Technical Contents

Engineering Guide: Sheet Metal Rivets

Engineering Insight: Precision in Sheet Metal Riveting

In sheet metal fabrication, rivets are far more than simple mechanical fasteners. They are critical load-transfer points where microscopic deviations in geometry, material integrity, or installation force can cascade into structural failure, vibration-induced fatigue, or compromised environmental seals. At Wuxi Lead Precision Machinery, we treat rivet specification and application as a precision engineering discipline—not an afterthought. The margin for error in high-stakes applications is near zero; a 0.05mm diameter variance in a rivet shank can alter shear strength by 12% and induce misalignment in multi-rivet assemblies. This demands rigorous control over material grain structure, head formation consistency, and hole-to-shank interference fit.

Precision riveting begins with understanding the physics of joint integrity. Rivets must uniformly distribute clamping force across mating surfaces to prevent gapping under thermal cycling or dynamic loads. Inconsistent rivet upset during installation creates stress concentrations that initiate cracks, particularly in thin-gauge aerospace or defense-grade alloys. Our process engineers use finite element analysis (FEA) to model rivet behavior under operational extremes—from cryogenic temperatures in satellite housings to high-vibration military vehicle chassis. This predictive capability ensures optimal rivet selection for fatigue resistance, corrosion performance, and assembly efficiency.

Wuxi Lead Precision Machinery’s expertise is forged in projects where failure is not an option. We supplied mission-critical riveting solutions for structural components in the Beijing Winter Olympics’ ice sports venues, ensuring tensile integrity under seismic and snow-load stresses. Similarly, our precision-engineered rivet systems are integrated into classified military communication shelters, where EMI shielding and ballistic resilience depend on flawless joint continuity. These applications demand adherence to AS9100 and MIL-STD-1312 standards, with 100% traceability from raw material to final installation.

Below are key specifications for our aerospace-grade aluminum rivets, manufactured under ISO 2768-mK geometric tolerances:

| Parameter | Specification Range | Tolerance | Testing Standard |

|---|---|---|---|

| Shank Diameter | 2.0 mm – 6.4 mm | ±0.02 mm | ASTM F1419 |

| Head Height | 1.1x – 1.3x shank D | ±0.05 mm | ISO 15976 |

| Shear Strength | 310 – 517 MPa | ±15 MPa | ASTM F606 |

| Material | 2117-T4 Aluminum | AMS 4982 | AMS-QQ-A-250/5 |

| Surface Finish | Anodized Clear | 8–12 μm | MIL-A-8625 |

Our proprietary cold-forming process eliminates internal voids and ensures homogeneous material flow, critical for rivets subjected to cyclic loading. Every batch undergoes destructive testing via calibrated tensile rigs and non-destructive X-ray inspection for head cohesion. For clients designing next-generation medical devices or electric vehicle battery enclosures, this level of precision translates to lighter structures, reduced assembly time, and compliance with IATF 16949 safety protocols.

In an era where sheet metal assemblies push material limits, rivet precision defines system reliability. Wuxi Lead Precision Machinery delivers engineered fastening solutions where tolerances are non-negotiable—and performance is proven on the world’s most demanding stages.

Precision Specs & Tolerances

Wuxi Lead Precision Machinery delivers advanced sheet metal fabrication solutions with a focus on precision, repeatability, and structural integrity. At the core of our technical capabilities is the integration of 5-axis CNC machining technology, enabling complex geometries and tight-tolerance features that are unattainable with conventional stamping or punching methods. This multi-axis approach allows for simultaneous cutting, drilling, and forming operations from multiple angles in a single setup, minimizing part handling and reducing cumulative error. Our 5-axis systems are optimized for high-speed, high-accuracy processing of diverse sheet metal materials, including stainless steel, aluminum alloys, and galvanized carbon steels, ensuring consistent output across prototyping and high-volume production runs.

