excels in marine environments with superior fatigue resistance. Aluminum’s thermal conductivity makes it ideal for heat dissipation in enclosures. However, its lower hardness necessitates precise CNC machining to avoid burring during cutting or bending. We recommend aluminum for weight-sensitive applications where corrosion resistance and electrical conductivity are paramount.

Steel Variants

Carbon steel (A36, 1018) provides high tensile strength and affordability for industrial enclosures, brackets, and machinery bases. For enhanced corrosion resistance, 304 and 316 stainless steel are indispensable in medical, food processing, and marine settings. 316 stainless, with molybdenum content, withstands chloride exposure far better than 304. Note that stainless steel’s work-hardening tendency requires specialized tooling and slower feed rates during CNC punching or laser cutting to prevent edge deformation. Steel remains the default choice for high-load structural applications demanding rigidity and impact resistance.

Titanium Alloys

Grade 5 (Ti-6Al-4V) titanium delivers unparalleled strength-to-weight performance in extreme conditions—critical for aerospace, defense, and chemical processing. Its biocompatibility also suits medical implants. Titanium resists crevice corrosion in seawater and maintains integrity up to 600°C. However, its low thermal conductivity and chemical reactivity necessitate strict inert-gas shielding during welding and aggressive parameter adjustments in CNC milling. We deploy titanium selectively where performance justifies its premium cost and complex fabrication requirements.

Anodizing for Aluminum

Anodizing is non-negotiable for aluminum parts exposed to abrasion or harsh environments. This electrochemical process thickens the natural oxide layer, enhancing surface hardness (up to 60 Rockwell C), corrosion resistance, and dye receptivity. Type II (sulfuric acid) anodizing at 15–25μm thickness suits most industrial enclosures, while Type III (hardcoat) at 25–50μm is mandatory for hydraulic components or high-wear surfaces. At Wuxi Lead, we enforce rigorous sealing in hot deionized water to prevent dye fading and ensure pore closure—critical for MIL-A-8625 compliance. Avoid anodizing on parts requiring electrical grounding; specify conductive clear coats instead.

Material Property Comparison

| Property | Aluminum 6061-T6 | Steel 304 Stainless | Titanium Grade 5 |

|---|---|---|---|

| Density (g/cm³) | 2.7 | 8.0 | 4.43 |

| Tensile Strength (MPa) | 310 | 585 | 900 |

| Corrosion Resistance | Good (marine grades better) | Excellent | Exceptional |

| Machinability Rating | High | Moderate | Low |

| Typical Thickness Range | 0.5–6.0 mm | 0.8–12.0 mm | 0.8–10.0 mm |

Material choice directly impacts manufacturability, lifecycle cost, and end-part reliability. Wuxi Lead Precision Machinery leverages decades of CNC expertise to optimize your selection—balancing performance needs with production efficiency. Contact our engineering team for a tailored material analysis based on your operational environment and tolerance requirements.

Manufacturing Process & QC

Design: Precision Engineering at the Foundation

At Wuxi Lead Precision Machinery, the sheet metal fabrication process begins with meticulous design engineering, forming the cornerstone of zero-defect manufacturing. Our in-house design team leverages advanced CAD/CAM software, including SolidWorks and AutoCAD, to translate client concepts into manufacturable, high-tolerance models. Every design undergoes comprehensive DFM (Design for Manufacturability) analysis to ensure optimal material utilization, structural integrity, and alignment with production capabilities. We collaborate closely with clients during this phase, providing 3D simulations and feasibility reports to validate geometry, tolerances, and assembly requirements. This proactive engineering approach eliminates potential flaws before physical production begins, reducing rework and accelerating time-to-market.

Prototyping: Validating Performance and Precision

Following design approval, we move to prototyping—a critical validation phase in our zero-defect strategy. Utilizing CNC punching, laser cutting, bending, and welding technologies, we produce functional prototypes that mirror final production quality. These prototypes undergo rigorous inspection using coordinate measuring machines (CMM), laser scanners, and first-article inspection reports (FAIR) to verify dimensional accuracy, surface finish, and mechanical performance. Any discrepancies are addressed through iterative refinement, ensuring the design is fully optimized. This stage not only confirms technical feasibility but also allows clients to evaluate form, fit, and function under real-world conditions. Our rapid prototyping capabilities reduce development cycles while maintaining the highest standards of precision.

