Technical Contents

Engineering Guide: Sheet Metal Rapid Prototyping

Engineering Insight: Precision as the Non-Negotiable Core of Sheet Metal Rapid Prototyping

In the high-stakes realm of sheet metal product development, rapid prototyping transcends mere speed. Its true value lies in delivering geometrically accurate, functionally representative parts that reliably validate design intent before committing to costly production tooling. Precision is not an optional feature; it is the foundational requirement determining whether a prototype provides actionable engineering data or misleading results. Sub-millimeter deviations in critical features, inconsistent bends, or surface imperfections introduced during prototyping directly translate to performance failures, assembly issues, or safety risks in the final product. For industries like aerospace, medical devices, and advanced automation, where regulatory compliance and operational integrity are paramount, tolerances must be held consistently across every prototype iteration. This demands more than just fast machinery; it requires deep process understanding, rigorous material science knowledge, and unwavering commitment to dimensional control from the initial flat pattern through forming, cutting, and finishing.

Wuxi Lead Precision Machinery operates at this precision frontier daily. Our engineering team’s expertise is forged not only through standard commercial projects but through the exacting demands of Tier-1 defense contractors and critical infrastructure for global events like the Beijing Winter Olympics. Prototyping components for military vehicle subsystems necessitates adherence to MIL-STD tolerances under extreme environmental validation, while Olympic venue structural elements required flawless dimensional repeatability across thousands of unique parts under intense schedule pressure. These experiences instill a culture where every prototype is treated as a pre-production validation step, not merely a visual model. We implement comprehensive in-process inspection protocols using calibrated CMMs and laser trackers, coupled with advanced geometric dimensioning and tolerancing (GD&T) analysis, ensuring that the physical prototype is a true digital twin. This meticulous approach eliminates costly design re-spins and accelerates the path from concept to certified production.

Our rapid prototyping capabilities are engineered specifically to meet these high-precision demands within accelerated timelines. The table below details our core technical specifications for sheet metal prototyping:

ENGINEERING SPECIFICATIONS FOR RAPID PROTOTYPING

| Parameter | Capability Range | Key Technology/Process |

|---|---|---|

| Material Thickness | 0.5mm – 6.0mm (Stainless, Al, Steel) | Laser/Punch Combi Systems |

| Tolerance (Form) | ±0.05mm (Critical Features) | CNC Press Brakes w/ Crowning |

| Tolerance (Hole) | ±0.03mm (Positional) | Multi-Station Turret Punching |

| Max. Part Size | 1500mm x 3000mm | 4kW Fiber Laser Cutting |

| Typical Turnaround | 3-7 Business Days (Complex Assemblies) | Integrated CAD/CAM Workflow |

This precision-centric methodology transforms rapid prototyping from a simple model-making exercise into a strategic risk mitigation tool. By guaranteeing that prototypes accurately reflect the intended production geometry and material behavior, Wuxi Lead Precision Machinery enables our clients to make confident engineering decisions, reduce time-to-market significantly, and achieve first-article success in final production. In sheet metal development, true speed is achieved only when precision is never compromised.

