Technical Contents

Engineering Guide: Sheet Metal Service

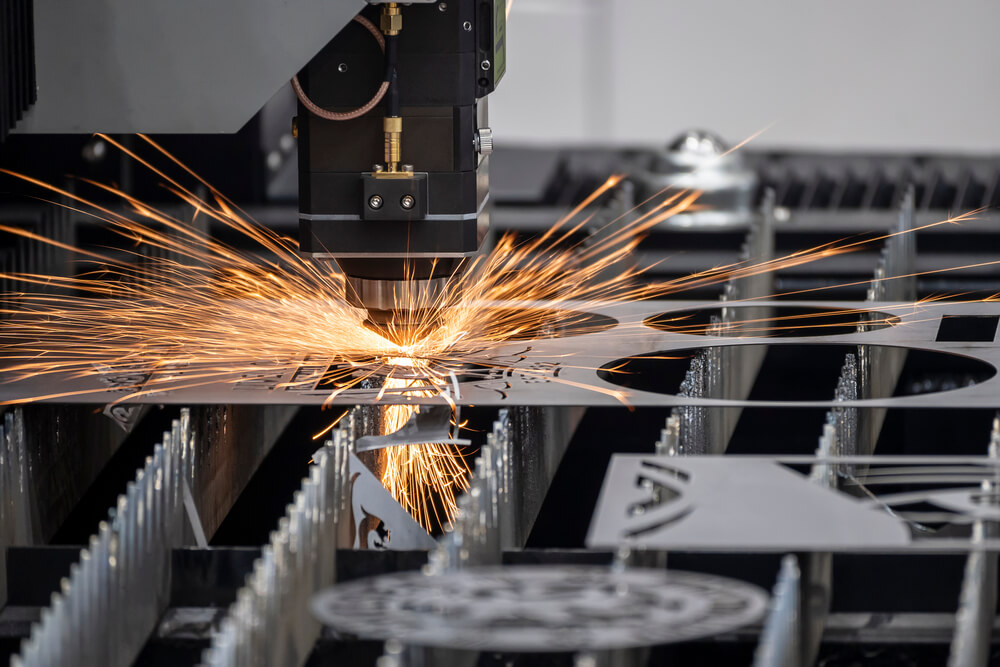

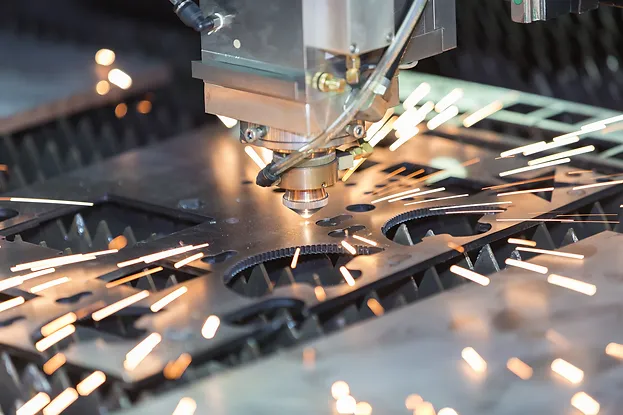

Engineering Insight: The Critical Role of Precision in Sheet Metal Services

In high-end manufacturing, the performance, reliability, and longevity of a product are often determined not by the final assembly, but by the precision of its individual components. Nowhere is this more evident than in sheet metal fabrication, where tolerances measured in fractions of a millimeter directly influence structural integrity, fit, and function. At Wuxi Lead Precision Machinery, we understand that precision is not an optional upgrade—it is the foundation of engineering excellence.

Sheet metal components are integral to industries ranging from aerospace and defense to medical devices and high-performance industrial equipment. These applications demand more than just accurate cutting or bending; they require a holistic approach to fabrication that integrates design validation, material science, and process control. Even minor deviations in flatness, hole placement, or bend angles can cascade into costly rework, system failure, or non-compliance with regulatory standards.

Our approach begins with advanced CNC-controlled processes, including laser cutting, precision press braking, and automated welding systems. Each machine is calibrated daily and monitored in real time to ensure dimensional consistency across production runs. But technology alone is not enough. Our engineering team brings over 15 years of experience in mission-critical fabrication, having delivered components for Olympic-standard sporting infrastructure and military-grade defense systems—applications where failure is not an option.

