Technical Contents

Engineering Guide: Sheet Metal Punching Machine

Engineering Insight: The Critical Role of Precision in Sheet Metal Punching Machines

In the world of high-end sheet metal fabrication, precision is not merely a performance metric—it is the foundation upon which quality, efficiency, and reliability are built. At Wuxi Lead Precision Machinery, we understand that even the smallest deviation in hole placement, edge alignment, or dimensional tolerance can cascade into costly rework, assembly failures, or compromised product integrity. This is especially critical in industries such as aerospace, defense, telecommunications, and precision instrumentation, where components must meet exacting standards and operate under extreme conditions.

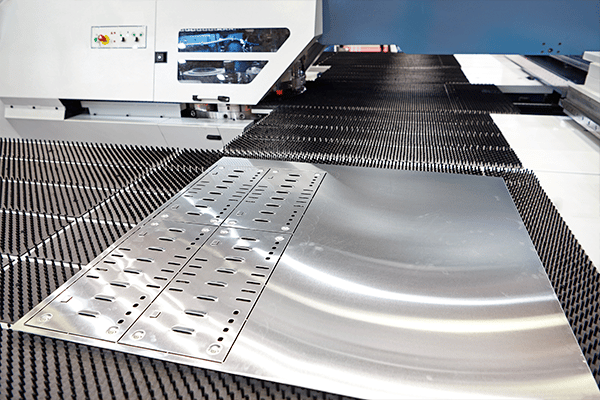

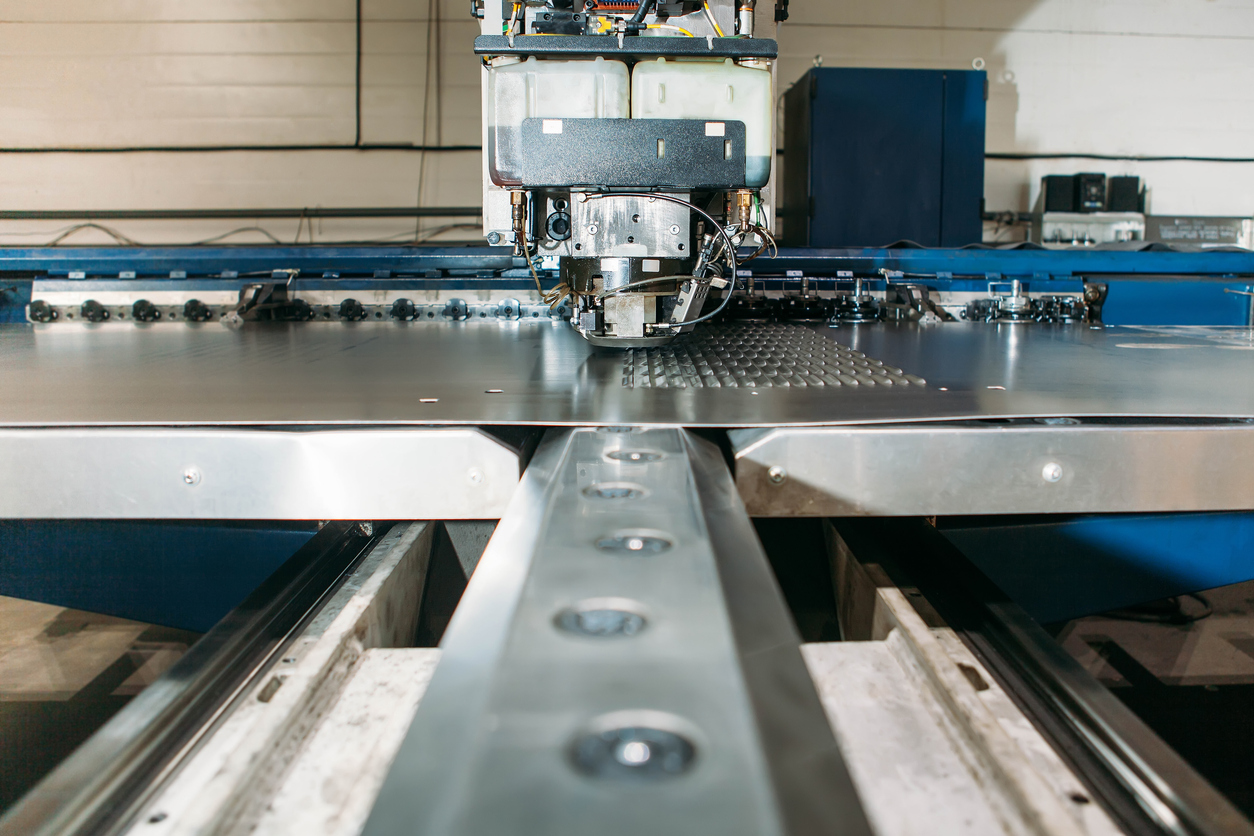

Sheet metal punching machines serve as the backbone of modern fabrication lines, enabling rapid, repeatable creation of complex geometries in metal sheets. However, the true measure of a punching machine lies not in its speed alone, but in its ability to maintain micron-level accuracy across thousands of strokes. Precision in punching ensures consistent hole diameter, burr-free edges, and perfect registration with secondary operations such as bending, welding, or coating. It also enables tighter nesting of parts, reducing material waste and improving yield—key factors in cost-sensitive, high-volume production environments.

At Wuxi Lead, our engineering philosophy is rooted in decades of refining mechanical accuracy, control stability, and structural rigidity. Our CNC turret punching machines are engineered with high-grade cast iron frames, precision-ground linear guides, and servo-electric or hydraulic hybrid drive systems that eliminate backlash and thermal drift. These design elements ensure long-term repeatability, even under continuous industrial operation.