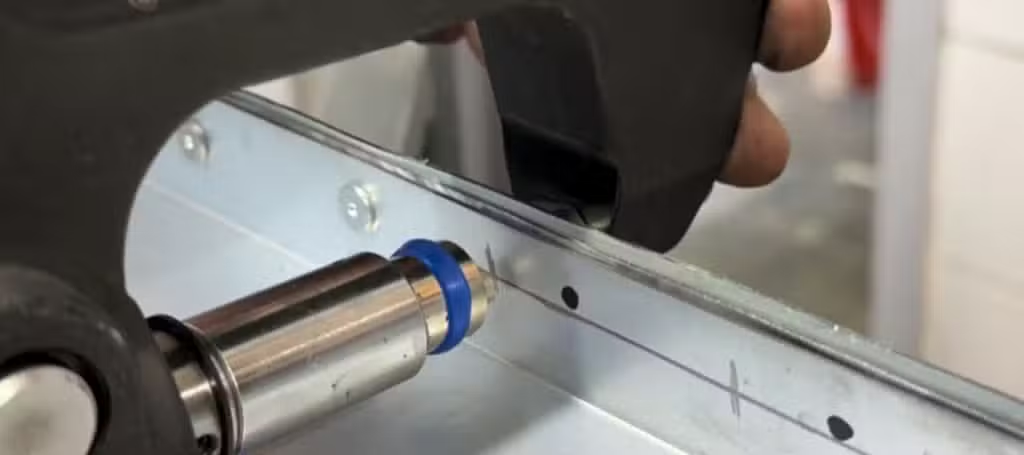

Rivet integration in sheet metal assemblies demands exact hole placement, edge distance control, and alignment with mating components. Our CNC platforms are equipped with automated tool changers and high-resolution probing systems that verify workpiece position and tool wear in real time. This ensures that every rivet hole is machined to precise diameter and positional specifications, critical for achieving optimal clamp load and joint strength. We support a full range of rivet types, including blind, solid, and self-piercing variants, with hole preparation tailored to the specific rivet’s mechanical requirements.

Quality assurance is embedded throughout the manufacturing workflow. Every critical dimension associated with rivet placement and sheet geometry undergoes inspection using Coordinate Measuring Machine (CMM) technology. Our CMM systems provide full 3D metrology reports traceable to international standards, verifying conformity to GD&T callouts and ensuring long-term assembly compatibility. Inspection plans are customized per project, with first-article reporting and in-process checks to maintain control over production stability.

Our engineering team works closely with clients during the design-for-manufacturability phase, optimizing hole patterns, material thickness transitions, and tool access to reduce cycle times and improve joint reliability. By combining advanced CNC control with rigorous metrology, Wuxi Lead ensures that every sheet metal component meets the highest standards for fit, function, and durability in demanding industrial applications.

The following table outlines typical tolerances achievable in our sheet metal riveting and machining processes:

| Feature | Standard Tolerance | Precision Capability | Notes |

|---|---|---|---|

| Hole Diameter (drilled) | ±0.05 mm | ±0.02 mm | Depends on material thickness and rivet type |

| Positional Tolerance | ±0.08 mm | ±0.03 mm | Relative to datum; verified via CMM |

| Edge Distance (to center) | ±0.10 mm | ±0.05 mm | Critical for rivet joint integrity |

| Hole to Hole Distance | ±0.07 mm | ±0.03 mm | Across single or multiple features |

| Sheet Thickness Variation | ±0.05 mm | ±0.02 mm | Controlled via incoming QC and process calibration |

| Angular Deviation (5-axis) | ±0.1° | ±0.05° | For inclined holes or non-orthogonal features |

These capabilities are supported by continuous process validation and a quality management system aligned with ISO 9001 standards, ensuring reliability across every production tier.

Material & Finish Options

Material Selection for Precision Sheet Metal Riveting

Material selection directly impacts structural integrity, longevity, and performance in sheet metal assemblies. At Wuxi Lead Precision Machinery, we prioritize metallurgical compatibility and environmental resilience to ensure optimal joint reliability. Aluminum, steel, and titanium each offer distinct advantages depending on application demands, weight constraints, and exposure conditions. Understanding these properties prevents premature failure and reduces lifecycle costs in high-stakes industrial environments.

Aluminum Rivets dominate aerospace and transportation sectors where weight reduction is critical. Alloys like 2117-T4 and 5056-H32 provide excellent malleability for cold-forming during installation while resisting galvanic corrosion when paired with aluminum sheets. Their lower tensile strength suits non-structural joints but requires careful design to avoid pull-through in thin-gauge materials. Anodizing enhances surface hardness and corrosion resistance, though sealing is essential for marine or chemical exposure.