Precision Specs & Tolerances

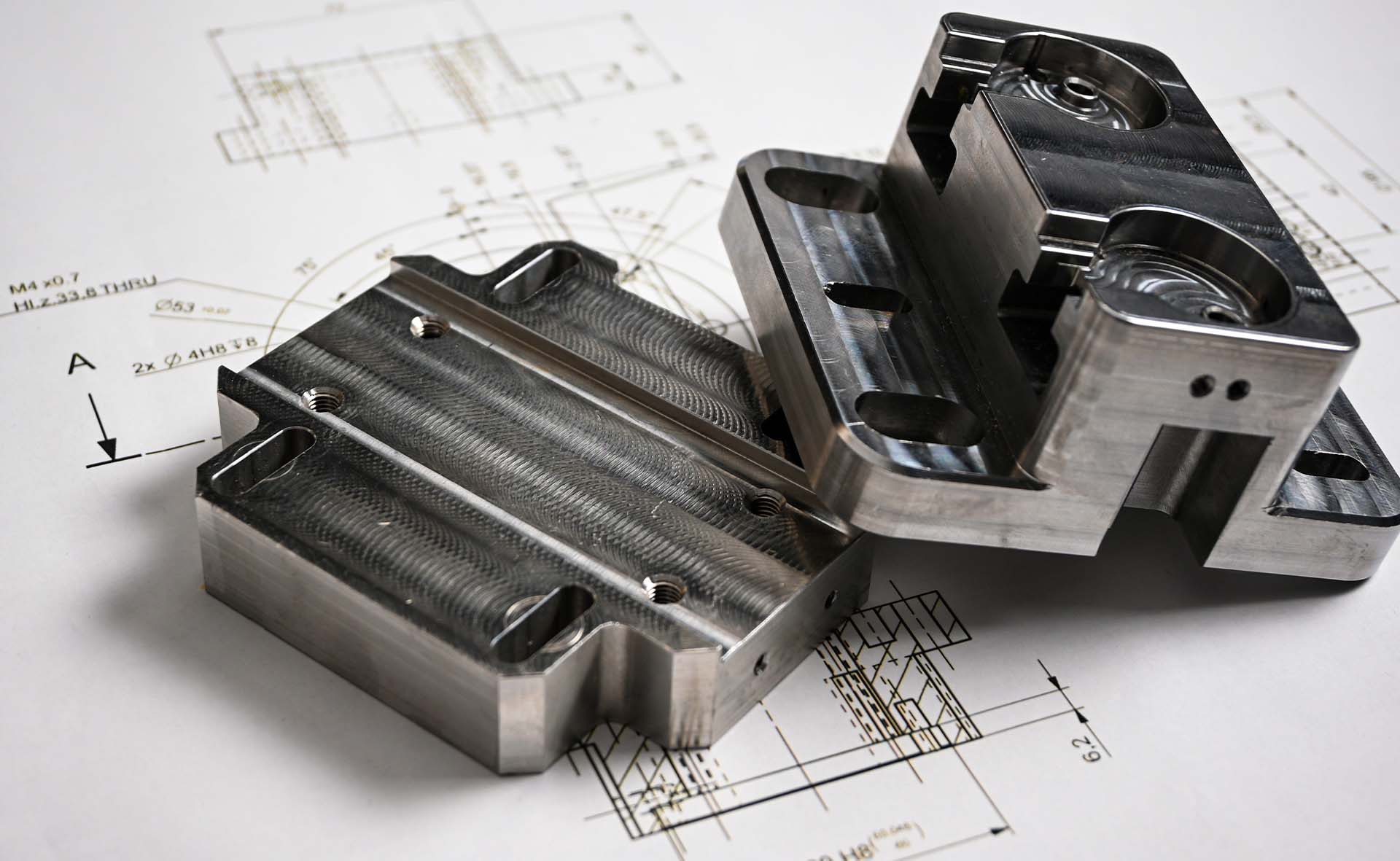

Wuxi Lead Precision Machinery delivers advanced sheet metal rapid prototyping services engineered for precision, speed, and repeatability. Our technical capabilities are built around state-of-the-art 5-axis CNC machining systems, enabling complex geometries and high accuracy in prototype development. These multi-axis platforms allow simultaneous movement across five planes, minimizing setup changes and ensuring tight alignment across intricate features. This capability is particularly critical in aerospace, medical, and industrial automation sectors, where form, fit, and function must be validated with production-intent accuracy during the prototyping phase.