Our commitment to precision is validated through real-world applications. Wuxi Lead machines have contributed to projects demanding the highest reliability, including components used in Olympic-standard sports equipment and mission-critical military hardware. These applications required not only adherence to ISO and GB standards but also zero-defect performance under rigorous third-party inspection. Our machines consistently delivered tolerances within ±0.05 mm, a testament to our engineering rigor and quality control.

We believe that true precision is not achieved through specifications alone, but through a holistic approach—integrating advanced mechanics, intelligent software, and robust manufacturing culture. Every machine we produce undergoes a 72-hour continuous load test, laser alignment verification, and dynamic performance calibration before shipment.

Below are key technical specifications that define the precision capabilities of our flagship CNC punching machines:

| Parameter | Specification |

|---|---|

| Positioning Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Maximum Punching Force | 300 kN |

| Table Size | 1270 mm × 2540 mm |

| Tool Stations | Up to 36 (Automatic Indexing) |

| Control System | Siemens or Delem CNC (Optional) |

| Stroke Rate (Max) | 600 strokes per minute |

| Material Thickness Range | 0.5 – 6.0 mm (Mild Steel) |

| Tool Life Monitoring | Integrated Sensor System |

Precision in sheet metal punching is not an optional upgrade—it is a non-negotiable standard. At Wuxi Lead Precision Machinery, we engineer every machine to exceed this standard, delivering performance trusted by industries where failure is not an option.