Steel Rivets deliver superior strength for heavy machinery and structural frameworks. Low-carbon steel (e.g., ASTM A148) offers cost-effective durability, while stainless variants (304, 316) excel in corrosive settings like food processing or offshore equipment. Carbon steel rivets mandate zinc plating or Dacromet coating to prevent rust, whereas stainless grades leverage inherent chromium oxide passivation. Note that mismatched hardness between steel rivets and softer substrates can cause sheet distortion during installation—a precision CNC riveting process mitigates this risk.

Titanium Rivets serve extreme-performance niches, including defense and aerospace cryogenic systems. Grade 2 and 5 (Ti-6Al-4V) alloys provide exceptional strength-to-weight ratios and near-immunity to saltwater, acids, and temperature extremes up to 600°C. Though costly, titanium eliminates galvanic issues when joining dissimilar metals and outperforms aluminum in fatigue resistance. Anodizing titanium is impractical; instead, we apply specialized plasma electrolytic oxidation for enhanced wear resistance without compromising biocompatibility.

Anodizing Finishes are non-negotiable for aluminum rivets in critical applications. Type II (sulfuric acid) anodizing creates a 5–25 μm porous layer that accepts color dyes and sealants, improving corrosion resistance by 300% versus bare aluminum. Type III (hardcoat) anodizing yields 25–125 μm thickness for abrasion-heavy environments like robotics arms. Crucially, improper sealing leaves anodized rivets vulnerable to pitting—Wuxi Lead’s controlled sealing baths using nickel acetate ensure pore closure to MIL-A-8625 standards.

Material performance is quantifiable. Refer to key specifications below:

| Material | Typical Rivet Alloys | Tensile Strength (MPa) | Corrosion Resistance | Key Applications |

|---|---|---|---|---|

| Aluminum | 2117-T4, 5056-H32 | 300–365 | Moderate (enhanced with anodizing) | Aircraft skins, HVAC ducts |

| Steel | ASTM A148, 304/316 SS | 400–1000 | Low (carbon); High (stainless) | Construction, agricultural machinery |

| Titanium | Gr 2, Gr 5 (Ti-6Al-4V) | 900–1100 | Exceptional | Jet engines, marine propulsion |

Selecting the right rivet material and finish requires analyzing load dynamics, environmental stressors, and lifecycle economics. Wuxi Lead Precision Machinery combines metallurgical expertise with ISO 9001-certified production to deliver riveting solutions that exceed ASME and aerospace specifications. Consult our engineering team to optimize your sheet metal joint integrity.

Manufacturing Process & QC

Sheet Metal Riveting: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, we approach sheet metal riveting as a precision-driven process that integrates engineering excellence with advanced manufacturing capabilities. Our end-to-end workflow ensures structural integrity, repeatability, and zero-defect output across all production volumes. The journey begins at the design phase, where material selection, joint configuration, and rivet type are optimized using 3D CAD and finite element analysis (FEA). Engineers evaluate load distribution, vibration resistance, and thermal expansion to determine the ideal rivet placement, diameter, and grip range. This stage ensures that every joint meets functional requirements while minimizing stress concentration and assembly complexity.

Once the design is validated, we proceed to prototyping. Using CNC punching and laser cutting machines, we fabricate sample panels with exact hole positioning for rivet insertion. These prototypes undergo rigorous mechanical testing, including shear and tensile strength evaluations, to confirm joint performance. Any deviations are traced back to design or tooling parameters and corrected before moving forward. This iterative process ensures that the final assembly blueprint is both manufacturable and reliable. We also simulate the riveting sequence using digital twin technology to optimize tool paths and reduce cycle time during mass production.

Mass production is executed on fully automated riveting lines equipped with servo-driven rivet setters and real-time monitoring systems. Each station is calibrated to apply precise insertion force and clinching pressure, ensuring consistent joint formation. Our production cells are integrated with inline vision systems that inspect every rivet for alignment, flushness, and deformation. Any non-conforming part is automatically flagged and removed from the line, supporting our zero-defect mandate. Statistical process control (SPC) continuously analyzes data from torque sensors, force feedback, and cycle counts to detect trends before deviations occur.