In the development of seating structures for Olympic venues, for example, our team achieved tolerances of ±0.1 mm across complex curved panels, ensuring both aesthetic uniformity and load-bearing reliability. Similarly, in military communication enclosures, we maintained strict EMI shielding integrity through precise seam alignment and material selection, meeting MIL-STD-810G environmental performance criteria.

Such achievements are only possible through a disciplined integration of design for manufacturability (DFM), in-process quality checks, and final inspection using coordinate measuring machines (CMM). We validate every stage—from raw material sourcing to final surface treatment—ensuring that each component meets or exceeds client specifications.

The following table outlines key precision capabilities in our sheet metal service line:

| Specification | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Laser Cutting Tolerance | ±0.1 mm |

| Press Brake Bending Accuracy | ±0.2° |

| Dimensional Tolerance (per ISO 2768-mK) | ±0.2 mm for parts up to 1 m |

| Hole Positioning Accuracy | ±0.15 mm |

| Surface Flatness (per ISO 1101) | 0.1 mm over 300 mm² |

| Welding Standards | ISO 15614-1, AWS D1.1 |

Precision in sheet metal fabrication is not merely about meeting specifications—it is about anticipating the functional demands of the final product. At Wuxi Lead Precision Machinery, we combine technical capability with real-world engineering insight to deliver components that perform under the most demanding conditions. When reliability is non-negotiable, precision is the only standard.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Fabrication

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions engineered for the most demanding industrial applications. Our core strength lies in integrating state-of-the-art multi-axis CNC technology with rigorous metrology, ensuring dimensional accuracy and repeatability that meets stringent global standards. We specialize in transforming complex designs into high-integrity components, minimizing waste and accelerating time-to-market for our clients across aerospace, medical, and advanced industrial sectors.

Our production backbone features multiple 5-axis CNC laser cutting and punching centers, including the Bystronic BySprint Fiber 6030 and Trumpf TruPunch 5000 series. These systems enable the precise fabrication of intricate geometries from 0.5mm to 6.0mm thickness in stainless steel, aluminum, and carbon steel alloys. The simultaneous 5-axis movement eliminates the need for secondary operations on complex bends or cutouts, significantly reducing handling errors and lead times. This capability is critical for components requiring tight angular relationships or compound contours, such as fluid manifolds, structural brackets, and enclosure systems where assembly integrity is non-negotiable.

Quality assurance is embedded throughout our process, anchored by Zeiss CONTURA G3 Coordinate Measuring Machines (CMM) with 0.0001mm resolution. Every critical feature undergoes 100% first-article inspection against CAD models, with statistical process control (SPC) monitoring applied to high-volume runs. Our AS9100-certified inspection protocols validate flatness, hole positioning, bend angles, and critical form tolerances, providing clients with comprehensive inspection reports traceable to international standards. This metrology-driven approach ensures components integrate flawlessly into final assemblies, reducing downstream rework and warranty costs.

Tolerance execution is fundamental to our value proposition. The table below details our standard achievable tolerances across common materials and processes, reflecting our commitment to precision engineering:

| Feature | Material Thickness | Standard Tolerance | Tight Tolerance Option |

|---|---|---|---|

| Hole Diameter | 0.5 – 3.0 mm | ±0.05 mm | ±0.02 mm |

| 3.1 – 6.0 mm | ±0.08 mm | ±0.03 mm | |

| Hole Position | All Thicknesses | ±0.10 mm | ±0.05 mm |

| Bend Angle | 0.5 – 2.0 mm | ±0.5° | ±0.25° |

| 2.1 – 6.0 mm | ±1.0° | ±0.5° | |

| Edge-to-Edge Distance | All Thicknesses | ±0.15 mm | ±0.08 mm |

| Flatness (per 100mm) | All Thicknesses | 0.10 mm | 0.05 mm |

These specifications are consistently achieved through optimized machine calibration, in-process gauging, and skilled operator oversight. We collaborate closely with engineering teams during Design for Manufacturability (DFM) reviews to identify opportunities for tolerance relaxation without compromising function, directly enhancing production efficiency and cost-effectiveness. Wuxi Lead’s fusion of 5-axis agility and metrology-grade verification delivers sheet metal components where precision is not merely specified, but guaranteed. This technical foundation supports our clients’ most ambitious product innovations with unwavering reliability.