Precision Specs & Tolerances

Technical Capabilities: Precision Sheet Metal Punching

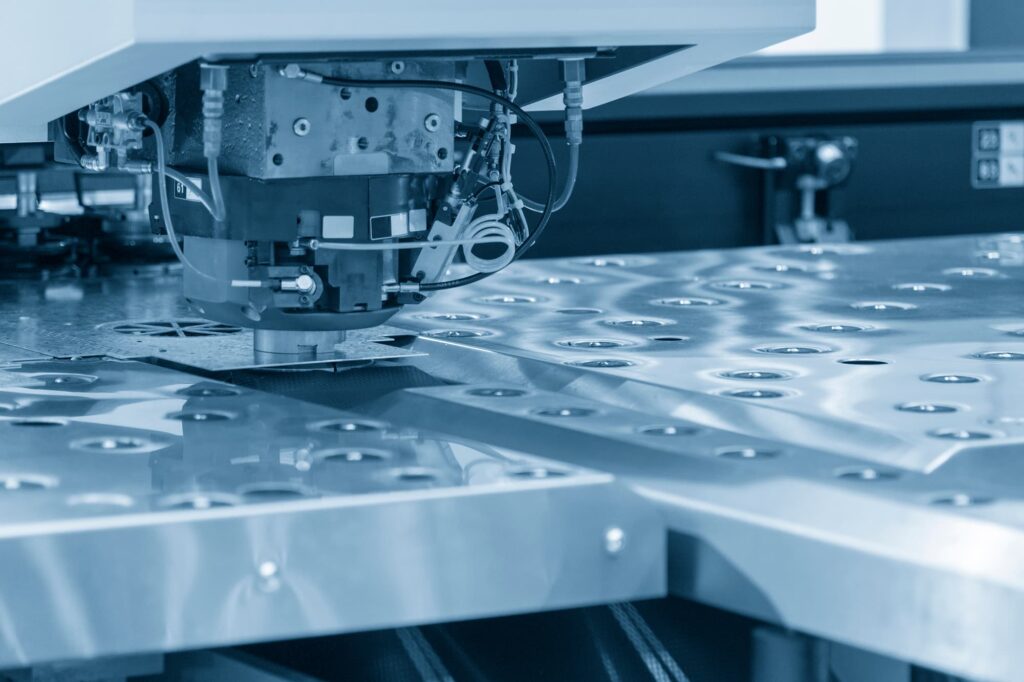

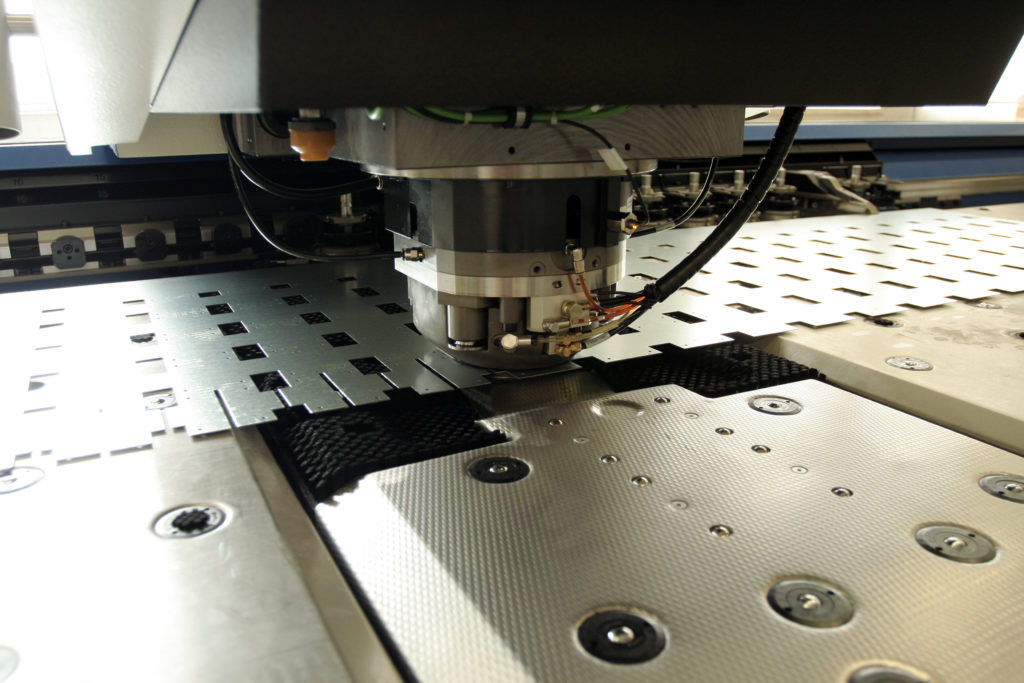

Wuxi Lead Precision Machinery delivers uncompromising accuracy and versatility in sheet metal fabrication through our advanced 5-axis CNC punching systems. These machines integrate multi-directional tooling, dynamic material handling, and real-time adaptive control to execute complex geometries on materials ranging from 0.5 mm to 6.0 mm thickness. Our capabilities extend beyond standard punching to include embossing, tapping, shearing, and forming operations within a single setup, eliminating secondary processes and reducing cumulative error. The 5-axis architecture enables simultaneous rotation and linear movement, allowing intricate 3D contours and off-center features that conventional 3-axis systems cannot achieve. This translates to reduced lead times for prototypes and production runs while maintaining strict adherence to geometric dimensioning and tolerancing (GD&T) requirements.

Critical to our process integrity is the seamless integration of Coordinate Measuring Machine (CMM) inspection at defined production milestones. Every component undergoes 100% first-article verification and statistical process control (SPC) sampling against CAD models. This closed-loop quality assurance ensures dimensional stability across batches, with deviations immediately corrected via machine calibration feedback. Our CMM systems, certified to ISO 10360-2 standards, validate features down to ±0.002 mm, providing clients with certified inspection reports traceable to NIST standards. This rigorous protocol minimizes scrap rates and guarantees that parts meet aerospace, medical, and industrial equipment specifications without rework.

Material compatibility spans carbon steel, stainless steel (including 304/316), aluminum alloys, and copper, processed under optimized lubrication and tool-path strategies to prevent burring or distortion. High-speed turret tooling with 60+ station capacity supports rapid feature sequencing, while automatic tool changers maintain throughput for mixed-part production. The machines’ rigid construction and thermal compensation systems ensure micron-level repeatability even during extended operations, critical for high-mix, low-volume manufacturing environments.