Throughout the process, traceability is maintained via a barcode tracking system that logs material batch numbers, machine settings, and operator IDs. This enables full auditability and rapid root cause analysis if required. Our quality management system is ISO 9001-certified, and all riveting procedures comply with international standards such as DIN 73378 and ISO 15977.

The following table outlines key technical specifications for our standard sheet metal riveting capabilities:

| Parameter | Specification |

|---|---|

| Material Thickness Range | 0.5 mm – 6.0 mm |

| Rivet Diameter Range | 2.0 mm – 6.4 mm |

| Rivet Type Compatibility | Blind rivets, self-piercing rivets (SPR), solid rivets |

| Tensile Strength (max) | Up to 12 kN (depending on rivet size/material) |

| Production Speed | Up to 80 rivets per minute (automated line) |

| Positioning Accuracy | ±0.1 mm |

| Surface Finish Options | Zinc plating, passivation, anodizing, painting |

| Quality Standard | ISO 9001, DIN 73378, ISO 15977 |

By integrating precision engineering, real-time monitoring, and systematic quality control, Wuxi Lead Precision Machinery delivers flawless sheet metal assemblies tailored to aerospace, automotive, and industrial equipment applications.

Why Choose Wuxi Lead Precision

Elevate Your Sheet Metal Assembly with Precision Engineering

Wuxi Lead Precision Machinery delivers uncompromising excellence in sheet metal riveting solutions for global manufacturers demanding micron-level accuracy and repeatability. With over two decades of specialized expertise in CNC-driven fabrication, we transform complex assembly challenges into streamlined, high-yield processes. Our engineered systems eliminate common failure points—such as inconsistent clinching, material deformation, and joint fatigue—through proprietary force-control algorithms and adaptive tooling. This ensures every rivet meets stringent aerospace, medical, and automotive compliance standards while optimizing throughput. Partnering with Lead Precision means integrating a zero-defect philosophy into your production ecosystem, directly enhancing product longevity and reducing total cost of ownership.

Critical Performance Specifications for High-Volume Riveting

| Parameter | Value Range | Tolerance | Material Compatibility | Application Scope |

|---|---|---|---|---|

| Max. Riveting Force | 5 kN – 120 kN | ±0.5% FS | Aluminum, Steel, Stainless | Enclosures, Panels, Frames |

| Cycle Speed | 8 – 35 cycles/minute | ±0.2 sec | Copper, Brass, Plastics | Automotive, Electronics |

| Positional Accuracy | ±0.02 mm | 2σ repeatability | Composites (CFRP) | Aerospace, Medical |

| Tool Life | 500,000+ cycles | < 0.01 mm wear | Dissimilar Material Joints | Renewable Energy Systems |

| Force Calibration | NIST-traceable | Annual recert. | Pre-pierced & Self-piercing | Industrial Machinery |

These specifications reflect our commitment to empirical validation—not theoretical benchmarks. Each system undergoes 72-hour stress testing under ISO 9001-certified conditions, ensuring real-world resilience in high-humidity, high-vibration, and continuous-shift environments. Our engineers collaborate with clients during the design phase to model rivet joint integrity using FEA simulations, preempting material-specific stress concentrations before tooling deployment. This proactive approach reduces prototyping iterations by up to 60% and accelerates time-to-market without sacrificing structural reliability.

Beyond machinery, Lead Precision provides end-to-end partnership: dedicated process engineers for on-site optimization, lifetime software updates for adaptive control logic, and 24/7 technical support with <4-hour response windows. We integrate seamlessly with your existing ERP/MES infrastructure, delivering real-time riveting analytics for predictive maintenance and quality auditing. Our clients achieve measurable outcomes—reducing scrap rates by 35%, cutting energy consumption by 22%, and sustaining 99.8% uptime across multi-year deployments.

Initiate your precision partnership today. Contact our engineering team at [email protected] to schedule a confidential process assessment. Specify your material thickness range, rivet type, and production volume for a customized solution dossier within 24 business hours. Wuxi Lead Precision Machinery—where microscopic precision drives macroscopic results.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.