Material & Finish Options

Material Selection in Precision Sheet Metal Fabrication

Selecting the appropriate material is a foundational step in achieving optimal performance, durability, and cost-efficiency in sheet metal fabrication. At Wuxi Lead Precision Machinery, we specialize in high-precision manufacturing processes that demand exacting material standards. The three most widely used metals in advanced sheet metal applications are aluminum, steel, and titanium—each offering distinct mechanical, thermal, and chemical properties suited to specific industrial environments.

Aluminum is favored for its excellent strength-to-weight ratio, corrosion resistance, and electrical conductivity. It is particularly ideal for aerospace, electronics, and transportation applications where weight reduction is critical. Grade 6061-T6 is among the most commonly used aluminum alloys due to its weldability and moderate strength. However, aluminum’s lower hardness compared to steel may require design adjustments in high-wear environments.

Steel remains the backbone of industrial fabrication, with carbon steel and stainless steel variants serving different needs. Carbon steel, such as ASTM A36 or SPCC, offers high tensile strength and is cost-effective for structural components. However, it requires protective finishes to resist oxidation. In contrast, stainless steel (e.g., 304 or 316) provides inherent corrosion resistance due to its chromium content, making it suitable for medical devices, food processing equipment, and outdoor enclosures.

Titanium, though more expensive and challenging to process, delivers unmatched strength-to-density performance and exceptional resistance to extreme temperatures and corrosive media. Grade 2 (commercially pure) and Grade 5 (Ti-6Al-4V) are frequently used in aerospace, defense, and high-performance automotive systems. Its low thermal conductivity requires specialized tooling and machining parameters during fabrication.

Surface finish selection is equally critical in determining a part’s longevity and functional aesthetics. Anodizing is a widely adopted electrochemical process for aluminum components. It enhances surface hardness, improves wear resistance, and allows for color coding through dye integration. Type II (sulfuric acid) anodizing is standard for decorative and moderate-duty applications, while Type III (hardcoat anodizing) provides a thicker, more durable oxide layer for industrial and military specifications.

Below is a comparative overview of key material properties relevant to sheet metal service applications.

| Material | Typical Grades | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Common Applications |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 5052-H32 | 2.7 | 310 | High | Aerospace, Electronics |

| Carbon Steel | SPCC, ASTM A36 | 7.85 | 400–550 | Low (requires coating) | Industrial Frames, Machinery |

| Stainless Steel | 304, 316 | 8.0 | 515–620 | Very High | Medical, Food Processing |

| Titanium | Gr2, Gr5 (Ti-6Al-4V) | 4.5 | 620–900 | Exceptional | Aerospace, Defense |

At Wuxi Lead, we support clients in aligning material and finish choices with functional requirements, environmental exposure, and production scalability. Our engineering team provides consultation from design to delivery, ensuring that every fabricated component meets the highest standards of precision and performance.

Manufacturing Process & QC

Precision Sheet Metal Production: The Zero Defects Process at Wuxi Lead

At Wuxi Lead Precision Machinery, our sheet metal fabrication process is engineered for absolute reliability, transforming client concepts into flawless production components through a rigorously controlled sequence. We eliminate defects at the source, ensuring every part meets exacting specifications from initial sketch to final shipment. This systematic approach delivers unparalleled consistency and reduces total project risk for our global industrial partners.

The process begins with Collaborative Design & Engineering. Our engineers partner directly with your team during the design phase, conducting comprehensive Design for Manufacturability (DFM) analysis. We scrutinize material selection, geometric complexity, tolerance stack-ups, and tooling requirements using advanced CAD/CAM simulation. This proactive review identifies potential production vulnerabilities before a single sheet is cut, optimizing the design for manufacturability and inherent quality. Material certifications and strict lot traceability are established at this critical stage.

Rigorous Prototyping & Validation follows immediately. Utilizing our high-speed CNC punching, laser cutting, and precision bending centers, we produce functional prototypes mirroring final production methods. Every prototype undergoes stringent First Article Inspection (FAI) against your original CAD data, employing Coordinate Measuring Machines (CMM) and optical comparators. Dimensional accuracy, material properties, and assembly fit are validated. Client feedback is integrated rapidly, and the process is refined until zero deviations are confirmed. This phase is non-negotiable; it de-risks mass production by proving the process capability.