Precision Tolerance Specifications

| Feature Type | Standard Tolerance | Tight Tolerance Option | Measurement Method |

|---|---|---|---|

| Hole Positioning | ±0.05 mm | ±0.02 mm | CMM (100% first article) |

| Hole Diameter | ±0.08 mm | ±0.03 mm | Optical Comparator |

| Feature-to-Feature | ±0.07 mm | ±0.03 mm | CMM (SPC sampling) |

| Flatness (per 100 mm) | 0.10 mm | 0.05 mm | Granite Surface Plate |

| Edge Straightness | 0.15 mm | 0.07 mm | Laser Tracker |

This technical foundation enables clients to realize designs previously constrained by traditional punching limitations. By combining 5-axis agility with metrology-grade validation, Wuxi Lead ensures that every component meets the exacting demands of advanced assembly lines, where precision directly impacts system performance and longevity. Our engineering team collaborates with clients during DFM analysis to optimize part geometry for maximum yield within these tolerance envelopes, reducing total cost of ownership through intelligent process design.

Material & Finish Options

When selecting materials for sheet metal punching operations, precision, durability, and compatibility with post-processing techniques are critical. At Wuxi Lead Precision Machinery, we engineer our CNC punching systems to handle a range of high-performance metals, with aluminum, steel, and titanium being the most widely used in industrial applications. Each material offers distinct mechanical properties and responds uniquely to punching forces, tool wear, and finishing processes.

Aluminum is favored for its lightweight nature, excellent thermal and electrical conductivity, and inherent corrosion resistance. It is particularly suitable for aerospace, electronics, and transportation sectors where weight reduction is a priority. However, aluminum’s softness and tendency to gall can lead to tool adhesion during high-speed punching. To mitigate this, our machines employ optimized punch geometries and coatings such as TiN or DLC (Diamond-Like Carbon), ensuring clean perforations and extended tool life.