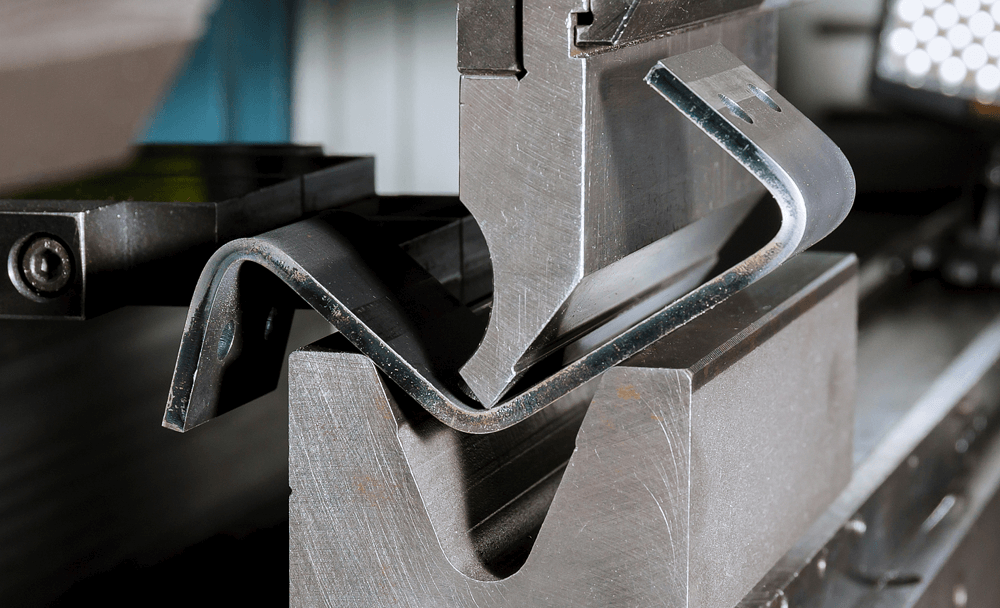

Our sheet metal processing includes laser cutting, precision bending, CNC punching, and automated welding—each integrated within a streamlined workflow optimized for rapid turnaround without compromising quality. The use of 5-axis CNC technology supports the fabrication of non-orthogonal bends, compound angles, and deep-draw features that are otherwise unattainable with conventional 3-axis systems. This level of flexibility ensures that design intent is preserved from CAD model to physical part, reducing the need for design compromises during early-stage development.

Quality assurance is embedded throughout the prototyping process. Every component undergoes rigorous inspection using a Coordinate Measuring Machine (CMM), providing traceable, high-resolution metrology data. CMM inspection validates geometric dimensioning and tolerancing (GD&T), surface profiles, and critical feature alignments in full compliance with ISO 10360 standards. This metrology-grade verification ensures that prototypes meet functional testing requirements and serve as reliable benchmarks for downstream production tooling.

Material versatility is another cornerstone of our technical offering. We process a wide range of sheet metals including aluminum alloys (e.g., 5052, 6061, 7075), stainless steels (304, 316), cold-rolled steel (CRS), and specialty alloys such as titanium and copper. Sheet thicknesses from 0.5 mm to 6.0 mm are supported with consistent edge quality and minimal deformation. Surface finishing options—including deburring, anodizing, powder coating, and passivation—are available to meet both functional and aesthetic specifications.

The following table outlines our standard technical specifications and achievable tolerances for sheet metal rapid prototyping:

| Parameter | Standard Capability | Tight Tolerance Option |

|---|---|---|

| Minimum Bend Radius | 1.0 x material thickness | 0.5 x material thickness |

| Hole Diameter (punched) | ≥ 1.0 mm | ≥ 0.8 mm |

| Hole Diameter (laser) | ≥ 0.5 mm | ≥ 0.3 mm |

| Part Flatness Tolerance | ±0.1 mm per 100 mm | ±0.05 mm per 100 mm |

| Edge Straightness | ±0.15 mm | ±0.1 mm |

| Hole-to-Hole Positional Tol | ±0.1 mm | ±0.05 mm |

| Bend Angle Accuracy | ±0.5° | ±0.25° |

| Overall Dimensional Tolerance | ±0.2 mm | ±0.1 mm |

| Surface Roughness (machined) | Ra 3.2 µm | Ra 1.6 µm |

All prototypes are manufactured under ISO 9001-certified processes, ensuring consistency, traceability, and full documentation upon request. Wuxi Lead Precision Machinery combines advanced hardware, metrology-grade inspection, and deep process expertise to deliver rapid prototypes that accelerate product development cycles while maintaining production-grade fidelity.

Material & Finish Options

Material Selection for Sheet Metal Rapid Prototyping: Critical Engineering Considerations

Selecting the optimal material for sheet metal rapid prototyping is a foundational engineering decision directly impacting prototype functionality, manufacturability, cost, and timeline. At Wuxi Lead Precision Machinery, our decades of precision fabrication experience underscore that material choice must align with the prototype’s intended application, environmental exposure, mechanical requirements, and finish specifications. Misalignment here often leads to costly redesigns or extended development cycles. Aluminum alloys, stainless steels, and titanium represent the core high-performance options, each offering distinct advantages and constraints for rapid iteration.

Aluminum, particularly 6061-T6 and 7075-T6, dominates rapid prototyping due to its exceptional strength-to-weight ratio, excellent machinability, and inherent corrosion resistance. Its lower density significantly reduces part weight, crucial for aerospace and mobility applications. Aluminum readily accepts anodizing, enhancing surface durability and enabling color coding. While 6061 offers superior weldability and general-purpose performance, 7075 provides higher strength for critical structural components, albeit with slightly reduced corrosion resistance and higher cost. Aluminum’s thermal conductivity also aids in heat dissipation during functional testing.