Zero Defects Mass Production leverages the validated process under our Statistical Process Control (SPC) framework. Production runs commence only after final sign-off on the approved prototype and documented process parameters. Real-time monitoring tracks critical variables like laser power stability, bending angles, and tool wear. In-line inspections at defined intervals, combined with automated vision systems for critical features, ensure continuous conformance. Our closed-loop system triggers immediate process correction at the first sign of drift, preventing non-conforming parts from progressing. Final inspection includes full dimensional reporting and batch traceability documentation, guaranteeing every shipped component meets the Zero Defects standard.

Our commitment is embedded in measurable capability. The table below details key production specifications underpinning this reliability:

| Parameter | Wuxi Lead Capability | Typical Industry Standard |

|---|---|---|

| Material Thickness | 0.5mm – 6.0mm | 0.8mm – 4.0mm |

| Tolerance (Bending) | ±0.05mm | ±0.2mm |

| Tolerance (Cutting) | ±0.02mm | ±0.1mm |

| Max. Part Size | 3000mm x 1500mm | 2000mm x 1000mm |

| Process Control | Real-time SPC + AI | Periodic Manual Checks |

This integrated Design-Prototype-Production flow, governed by our Zero Defects philosophy, eliminates costly rework and delays. Wuxi Lead delivers not just parts, but guaranteed performance and seamless integration into your assembly line, protecting your brand reputation and bottom line. Partner with us for sheet metal solutions where perfection is the only acceptable outcome.

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Unmatched Sheet Metal Fabrication Expertise

At Wuxi Lead Precision Machinery, we don’t just deliver parts—we deliver precision, reliability, and long-term value. As a global leader in high-end sheet metal fabrication, we specialize in turning complex engineering challenges into seamless manufacturing outcomes. Our clients across aerospace, medical, automation, and industrial equipment sectors rely on us not only for superior craftsmanship but also for a partnership built on transparency, responsiveness, and technical mastery.

When you choose to partner with Lead Precision, you gain access to a fully integrated manufacturing ecosystem. From initial design consultation to final assembly, our team ensures every component meets the most stringent quality standards. Our ISO 9001-certified processes, combined with state-of-the-art CNC technology, allow us to maintain tolerances down to ±0.05 mm across diverse materials including stainless steel, aluminum, carbon steel, and specialty alloys. Whether your project demands low-volume prototypes or high-volume production runs, our scalable infrastructure adapts to your needs without compromising consistency.

Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase, identifying opportunities to reduce cost, improve performance, and accelerate time to market. With in-house capabilities spanning laser cutting, CNC bending, robotic welding, and precision assembly, we eliminate supply chain dependencies and maintain full control over quality and delivery timelines.

We understand that in high-performance industries, a single component failure is not an option. That’s why every part we produce undergoes rigorous inspection using coordinate measuring machines (CMM), optical comparators, and material verification systems. Our traceability protocols ensure full documentation for every batch, providing peace of mind for regulated applications.

Below are key technical specifications that define our sheet metal fabrication capabilities:

| Specification | Capability |

|---|---|

| Material Thickness Range | 0.5 mm – 25 mm |

| Max Working Size | 4000 mm × 2000 mm |

| Tolerance | ±0.05 mm (standard), tighter upon request |

| Laser Cutting Accuracy | ±0.1 mm |

| Bending Tolerance | ±0.2° |

| Welding Processes | MIG, TIG, Spot, Robotic Welding |

| Surface Finishes | Bead blast, powder coating, anodizing, passivation |

| Quality Standards | ISO 9001:2015, ISO 14001, IATF 16949 (automotive) |

Partnering with Lead Precision means aligning with a manufacturer that prioritizes innovation, integrity, and precision. We are committed to being an extension of your engineering team—responsive, technically agile, and fully invested in your success.

For immediate assistance or to submit a project inquiry, contact us at [email protected]. Our engineering support team responds within 12 hours and is equipped to provide detailed feedback, DFM reports, and competitive pricing. Let’s build the future of precision manufacturing—together.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.