Steel, particularly cold-rolled steel (CRS) and stainless steel, remains the backbone of structural and industrial enclosures due to its strength, formability, and cost efficiency. Mild steel is highly punchable and ideal for high-volume production runs. Stainless steel, while more abrasive, provides superior corrosion resistance and aesthetic appeal. Punching stainless requires higher tonnage and wear-resistant tooling—our servo-driven punching systems deliver consistent force distribution, minimizing deformation and burr formation.

Titanium is reserved for extreme environments such as aerospace, defense, and medical devices. It offers an exceptional strength-to-density ratio and outstanding resistance to heat and corrosion. However, titanium’s low thermal conductivity and high chemical reactivity pose challenges during punching, including rapid tool wear and potential for work hardening. Precision control of punch speed and clearance is essential. Our adaptive control systems allow for real-time adjustments, ensuring dimensional accuracy and minimizing stress on the material.

Post-punching finishes further define performance and appearance. Anodizing is a critical surface treatment for aluminum components. This electrochemical process thickens the natural oxide layer, enhancing corrosion resistance, wear performance, and adhesion for paints or primers. Type II (sulfuric acid) anodizing is commonly used for decorative and protective finishes, while Type III (hard coat anodizing) delivers industrial-grade durability. It is important to note that anodizing requires precise dimensional allowances, as the coating builds up on the surface—typically 0.0002” to 0.001” per side. Our engineering team recommends final punching operations before anodizing to maintain tight tolerances.

Below is a comparative overview of key material properties relevant to punching operations.

| Material | Tensile Strength (MPa) | Hardness (HB) | Punch Clearance (%) | Tool Coating Recommendation | Common Applications |

|---|---|---|---|---|---|

| Aluminum 6061 | 310 | 95 | 12–15% | TiN, DLC | Enclosures, Heat Sinks |

| Mild Steel | 400–500 | 120 | 10–12% | TiCN, CrN | Panels, Brackets |

| Stainless 304 | 505–860 | 180 | 15–20% | TiAlN | Food Equipment, Medical |

| Titanium Grade 2 | 345 | 150 | 20–25% | Diamond-coated | Aerospace, Defense |

Selecting the right material and finish ensures optimal performance, longevity, and cost-efficiency in sheet metal fabrication. At Wuxi Lead Precision Machinery, we support advanced material processing through intelligent machine design and application-specific tooling solutions.

Manufacturing Process & QC

Sheet Metal Punching Process: Precision Engineering from Concept to Volume

At Wuxi Lead Precision Machinery, our sheet metal punching process is engineered for uncompromising quality and efficiency, ensuring Zero Defects from initial design through high-volume production. This integrated approach minimizes waste, accelerates time-to-market, and guarantees parts meet exacting dimensional and functional specifications. The foundation lies in rigorous Design for Manufacturability (DFM) analysis. Our engineering team collaborates closely with clients during the conceptual phase, utilizing advanced CAD/CAM software to scrutinize part geometry, material selection, and tooling requirements. Critical factors such as minimum hole diameters, bend allowances, and feature spacing are validated against machine capabilities and material behavior. This proactive DFM stage eliminates potential manufacturability issues before metal is cut, preventing costly redesigns and ensuring the design inherently supports defect-free production.

Prototyping transitions validated designs into tangible, functionally tested components. Using our high-precision punching centers, we produce initial batches under controlled conditions mirroring mass production parameters. Every prototype undergoes comprehensive metrological inspection against the original CAD model and client specifications using coordinate measuring machines (CMMs) and optical comparators. This phase is not merely about part creation; it is statistically validated process confirmation. We measure critical dimensions, hole positional accuracy, edge quality, and burr levels, feeding data back to refine the CNC program and tooling setup. Only when prototypes consistently achieve zero non-conformities do we authorize progression to full-scale manufacturing.