Mass Production: Scalable Excellence with Zero Defects

With prototype validation complete, we transition seamlessly into mass production using fully integrated sheet metal systems. Our automated production lines—equipped with Amada and Trumpf machinery—ensure consistent repeatability and throughput. Every component is manufactured under strict ISO 9001-certified quality management protocols, with real-time process monitoring and in-line inspection at key stages. We implement Statistical Process Control (SPC) and Poka-Yoke (error-proofing) systems to detect and prevent deviations before they occur. Final assemblies undergo 100% visual and dimensional inspection, supported by material traceability and batch documentation. This disciplined approach ensures every part meets exact specifications, achieving true zero-defect output across production runs.

Key Production Specifications

| Parameter | Capability | Tolerance Range |

|---|---|---|

| Material Thickness | 0.5 mm – 25 mm | ±0.1 mm (standard) |

| Laser Cutting Accuracy | Up to ±0.05 mm | ISO 2768-m |

| CNC Bending Tolerance | ±0.2° angular, ±0.1 mm linear | Based on DIN 6930 |

| Welding Processes | MIG, TIG, Spot, Robotic Automation | ISO 3834 Certified |

| Surface Finish Options | Mill, Powder Coating, Anodizing, Plating | Ra ≤ 1.6 µm (machined) |

| Production Capacity | Up to 500,000 units/month | Scalable per client demand |

| Quality Standards | ISO 9001, ISO 14001, RoHS Compliant | Full traceability |

Through integrated design, precision prototyping, and disciplined mass production, Wuxi Lead delivers sheet metal systems that meet the most demanding industrial requirements—on time, at scale, and with zero defects.

Why Choose Wuxi Lead Precision

Strategic Partnership for Advanced Sheet Metal Fabrication

Wuxi Lead Precision Machinery stands as your definitive engineering partner for mission-critical sheet metal systems. We transcend conventional contract manufacturing by integrating deep technical collaboration with industrial-grade execution. Our facility in Wuxi operates under ISO 9001-certified processes, ensuring every component meets aerospace, medical, and semiconductor industry tolerances. When you partner with us, you gain direct access to our engineering team for concurrent design analysis—identifying manufacturability improvements before tooling begins. This proactive approach reduces time-to-market by up to 30% while eliminating costly revisions. Our commitment extends beyond delivery: we implement rigorous first-article inspection protocols and real-time SPC monitoring to guarantee batch-to-batch consistency, even for low-volume high-mix production runs.

Technical excellence is non-negotiable in precision sheet metal fabrication. Our integrated production ecosystem combines German-engineered machinery with proprietary quality control algorithms. The table below details core capabilities that differentiate our systems:

| Capability | Specification | Industry Benchmark |

|---|---|---|

| Laser Cutting Accuracy | ±0.03 mm | ±0.10 mm |

| Press Brake Tolerance | ±0.05° angular | ±0.25° |

| Material Thickness Range | 0.5–6.0 mm | 0.8–4.0 mm |

| Surface Roughness (Ra) | ≤0.8 μm | ≤1.6 μm |

| First-Pass Yield Rate | 99.2% | 95.0% |

These metrics reflect our investment in 5-axis Amada CNC systems, automated fiber laser cutters with 4 kW power, and cleanroom assembly zones for sensitive components. Unlike commodity suppliers, we prioritize dimensional stability through controlled thermal stress relief and in-process metrology using Hexagon CMMs. Every shipment includes full traceability documentation—from material mill certificates to final inspection reports—meeting AS9100 and ISO 13485 requirements without surcharge.

Initiate your precision fabrication partnership by contacting our engineering team directly. Forward your technical drawings and production requirements to [email protected] for a confidential capability assessment. Within 24 business hours, you will receive a detailed manufacturability report with DFM recommendations, lead time analysis, and a formal quotation. Our sales engineers—each with 15+ years in metal fabrication—will schedule a virtual technical review to address material selection, tolerance stack-ups, and secondary process integration. For urgent prototyping needs, leverage our 72-hour rapid validation service with expedited shipping from Wuxi to global hubs. Do not settle for suppliers who treat sheet metal as a transactional commodity. Partner with engineers who treat your specifications as their primary design constraint. Contact [email protected] today to establish a precision manufacturing alliance built on technical accountability.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.