Stainless steel, primarily grades 304 and 316, is indispensable when superior strength, high-temperature resistance, or exceptional corrosion resistance in harsh environments (e.g., medical, marine, chemical) is paramount. Grade 304 offers a balanced combination of formability, weldability, and corrosion resistance for most industrial applications. Grade 316, with added molybdenum, provides enhanced resistance to chlorides and acids, making it suitable for marine and pharmaceutical uses. Stainless steel prototypes maintain dimensional stability under load and temperature extremes but are denser and more challenging to machine than aluminum, potentially affecting lead times for complex geometries.

Titanium alloys, such as Grade 2 and 6Al-4V (Grade 5), are reserved for the most demanding applications requiring the ultimate strength-to-weight ratio, extreme corrosion resistance (especially in saltwater), and biocompatibility. Its use is common in aerospace, defense, and medical implant prototyping. However, titanium’s high cost, significant machining difficulty due to low thermal conductivity and work hardening, and specialized welding requirements substantially increase prototype cost and lead time. Its application should be rigorously justified by performance requirements exceeding aluminum or steel capabilities.

The following table summarizes key comparative properties for rapid prototyping selection:

| Material | Key Alloys | Density (g/cm³) | Tensile Strength (MPa) | Corrosion Resistance | Machinability Rating |

|---|---|---|---|---|---|

| Aluminum | 6061-T6, 7075-T6 | 2.7 | 310-570 | Good (Anodized: Excellent) | Excellent |

| Stainless Steel | 304, 316 | 8.0 | 515-690 | Excellent | Moderate to Good |

| Titanium | Gr 2, Gr 5 (6Al-4V) | 4.5 | 345-900 | Exceptional | Poor |

Surface finish, particularly anodizing for aluminum, is integral to material performance. Type II (Sulfuric Acid) anodizing provides good corrosion and wear resistance with dyeing capability. Type III (Hardcoat) anodizing delivers superior abrasion resistance and thickness for functional prototypes subjected to wear. Wuxi Lead’s integrated anodizing lines ensure precise control over coating thickness, hardness, and color consistency, critical for validating final part performance. Material selection is never one-size-fits-all; it requires balancing performance needs against prototyping speed and cost. Our engineering team collaborates closely with clients to select the optimal material-finish combination, ensuring your rapid prototype accurately mirrors final production intent and accelerates time-to-market.

Manufacturing Process & QC

Sheet Metal Rapid Prototyping: From Design to Zero-Defect Mass Production

At Wuxi Lead Precision Machinery, our sheet metal rapid prototyping process is engineered for precision, speed, and flawless scalability. We integrate advanced manufacturing technologies with rigorous quality control to ensure a seamless transition from initial design to full-scale production—every component meets exact specifications with zero defects.

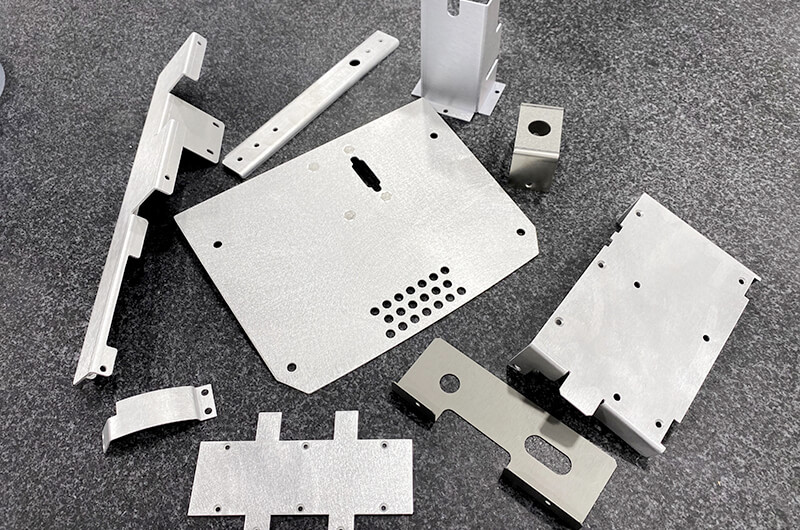

The process begins with design validation. Our engineering team collaborates with clients to review CAD models, assess material suitability, and optimize for manufacturability. Using 3D modeling and simulation software, we identify potential structural or fabrication challenges early, reducing rework and accelerating time to prototype. Material selection—ranging from cold-rolled steel and aluminum to stainless steel and galvanized alloys—is finalized based on application requirements such as strength, corrosion resistance, and environmental exposure.