Mass production leverages the perfected process with integrated quality assurance systems operating in real-time. Our state-of-the-art punching machines execute the validated programs with micron-level repeatability. Crucially, Zero Defects is maintained through continuous in-process monitoring. Sensors track tonnage, tool wear, and sheet positioning, triggering automatic corrections or halts if parameters deviate beyond pre-set tolerances. Statistical Process Control (SPC) charts analyze key characteristics from every production run, enabling predictive adjustments before defects occur. Each part batch undergoes final random sampling per AQL standards, with full traceability from raw material lot to finished component. This closed-loop system, combining superior machine performance with embedded quality protocols, ensures consistent output meeting the most stringent aerospace, medical, and industrial standards.

Wuxi Lead Precision Punching Machine Specifications for Zero Defects Production

| Parameter | Specification | Significance for Zero Defects |

|---|---|---|

| Positioning Accuracy | ≤ ±0.02 mm | Ensures exact feature placement across the sheet |

| Repeatability | ≤ ±0.01 mm | Guarantees consistent part-to-part uniformity |

| Tool Turret Capacity | 60 Stations Standard | Minimizes tool change downtime & setup errors |

| Max. Stroke Rate | 1200 strokes/min | Maintains stability & precision at high throughput |

| CNC Control System | Siemens 840D Solution4 | Enables real-time process monitoring & correction |

| Material Thickness Range | 0.5 – 6.0 mm Steel | Optimized for common industrial sheet applications |

Why Choose Wuxi Lead Precision

Partner with Lead Precision for Advanced Sheet Metal Punching Solutions

At Wuxi Lead Precision Machinery, we understand that precision, efficiency, and reliability are not just goals—they are requirements in modern sheet metal fabrication. As a trusted leader in high-performance CNC machinery, we specialize in engineering sheet metal punching machines that deliver unmatched accuracy, speed, and durability for demanding industrial applications. Whether you operate in aerospace, automotive, electronics, or heavy equipment manufacturing, our machines are built to elevate your production standards and optimize your operational output.

Our sheet metal punching machines are designed with cutting-edge technology, incorporating servo-electric and hydraulic hybrid drive systems, advanced tool changers, and intelligent control interfaces. Every machine is engineered to reduce cycle times, minimize material waste, and support complex punching patterns with micron-level repeatability. With modular configurations and scalable automation options, our systems integrate seamlessly into existing production lines or serve as the foundation for fully automated fabrication cells.

We don’t just supply machinery—we deliver long-term partnerships. From initial consultation to installation, training, and ongoing technical support, our engineering team works closely with your operations to ensure maximum uptime and performance. Our global service network provides rapid response, remote diagnostics, and spare parts logistics, so your production never slows down.

When you choose Wuxi Lead Precision Machinery, you’re choosing a manufacturer that prioritizes innovation, quality control, and customer success. Our ISO 9001-certified production facility in Wuxi, China, adheres to international standards, ensuring every component meets rigorous performance benchmarks. We collaborate with industry leaders worldwide, tailoring solutions that address specific material types, thickness ranges, and throughput requirements.

To learn how our sheet metal punching machines can transform your fabrication process, contact us today. Our application engineers are ready to discuss your production needs, conduct feasibility analyses, and recommend the optimal machine configuration for your facility.

Technical Specifications

| Parameter | Specification |

|——————————-|———————————————-|

| Max Punching Force | 300 kN |

| Stroke Rate | Up to 1,200 strokes per minute |

| Material Thickness Range | 0.5 – 6.0 mm (mild steel) |

| Tool Stations | 30 (standard), up to 60 (custom) |

| Positioning Accuracy | ±0.05 mm |

| Control System | Siemens 840D / Mitsubishi M80 |

| Sheet Size Capacity | Up to 2500 x 1250 mm |

| Drive Type | Servo-electric with optional hybrid system |

| Tool Change Time (avg.) | < 2 seconds per station |

| Interface | Touchscreen HMI with CAD/CAM integration |

Contact us at [email protected] to schedule a consultation, request a demo, or receive a detailed product catalog. Let Wuxi Lead Precision Machinery be your strategic partner in precision manufacturing.

⚙️ Precision Cost Estimator

Estimate relative manufacturing effort based on tolerance.