Next, we move to rapid prototyping. Utilizing high-precision CNC turret punching, laser cutting, and press braking, we produce functional prototypes within 3–7 days. These prototypes are not mockups but fully operational parts, built to mirror final production quality. Each prototype undergoes dimensional inspection using coordinate measuring machines (CMM) and first-article testing to verify compliance with geometric dimensioning and tolerancing (GD&T) standards. This stage ensures form, fit, and function align with design intent before any production launch.

Once approved, we transition to zero-defect mass production. Our automated production lines leverage Industry 4.0 principles, integrating real-time monitoring and statistical process control (SPC) to detect deviations instantly. Every stage—cutting, bending, welding, surface finishing, and assembly—is governed by documented quality checkpoints. In-process inspections, combined with final QA audits, guarantee consistency across batches. Our ISO 9001-certified workflow eliminates variability, ensuring every unit performs identically to the approved prototype.

Throughout the entire process, traceability is maintained via digital work orders and batch tracking. Any non-conformance triggers immediate root cause analysis and corrective action, preventing recurrence. This closed-loop quality system is the foundation of our zero-defect commitment.

| Specification | Capability |

|---|---|

| Material Thickness | 0.5 mm – 4.0 mm |

| Tolerance (Standard) | ±0.1 mm (bending), ±0.05 mm (cutting) |

| Minimum Hole Diameter | 1.0 mm (steel), 0.8 mm (aluminum) |

| Max Part Size | 1500 mm × 3000 mm |

| Surface Roughness (Ra) | ≤1.6 µm (after finishing) |

| Lead Time (Prototype) | 3–7 working days |

| Production Capacity | Up to 50,000 units/month |

| Quality Standards | ISO 9001, GD&T ASME Y14.5 |

Our integrated approach ensures that design integrity is preserved from concept to volume output. At Wuxi Lead, rapid prototyping is not just about speed—it’s about building perfection into every phase of production.

Why Choose Wuxi Lead Precision

Elevate Your Product Development Cycle with Precision Engineering

In the competitive landscape of advanced manufacturing, rapid prototyping is not merely a phase—it is the critical pivot point between concept validation and scalable production. Delays or inaccuracies here cascade into costly redesigns, missed market windows, and eroded ROI. Wuxi Lead Precision Machinery exists to eliminate these risks. As your dedicated partner in sheet metal rapid prototyping, we merge German-engineered machinery with ISO 9001-certified processes to deliver functional prototypes that mirror production intent with zero compromise. Our facility in Wuxi operates under stringent environmental controls, ensuring dimensional stability and material integrity from the first cut to final surface treatment. This precision accelerates your time-to-market while de-risking the transition to volume manufacturing.

Our technical capabilities are engineered for complexity. The table below details how Lead Precision outperforms industry benchmarks in critical prototyping parameters:

| Specification | Lead Precision Standard | Industry Typical |

|---|---|---|

| Lead Time | 72 hours | 5–7 business days |

| Geometric Tolerance | ±0.05 mm | ±0.1–0.2 mm |

| Material Range | Steel, Aluminum, Copper, Brass, Exotic Alloys | Limited to common grades |

| Max. Part Size | 3000 × 1500 × 3 mm | 2000 × 1000 × 2 mm |

| Surface Finishes | Anodizing, Powder Coat, Passivation, Brushing | Basic options only |

This performance stems from our integrated workflow: your CAD files undergo automated manufacturability analysis within 2 hours of submission, followed by laser cutting on Bystronic systems with 0.01 mm repeatability. CNC bending utilizes AMADA EG-6014R press brakes with real-time springback compensation, while robotic welding ensures joint integrity for structural prototypes. Every component undergoes CMM validation against your original specifications—no assumptions, no approximations.

When prototyping demands intersect with urgent commercial timelines, generic suppliers falter. We succeed by treating your prototype as the blueprint for success. Our engineering team collaborates directly with your R&D staff to resolve design ambiguities pre-production, preventing iterations that stall progress. This proactive partnership reduces prototype rejection rates by up to 65% compared to transactional vendors.

Your next breakthrough prototype requires a partner who views precision as non-negotiable. Contact us today to activate a streamlined prototyping workflow where speed never sacrifices accuracy. Email [email protected] with your project specifications and timeline. Within 4 business hours, our application engineers will respond with a detailed process plan—including DFM feedback, material sourcing strategy, and exact delivery commitment. Do not let prototyping bottlenecks constrain your innovation. Partner with Lead Precision: where engineering rigor meets rapid execution.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.